Just a thought & I maybe wrong but maybe CAD can,t take into account the rounded profile of steel?? .

Sorry if that doesn,t help you tho

cheers

andy

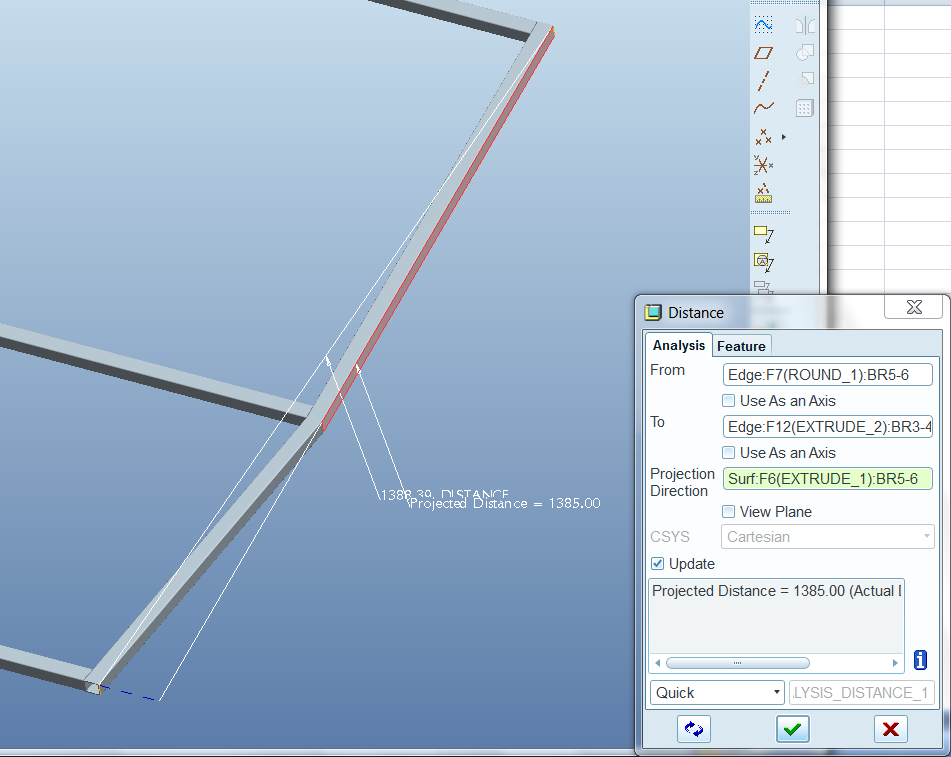

Hi all, I recently got hold of a copy of the haynes roadster and have just started building a CAD model. Starting with the bottom rails ive modelled

them as per drawings in the appendix but when assembling them together there are several rails that pass through each other, checking the lengths

against the plan dimensions in chapter 1 it seems the cut dimensions do not directly translate.

What is the purpose of this and what dimensions should i be following?

I,m not a CAD operator so can,t comment why CAD seems to struggle computing the dimensions but when actually building the chassis in steel, the

dimensions in the book are spot on, tho there have been a few revised dimensions from the books first edition, tho they are mainly to do with the

length of the wishbones , there is one small dimension fault, namely the SW parts, SW1 needs a 19degree compound angle & not 23 as stated in the

book.

Just a thought & I maybe wrong but maybe CAD can,t take into account the rounded profile of steel?? .

Sorry if that doesn,t help you tho

cheers

andy

quote:

Originally posted by handyandy

I,m not a CAD operator so can,t comment why CAD seems to struggle computing the dimensions but when actually building the chassis in steel, the dimensions in the book are spot on, tho there have been a few revised dimensions from the books first edition, tho they are mainly to do with the length of the wishbones , there is one small dimension fault, namely the SW parts, SW1 needs a 19degree compound angle & not 23 as stated in the book.

Just a thought & I maybe wrong but maybe CAD can,t take into account the rounded profile of steel?? .

Sorry if that doesn,t help you tho

cheers

andy

I,m just doing some calculations, will get back to in a few mins.

It,ll be interesting see if we can work out whats happening, tho I have heard in the past that CAD doesn,t like working beyond 0.1 when it has to

allow for angles, not sure how true that is tho .

cheers

andy

quote:

Originally posted by handyandy

I,m just doing some calculations, will get back to in a few mins.

It,ll be interesting see if we can work out whats happening, tho I have heard in the past that CAD doesn,t like working beyond 0.1 when it has to allow for angles, not sure how true that is tho .

cheers

andy

The dimensions in the book are to zero decimal places. You are never going to be able to create a CAD model by assembling individual tubes. The best

way by far is to create a weldment which is a single part file made up of individual bodies which are dimensioned as per the chapters.

