scudderfish

|

| posted on 29/4/10 at 02:37 PM |

|

|

EDIS cranking signal cutting out after about 4 seconds

Still not running

When I'm cranking, I see the engine doing about 120rpm for about 4 or 5 seconds, and then MS reports 0rpm even though I am continuing cranking.

Any ideas what would cause this?

|

|

|

|

|

turbodisplay

|

| posted on 29/4/10 at 02:56 PM |

|

|

Whilst it is my own ecu I had this problem, I guess it maybe that the engine is not making the 300 rpm required for megasquirt to go from crank to

run.

The engine runs on cranking enrichment until the plugs get too wet/ sooty and cuts out.

DARREN

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

rayward

|

| posted on 29/4/10 at 03:13 PM |

|

|

is your VR sensor polarity correct ?

Ray

|

|

|

scudderfish

|

| posted on 29/4/10 at 04:25 PM |

|

|

It's not even sparking yet, let alone staying in the startup enrichment phase and flooding. I'm getting no spark and the MS thinks the

engine has stopped turning eventhough it still is.

|

|

|

blakep82

|

| posted on 29/4/10 at 04:59 PM |

|

|

wonder if the sensor's too far away from the trigger wheel to get a decent signal, its like a little magnet inside, opening and closing as the

teeth pass, i think it maybe just loses it and can't pick it up again. how close is it? it should be like 1mm away or something

________________________

IVA manual link http://www.businesslink.gov.uk/bdotg/action/detail?type=RESOURCES&itemId=1081997083

don't write OT on a new thread title, you're creating the topic, everything you write is very much ON topic!

|

|

|

cd.thomson

|

| posted on 29/4/10 at 05:05 PM |

|

|

no spark at all means an edis issue, so common suspects are the trigger wheel, sensor, edis wiring, edis internals, coil pack and ht leads.

Craig

|

|

|

scudderfish

|

| posted on 29/4/10 at 08:35 PM |

|

|

Thanks for the comments so far. Done a bit more digging tonight and have found the following :-

1) Good 12v to the EDIS

2) Good 12v to the coil packs

3) Good earth on the EDIS

4) Picked loom tape apart and verified that VR sensor connected to the right wires on EDIS plug

5) Swapped polarity of VR sensor, lost cranking 120rpm signal to megasquirt

6) Swapped VR sensor wires back to how they were, still lost 120rpm signal

Don't know exact gap between sensor and trigger wheel, but it is about the thickness of two sheets of paper

|

|

|

atspeed racing

|

| posted on 30/4/10 at 08:58 AM |

|

|

does your ignition fed live to the ecu disapear under cranking? (obvious but i have seen it!)

wave a screwdriver in front of the crank sensor, and see if the MS sees a crank signal.

what material is your trigger wheel made from?

what is the gap between trigger wheel and sensor?

- colin.

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

scudderfish

|

| posted on 30/4/10 at 09:53 AM |

|

|

quote:

Originally posted by atspeed racing

does your ignition fed live to the ecu disapear under cranking? (obvious but i have seen it!)

I thought at first I may have powered the EDIS module off the same feed as the fuel pump relay, but this is not the case. I've got very

simplified power wiring, I have the choice behind the scuttle of either permanent 12v, 12v switched on the key, or 12v switched by the ECU (fuel

pump/injectors etc). MS (for now) lives on the permanent feed, and the EDIS on the key switched feed

quote:

what material is your trigger wheel made from?

Steel. I got it from triggerwheels.com so I assume they know what to make it from

quote:

what is the gap between trigger wheel and sensor?

I've not measured it with a feeler guage (don't have one), but it is about two sheets of paper.

|

|

|

scudderfish

|

| posted on 2/5/10 at 11:55 AM |

|

|

A bit more progress. I found a Megajolt site that had some diagnostics to carry out. On cranking the VR sensor should put out about 2.5v AC. I was

seeing <1v. Looking closely at my mount, although the sensor appeared to be close enough, it wasn't sitting square to the trigger wheel.

Time to make a better bracket.

|

|

|

David Jenkins

|

| posted on 2/5/10 at 12:00 PM |

|

|

While you're at it - make sure that the new bracket is really rigid, with no 'bounce'. There's a well-known symptom of

misfiring at around 4,000 rpm that's usually caused by a vibrating VR sensor.

This isn't a Megajolt issue - it's general with any symptom that uses Ford's VR sensor and EDIS.

|

|

|

scudderfish

|

| posted on 2/5/10 at 03:19 PM |

|

|

One step forward, one step back. Welded up a new bracket (not pretty, but I'm learning) and cracked out the voltmeter. Now I get 1.2v  The

sensor is not too far away as it was actually touching the trigger wheel and has the scars to prove it. I put a washer in and the reading goes down

to 0.8v. I'm stumped. The

sensor is not too far away as it was actually touching the trigger wheel and has the scars to prove it. I put a washer in and the reading goes down

to 0.8v. I'm stumped.

The sensor is one of these

http://www.partsjunction.co.uk/index.php?main_page=product_info&products_id=120325

[Edited on 2/5/10 by scudderfish]

|

|

|

omega 24 v6

|

| posted on 2/5/10 at 05:18 PM |

|

|

Erm what is your wheel made out of?? Stainless?? could be a problem as it is not magnetic.

