Rosco's haynes Build

Rosco86 - 26/10/14 at 07:09 PM

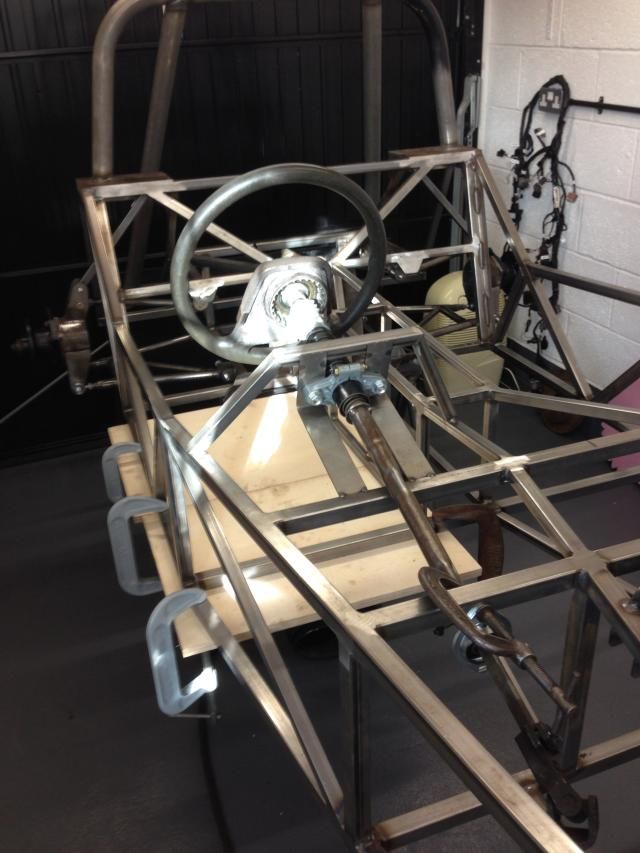

Started my build last weekend, with the help of my Dad, just thought I would start a thread to share with you guys and get a few pointers along the

way

A bit of background info, I'm 28, and a cnc miller by trade and my dads a carpenter so between us we get on with things ok, I've always

loved cars and always wanted to build a kit car, I'm going down the bike engine route in a bare bones track chassis no luxury much to my dads

disappointment, I'm going to work to the book and get it on the road as soon as I can, funds permitting, and then after that I will start

replacing the uprights for cnc aluminium ones etc, but if I start doing those things now I will never get finished

First I got some sierra bits from a breakers yard for a bargain price,

I have stripped the hubs and they are at the blasters as we speak

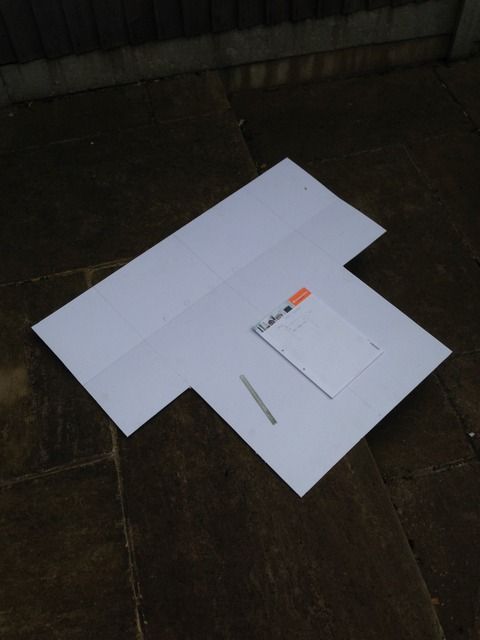

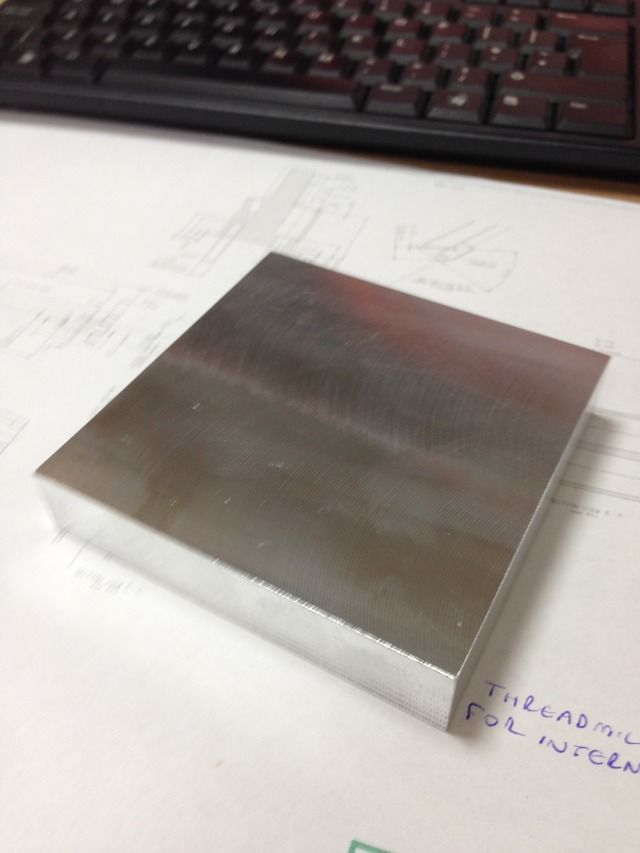

Material ready to get started

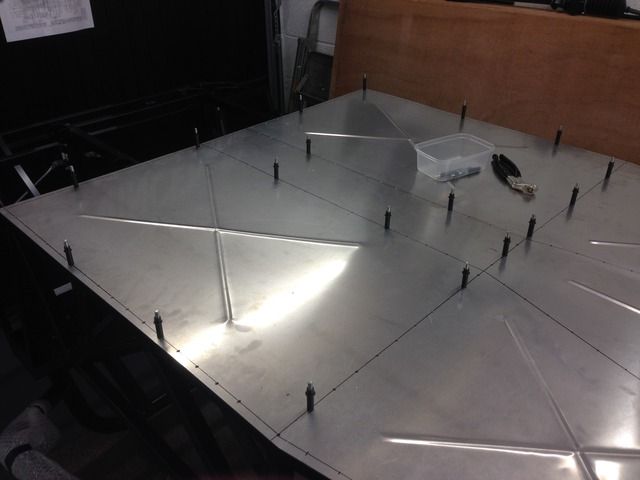

Next we built a build table, we used a sheet of ply for the frame, and a sheet for the top

Then got things marked out and started cutting

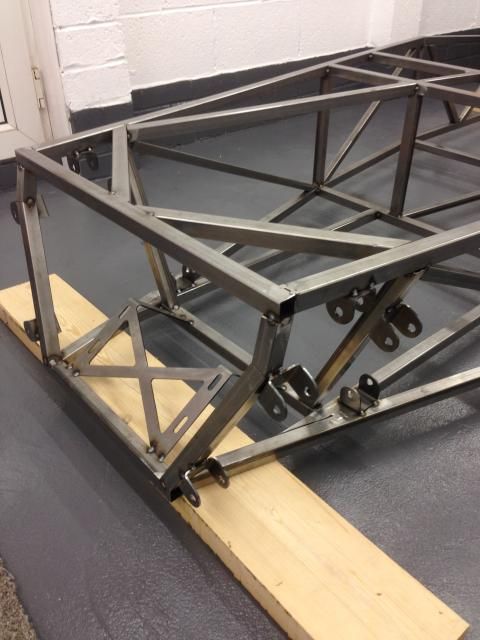

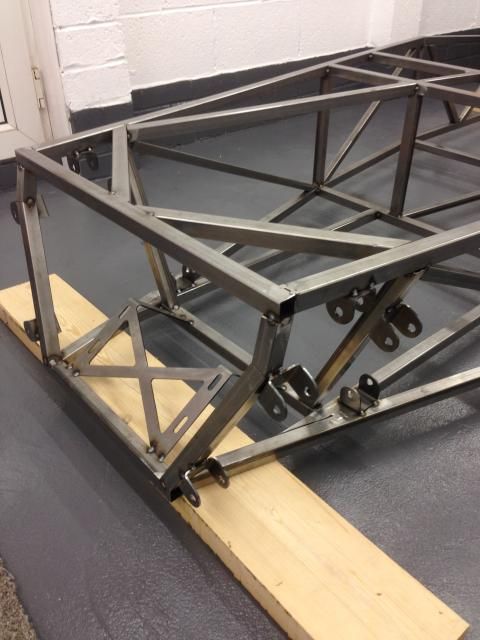

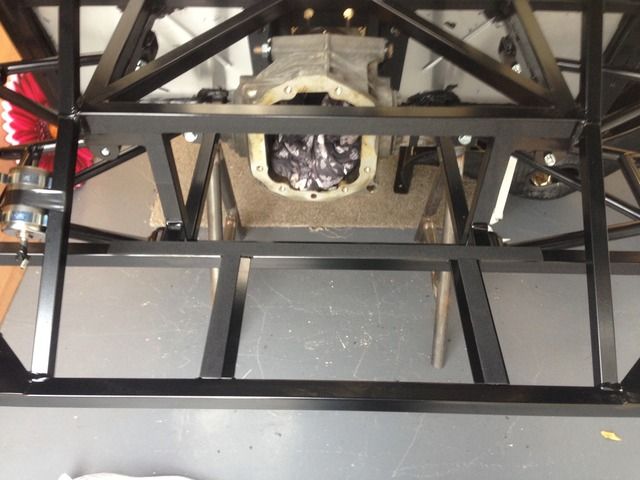

Front frame done

I was surprised how quick it started to take shape considering we cut the box as we went along

Next up the tunnel and cross braces

Then the diff cage

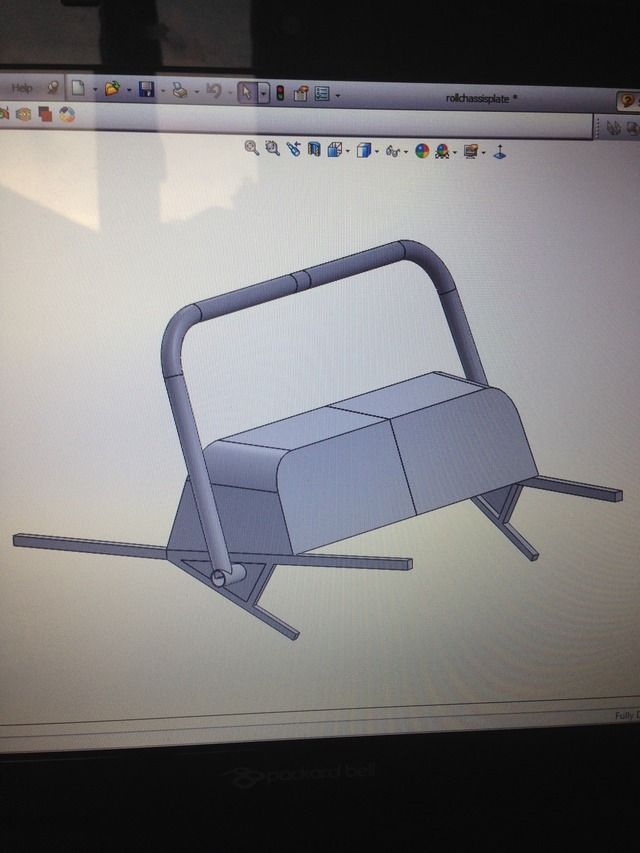

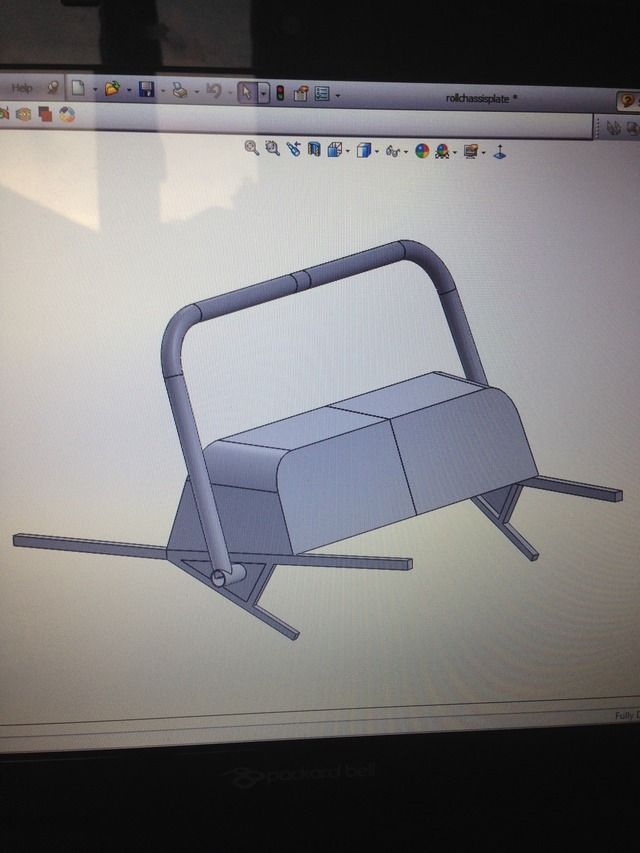

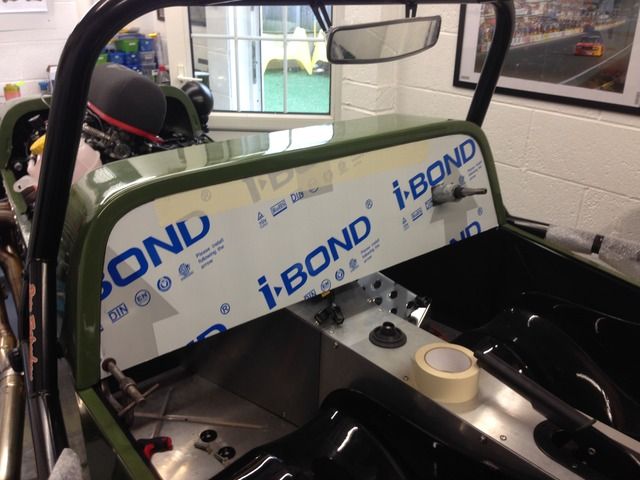

Got my roll bar bent up yesterday by Tom at www.tube-bender.co.uk, not to far from my house, bent out of 2" cds tube, well pleased with it,

I'm aiming to meet msa spec but not sure if the rear stays can be angled out, I'm going for a full cage but just got the rear hoop until I

get my

Scuttle mounted and see what room I've got

It's only clamped on for now as I've got to finish drawing up my parts for laser cutting this week hopefully

And that's about where I'm up to

Thanks for looking

Ben_Copeland - 26/10/14 at 07:34 PM

Good luck with the build. Any questions just ask

[Edited on 26/10/14 by Ben_Copeland]

RichieW - 26/10/14 at 07:54 PM

Nice to see a scratch build. There are fewer of them about these days.

madteg - 26/10/14 at 07:54 PM

Looks like you are doing a very good job, keep us up to date on your build.

gaz05 - 27/10/14 at 12:43 AM

I think you've got U7 in the wrong place. It's a common mistake. I did it also. It's not welded level with BR9 but with the bottom

transmission tunnel tube. That way it leaves more space for the pedals and you can still get a type 9 box in if you ever want to change to cec

later.

Edit. I think I'd look into putting some decent supports to the centre of the table as well. Mine bowed and I had to stiffen it with some 4x2.

Best of luck. Mine took me four years and only got on the road last weekend. It was worth it

[Edited on 27/10/14 by gaz05]

big_wasa - 27/10/14 at 11:22 AM

quote:

Originally posted by RichieW

Nice to see a scratch build. There are fewer of them about these days.

second that

Rosco86 - 27/10/14 at 08:09 PM

Cheers for the comments,

Yeah it was in the wrong place but I realised and moved it

The table has 3 200mm wide on edge ply strips running the length of the bench, you just can't see them lol

I was thinking about just putting a straight tunnel in, but wasn't really sure until I get an engine

nick205 - 27/10/14 at 08:14 PM

quote:

Originally posted by big_wasa

quote:

Originally posted by RichieW

Nice to see a scratch build. There are fewer of them about these days.

second that

Me too!

Something I'd like to do myself given time.

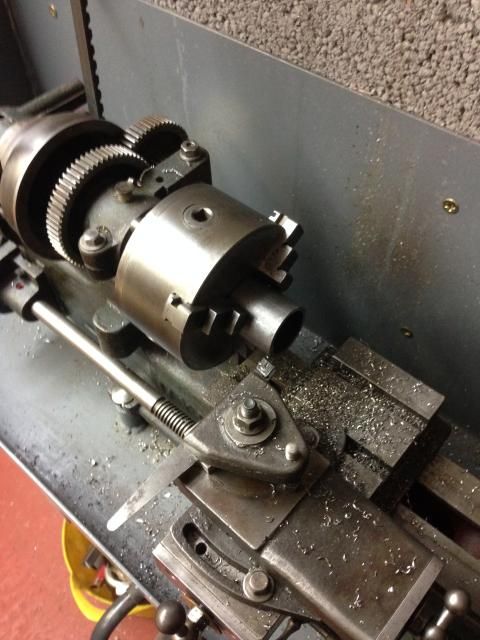

Rosco86 - 28/10/14 at 10:08 PM

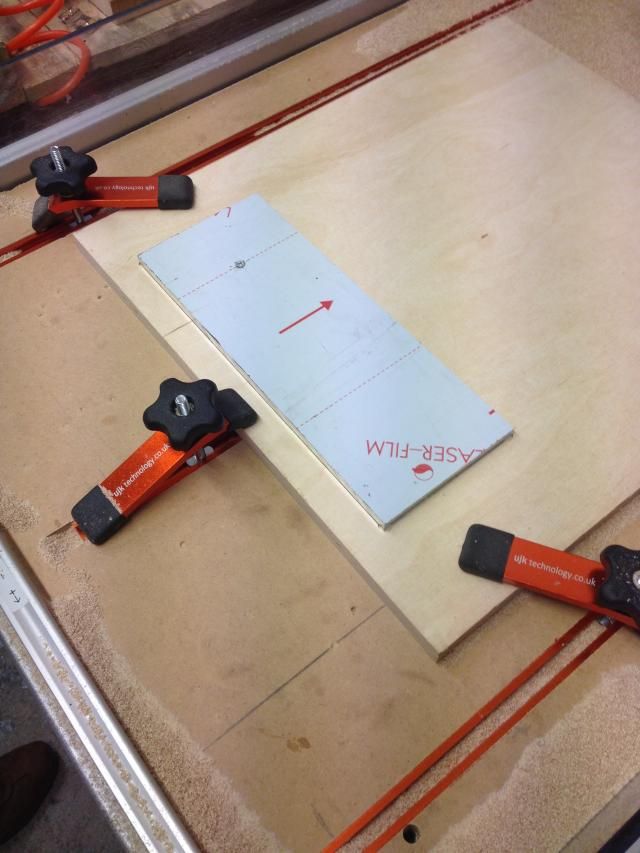

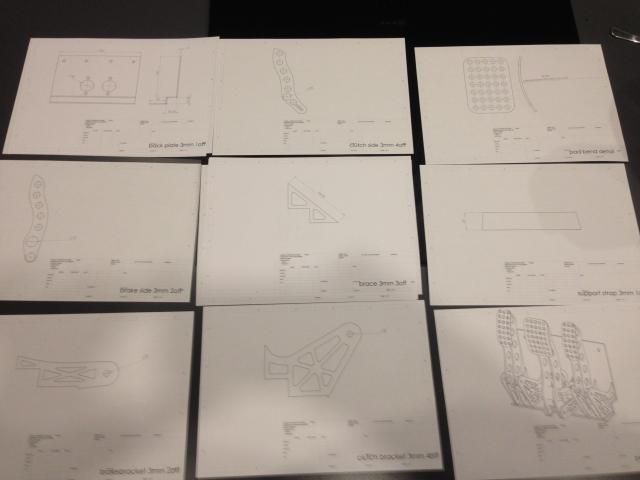

A bit more done tonight, took my cad drawings down to the laser cutters after work, hopefully get some bits back for the weekend!

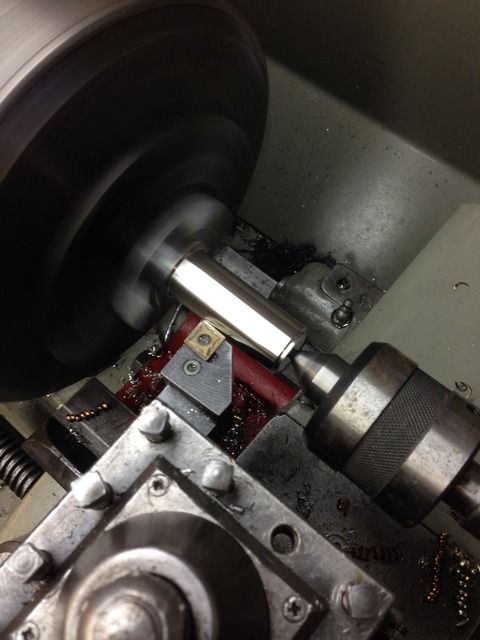

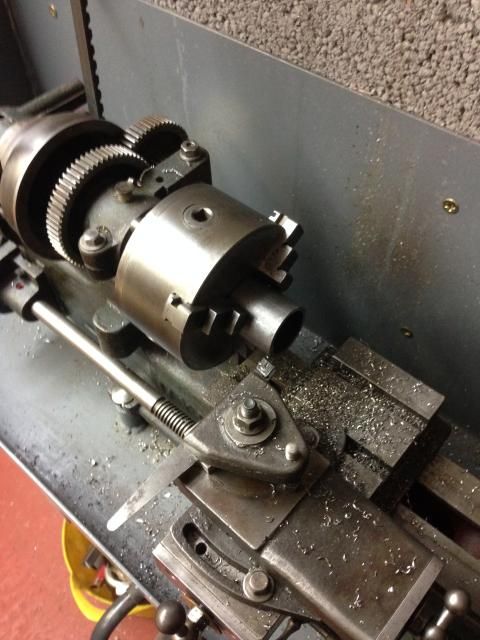

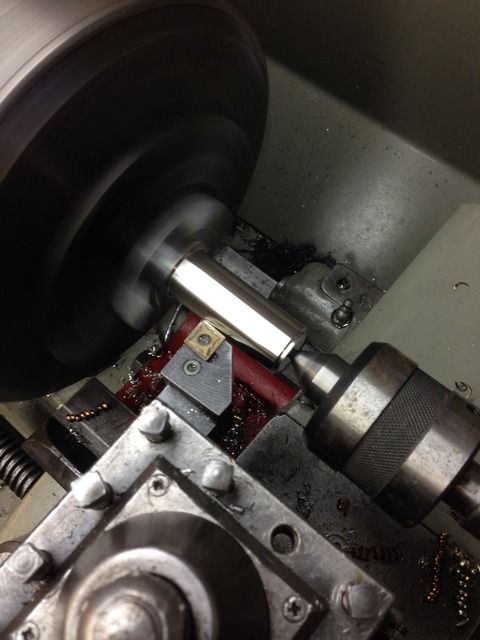

Also cut and turned to length the wishbone bush tubes, just got to bore them out to size, not sure if my little lathe will cope, might have to

upgrade!

