Description

So this is how it started. I built a table out of some ply wood and 75mm x50mm. The tubes for the frame are 25mm x 25mm and are 1.6 mm thick

Hi Guys

My name is Derk. I live in Johannesburg, South Africa with my beautiful wife Katie.

I've been building a Haynes roadster for the last four months or so and have learned so much by reading other peoples builds on this forum.

I'll post some of the pics of my build up that will hopefully be of help to other builders.

[Edited on 17/8/14 by Derkjohn]

Description

So this is how it started. I built a table out of some ply wood and 75mm x50mm. The tubes for the frame are 25mm x 25mm and are 1.6 mm thick

Description

The nose section being built up. The book was a bit confusing on the developed length I thought. But that might just have been my ignorance

Description

More tubes being tacked together

This is the donor vehicle I bought a few weeks into the build. It is a 1990 2L Ford Sapphire (I think these are exclusive to South Africa) but all the

suspension and drive train components are the same as the Sierra.

Description

Some of the parts that I stripped out

Description

The rear brakes are drums, but I have since bought a 1991 3L (essex) Sapphire and will be using the discs from that

[Edited on 17/8/14 by Derkjohn]

Description

Description

Making the rear shock and roll bar supports

Description

Description

Trail fitting the engine

Description

I decided to weld the diff mounts directly onto the chassis. Simplify and add lightness

quote:

Originally posted by Derkjohn

Description

The nose section being built up. The book was a bit confusing on the developed length I thought. But that might just have been my ignorance

Thats great Derk but can we see pictures of Katie please

quote:

Originally posted by Slimy38

quote:

Originally posted by Derkjohn

Description

The nose section being built up. The book was a bit confusing on the developed length I thought. But that might just have been my ignorance

The nose section in the book is wrong, from memory one of the measurements is too short and the angles don't quite make sense. So I'm not surprised you were confused!!

Have you looked at the amendment that are on the Haynes forum;

http://www.haynes.co.uk/forums/showthread.php?t=2430

You're probably already a fair bit through but it might still be worth looking at them.

Description

I decided to lower the back of the transmission tunnel to give me some more elbow space.

Description

Description

Here is what I did for the pedals. I figured I would try to get the standard Sierra pedals to fit to save the effort of building them from from

scratch. So far it seems to be working great! I hope I don't run into trouble later on.

quote:

Originally posted by maccmike

Thats great Derk but can we see pictures of Katie please

welcome Derk, great work so far keep us posted and good luck with the build, don't be shy to ask questions as there is a wealth of knolage on

here, oh by the way we like pics

gary

welcome Derk, great work so far keep us posted and good luck with the build, don't be shy to ask questions as there is a wealth of knolage on

here, oh by the way we like pics

gary

Nice to see a scratch build these days. Be warned making one change to the book can have so many knock on changes down the road.

Like have you left enough room for the hand brake cables / Fuel pipes and electrics in the rear of the tunnel ?

Description

Description

Making up the suspension brackets. I managed to make 16 of them only to realise the were 10mm to short.  Once I had re-cut them again I made a

little jig to help me bend them at the correct length.

Once I had re-cut them again I made a

little jig to help me bend them at the correct length.

Description

The floors are made from 1mm mild steal. I put two diagonal bend lines on each to help prevent the drumming effect once welded. This worked well for

the front section, however I didn't bend the back as that's where the seat supports go. I ended up having to heat shrink the back section to

get it tight.

Description

Radiator mountings. I realised that the books radiator is mounted upside down

Description

Description

Description

Description

I'm making my scuttle out of steel and aluminium plate.

Description

Red Oxide!

Description

This is where I'm at now. I painted the frame with red oxide followed by a product called Raptor liner by U-pol. Its usually used to line pick-up

truck loading bays but I thinned it down and applied it with a standard spray gun, except on the floors where I used a textured effect spray gun.

quote:

Originally posted by big_wasa

Nice to see a scratch build these days. Be warned making one change to the book can have so many knock on changes down the road.