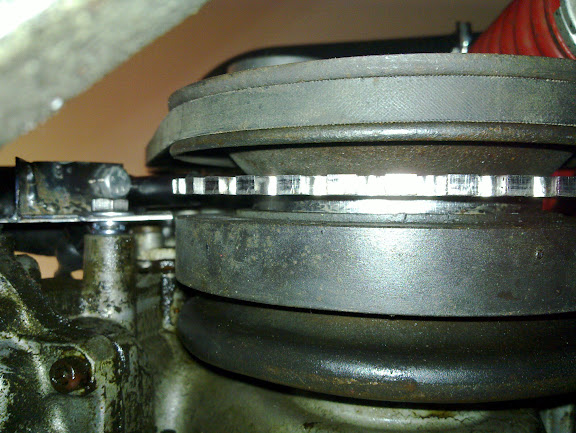

Also on second thought It LOOKS like there may not be enough room between the trigger wheel and the other pulleys. this will lead to the sensor seeing

a full steel wheel passing it and not generate the sine wave ( with the gap step where the missing tooth is).

[Edited on 2/5/10 by omega 24 v6]

If it looks wrong it probably is wrong.

|

|

|

scudderfish

|

| posted on 2/5/10 at 05:27 PM |

|

|

quote:

Originally posted by omega 24 v6

Erm what is your wheel made out of??

Steel. The magnet in the sensor wants to stick to it.

|

|

|

omega 24 v6

|

| posted on 2/5/10 at 05:28 PM |

|

|

Edited my post

If it looks wrong it probably is wrong.

|

|

|

scudderfish

|

| posted on 2/5/10 at 05:32 PM |

|

|

Here's another view. I'll see if I can measure the gap.

|

|

|

omega 24 v6

|

| posted on 2/5/10 at 05:41 PM |

|

|

Mmm that does look a bit wider than the last piccy.

Another thought ( and it is just that so I may be being daft) But is it possible that the sensor couls be 90 degrees out??

ANYONE??????

[Edited on 2/5/10 by omega 24 v6]

If it looks wrong it probably is wrong.

|

|

|

scudderfish

|

| posted on 2/5/10 at 05:58 PM |

|

|

The view from underneath, I think the spacing is actually fine, but it is good to eliminate possibilities.

It could be that the sensor is duff, but I'm more inclined to suspect my incompetence.

|

|

|

scudderfish

|

| posted on 2/5/10 at 06:43 PM |

|

|

I'm getting a new sensor tomorrow, even if it's only to prove that the one I currently have is good.

|

|

|

matt_gsxr

|

| posted on 2/5/10 at 08:46 PM |

|

|

Hi there,

It may be the photo, but...

It looks like your sensor isn't radial to the wheel, what I mean is, the sensor should point towards the centre of the trigger wheel. If it

isn't then it would exhibit similar symptoms to a wheel that is too far away. It also looks like it was catching at one side but not the

other.

Just a thought.

Matt

|

|

|

scudderfish

|

| posted on 2/5/10 at 09:02 PM |

|

|

I think/hope it is distortion in the photo  When a first mounted it, it was located towards the rear of the engine, but I brought it forward. It

was this time that the sensor was in contact with the trigger wheel, and it scratched the base of the sensor across the centre and full width, which

implies the location is at least close to right. When a first mounted it, it was located towards the rear of the engine, but I brought it forward. It

was this time that the sensor was in contact with the trigger wheel, and it scratched the base of the sensor across the centre and full width, which

implies the location is at least close to right.

|

|

|

matt_gsxr

|

| posted on 3/5/10 at 09:50 AM |

|

|

Fair enough.

New sensor sounds like a good plan.

Matt

|

|

|

scudderfish

|

| posted on 3/5/10 at 01:06 PM |

|

|

OK, so it isn't the sensor. The new one gives the same readings. Options now are :-

1) The mount - likely culprit and I mentally have a new design which should be better

2) Wiring - less likely, but easier to check out. The cable I'm currently using is two core screened microphone cable from Maplin.

I have a spare plug so I'll solder it up with some test leads to eliminate the cable and then crack out the angry grinder and make up a new

bracket.

|

|

|

scudderfish

|

| posted on 3/5/10 at 02:32 PM |

|

|

It ain't the wiring, it's definitely the mount. I took the crank bolt out (always good exercise on a RV8) and slid the pulley assembly

forward. This gave me a much better view of the alignment against the crank damper, and as postulated, the sensor is not at 90 degrees to the spinney

bits. The bracket is held on by two bolts, so I removed one and rotated the bracket until the sensor was pointing in the right way. The resultant

gap is quite embarrassing  Anyway, it means I'm not at a dead end and can fiddle with something else in the hope that it will work Anyway, it means I'm not at a dead end and can fiddle with something else in the hope that it will work

|

|

|

omega 24 v6

|

| posted on 3/5/10 at 03:25 PM |

|

|

will be interesting to see if it is that.

My understanding was that an AC voltage wouls be produced by cutting a magnetic field with a toothed wheel Now obviously the sensor is the magnet and

a magnet has a north and south pole. I did not think it needed to be aligned to get it to work though ( although i did suggest looking at it in an

earlier post). If this does work for you it may be of great interest to oyhers on many forums who are using aftermarkey wheels and getting a poor

signal.

If it looks wrong it probably is wrong.

|

|

|