Rosco86 - 30/10/14 at 07:35 PM

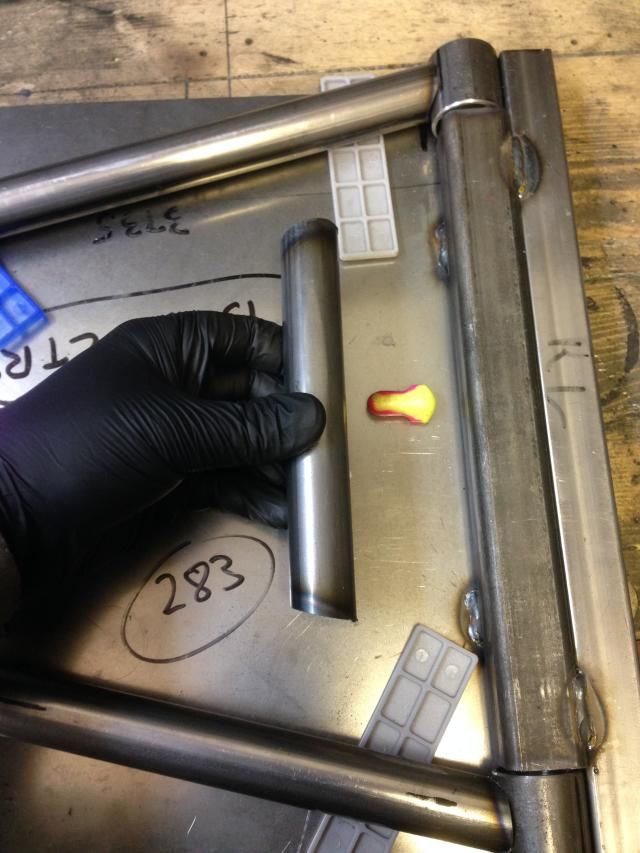

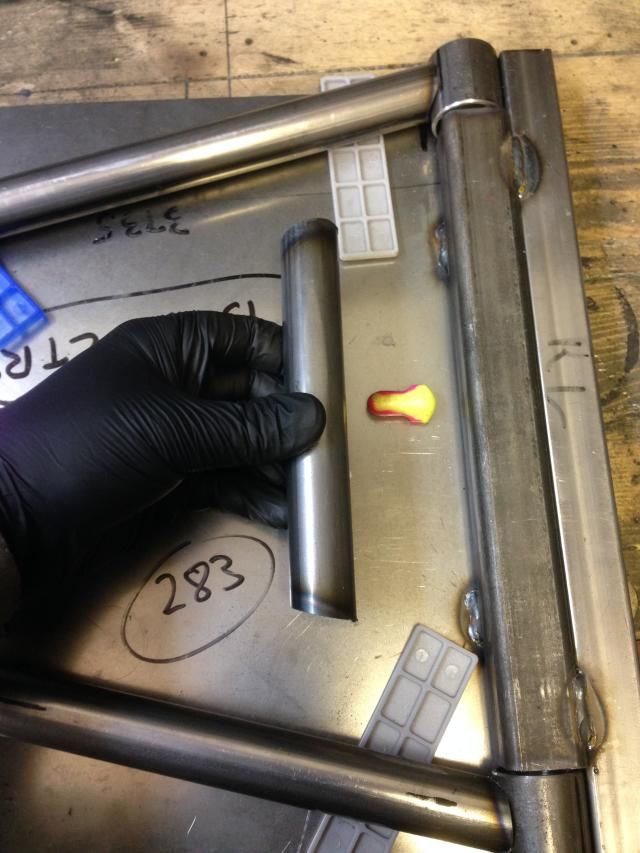

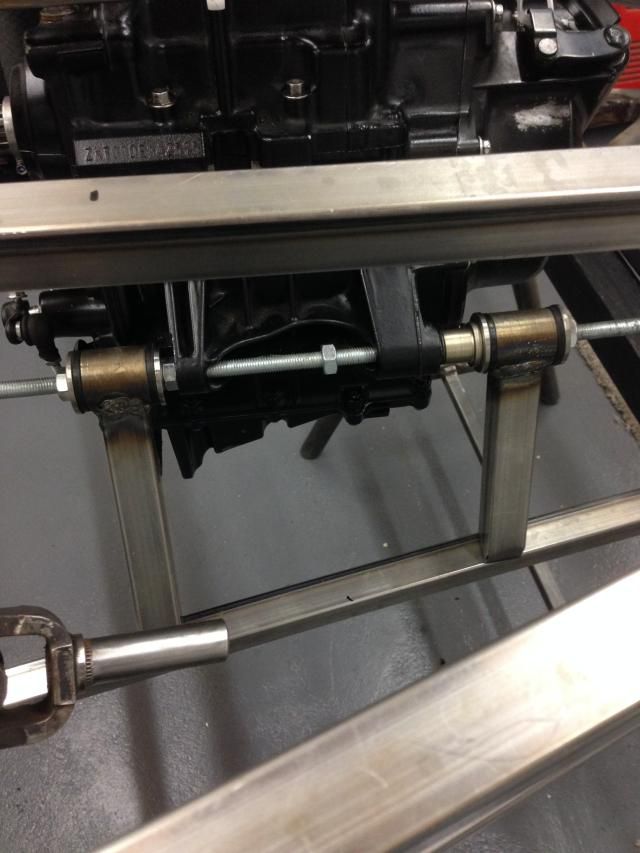

Some more progress ready for a busy weekend

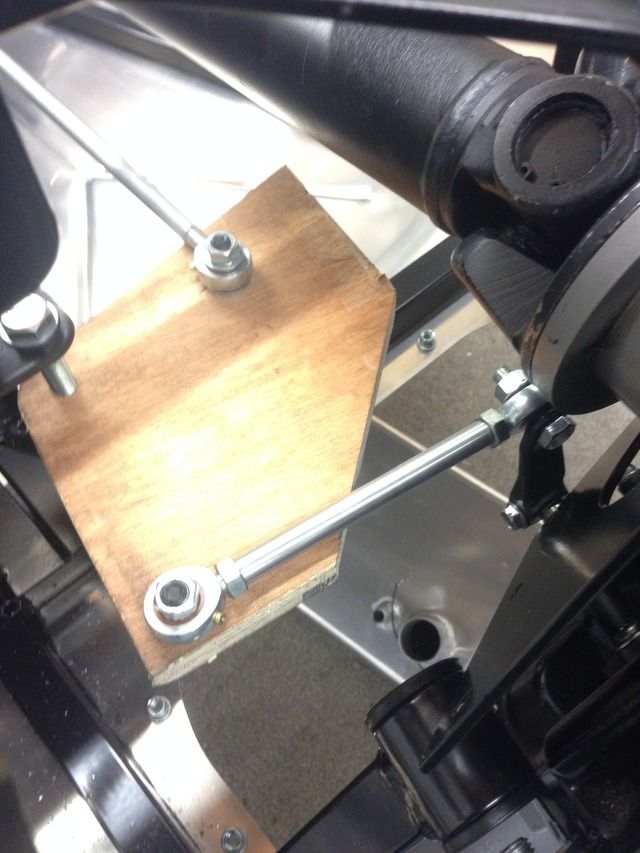

Made my wishbone end threaded tubes and got my laser cutting back, also I got the sheets cut out for the wishbones jigs so there nice and square

Digimon - 31/10/14 at 11:13 AM

Brilliant post so far Rosco, keep it up

Rosco86 - 2/11/14 at 06:05 PM

We had another good weekend, my dad help too so got a bit done

Started off welding up the shock towers, my weldings ok but my mate who's a pro is going to weld my chassis up

Then tacked the roll bar on

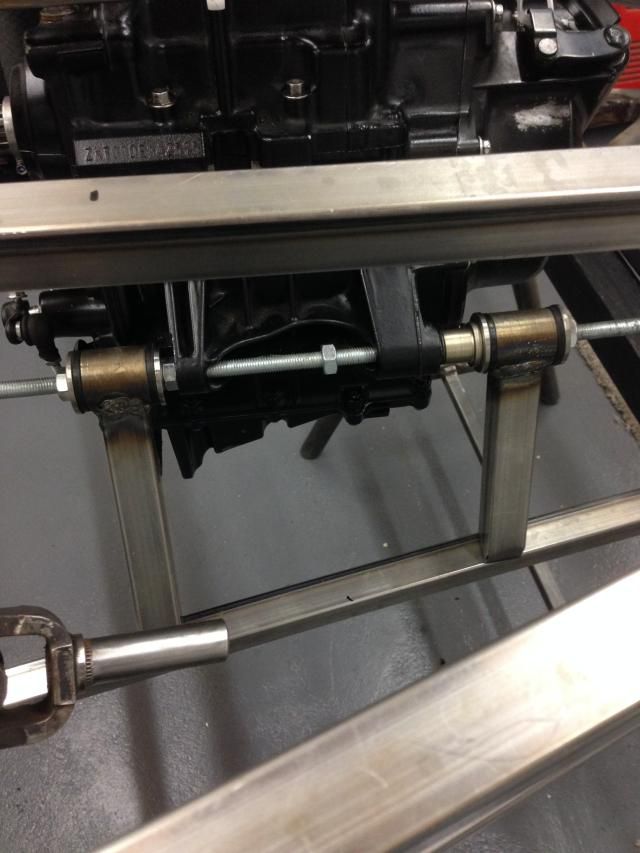

Then the diff mounts

Then made some foot plates for the rear stays

Next all the suspension brackets, which took a bit of time to make sure they were as good as they could be, we tweaked the legs of the front frame out

to close the gap between the brackets so no packing was needed

Then took it from my workshop into my garage ready to go for welding next week

That's that, got the workshop tied out so we could move again as it was getting a bit tight with the chassis in there,

Then just cut the tube up ready for the wishbones

Thanks for looking!

Rosco86 - 9/11/14 at 07:31 PM

Got my chassis welded up this week

Sorry about the photo quality

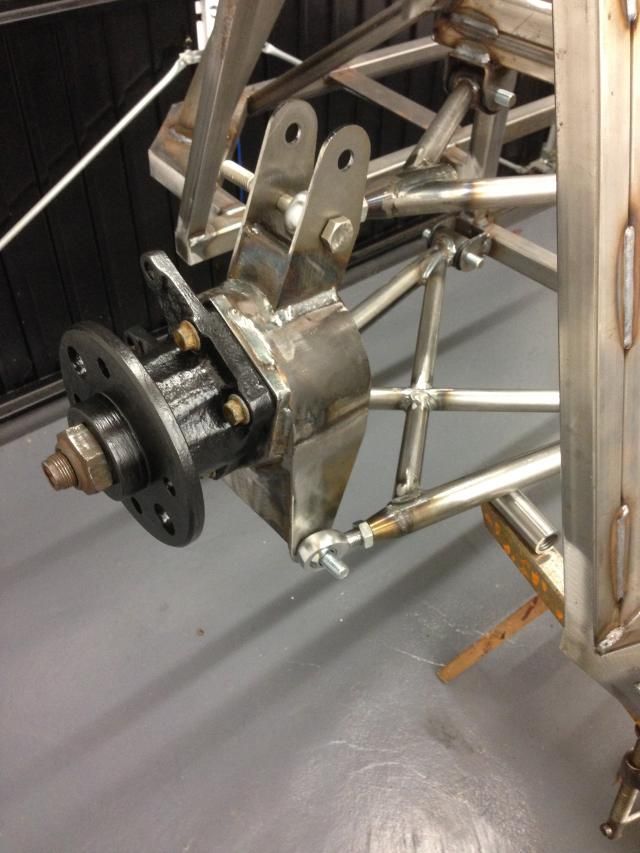

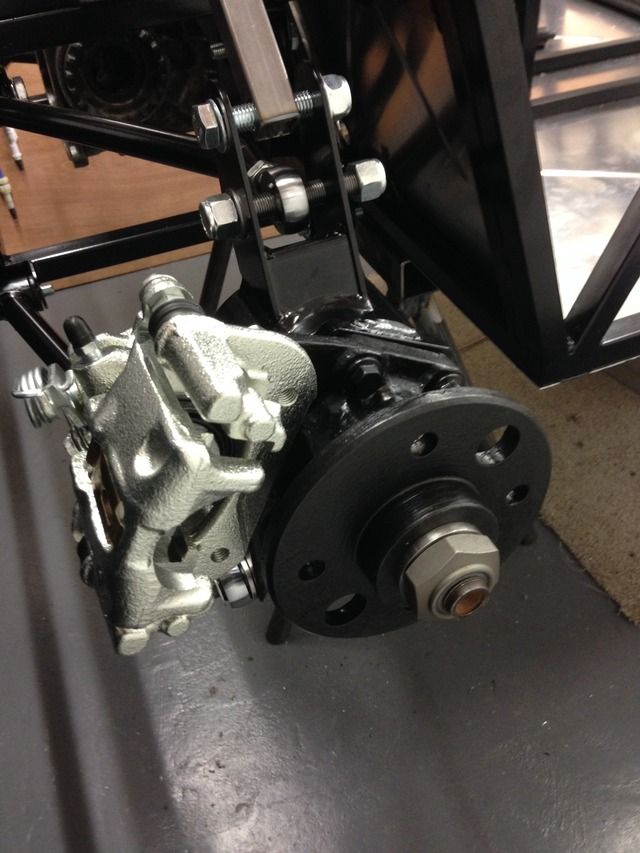

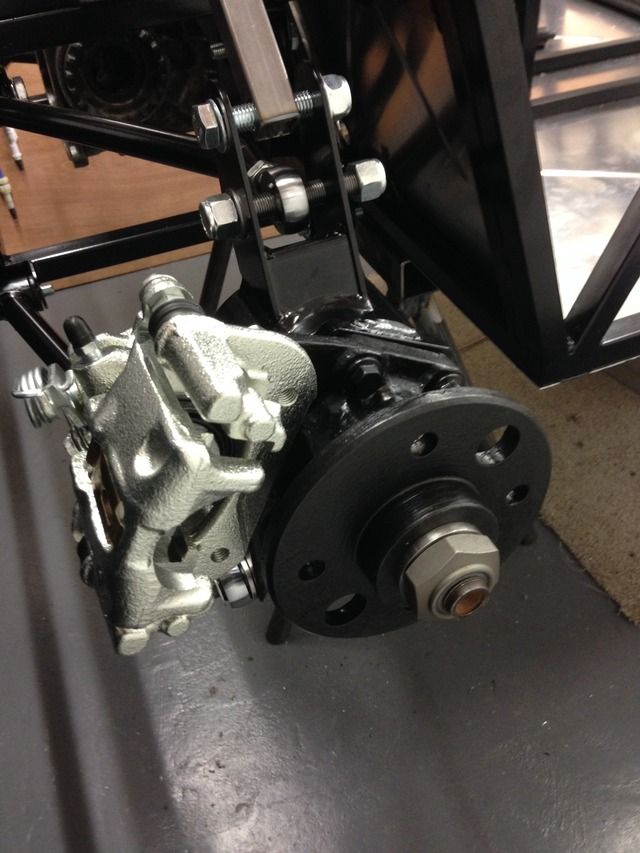

Also I got my hubs back from the blasters so I can get them painted and built up

That's about it for this weekend

big_wasa - 9/11/14 at 07:45 PM

Nice work

Digimon - 18/11/14 at 10:31 AM

Any updates Rosco?

Rosco86 - 18/11/14 at 09:39 PM

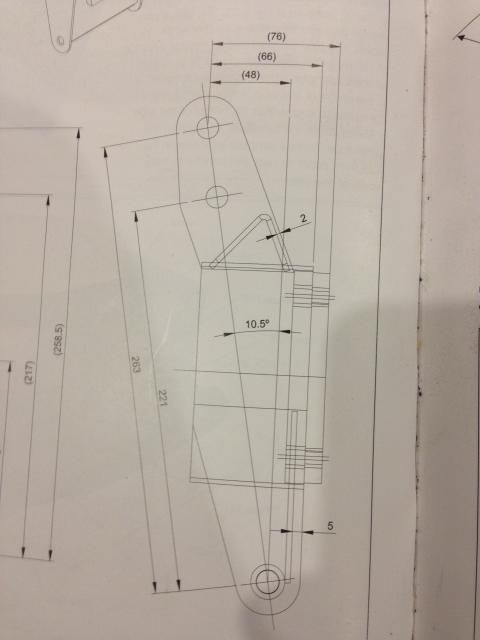

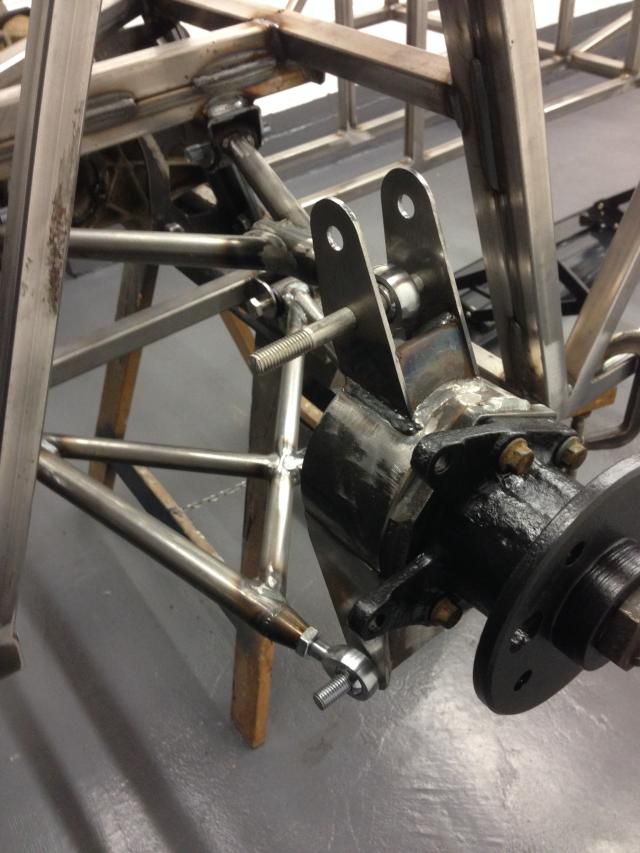

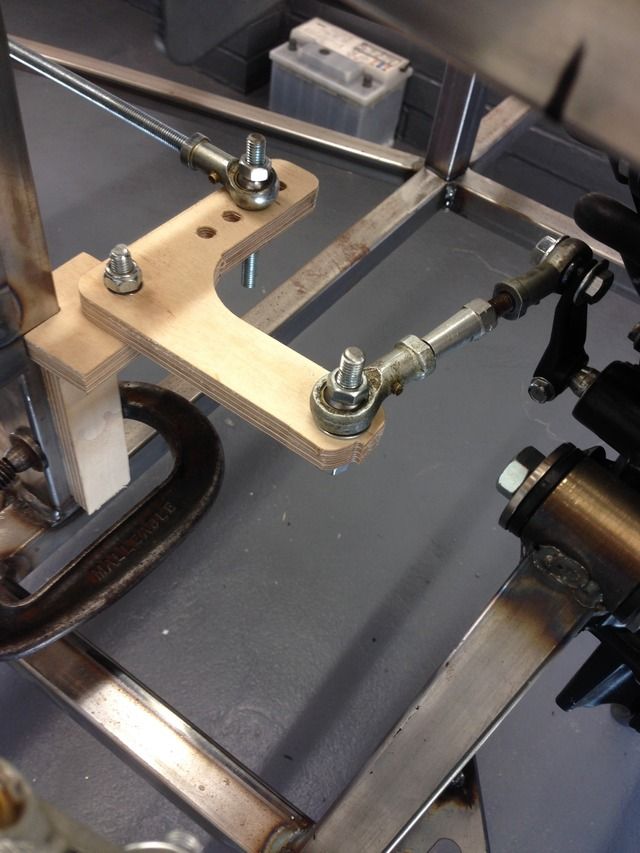

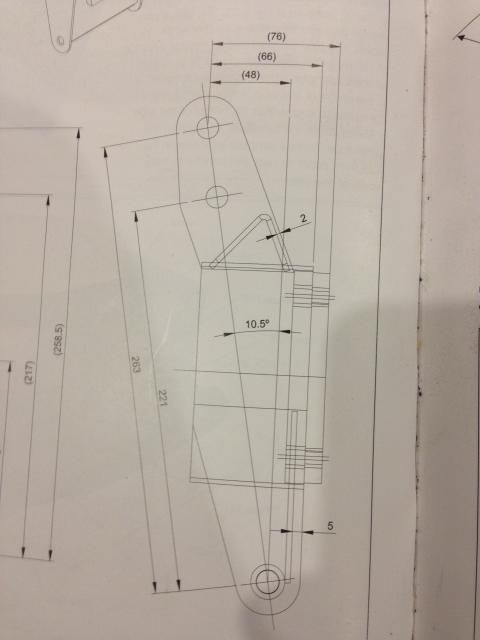

Not so much progress as as I would of liked but never the less, I've made all my wishbone jigs and made a start on them but got side tracked with

the rear uprights

Added a bit to the jig to help position the tube and side plates

I've rotated the front plate as from what I can work out it should make the handbrake cable on the rear discs fit better,

Does it look right to everyone?

