will121

|

| posted on 5/6/12 at 06:42 PM |

|

|

is there a theory to setting rev's for a shift light

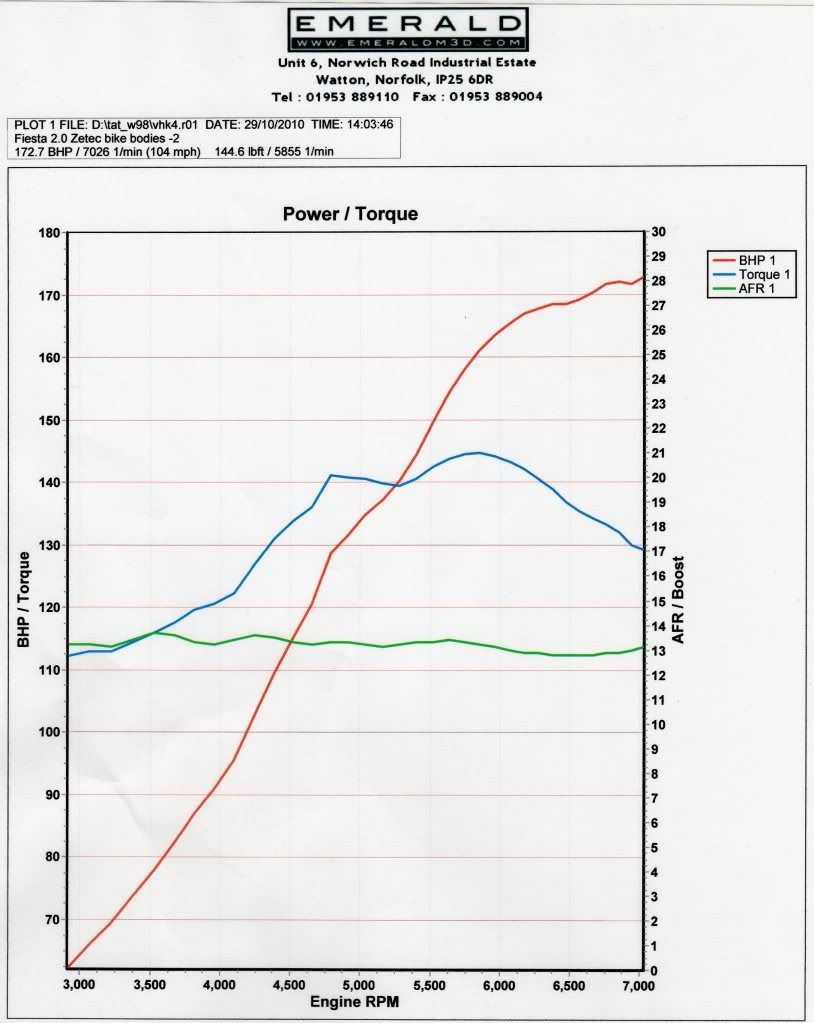

Is there a theory for what rev's to set a shift light to? between max revs power/torque or just at peak bhp before power drops off? currently

still making power at Soft rev limit set to 7000rpm hard cut at 7200, engine is silvertop zetec has ARP rod bolts but not sure want to rev it any

higher.

Ive attached a copy of RR print out for info.

McGill do a cheap red warning/shift light (link) but im not

sure if red is best colour, anyone know if a cheap orange one?

|

|

|

|

|

mark chandler

|

| posted on 5/6/12 at 07:10 PM |

|

|

Yes there is, you calculate the torque at the wheels for given gear ratio's, when the next gear applies more torque than the previous you shift,

simples

|

|

|

v8kid

|

| posted on 5/6/12 at 08:07 PM |

|

|

So what you do is plot the torque in each gear against the speed and where the plots for each gear cross is the point to change gear. In practice

allow a couple of hundred extra rpm for slowing down during gear change.

Unfortunately you end up with a different rpm for each gear and also different going up from down.... Life's a bitch and then you die

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

will121

|

| posted on 5/6/12 at 08:21 PM |

|

|

quote:

Originally posted by v8kid

So what you do is plot the torque in each gear against the speed and where the plots for each gear cross is the point to change gear. In practice

allow a couple of hundred extra rpm for slowing down during gear change.

Unfortunately you end up with a different rpm for each gear and also different going up from down.... Life's a bitch and then you die

all i have is the original RR print out and no idea what gear it was in, would you need a torque curve for each gear?

thanks

|

|

|

Slimy38

|

| posted on 5/6/12 at 08:44 PM |

|

|

I might have misunderstood what v8kid is talking about, but the torque curve doesn't change depending on what gear you're in (at least the

engine torque doesn't). The difference in shift revs comes from the differences in gear ratio's. So for example, if the rev difference

between third and fourth is larger than second to third, then you'll have to shift later to keep it in the torque curve.

Or in simple terms, as long as each shift doesn't drop more than 2,000 revs, you can set your shift light at 6,500 and you should always have at

least 140 lbft of torque to have fun with.

|

|

|

mark chandler

|

| posted on 5/6/12 at 08:58 PM |

|

|

quote:

Originally posted by v8kid

So what you do is plot the torque in each gear against the speed and where the plots for each gear cross is the point to change gear. In practice

allow a couple of hundred extra rpm for slowing down during gear change.

Unfortunately you end up with a different rpm for each gear and also different going up from down.... Life's a bitch and then you die

Your understanding is correct.

You plot the driven wheel torque, cars are generally rolling roaded in 3rd BTW (does 7000rpm in third = 100mph?), and yes the actual gear change

points will vary if the gears are not evenly spaced hence close ratio gearboxes to even things out.

You just need to plot the torque in excel then ratio out, it will not be perfect but just aim for the speeds you mostly use, as an example my V40

Diesel volvo is hopeless above 4000rpm, so going up a gear moves things along, my turbo blade is no quicker hanging on to a gear over 9500rpm,

although once in top it will go to 11,500rpm.

From your graph 6500 looks about right as an upshift will drop you back in the sweet zone as the torque is now falling away.

Regards Mark

[Edited on 5/6/12 by mark chandler]

|

|

|

v8kid

|

| posted on 6/6/12 at 06:22 AM |

|

|

It's the torque at the wheels that pushes you along so that's the figure we are interested in. As already said you can plot the torque at

the wheels in each gear against the speed in excel and where the plots cross is the ideal change speed. As every gear will have a different change rpm

unless you have a memory like Lewis hamiltons compute best just pick one

You'd be surprised how quickly the sales people at B&Q try and assist you after ignoring you for the past 15 minutes when you try and start a

chainsaw

|

|

|

loggyboy

|

| posted on 6/6/12 at 09:53 AM |

|

|

Whilst Ive never set one up, I have allways figured that you need to look at gear ratios as well, as if you have a wide ratio box, then you will step

back more revs each time you change gear, and you ideally want your peak power to be fairly central on your range., ie if you change just after peak

power, but you then drop the revs to point where there is less power, then you are not spending the time in gear in the optimum range, so if as your

curve has a fairly even drop off, centrered at 5700revs, then you want to set it so that you hit that peak half way through the time in gear.

make any sense? lol

Mistral Motorsport

|

|

|