Like have you left enough room for the hand brake cables / Fuel pipes and electrics in the rear of the tunnel ?

Description

Description

Here's a bit of info on the engine. Its a 2.0 L pinto. The 2.9 cosworth pistons that seem quite popular in the UK aren't available in SA as

we only ever had the Ford v6 in the Essex version. So the pistons are just 1mm oversize standard pistons. I've had the flywheel lightened and the

bottom end balanced. Other than that it's stock. On the head side of things I've opted for a 288 deg camshaft and I've gas-flowed the

head with the help of David Vissard's book. The plan is to run a set of R1 throttle bodies that I have. They are the ones that still have the

vacuum operated venturi but also run fuel injectors. Apparently they only came out for a year or so after which the R1's ran normal throttle

bodies.

[Edited on 17/8/14 by Derkjohn]

Description

Description

These are the seats I'm using. I found them in a beach buggy in a scrap yard. They were slightly to wide, but as they are made from steel tubing

I was able to bend the edges in and make them fit  I then had them re-covered for R1700 (90£) Not bad eh?

I then had them re-covered for R1700 (90£) Not bad eh?

Looking like a good build there Derk, keep up the good work.

Get Katie to sit in the car and make the brum brum noises and post the pic

Good work Derk, where did you the get the seats recovered? I need the same done to my pair. That seems like a good price.

Where are you in Jo'burg? I am in Fourways area, i just got a seven 3 weeks ago and am slowly getting it up to spec.

Keith

quote:

Originally posted by Slater

Good work Derk, where did you the get the seats recovered? I need the same done to my pair. That seems like a good price.

Where are you in Jo'burg? I am in Fourways area, i just got a seven 3 weeks ago and am slowly getting it up to spec.

Keith

Thanks i will call him tomorrow

I've managed to get a bit more done over the last few weeks.

Description

The engine, diff and gearbox has been fitted.

Description

Description

Front wishbones being made up.

Description

Front suspension complete

Description

The brakes are from a 3.0L Sierra and are slightly larger than the 2.0l brakes. I wanted 3.0 discs as these have discs on the rear opposed to the 2.0l

which has drums. And yes, I couldn't resist painting the callipers red

[Edited on 12/10/14 by Derkjohn]

