speed8

|

| posted on 20/10/09 at 03:16 PM |

|

|

R1 Silencer - Opening it up??

Not sure if it should be here or in the Engines forum but hey ho....

In the interests of track day noise level reductions and the way things seem to be going, I've got an R1 silencer in the garage from an 02-03

bike. It's titanium on the inlet end and the outlet is something else (it's magnetic so not titanium). I've found a local exhaust

fabricator who can weld titanium for me but he asked me to open it up and send him some pictures so he can see whats what so we can figure out what to

do with the link pipe.

I removed the end caps but the inner pieces seem to be soldered on to the blue outer piece.

Anybody know how to separate them.

I'll try and stick up a picture in a bit to show what I mean. If it's just solder I guess I can take a blowtorch to it to melt it then

separate?

Cheers

|

|

|

|

|

RickRick

|

| posted on 20/10/09 at 03:45 PM |

|

|

i've got to the same point, my brother recons it's electron beam welded, so running an angle grinder around the joint would fix it, but

i've not tried on mine yet

|

|

|

speed8

|

| posted on 20/10/09 at 04:55 PM |

|

|

I tried with the blowtorch till it was red hot and didn't melt so I guess it's not solder.

I've got a Dremel with a fine cutting disc so I might try that in the morning but I'll need to seal it up again once I've sorted out

the link pipe.

|

|

|

rick q

|

| posted on 21/10/09 at 03:14 AM |

|

|

I've used one on mine - but gutted and turned into a conventional straight through muffler.

To get the internal end caps off, I used an angry grinder with a thin (1mm?) blade, cutting only through the outer titanium case. The cut was made

just past the line of rivets. Note that titanium throws very hot white sparks when you grind it!

The end cap is then separated from the remaining strip of the titanium outer. You end up with a muffler that's about 20mm shorter than you

started with.

I believe the end caps are silver soldered in.

The gizzards appear very restrictive with three separate chambers - which is why I threw that away and made a straight through muffler out of what was

left.

See http://www.locostbuilders.co.uk/photos.php?action=showphoto&photo=IMGP2718.JPG

|

|

|

speed8

|

| posted on 21/10/09 at 10:54 AM |

|

|

Cool, I'll try that then. I've no problem with it being a bit shorter than standard as I was going to remove the cat anyway. I just want

something thats quiet enough for the way track days are going these days.

|

|

|

bassett

|

| posted on 21/10/09 at 01:07 PM |

|

|

can you use any sort of weld to get this back together or must it be done properly?

My MNR Blog Updated Jan 2010 - Track Day Prep Begins!

|

|

|

speed8

|

| posted on 21/10/09 at 02:05 PM |

|

|

You can't weld stainless to titanium or vice versa (at least not without difficulty and risking cracking in the weld). The inlet piece is

titanium and the outer housing also but everything else is slightly magnetic so probably stainless. I've now cut off the titanium inlet and will

try and get a custom made inlet to replace it.

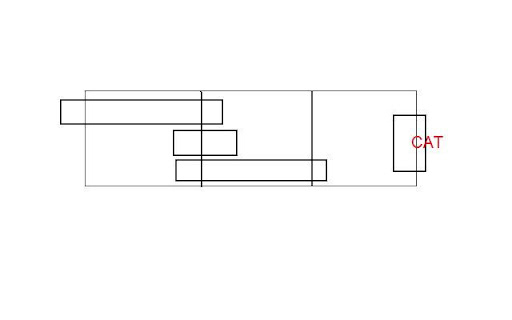

Here's some pictures of the insides and a little drawing. Hopefully I'm booked in for next week to get it welded up. I'll add to the

post how I get on.

|

|

|

rick q

|

| posted on 21/10/09 at 11:11 PM |

|

|

Because mine ended up a mix of materials (anything visible was titanium - everything else was stainless) I ended up bolting it together internally.

Took three goes before it held together - but it's now been on the car for about 3 years.

Make sure you pack it with SS wool (not mild steel or fibreglass - both of which disappear). I also wrapped the louvred core I put through mine fine

SS mesh to stop the wool getting out.

|

|

|

bassett

|

| posted on 22/10/09 at 12:09 PM |

|

|

Top work but at the same time it sounds a lot of work for something i thought would be a cut to size and bang on job and possibly more restrictive

than what it would be replacing.

My MNR Blog Updated Jan 2010 - Track Day Prep Begins!

|

|

|

speed8

|

| posted on 22/10/09 at 12:18 PM |

|

|

There was nothing on there. The last thing that was on was an SVA can that I had borrowed. I was going to have a silencer made up but some of my local

tracks look like they'll be lowering noise limits if they haven't done already so I wanted something that should be fairly quiet as I only

just passed noise on SVA.

Once it's done I can get it measured then maybe play with it to tweak the sound.

|

|

|

bassett

|

| posted on 22/10/09 at 05:19 PM |

|

|

Hope it works for you, i was hoping it would be the opposite where its actually nosier and more original sounding compared to the bike as my MNR 100db

can is huge, heavy, and a drowned out quieter rumbled which you cant even hear over the induction noise, all beit with open filter.

My MNR Blog Updated Jan 2010 - Track Day Prep Begins!

|

|

|