I can assure you that the CAD drawings are correct

As I,ve already said, I,m not a CAD user so don,t really know its limitations,

BUT......

here,s me thinking from "top of my head"

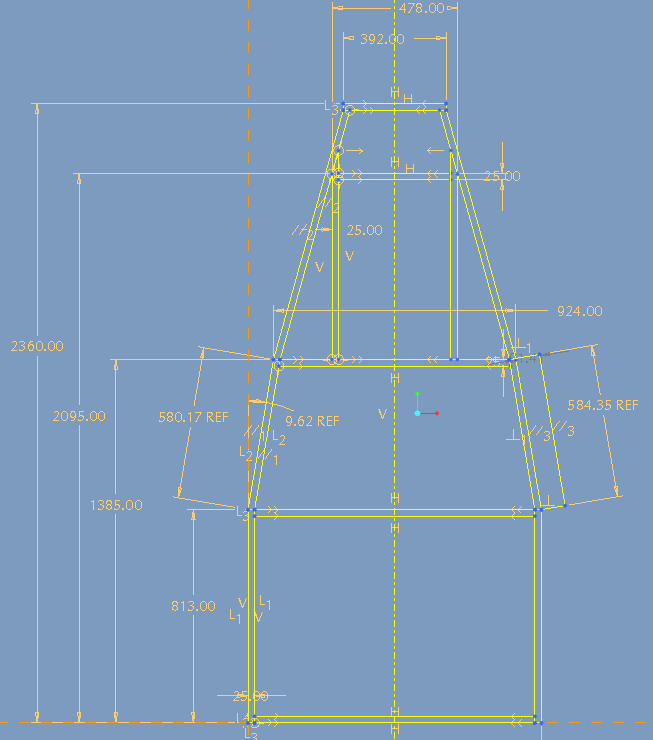

Instead of using the dimensions of the bottom rails , as in your sketch above , you have BR5 as 813mm & BR3 as 584mm which is as per book

dimensions.......

here,s my suggestion for seeing if you can get CAD to "understand" the measurements/angles...............

how about putting in the total chassis bottom rail dimension in as 2360mm which is the total distance between the rearward face of BR12 to the forward

face of FF1, which would create the outer perimeter of the chassis & see if CAD will then work out the dimensions that it can accept once putting

in the some angles (eg 10degree,s of BR3 & 4, & the 16degree,s of BR1 & 2 ) & seeing if it will work that way......again, I don,t know

if it will but setting the outer parameters of the chassis into the CAD drawing & see what happens.......just a thought

I,ve cut over 40 chassis,s for the Roadster & have not had a problem with the bottom rails when fabricating it in steel, CAD is not something I

know much about ( read.....zilch  ).

).

cheers

andy

quote:

Originally posted by Mad Dave

The dimensions in the book are to zero decimal places. You are never going to be able to create a CAD model by assembling individual tubes. The best way by far is to create a weldment which is a single part file made up of individual bodies which are dimensioned as per the chapters.

I can assure you that the CAD drawings are correct

quote:

As I,ve already said, I,m not a CAD user so don,t really know its limitations, BUT...... here,s me thinking from "top of my head" Instead of using the dimensions of the bottom rails , as in your sketch above , you have BR5 as 813mm & BR3 as 584mm which is as per book dimensions....... here,s my suggestion for seeing if you can get CAD to "understand" the measurements/angles............... how about putting in the total chassis bottom rail dimension in as 2360mm which is the total distance between the rearward face of BR12 to the forward face of FF1, which would create the outer perimeter of the chassis & see if CAD will then work out the dimensions that it can accept once putting in the some angles (eg 10degree,s of BR3 & 4, & the 16degree,s of BR1 & 2 ) & seeing if it will work that way......again, I don,t know if it will but setting the outer parameters of the chassis into the CAD drawing & see what happens.......just a thought I,ve cut over 40 chassis,s for the Roadster & have not had a problem with the bottom rails when fabricating it in steel, CAD is not something I know much about ( read.....zilch ). cheers andy

i had a chat with chris about this about 2 years ago when i built my car. when he wrote the book he purposely decided not to go to 0.1mm etc as it

was decided that the average home builder wouldn't be able to achieve that level of accuracy especially on the compound joints. if your going to

cut the box on a tube laser i know of a man that may have a digital cut list.

to be honest it would be overkill to go to an accuracy of more than half a millimetre.

I've CAD'd the thing in solidworks (not finished yet, but about 60%) and I struggled at first too, but then got it all spot on (except where I purposefully changed the design) to within 1 decimal place. As said, there will be differences of 0.1mm etc. which are irrelevant.

Hi,

Just out of interest - is there a reason why you're spending so long thinking/discussing/deliberating/drawing instead of just making it?