Also I think the 66mm in the drawing below should be 70mm, I've posted a thread here if anyone can help

http://www.haynes.co.uk/forums/showthread.php?p=99211#post99211

[Edited on 18/11/14 by Rosco86]

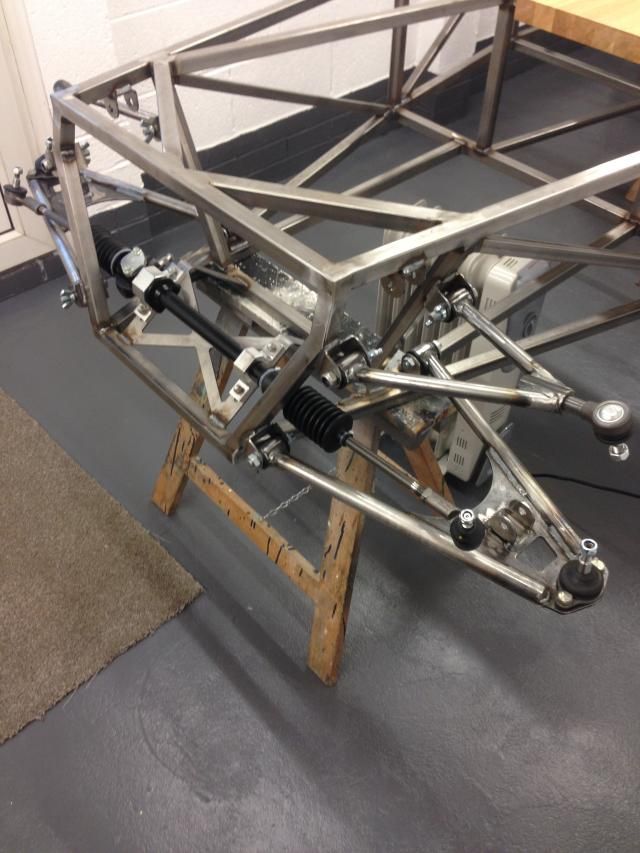

Rosco86 - 7/12/14 at 06:05 PM

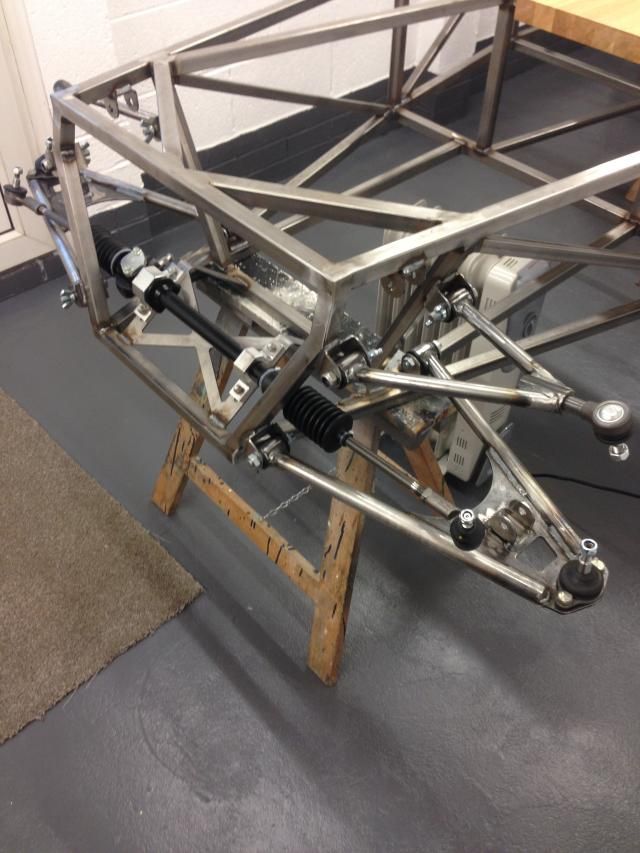

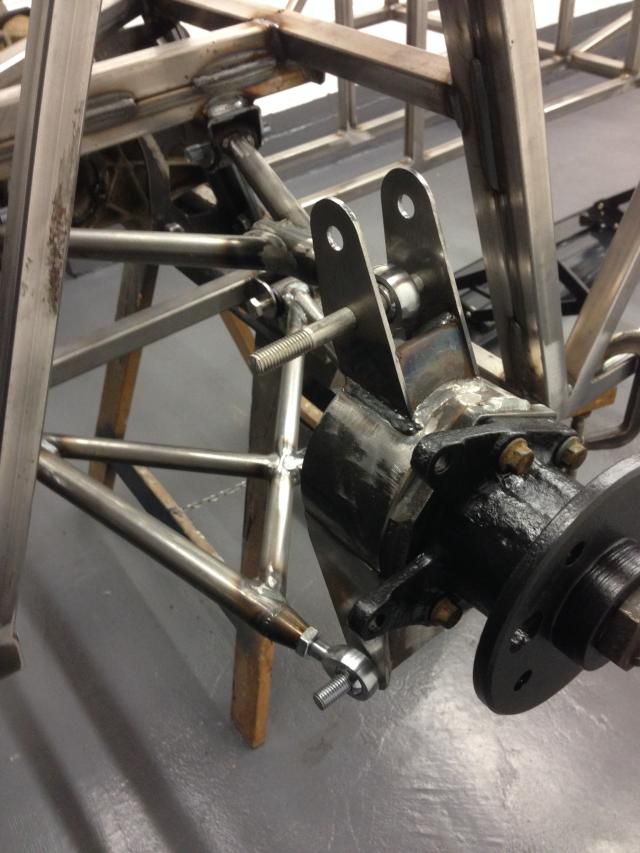

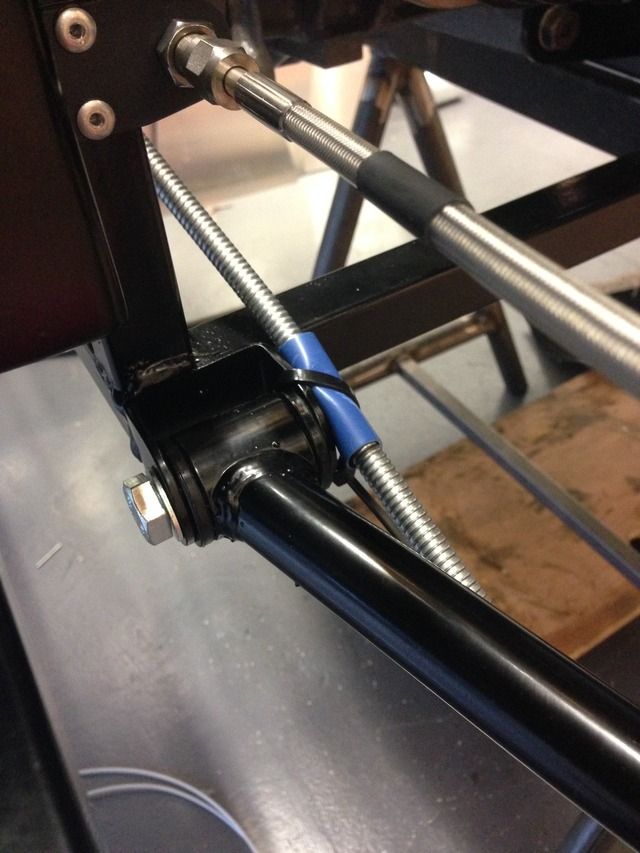

Bit of an update, got my rear hubs fully welded, and made my front wishbones, just waiting on my mushrooms for the front so I can fit my hubs

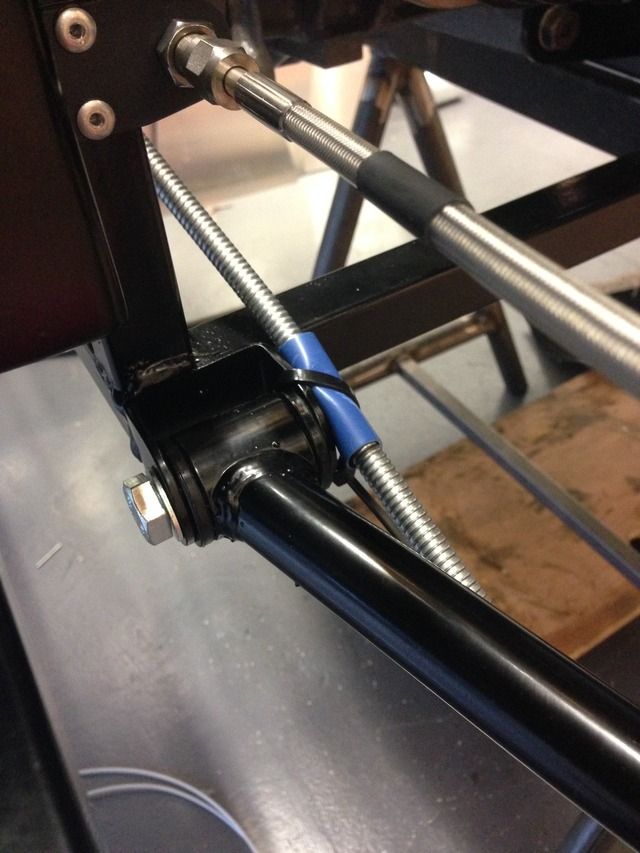

Oh and got my rack and got it fitted, need some steering extensions now

Also I'm after a column if anyone's got one?

Onto the rears next, hopefully get some wheels on it before christmas

mark chandler - 7/12/14 at 07:27 PM

Great looking build, such a tidy workshop !

Rear roll bar stays, in the blue book there is a minimum angle that these must meet, be worth checking this angle is met.

With a bike engine all you should need is the hoop and stays due to engine size (depends on cc), however you would be wise to add a diagonal at this

point in the build, you must also be cognisant of the height rule when setting out your seat mountings, lower is of course better so mock up a nose

cone then stretch a piece of string.

Regards Mark

Rosco86 - 7/12/14 at 08:08 PM

quote:

Originally posted by mark chandler

Great looking build, such a tidy workshop !

Rear roll bar stays, in the blue book there is a minimum angle that these must meet, be worth checking this angle is met.

With a bike engine all you should need is the hoop and stays due to engine size (depends on cc), however you would be wise to add a diagonal at this

point in the build, you must also be cognisant of the height rule when setting out your seat mountings, lower is of course better so mock up a nose

cone then stretch a piece of string.

Regards Mark

Haha thanks, that's my garage, I do all my fabricating in my workshop at the bottom of my garden!

Yeah the min angle is 30deg mine are 27deg, but they are all the way back on the chassis so a bit rubbish really, I'm not building it to compete,

but would it fail do you think?

Yeah I'm going to use grp seats and they will be right on the floor, I want a rear hoop diagonal but the haynes book says to have a horizontal

with harness mounts in, so I'm waiting to get my seats to see if my harness will be ok in the top of the chassis, then I can have a diagonal

I'm going for a full cage I think, just waiting to get my scuttle before I sort the front hoop

tajgreidotu - 7/12/14 at 08:36 PM

Congratulations for the clean build. I'm just 2 steps behind you, so its nice to see your progress.

Just to clarify, in this picture the tube RS15 should go on the opposite side. Did you do it on purpose?

I forgot to weld it while doing the box, im afraid maybe is too late

Have fun!

Rosco86 - 7/12/14 at 09:03 PM

Thanks, no I've done it wrong, just had to go and have a look in the book, I don't no how I managed that, I've used 5mm think plate

where the shock bracket mounts to, but I might still add another RS15 in the correct place

Well done for spotting it! Bit annoyed I've slipped up though!

mark chandler - 7/12/14 at 09:09 PM

I cannot see failing, plenty of cars are similar and do not get pulled up, mounting belts on a horizontal bar requires very short rear straps, mine

has a diagonal and the harness mounts are on the rear stays which gives a little more length.

It's best to build for as it opens options, just follow the blue book and you will be fine

Rosco86 - 7/12/14 at 09:54 PM

quote:

Originally posted by mark chandler

I cannot see failing, plenty of cars are similar and do not get pulled up, mounting belts on a horizontal bar requires very short rear straps, mine

has a diagonal and the harness mounts are on the rear stays which gives a little more length.

It's best to build for as it opens options, just follow the blue book and you will be fine

Ok that's cool then, it's a bit hard to measure the angle as they are splayed out so should be ok,

Mounting on the rear stays sounds good, do you have a picture?

Yeah I'm trying to meet msa spec, that's why I've used cds tube

Thanks for your advice too

tajgreidotu - 8/12/14 at 03:27 PM

quote:

Originally posted by Rosco86

Thanks, no I've done it wrong, just had to go and have a look in the book, I don't no how I managed that, I've used 5mm think plate

where the shock bracket mounts to, but I might still add another RS15 in the correct place

Well done for spotting it! Bit annoyed I've slipped up though!

Let me know how you fix it, ill have to do it too

nick205 - 8/12/14 at 04:16 PM

Very nice to watch it coming together.

I do like the use of wing nuts on the wishbone bolts whilst building. I made the mistake of fitting with nylon lock nuts, then making myself replace

them on final fitting.

Rosco86 - 14/12/14 at 08:33 PM

Well had a full day on the car today, got my front hubs fitted then cracked on with my rear wishbones,

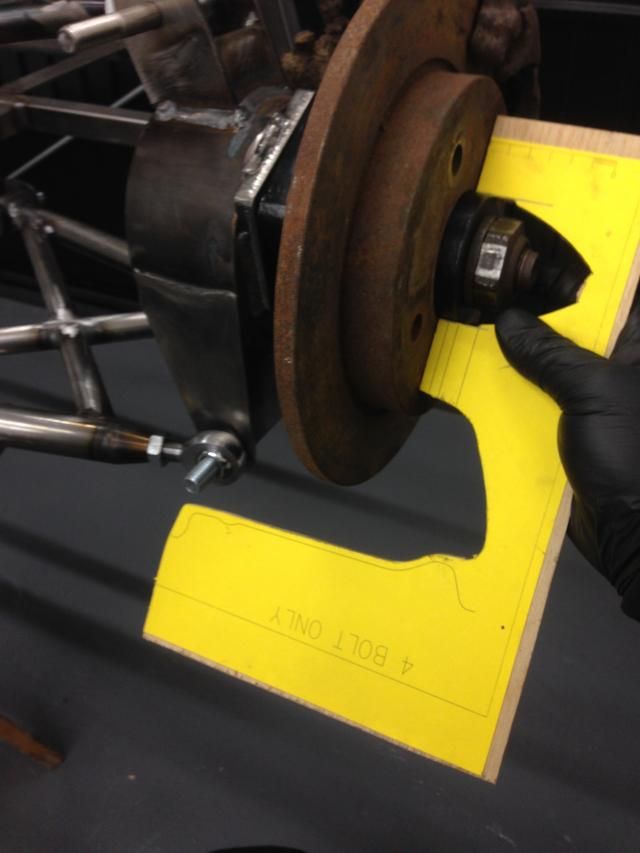

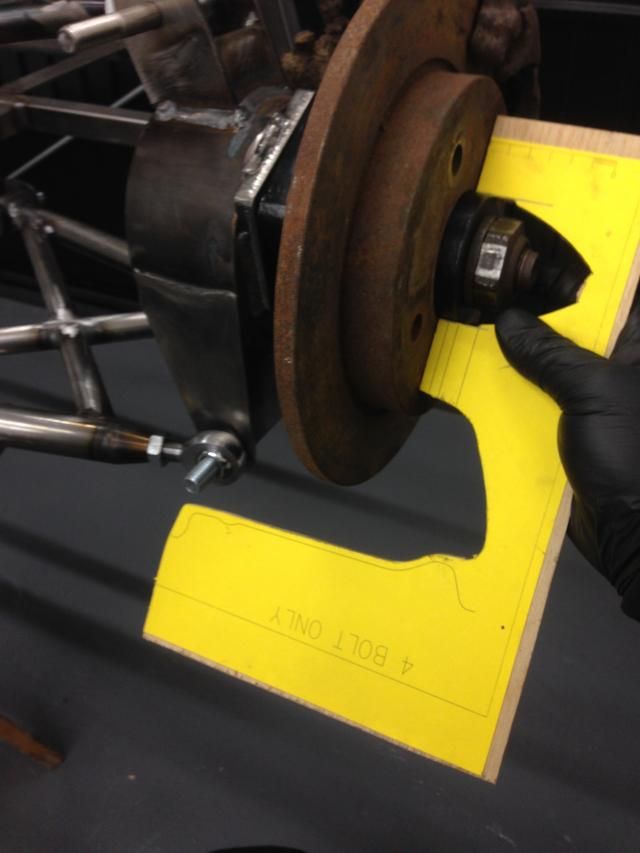

I had offered up some rod ends on my rear hubs, and checked with a 13" wheel template from team dynamics, and they will fit

I don't no why but I have the latest book with the new 10mm longer wishbones but the jig drawings look like they haven't been changed, so I

had made my jigs to that, then when I had made a wishbone and checked the bush centres they were 10mm short, to say I was unhappy was an

understatement, I can't believe there's nothing on the amendments page just to give you a heads up, I think i will get away with it as I

have wound my rod ends out 5mm and I might skim 5mm off the matting face on the stub axle or put a spacer behind the hub, so a std driveshaft fits

The rod ends are still in the tube insert a full 1" and they are only threaded that much so that's ok, just didn't really want them

wound out to far

Just got to sort some spaces and washers out for either side of the rod ends

rdodger - 15/12/14 at 08:19 PM

Lovely build. Some really nice fabrication.

What rod ends are you using? M12 or 1/2"?

Rosco86 - 15/12/14 at 08:27 PM

quote:

Originally posted by rdodger

Lovely build. Some really nice fabrication.

What rod ends are you using? M12 or 1/2"?

1/2" just that bit bigger, seems the size most people use from my searches

I like to get a bit done most nights, i got a spot of paint on a few of my sierra bits, only a thin coat so probably give them another coat

[Edited on 15/12/14 by Rosco86]

Ugg10 - 15/12/14 at 08:48 PM

Some nice work, cracking project.

Stating the obvious, the template you did for the wheels also had to clear the calipers which is where it will foul if any where. I would double check

with the caliper in place on the disc as well.

Rosco86 - 20/12/14 at 07:56 PM

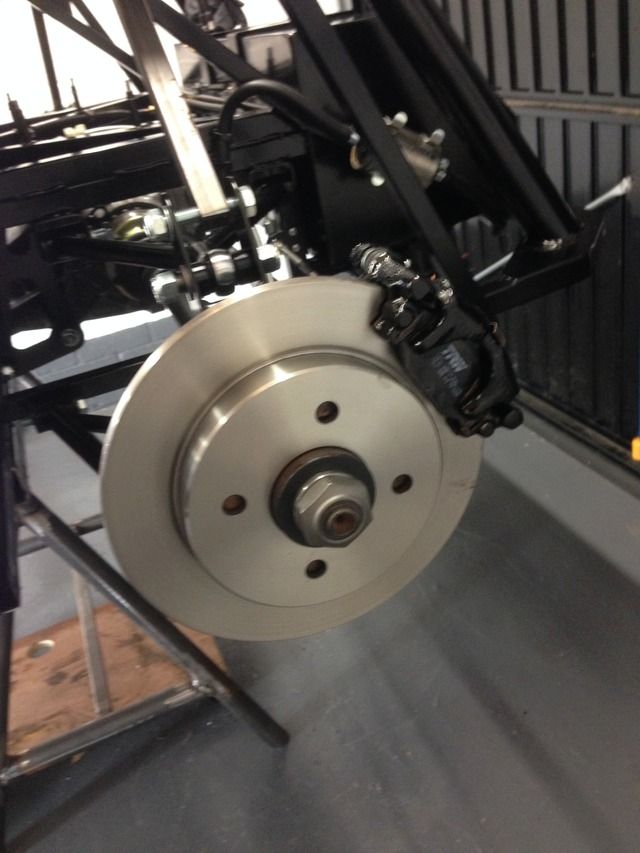

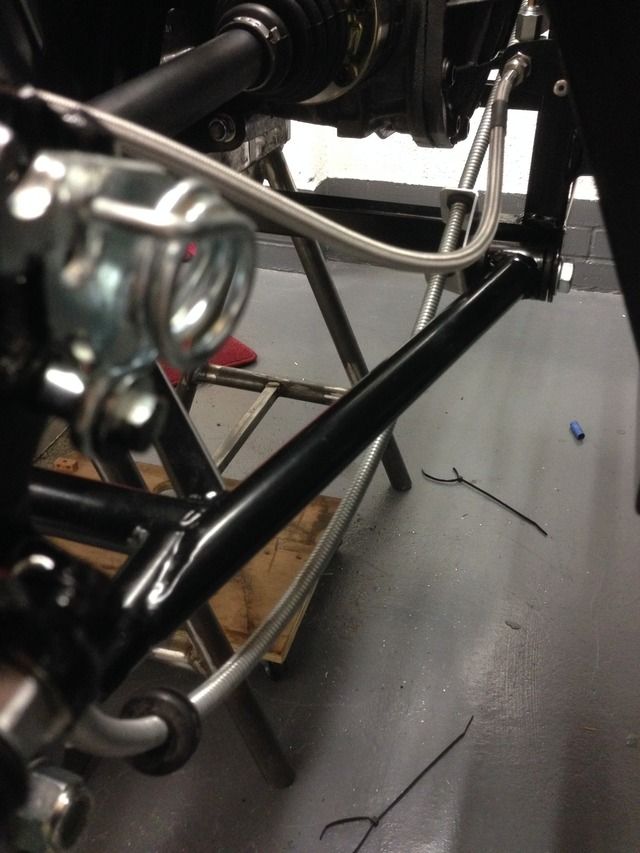

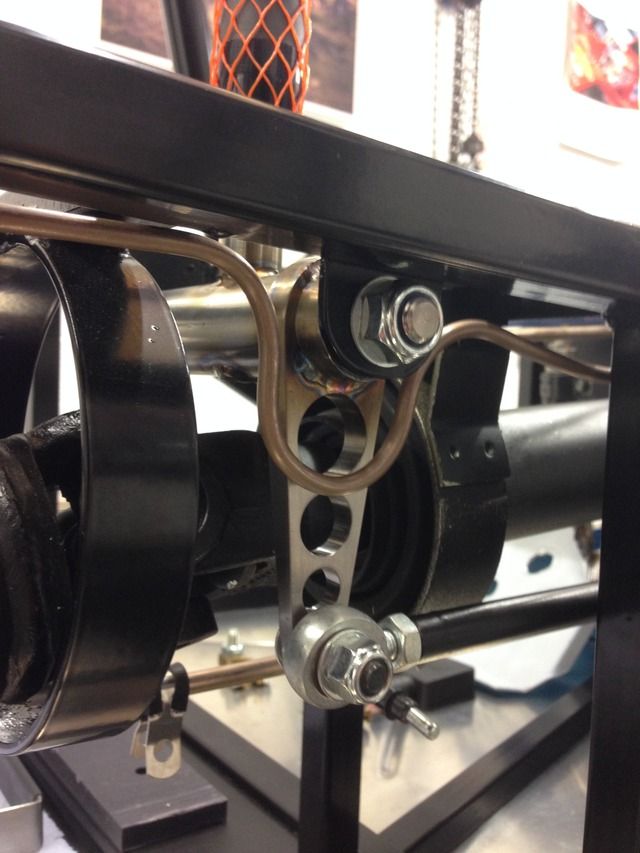

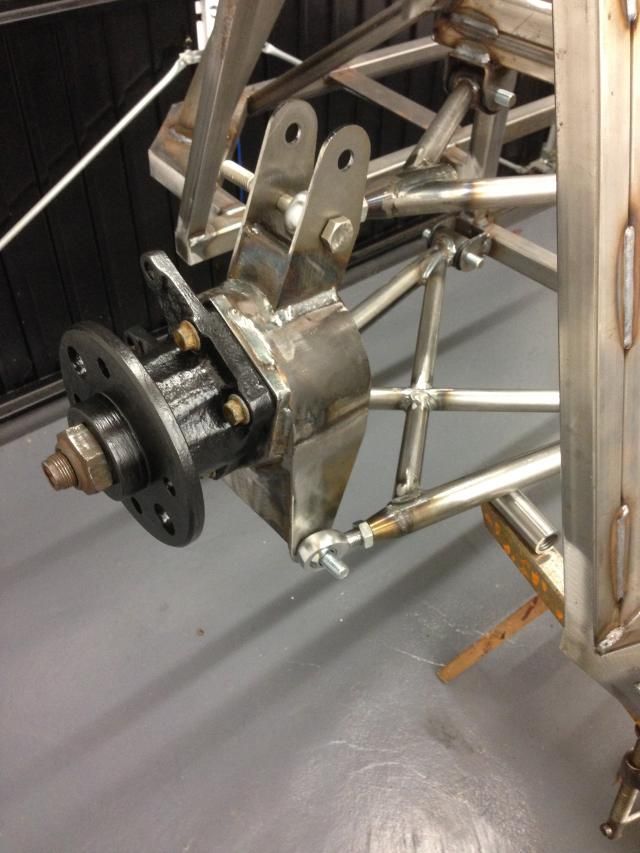

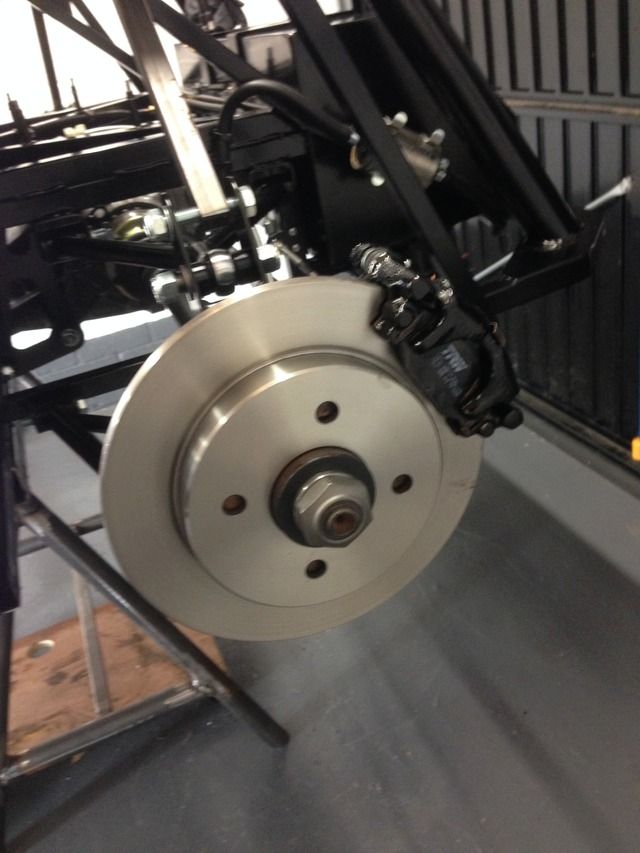

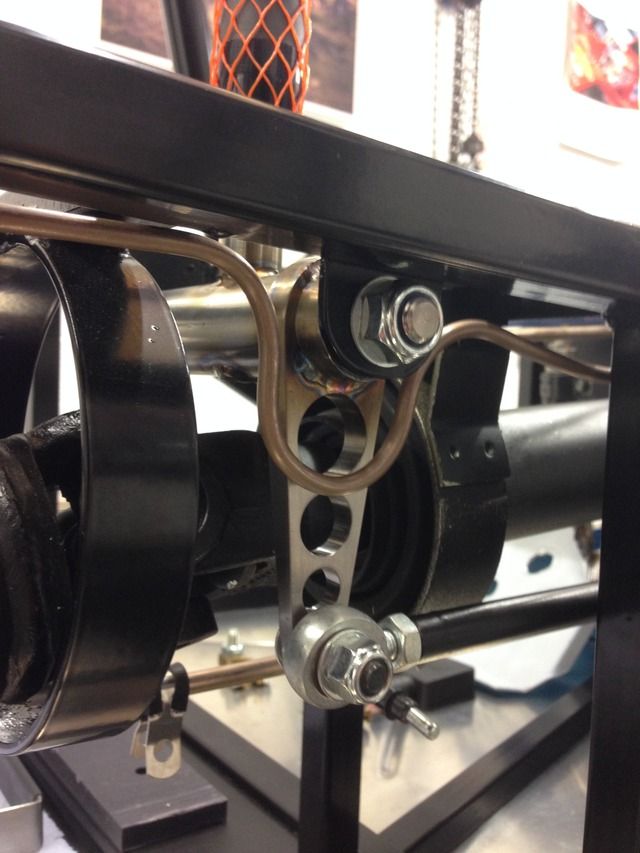

Got my rear wishbones back from the welders and built up my rear hubs and got it all together also put my front hubs back on