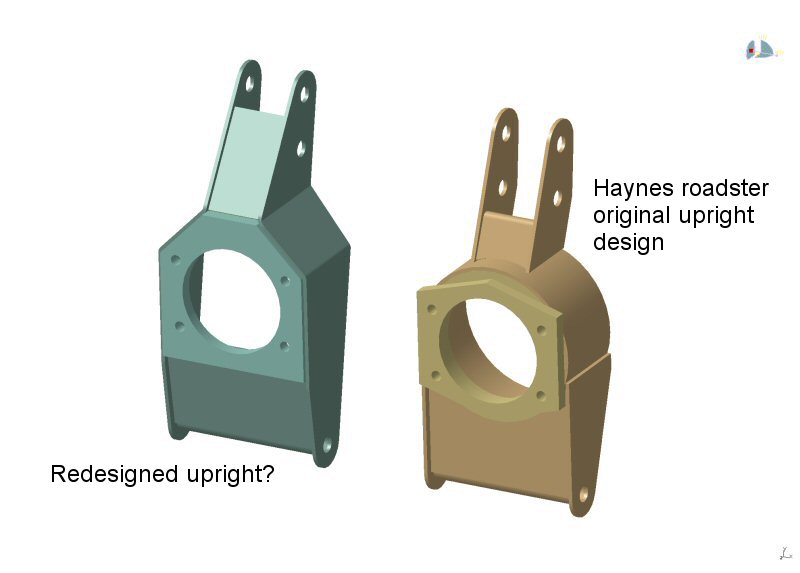

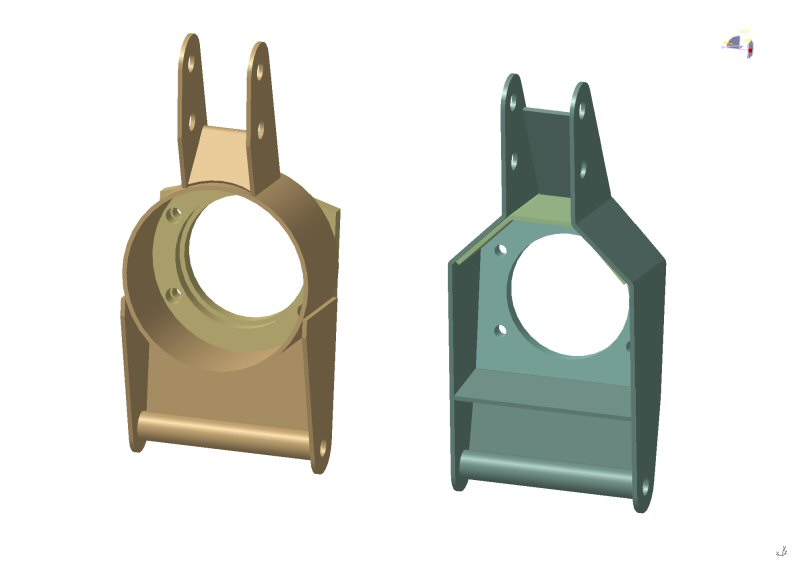

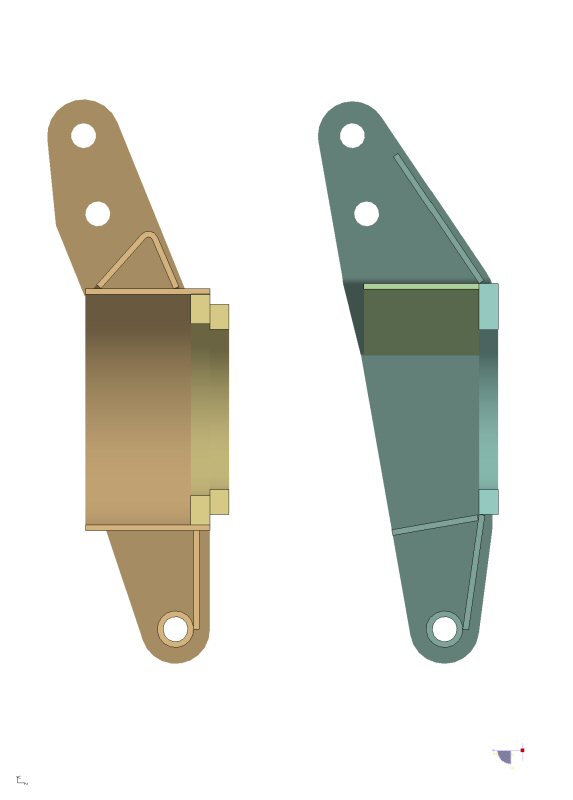

I've been thinking about re-designing the rear uprights for my Haynes Roadster. The book uprights seem unnecessarily complicated and heavy

compared to other designs I have seen. I've drawn up some plans for some uprights which should be a lot easier to make up. The suspension

geometry remains the same as the original uprightsI would value your opinions and ideas on these.

Description

Hi Derk.

Me and my borther have just started building our Haynes Roadster, and I'm thinking about a re-designed rear upright similar to what you are

thinking, and for the same reasons.

My first thought was that the sides (between the upper and lower a-arms mounting points) should be one continuous piece without welds, for better

safety. Then I also thought that it should be able to design the upright with fewer parts.

This is what I came up with, but we haven't decided which design we should use... The benefit with the original design is that the cross-section

of a circle is stiffer (flexes less) than the cross-section of a sqaure.

Hi all, I thought I'd post an update here to close off this thread.

Since my last post, I've moved to England with my family, taking the car with me. I've now decided to sell it, as we're relocating

again.

Description

Description

Description

Description

Description

Description