There is no need to model the Roadster unless you plan to modify it

The original book models and drawings were done in Solidworks so are accurate. It is pointless trying to get dimensions to 0.1mm because how are you

going to achieve that with a bandsaw? Anyway it's not a bad thing to have a slight gap between tubes when welding. Just make sure you

accurately mark out the chassis base on your build table

Haynes Roadster CAD iso a

Haynes Roadster CAD iso b

[Edited on 8/1/11 by Mad Dave]

@reservoir cogs,

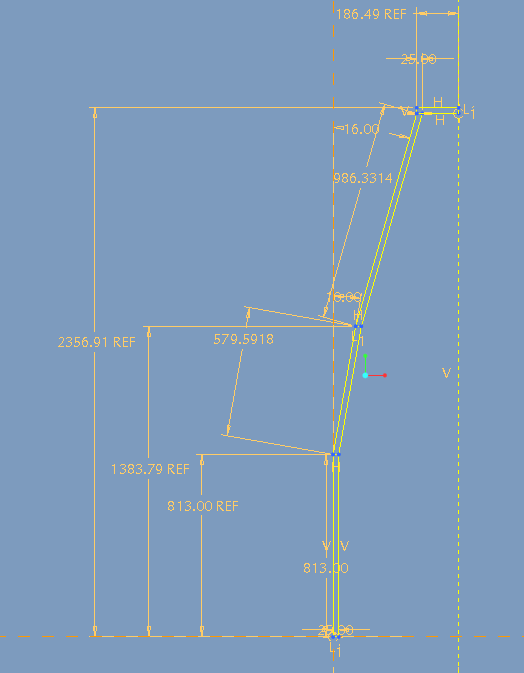

I modeled the bottom chassis rail components in sketchup and am getting similar discrepancies, too. I also calculated the angles manually and arrived

at the same deviations. I was wondering what approach you used in resolving the issue (if you ever did) - if you altered the angles of the B3 and B4

rails, modified their dimensions instead, or re-positioned BR10.

Since per forum postings, the dimensions in the book has been determined to be correct, I am really perplexed by the discrepancies cropping up since

all the values are zero decimal point and hence are not subject to precision rounding, if any at all. Moreover, the same deviations came up when I

manually calculated the positions, independent of sketchup or any CAD program.

Is it possible that during the actual build, adjustments were made to rectify the discrepancies? After all the values concerned are very minimal

relative to the overall dimensions. The way I see it, though I might be 100% wrong, it would be easy to pull BR3 and BR4 outward to accommodate BR10

at its intended position.

Anyways, reason why I am modeling the chassis first is that I plan to modify it and expand the width and other dimensions accordingly. Also, being an

architect, I guess I am used to working off CAD drawings and have been conditioned to be bothered by both design and structural issues, however minor

they may be.

TIA.

CAD really does have it's limitations :-)

It fools us into assuming that whats' 'on screen' is what you will actually be welding together.. As if

This isn't Boeing kids, there's ...no.. direct to robotised fabrication possibilities Here :-)

To build this thing you will need to pencil out the frame outline onto a build table, then build the thing, piece by piece, just like those Model

Airplanes' one built as a kid.

Any 'CAD' errors will be looong forgotten, as new and improved errors will surface.

Even a hacksaw cut cannot be 'that' precise.

I'd be far more concerned with 'fixin' the load paths from "Ron's" errm .. odd, suspension bracket mounting

/design/locations than the ultimate length of a tube... which will invariably (if Human:-) get cut a mm or so 'inaccurately'.

[Edited on 1/3/11 by Bare]

@Bare,

While I acknowledge CAD has its limitations, what bothers me is that if you manually draw out the lay-out, the angles are off. And if you manually

calculate the angles pertinent to the dimensions or vice-versa, they are also off. Reservoir cogs got similar errors and in fact has posted them here.

Thus the discrepancy has nothing to do with CAD and its so-called limitations.

I submit I am a complete noob when it comes to car building, and perhaps such discrepancy is well-accepted since this can be corrected during the

actual build. It is just that I am more used to nitpicking details in architectural/construction CAD drawings since such oversights and/or errors can

result in disastrous results post-construction.

Are you sure you're measuring your BR3/4 and 8/9 correctly? The length of 584mm is the overall maximum length of the steel section, if you only

look at one side of the box section it'll be less than that (by 10 degrees over 25mm, whatever that is).

I have a feeling your file shows the reference dimension of the outer side of BR3/4.

Check your diagonals as per the book schematic, if they're within 0.5mm, then you're fine.

@PSpirine,

Thanks for the reply.

Yes. Each side of the BR3/4 is 584mm, and the resultant side where I applied the 10 degrees is 25.4mm x 25mm.

I have not tried to place the BR8/9 bars yet.

BR

Finally found the answer in the Haynes forum. Not sure if I am allowed to post a link but it is in the chassis subforum under the "the haynes

chassis design. Per user eSteve,

quote:

We basically have two sets of information enabling us to build the lower chassis, that given in fig 4.2 and that given in the cutting list by way of the dimensions of the bottom rails. Either could be used to construct the bottom rails, but the correct one is fig 4.2 as stated by Chris Gibbs (see below) and for the reason I give above i.e the limit on the tolerances of the cutting list, to the nearest degree and millimetre.

Remember to keep a foot in the real world whilst modelling. Think about construction. The dimensions given in fig 4.2 are the important ones and what a welder would use to build the chassis rails, in fact all the lower chassis could be built from the dimension given in fig 4.2. Without using the cutting list for the lower rails! This is why Chris Gibbs states that fig 4.2 is used to layout the chassis and tubes are cut to the correct length to fit, (note: not necessarily cut to the cutting list lengths and angles).