Fitted the old calliper to double check clearance, it's just the handbrake bit that needs modifying but I had read about this already

bart - 20/12/14 at 11:17 PM

good build keep going

Rosco86 - 22/12/14 at 07:35 AM

after sleeping on this a couple of nights, im going to remake the rear wishbones so the rod ends are straight, and have a bend in the side tubes, its

not because of the angle its more to do with the clearance either side of the hub, as when you wind the joints in and out the gap changes, also they

could do with being 5mm longer to suit std drive shafts, as the jig drawing in the book was wrong

Rosco86 - 26/12/14 at 08:28 PM

Well got a bit of time on my mk2 rear wishbones today, decided against the bend so notched them on the angle instead

I'm thinking about putting a tube here, notched round the two

And a tube at the back, obviously longer

These tubes are 25mm diameter, does anyone think I need a diagonal, I could use 19mm tube, just trying to keep the weight down, I have seen rear

wishbones with no diagonals just two cross bars like in my pictures

Rosco86 - 27/12/14 at 03:29 PM

Got a bit more done this morning

Rosco86 - 28/12/14 at 08:18 PM

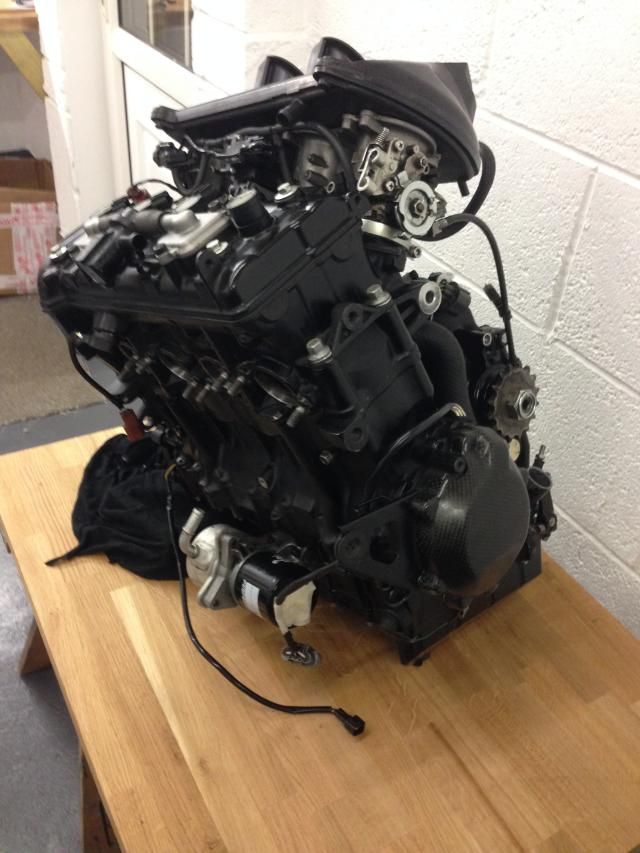

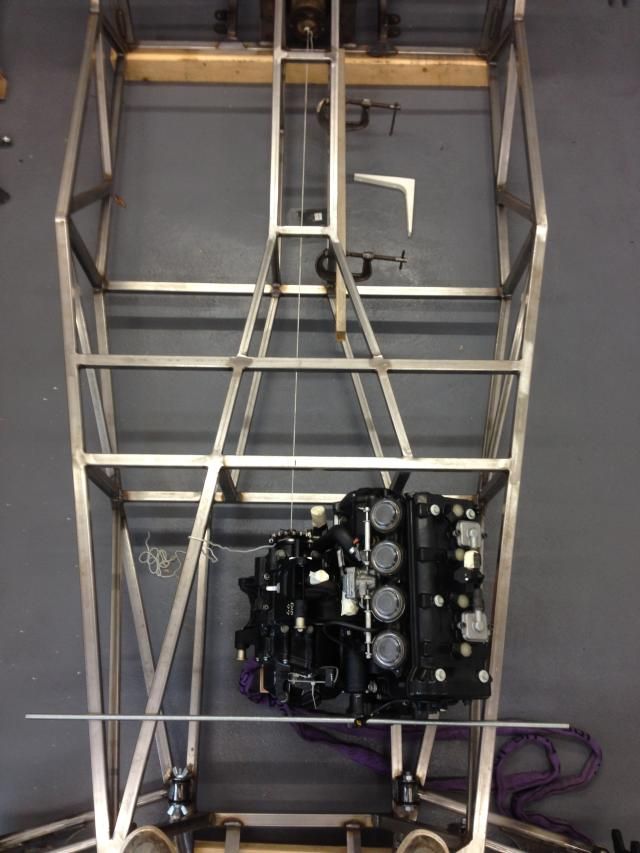

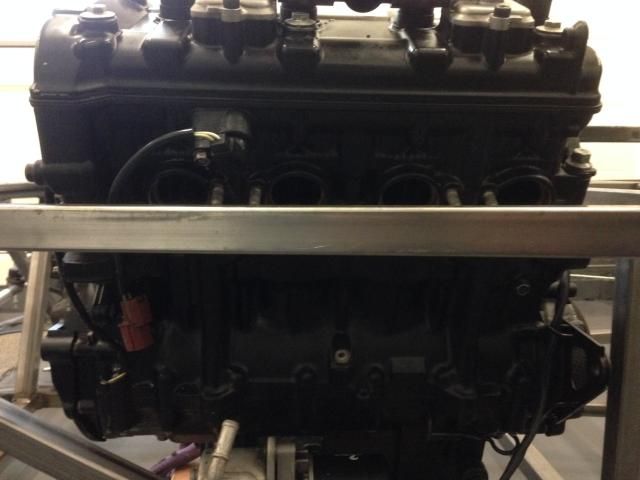

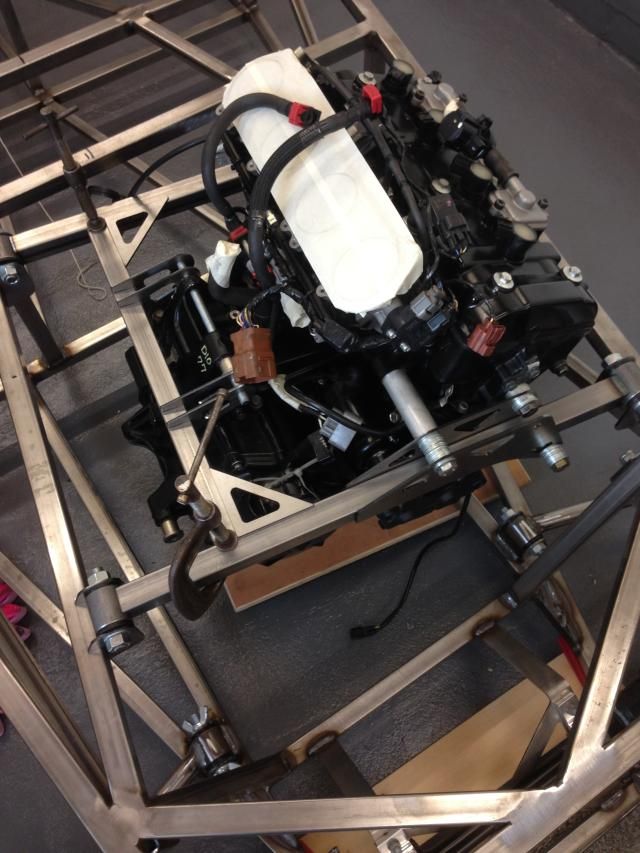

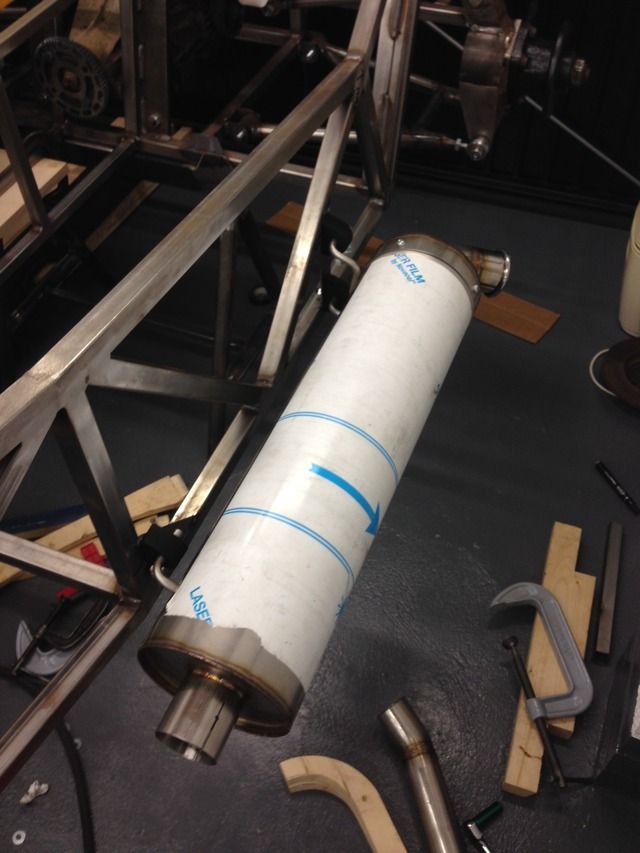

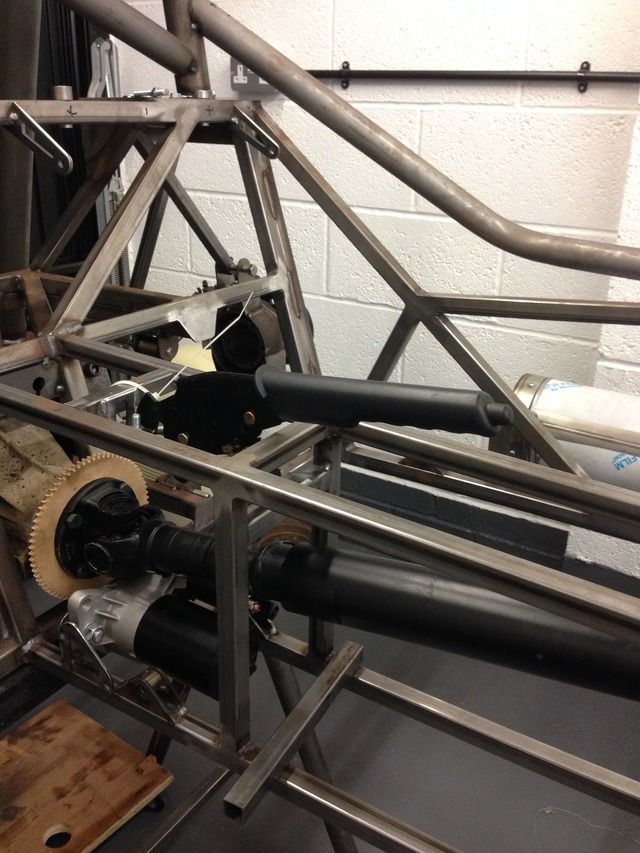

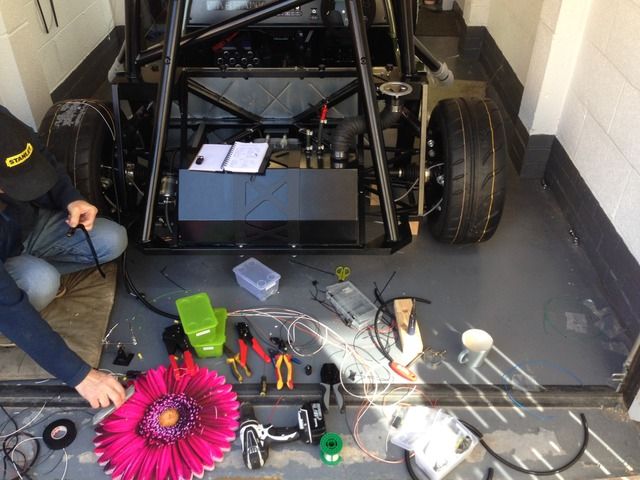

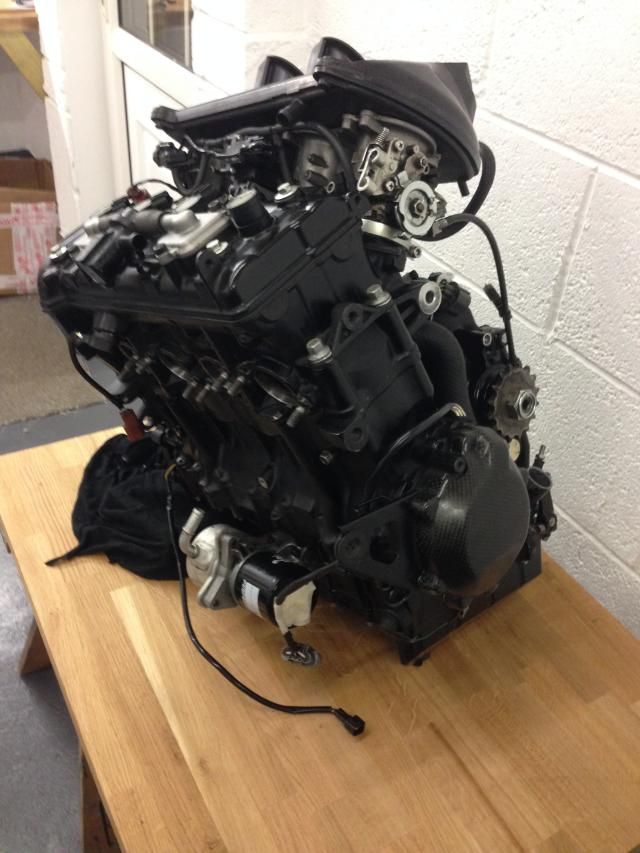

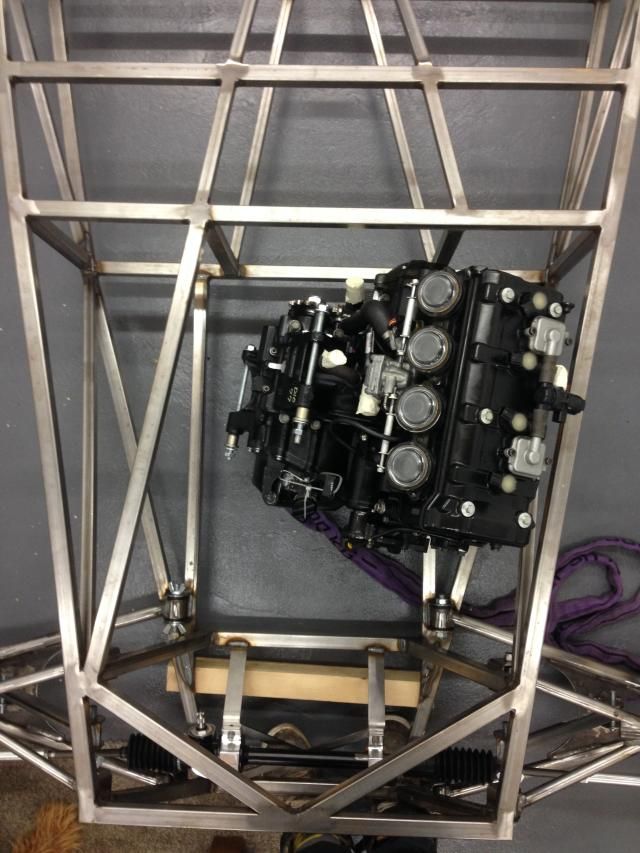

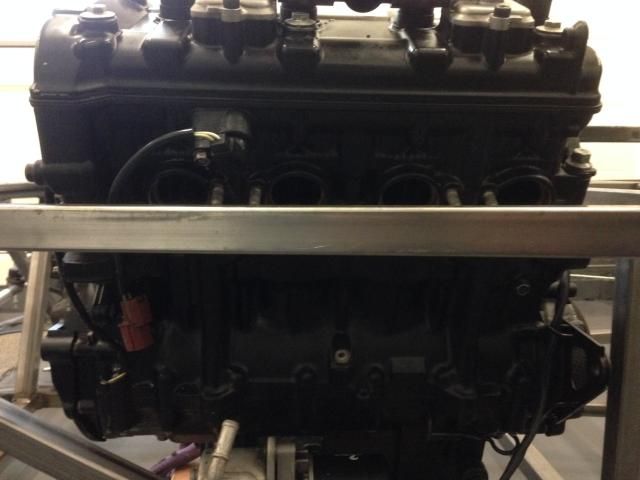

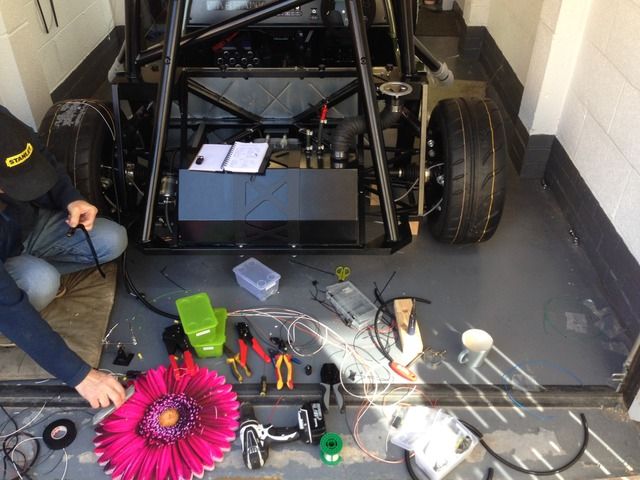

Well had a good day, went and collected an engine from Malc at Yorkshire engines, was a long drive there and back, left at 7:30 and got home about

2:30

It's a 2010 zx10-r

And a fancy shot of my garage

YODI - 29/12/14 at 09:46 PM

Watching this now, keep up the good work mate

BigMac - 30/12/14 at 08:31 PM

Lovely job so far, methodical, great quality and looks great- I will watch with interest! Great job!

Rosco86 - 30/12/14 at 09:55 PM

Cheers for the comments!

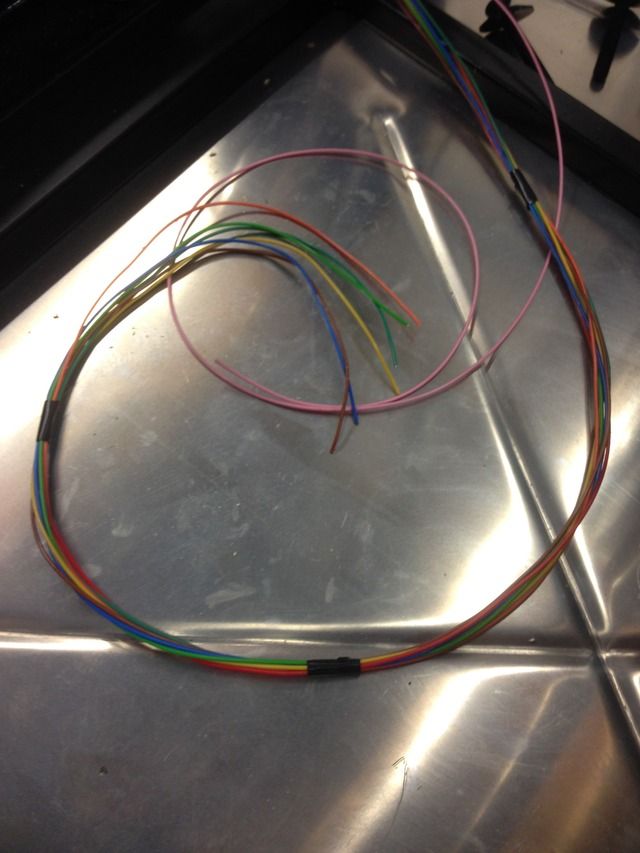

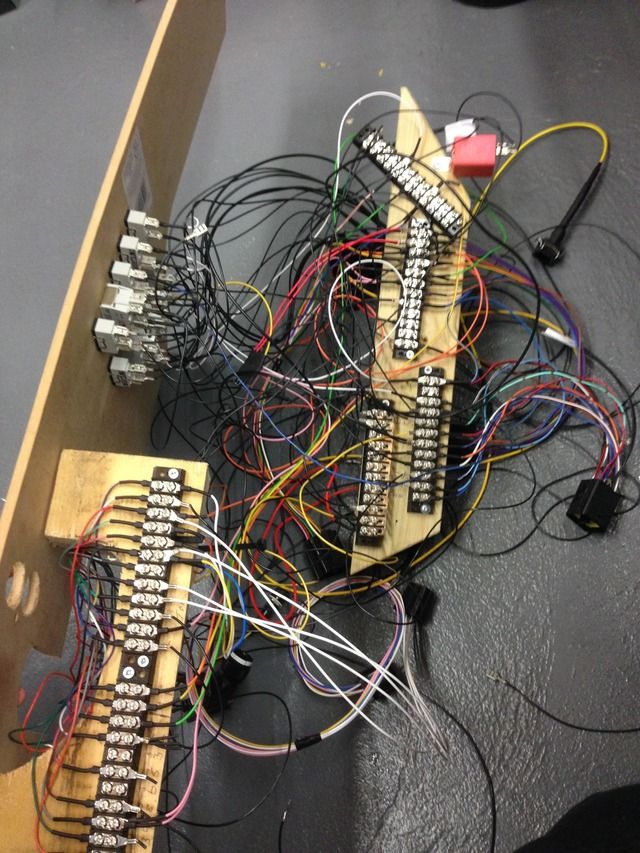

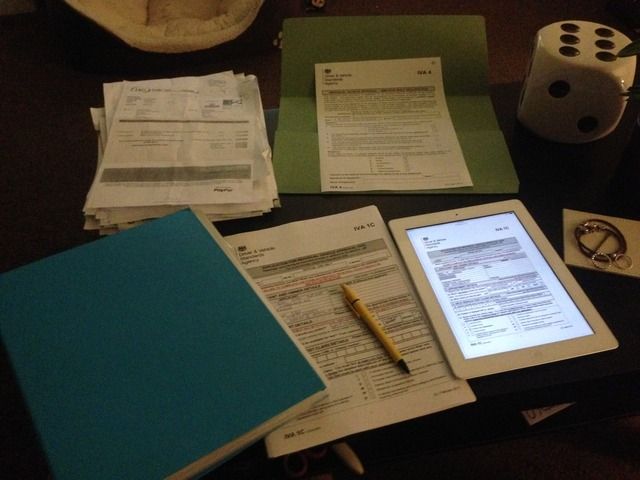

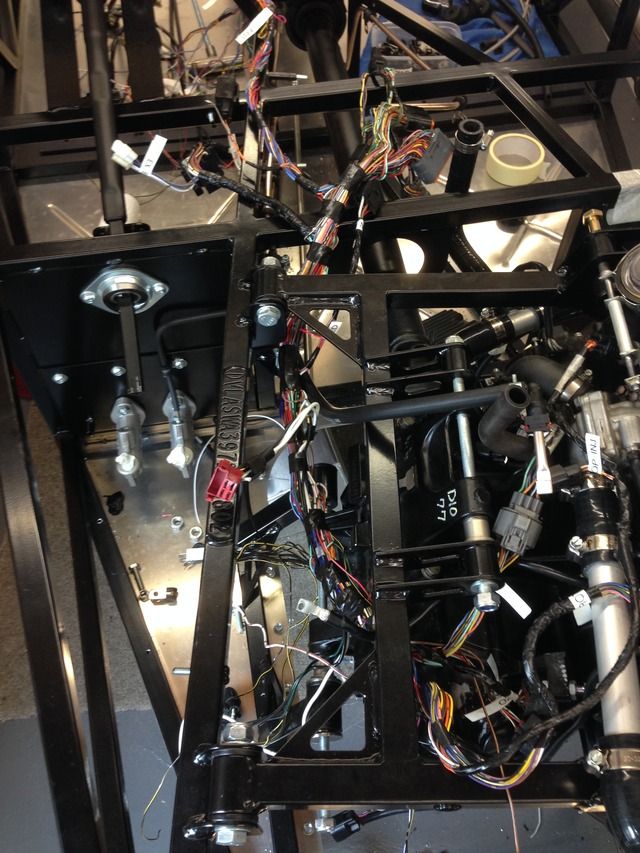

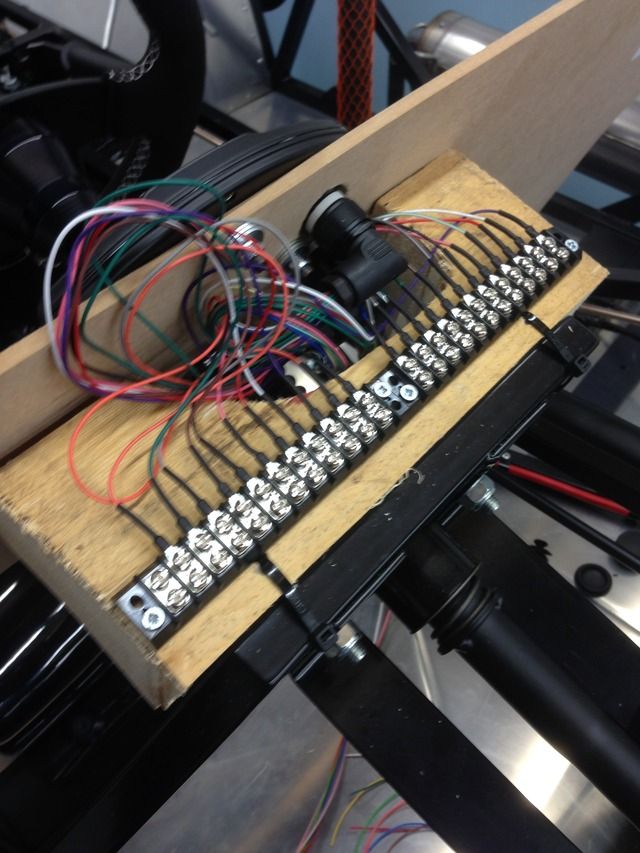

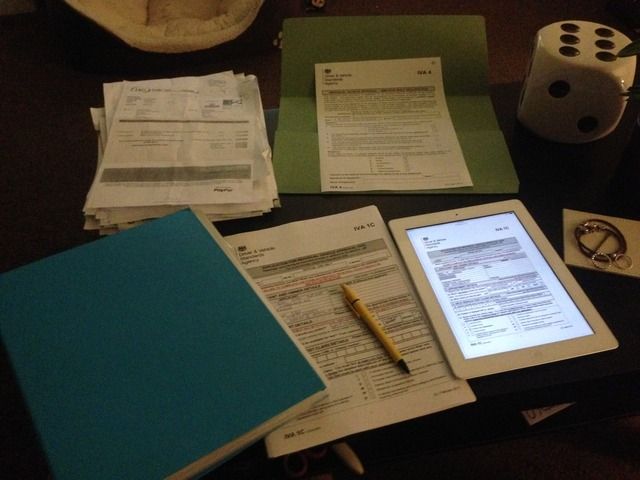

Sat down with my bike loom and labeled every plug using the wiring diagram to work out what's what

I think I'm going to use the bike loom as a base and extend and alter it to suit

Oh how I love my label machine!

Also my mate gave me a hoist, it was filthy so gave it a good clean and re grease, also shortend the loop chain from about 4 meters to a small hoop

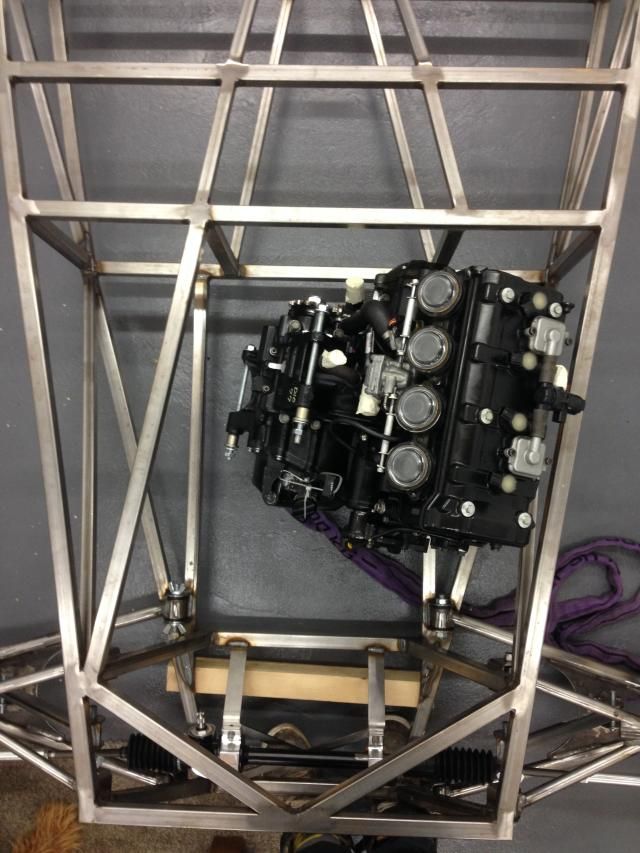

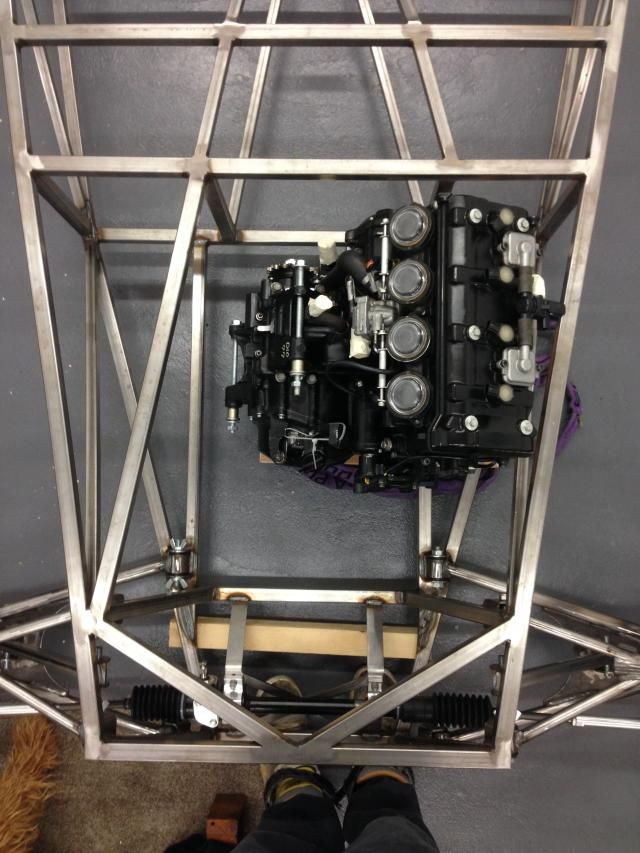

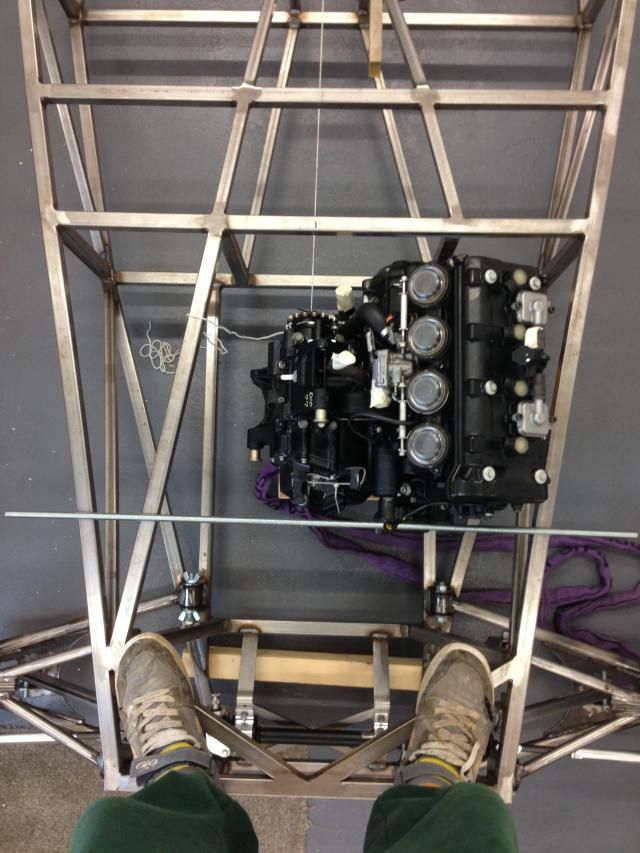

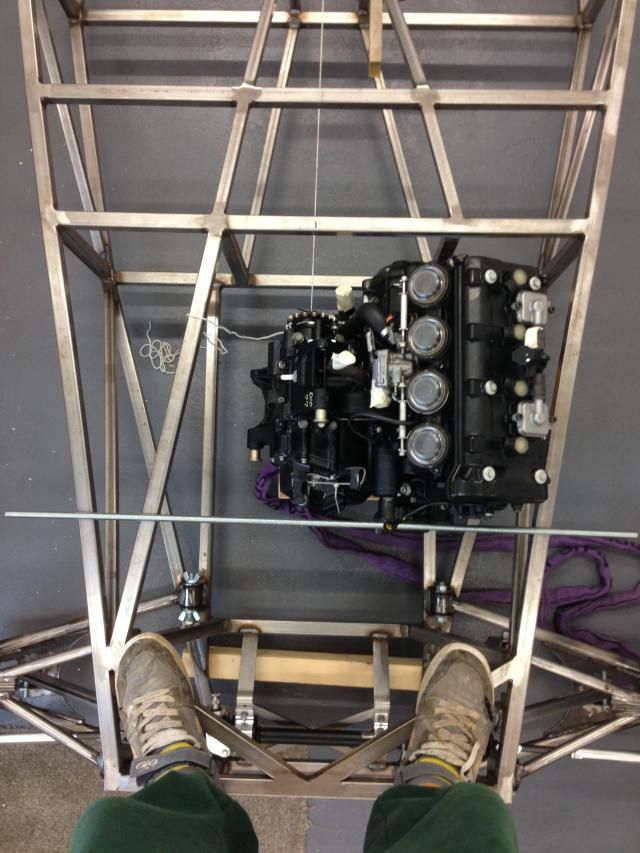

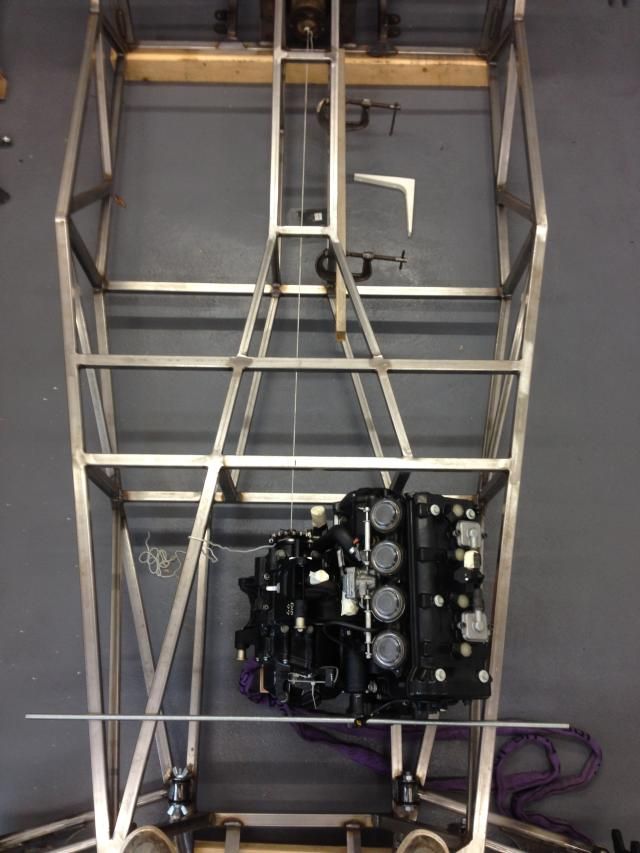

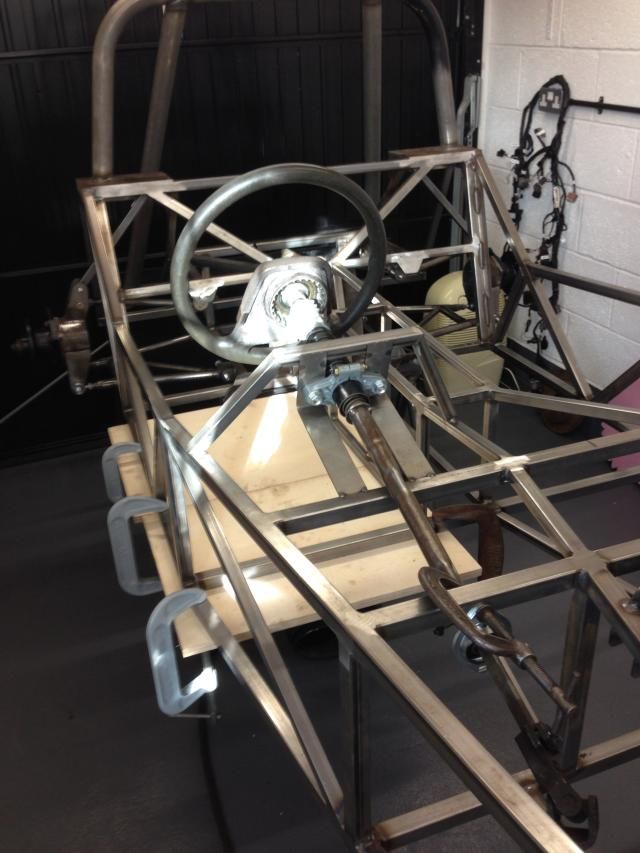

Rosco86 - 31/12/14 at 06:01 PM

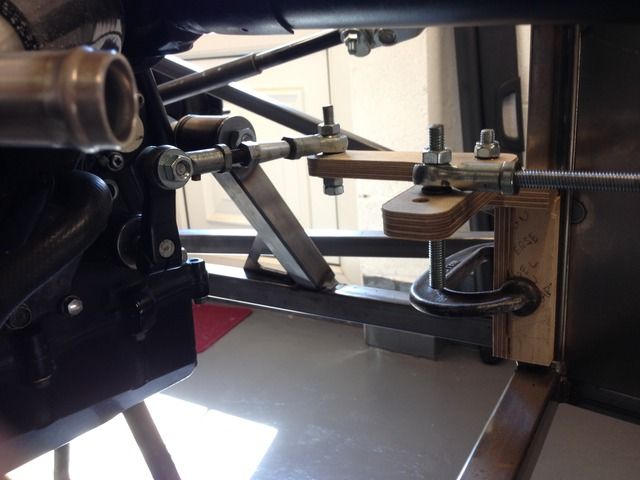

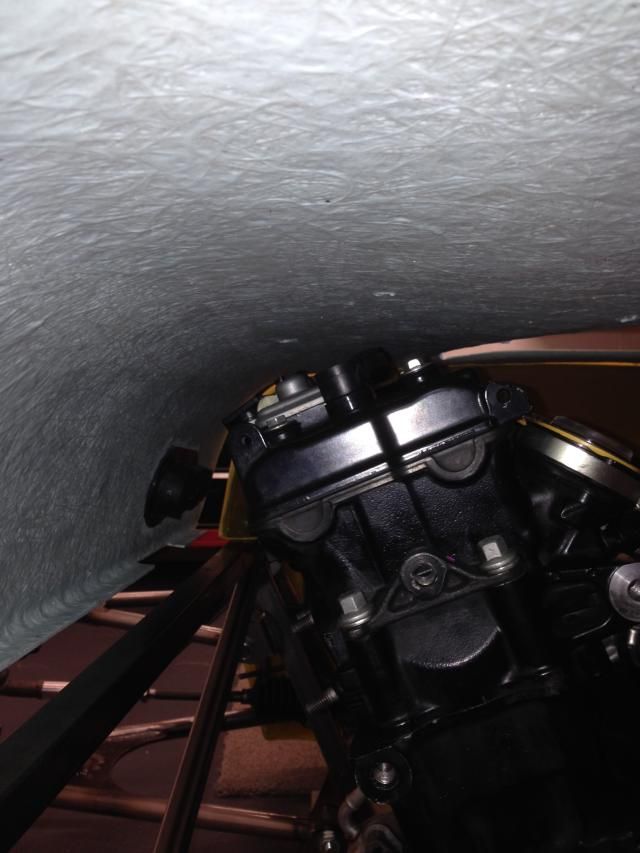

Bit more done today, had my dad helping me today!

Got the engine slung up so it's picking it up somewhere near level of how it will sit in the car

Then decided to make a trolly for the rsj as the clamp I had didn't slide very wheel

Then we made a trolly to sit the engine on, so we could drop the car over and move it around, then once happy with the position I get get the mounting

cradle sorted without having to have it dangling in mid air

I can rase the car up or down to alter the mounting height, I'm just waiting to hear back from AB performance on his zx10 sump height, I'm

hoping to have the underside of the sump flush with the underside of the car

I need to decide on position next, from the pictures I've seen most seem to be mounted towards the rear of the engine bay

But some seem to be straight and some to be on an angle parallel with the side rail, on reading it looks like the output flange and the diff flange

are supposed to be parallel, if anyone could help out that would be great

Thanks for looking

Ben_Copeland - 31/12/14 at 06:18 PM

Good work so far !

big_wasa - 31/12/14 at 06:24 PM

Nice to see a scratch build take shape

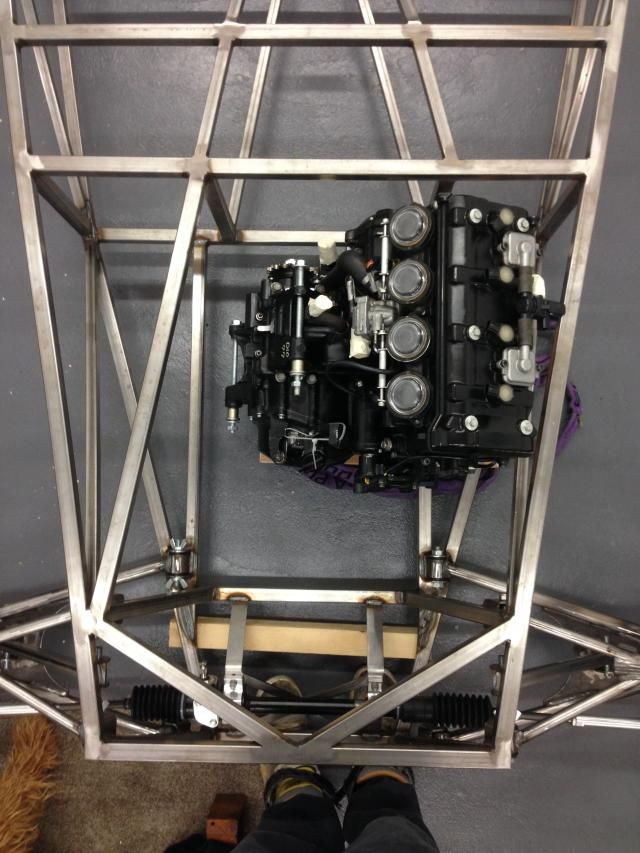

Rosco86 - 1/1/15 at 12:56 PM

Cheers, slowly getting there!

Rosco86 - 1/1/15 at 01:16 PM

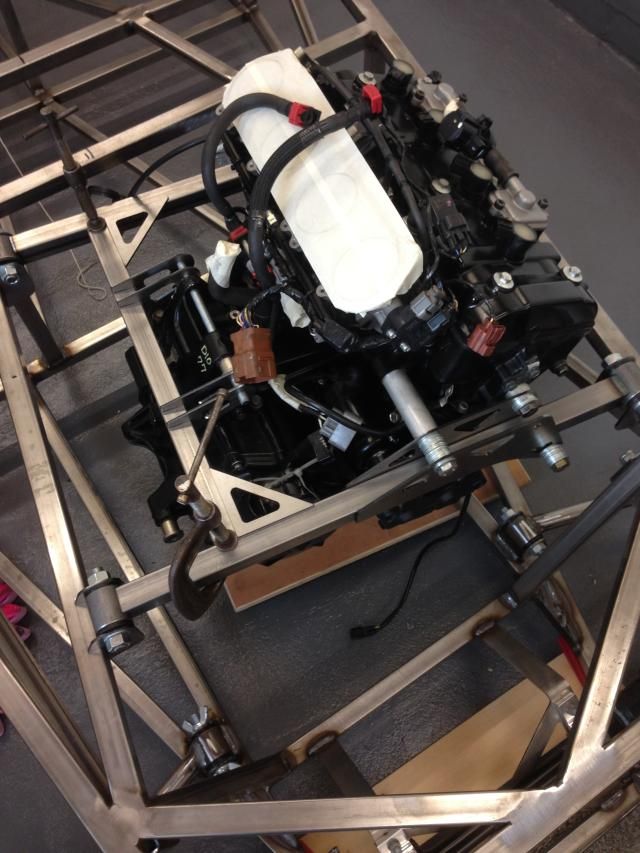

Just been looking at engine position and I'm sort of happy with this current position

Running the engine dead inline it seems to put the output shaft in a good position

If I turn the engine so it's parallel to the outer chassis rail it just skews the output shaft but doesn't improve the position for the

prop

And from what I've read it's better for the flanges to be parallel

In this position the total prop length would be 1460mm but I could move the engine back 50mm if I moved the passenger footwell upright back

I have strung a ling between and it's at an angle from the horizontal of about 4 deg, I take it I will still need a 2 piece prop with a centre

bearing and a slight kink in the centre so the UJ's aren't running straight

My main doubt is the more photos of people builds I look at the more seem to have the engine skewed

If anyone could agree or disagree that would be great!

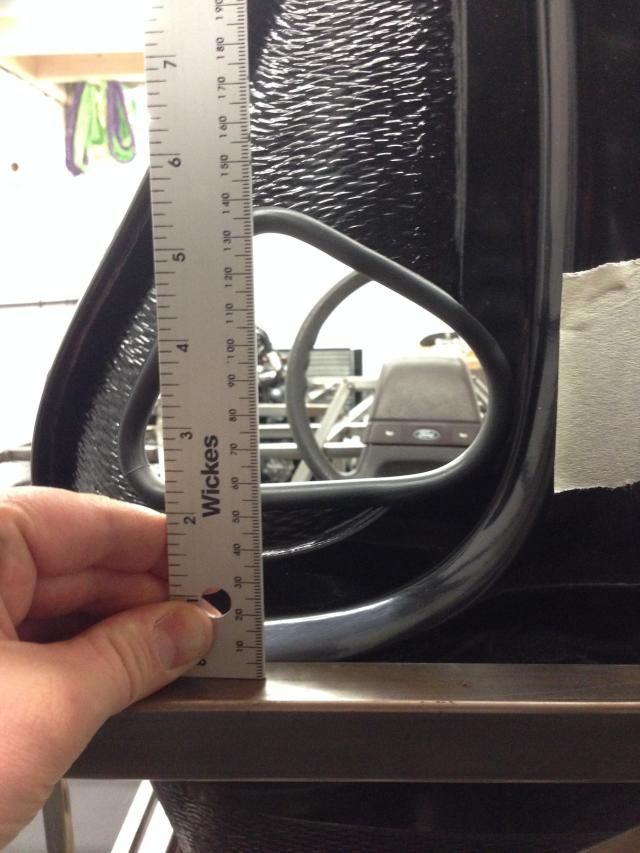

Rosco86 - 1/1/15 at 03:01 PM

Few exhaust clearance pics

That's looking straight at the side

That's looking straight down the axis of the exhaust ports

And that's a ruler coming straight out of the port

Hopefully I might be able to drop the engine down a tad more, just waiting on AB performance to give me some sump dimensions

CosKev3 - 3/1/15 at 10:20 AM

Great pics and workmanship!

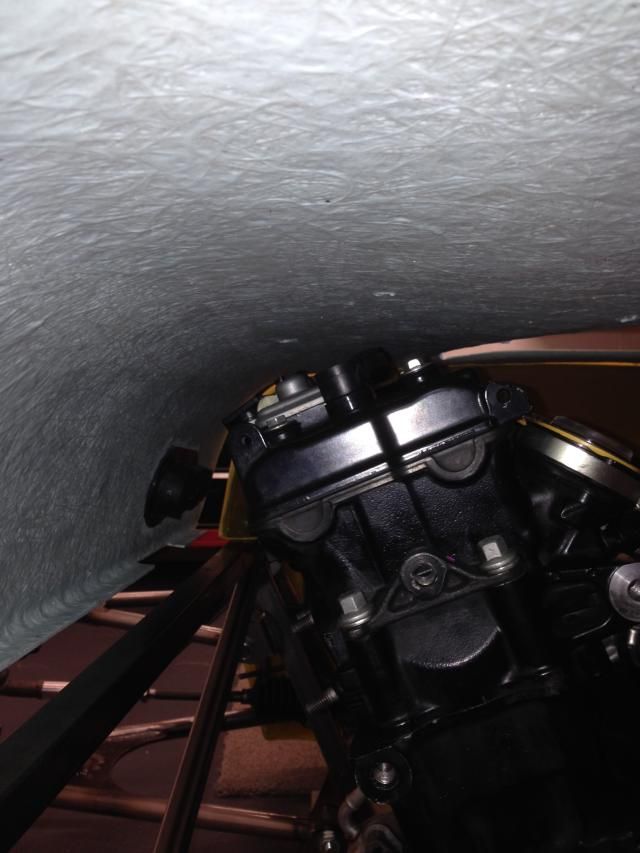

Rosco86 - 5/1/15 at 09:08 PM

Well spoke to AB performance today, real nice chap with some good ideas backed up with some good evidence,

So I've moved it again, haha

Think I've got clearance around everything that I need to have

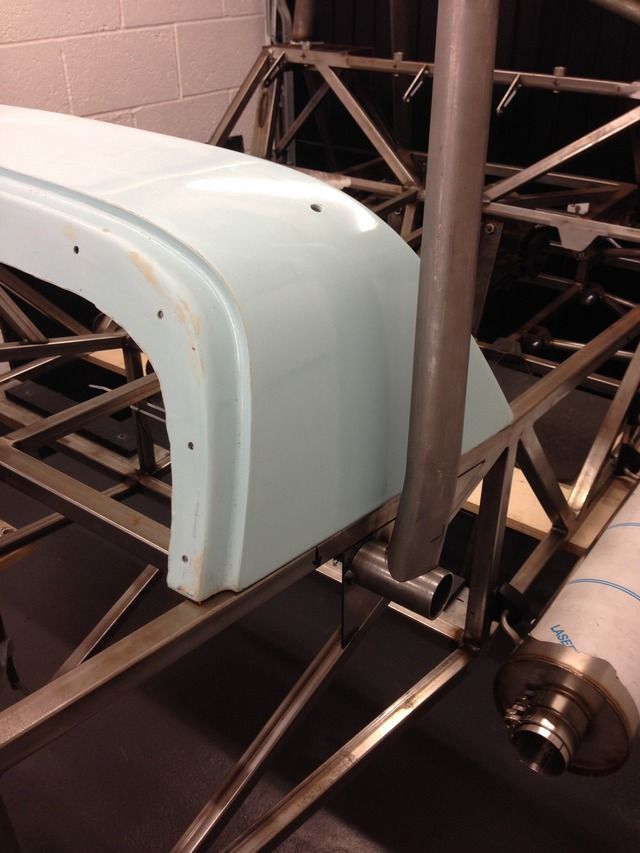

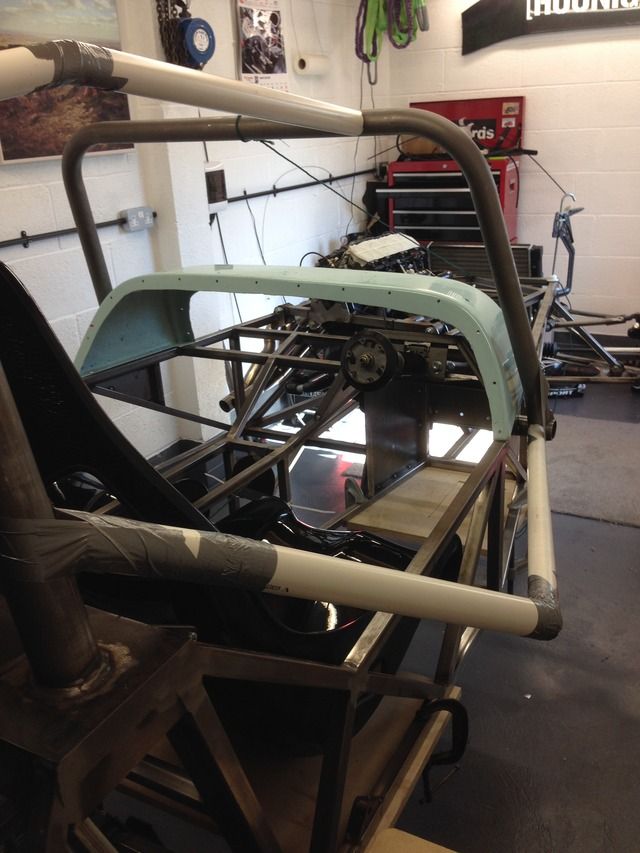

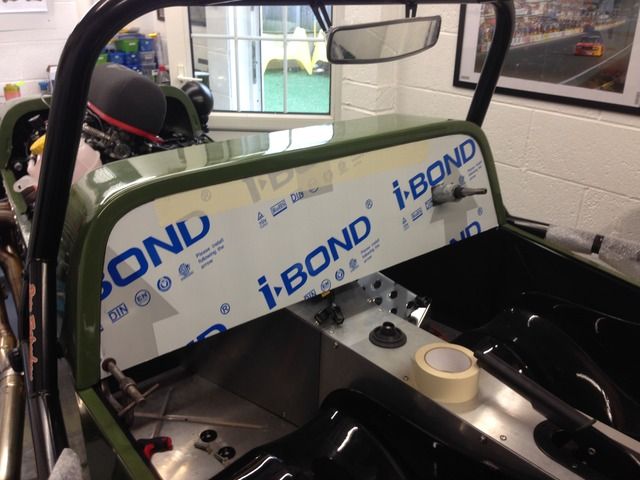

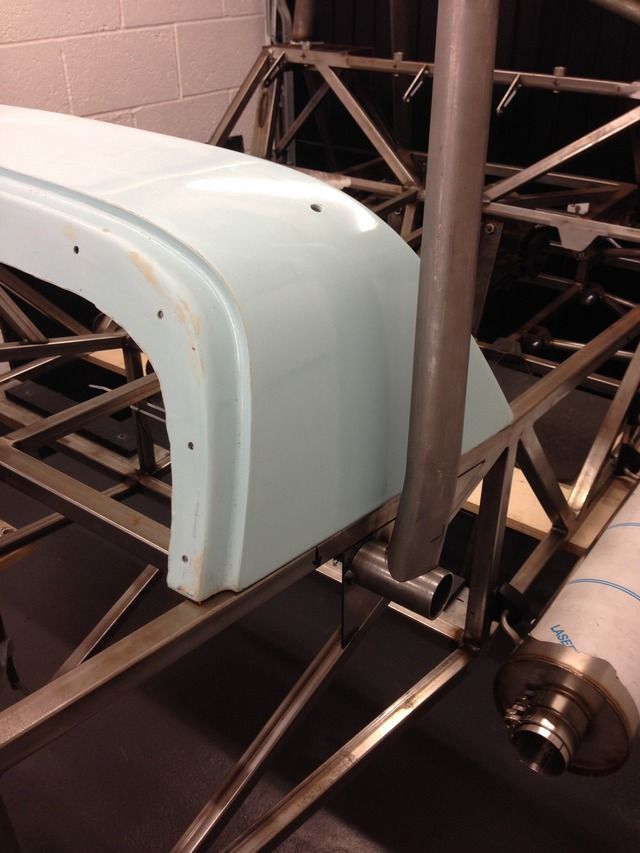

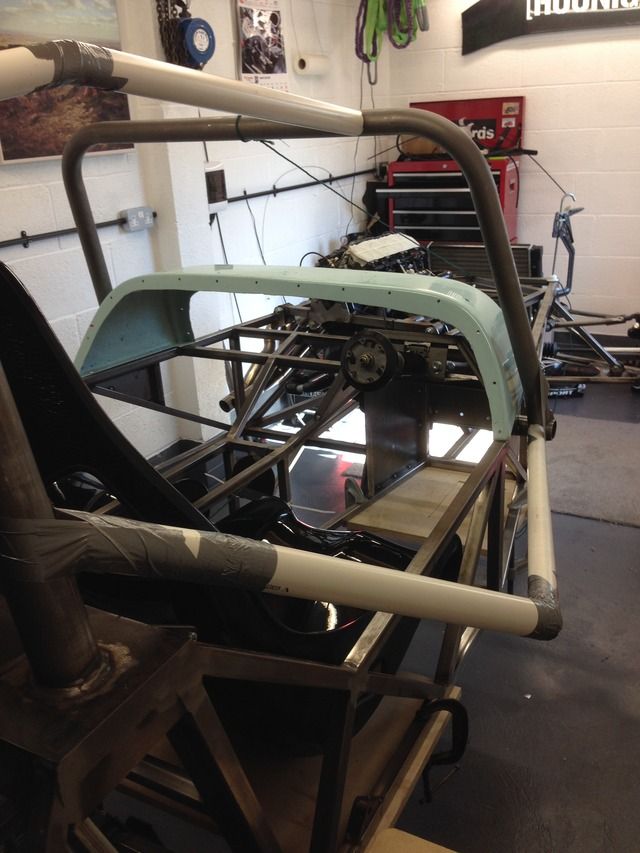

So Tatley off the haynes forum who lives not to far from me has kindly lent me his body work so I can mock things up

Looking a bit like a car!

There's a bit of clearance over the top, this is saturn body work but I'm holding that the exquinox may be has a bit more

rdodger - 5/1/15 at 10:01 PM

What's the thinking behind the position of the engine? Is it just for clearance?

Rosco86 - 6/1/15 at 08:22 PM

Engine position thoughts

Access to all areas of the engine, to save removing the engine if anything needs replacing

Keeping some weight upfront to help keep some heat in the tyres

Height wise, keep the sump flush with the bottom of the chassis, this means you can run the whole car an inch lower than if the sump was sitting below

by an inch,

I thought this was really good advice and made a lot of sense

On the piss, just seems to fit better for the exhaust and loads are mounted like this so must be ok for the prop

I don't want to drop the engine down as I want the underside flush, and an inch wouldn't solve the problem, looks like I'm going to

have to mod the bonnet with a scoop or just use a filter like you say and let it sit out the top, also I've got to refit the top injectors,

CosKev3 - 6/1/15 at 10:01 PM

If it's track only the bonnet being cut/filter sticking out isn't a problem,just if IVA'ing would be a harder job.

Rosco86 - 9/1/15 at 08:01 PM

quote:

Originally posted by CosKev3

If it's track only the bonnet being cut/filter sticking out isn't a problem,just if IVA'ing would be a harder job.

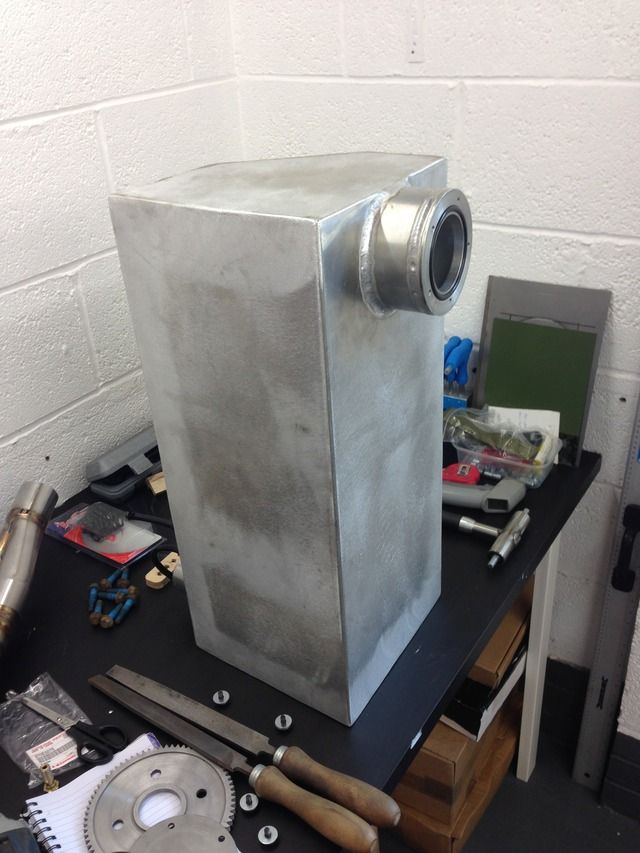

Yeah, I will have to make a nice air box I think

Rosco86 - 9/1/15 at 08:01 PM

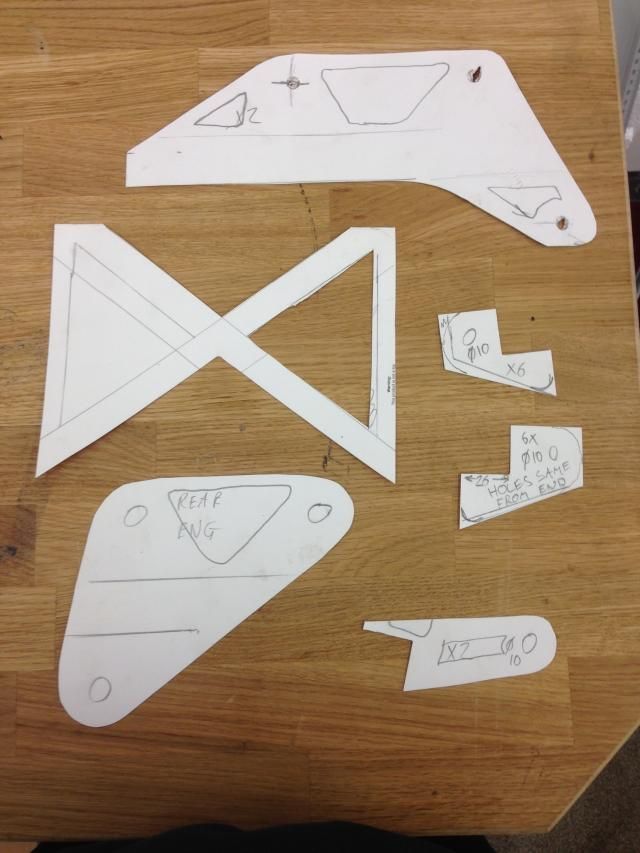

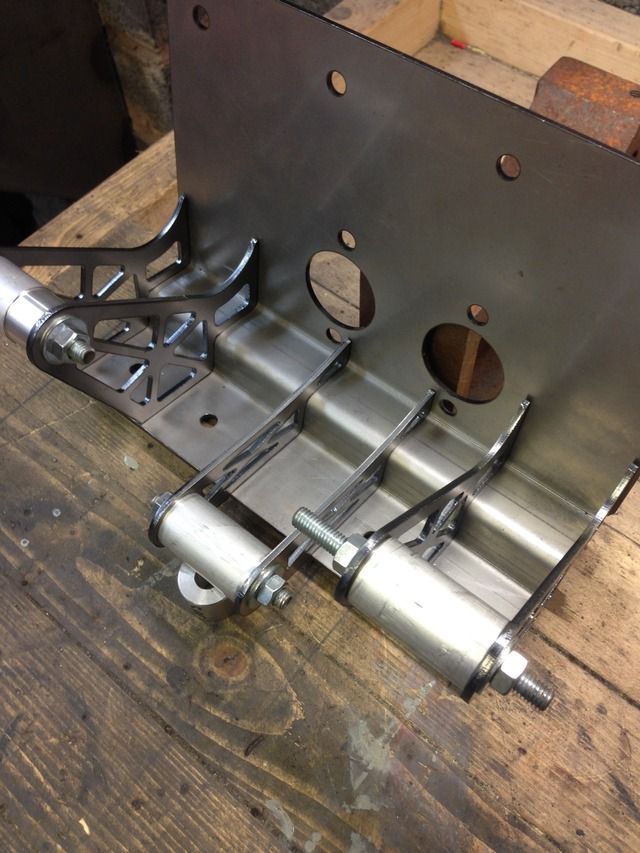

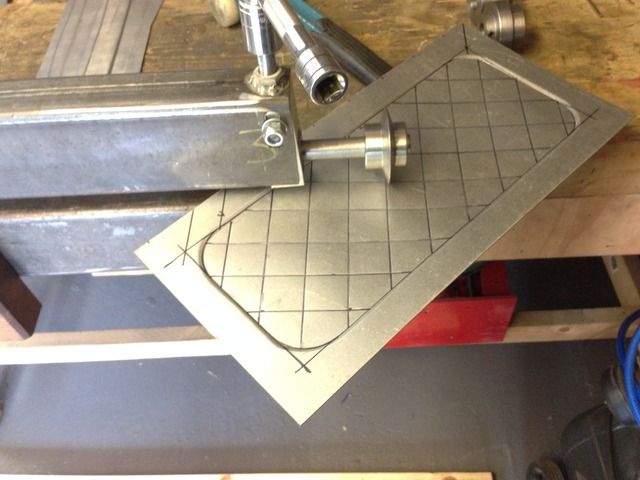

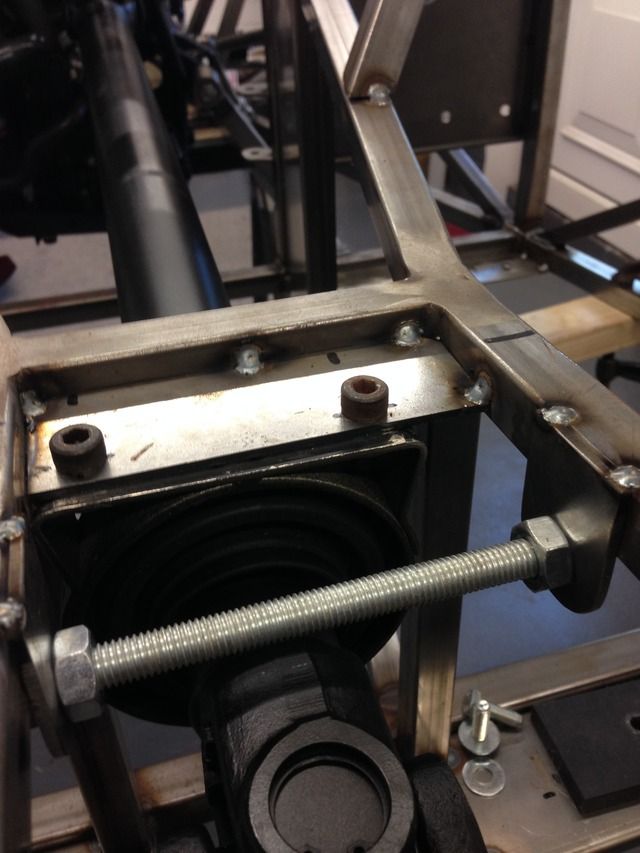

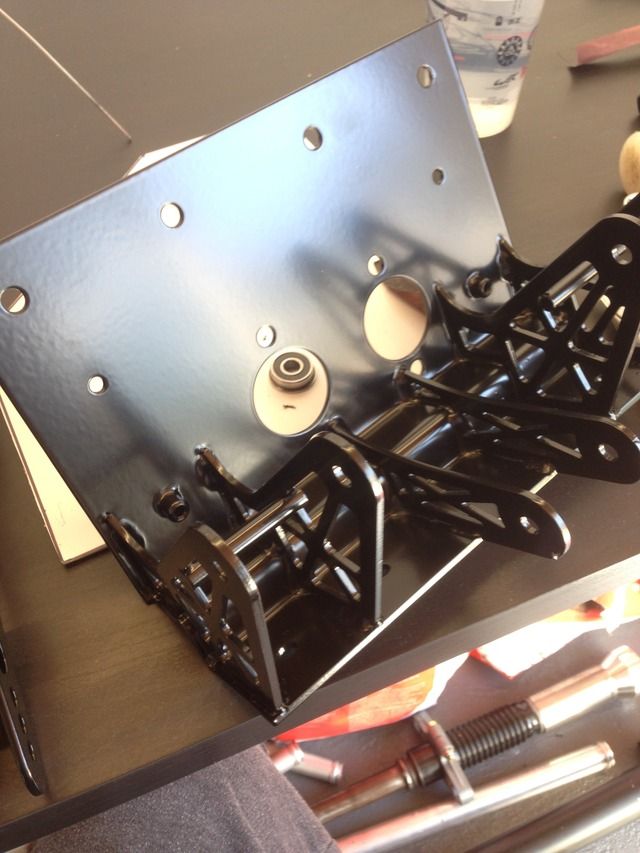

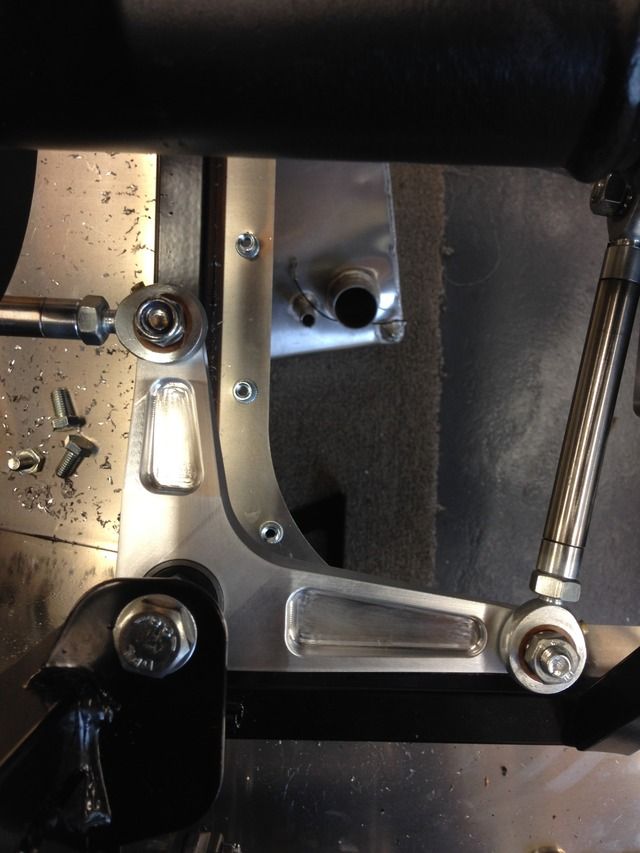

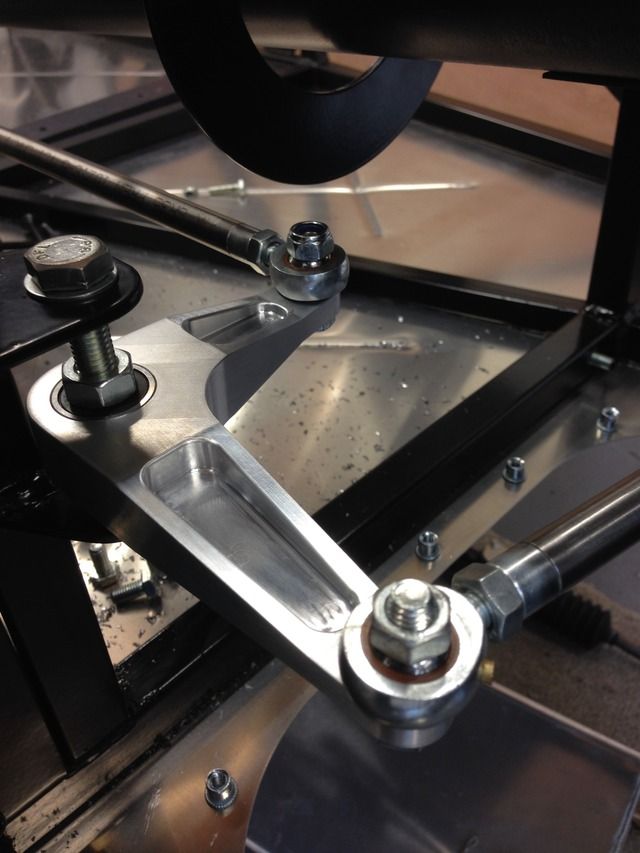

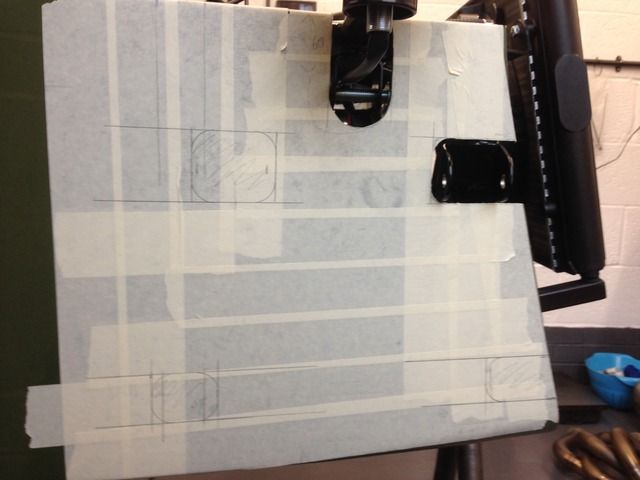

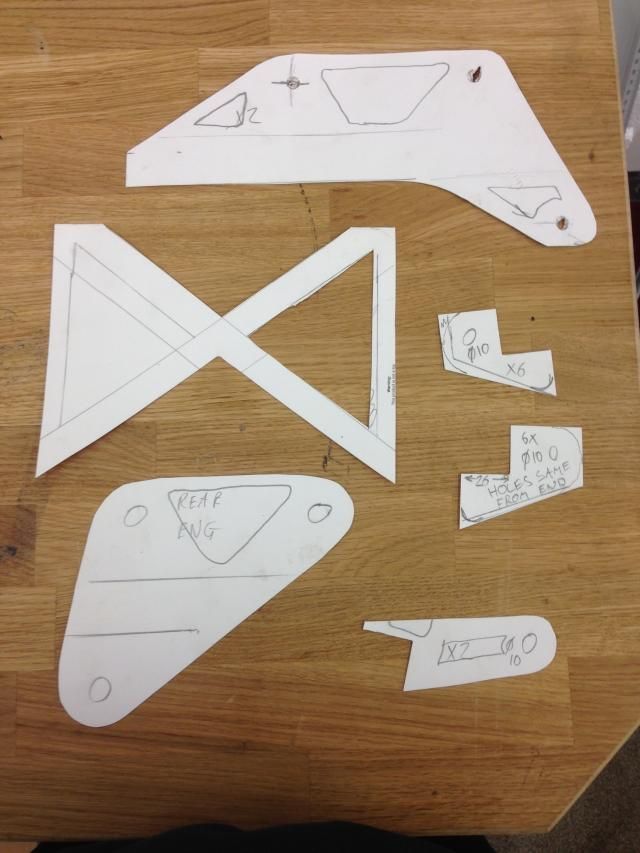

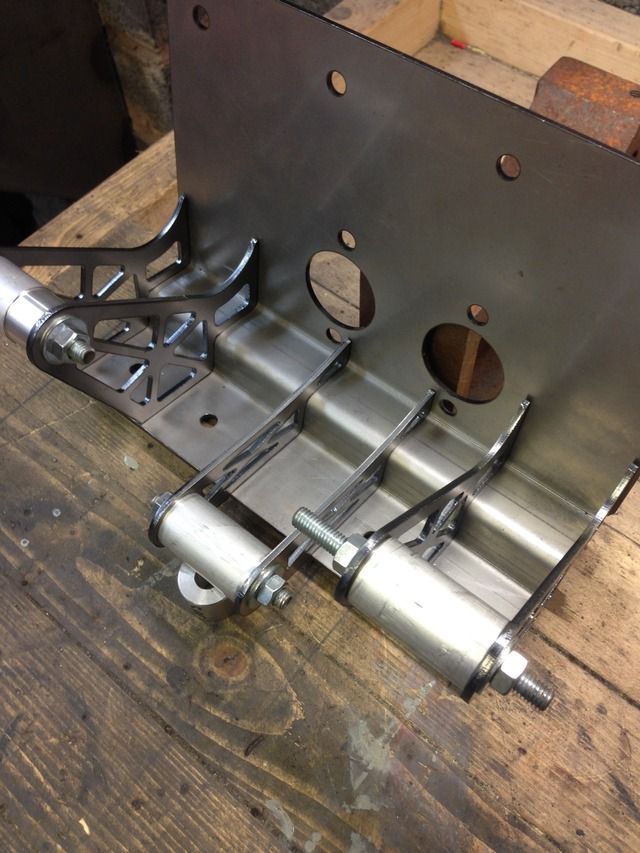

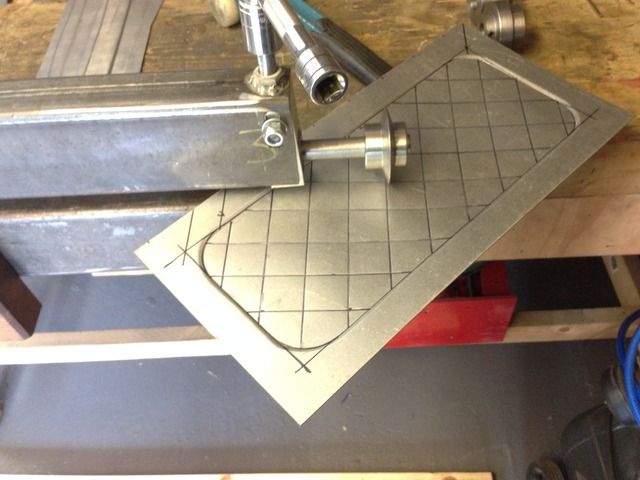

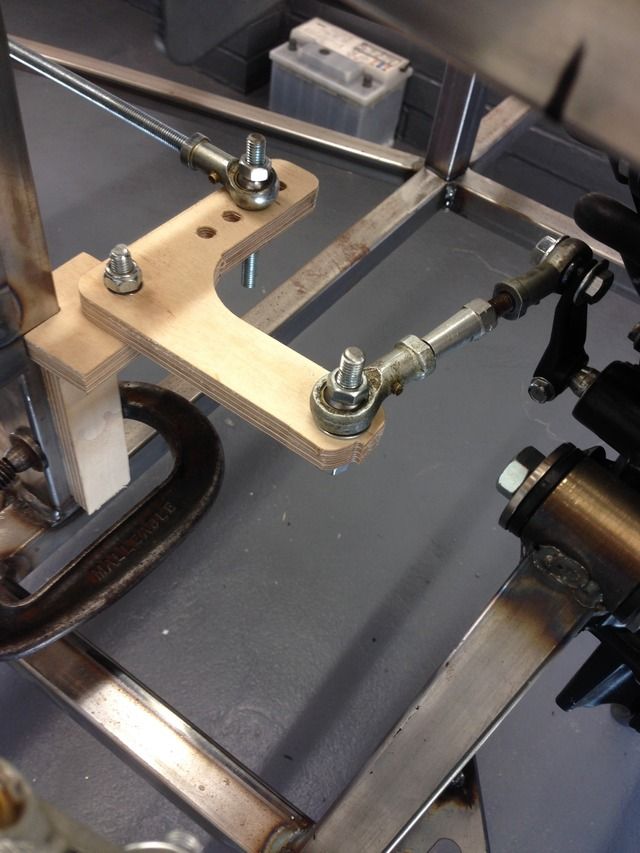

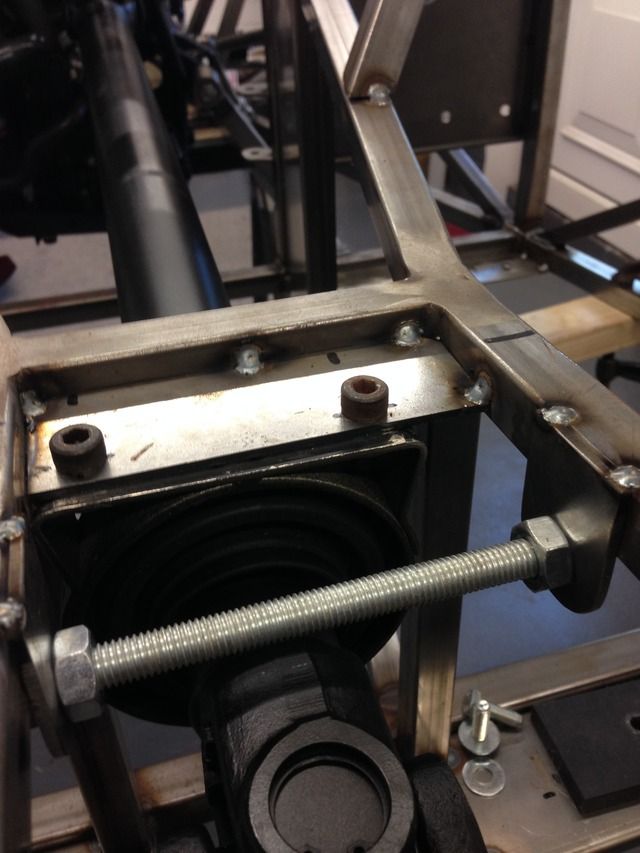

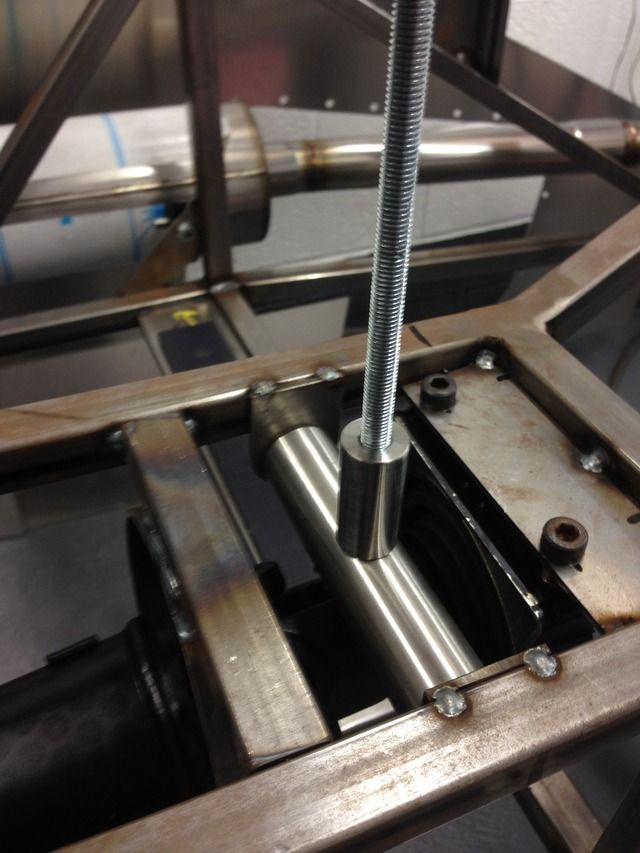

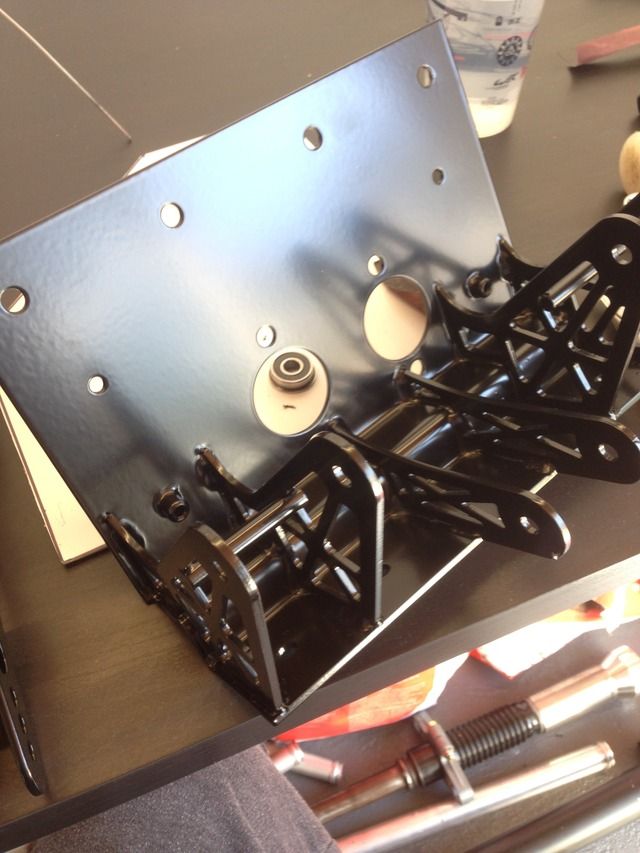

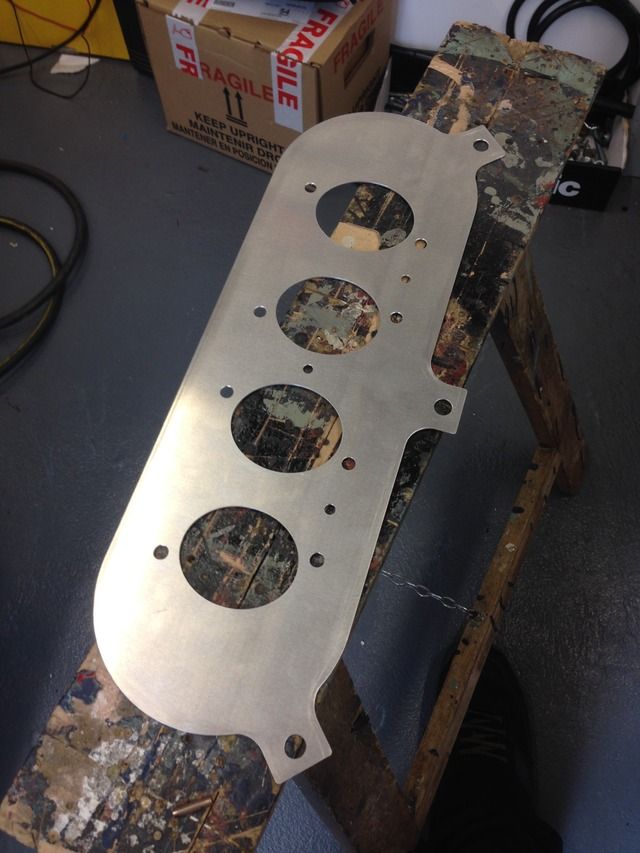

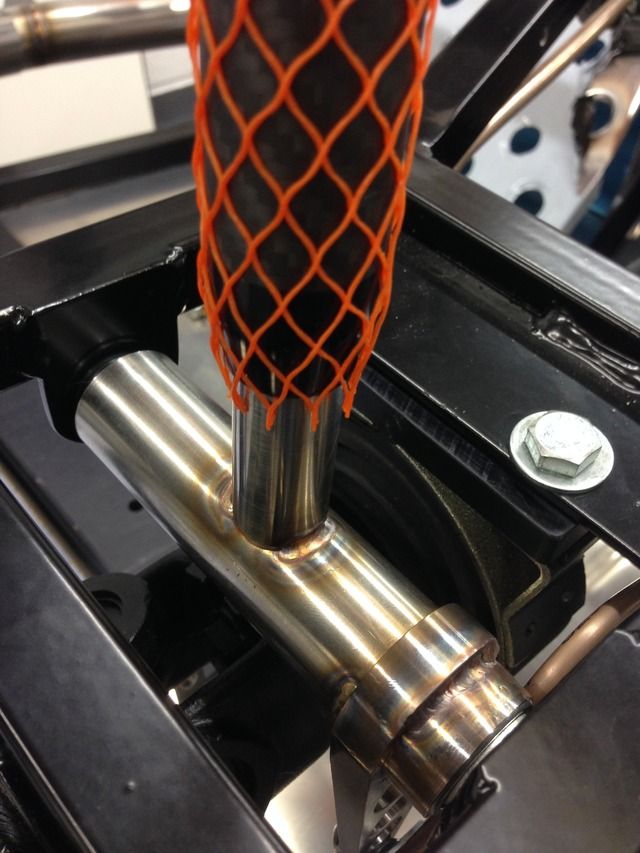

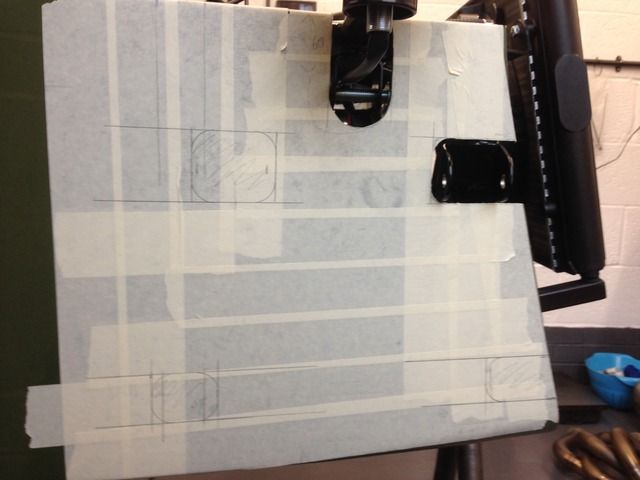

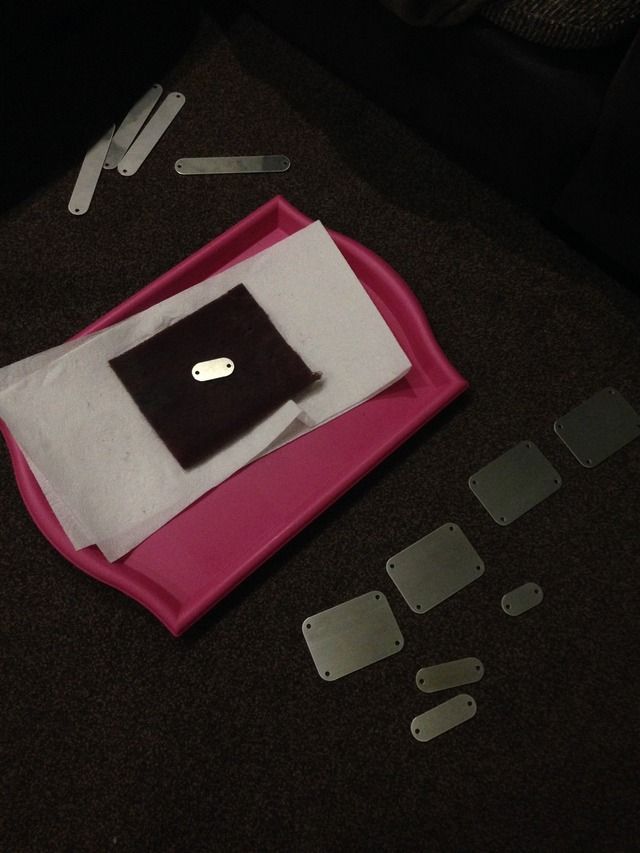

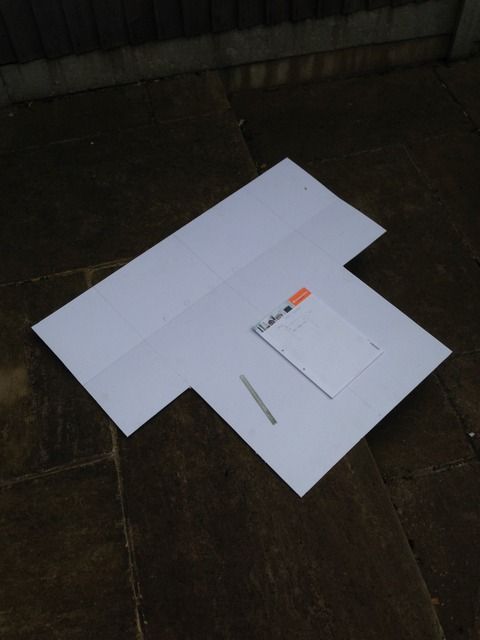

Well had a measure up for my engine cradle and made some paper templates

Looked ok so drew them up and got them laser cut out

So that's a job for the weekend, also got a polo rad to get mounted

Rosco86 - 10/1/15 at 05:37 PM

Got my radiator mounted today while I still had my borrowed nose cone, I will sort the top brackets later

Some rubber grommets off ebay

Then I set about making some spacers for my engine mounts, faced and centre drilled them in the lathe, then drilled

Them through on the pillar drill as my lathes a bit small for drilling

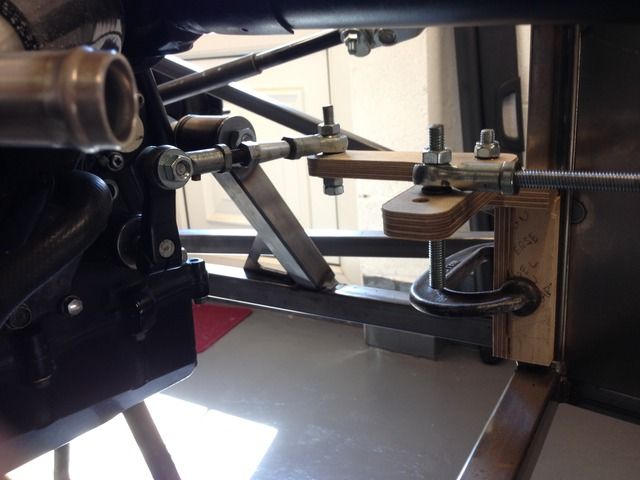

That's the rear mount offered up

And that's the front

I decided to rubber mount my engine cradle, so have used some spare wishbone bushes I had left, I will see what it's like but could

Always make some softer bushes if I need to

Struggling for bolts, hence the washers, there m10x1.25 so not really very comon

I'm going to weld spacer tubes In between the plates

Side engine mount

Ready to tack up tomorrow

rdodger - 10/1/15 at 06:18 PM

Beautifully done

wylliezx9r - 10/1/15 at 07:12 PM

Wow that's the best cradle I've ever seen. Good work.

Rosco86 - 11/1/15 at 04:42 PM

Cheers guys, pretty pleased with how it's turned out

I looked at other cradles and didn't really fancy mounting on just one bolt either side, I no it's going to be a bit heavier, but I will

lose the weight elsewhere if I can

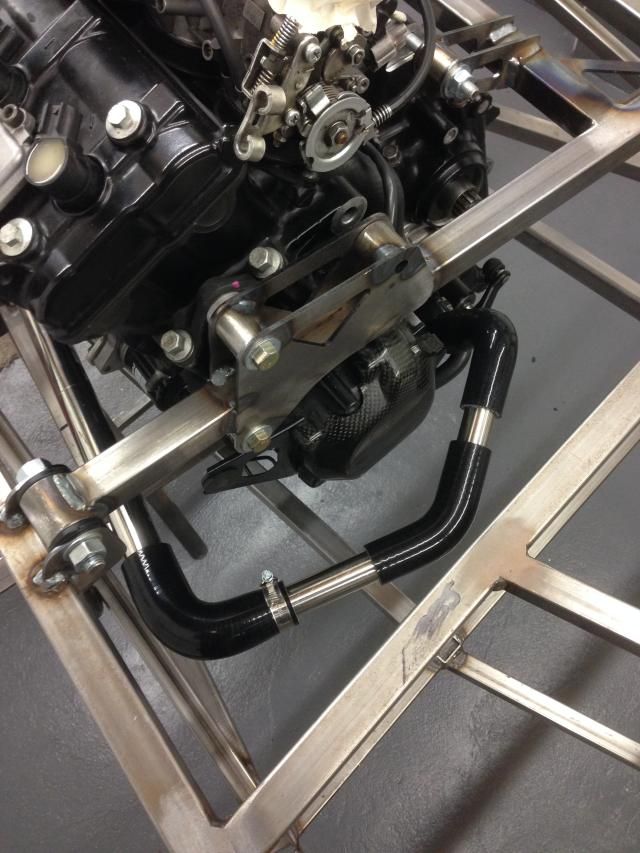

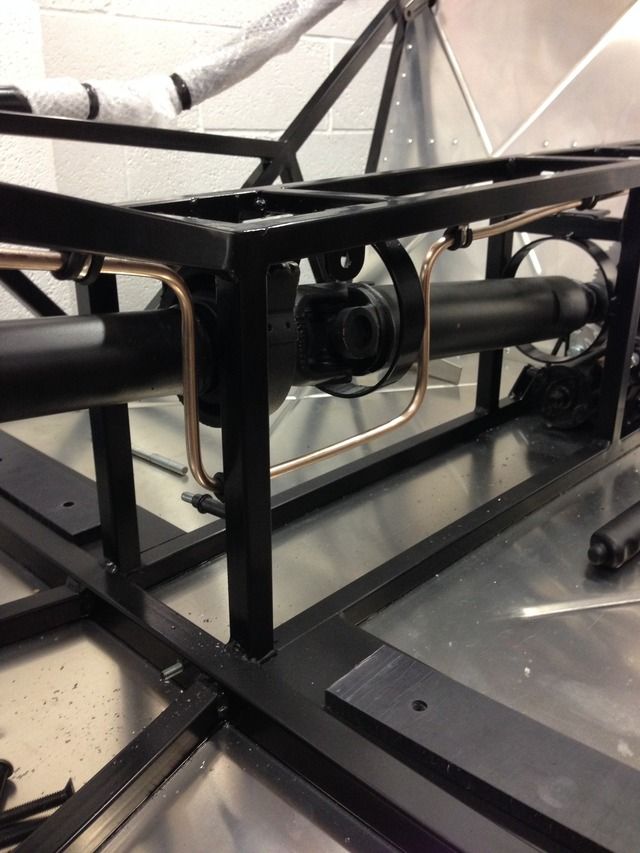

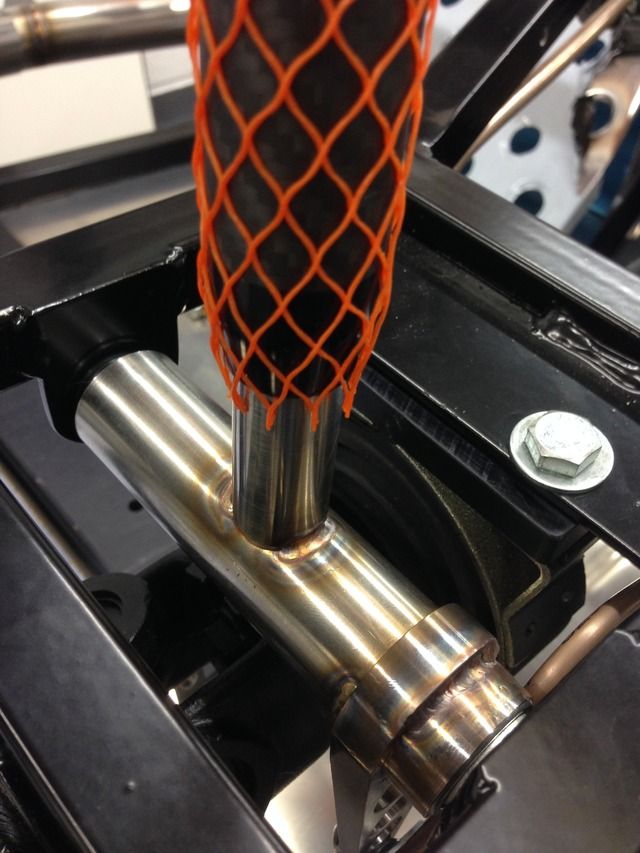

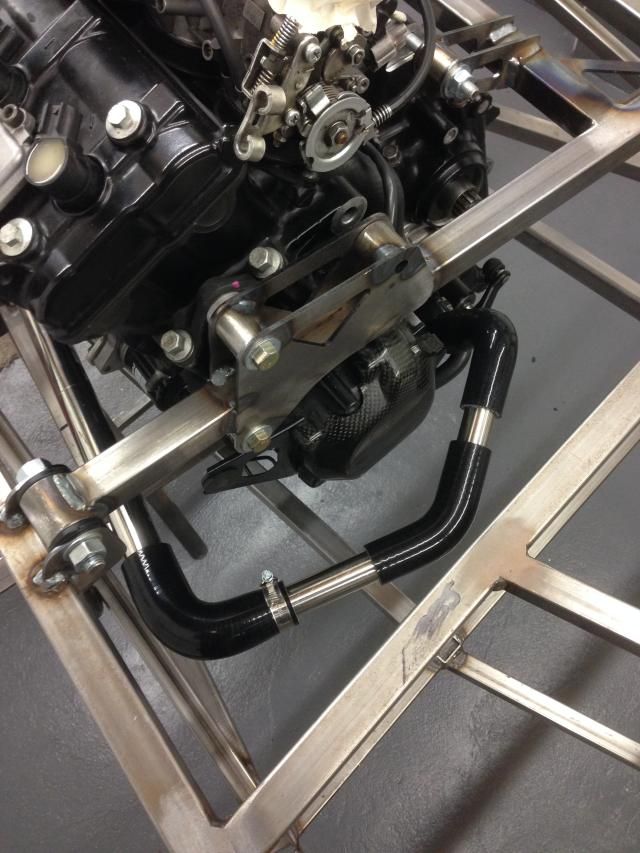

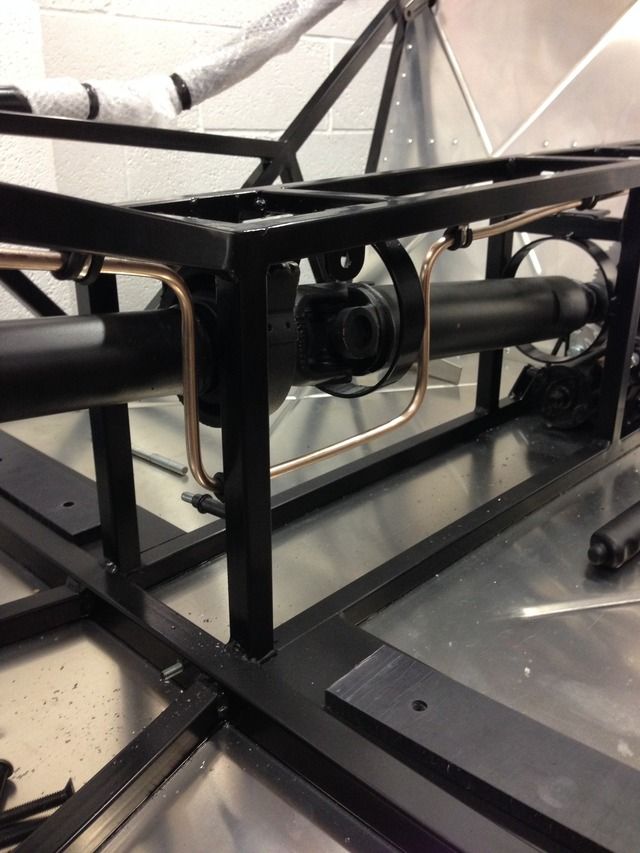

Got it tacked up today and worked out my coolant pipes

And one of the pooch

Digimon - 11/1/15 at 07:10 PM

quote:

Originally posted by Rosco86

That cradle is a piece of artwork, nicely done

Rosco86 - 11/1/15 at 08:27 PM

quote:

Originally posted by Digimon

That cradle is a piece of artwork, nicely done

Haha thanks, quite pleased with it myself

Ben_Copeland - 11/1/15 at 08:30 PM

Ross did you see the dimensions that where posted for equinox bodywork. I know you've asked me for a few but might help with the engine locations

CosKev3 - 11/1/15 at 09:16 PM

Cradle looks mint

Love the bottom rad mounts too,simple but brilliant idea.

Rosco86 - 11/1/15 at 10:04 PM

quote:

Originally posted by Ben_Copeland

Ross did you see the dimensions that where posted for equinox bodywork. I know you've asked me for a few but might help with the engine locations

Yeah ive seen them, i borrowed some bodywork to, think im happy with the position, hopefully all will work out ok

Rosco86 - 11/1/15 at 10:05 PM

quote:

Originally posted by CosKev3

Cradle looks mint

Love the bottom rad mounts too,simple but brilliant idea.

Cheers, just need to blank the ends off to stop them filling with crud!

Rosco86 - 12/1/15 at 10:04 PM

Busy evening tonight,

My mate tacking up my wishbones

All welded

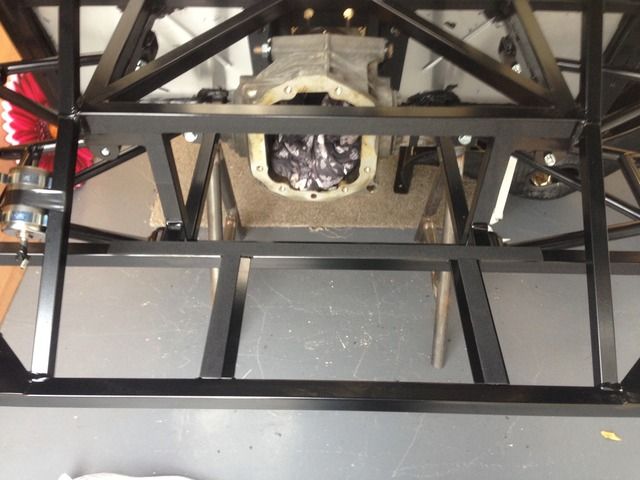

Rear end assembled again

Might have to remake to top ones to, just because I made them to the book jig that hadn't been up issued although the wishbone drawing had!

Argh!!

Popped and got some bits off my mate who runs an ebay shop

Then got it back on the stands and the engine bolted back in

Got loads to do now, I've got everything to get my cooling hoses done, also going to start to look at making an exhaust manifold and a fuel

tank

Also sort out my lower engine mount

Rosco86 - 13/1/15 at 09:14 PM

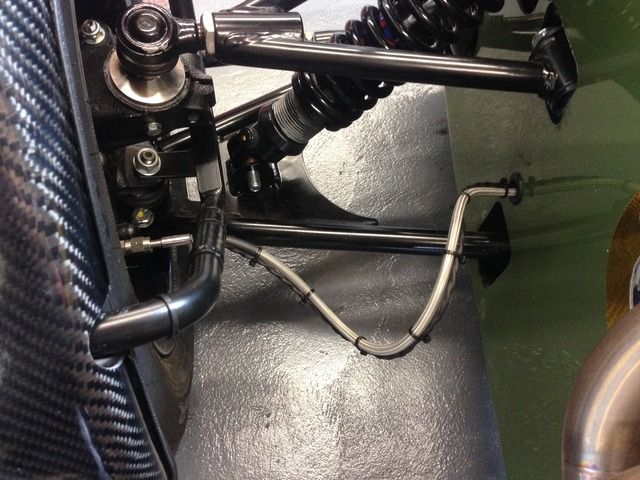

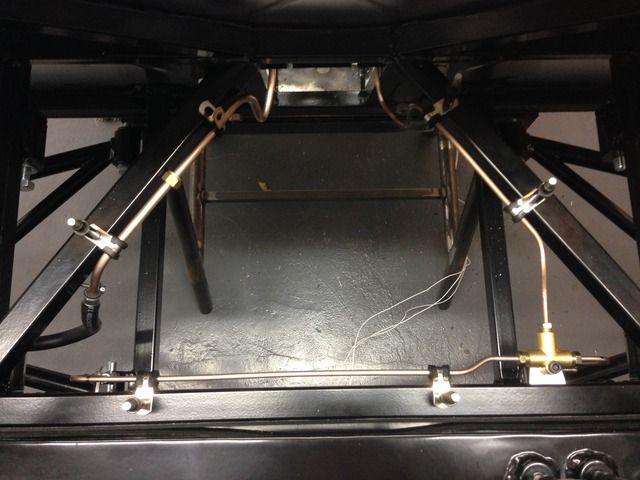

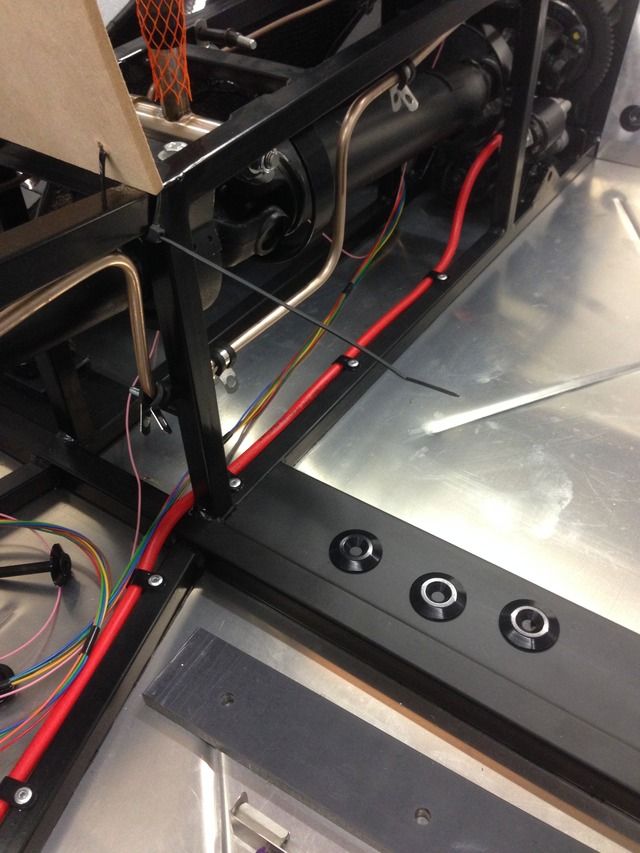

Got my coolant hoses on tonight

That's the oil cooler return T'ed into the out flow

That's running from the lower rad to the back of the engine

I've used 25mm and 32mm stainless pipe to make the joins and runs, I might get the outside blasted and powder coated to keep it looking factory

tho

Rosco86 - 13/1/15 at 09:17 PM

I just need to decide where I'm going to T my header tank into and make a few brackets to support the tube in places to stop the silicone rubbing

anywhere!

Rosco86 - 17/1/15 at 03:32 PM

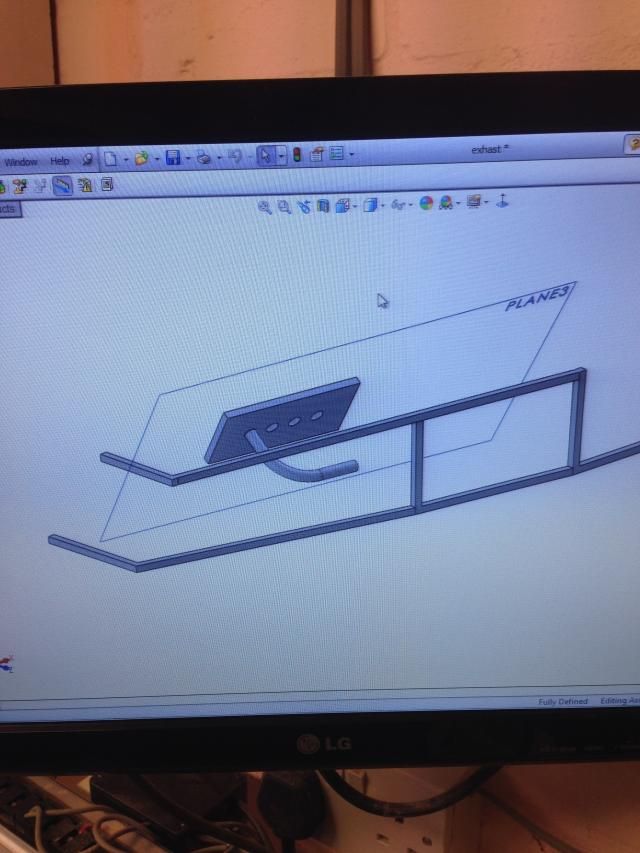

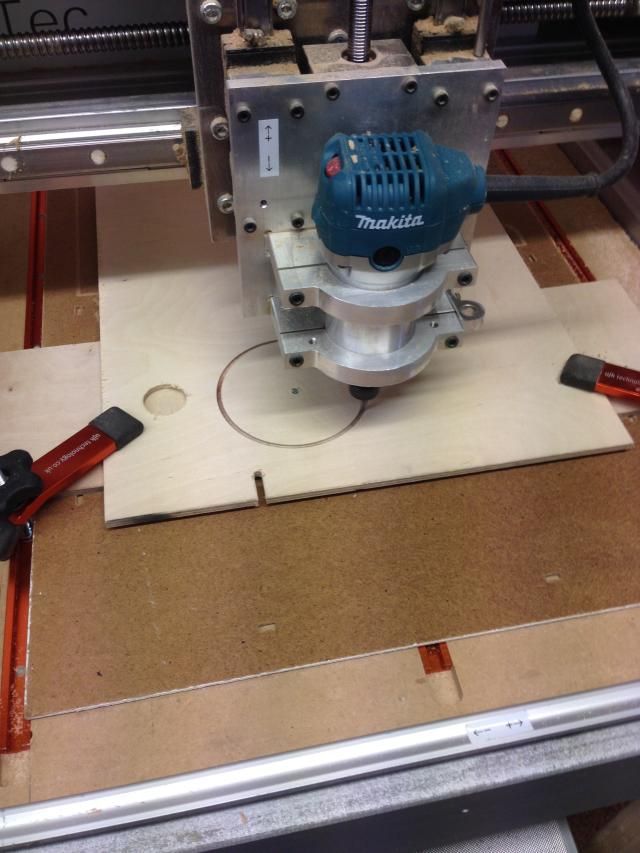

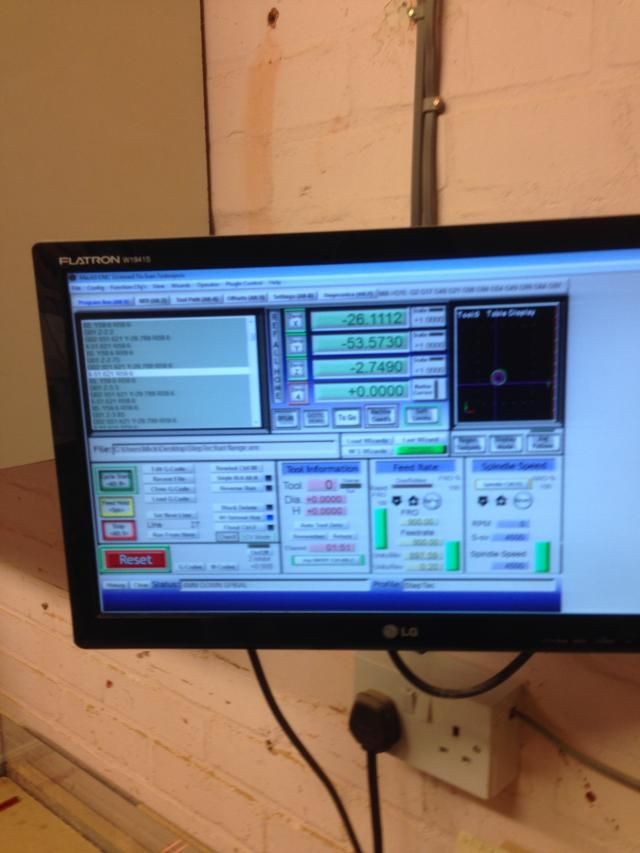

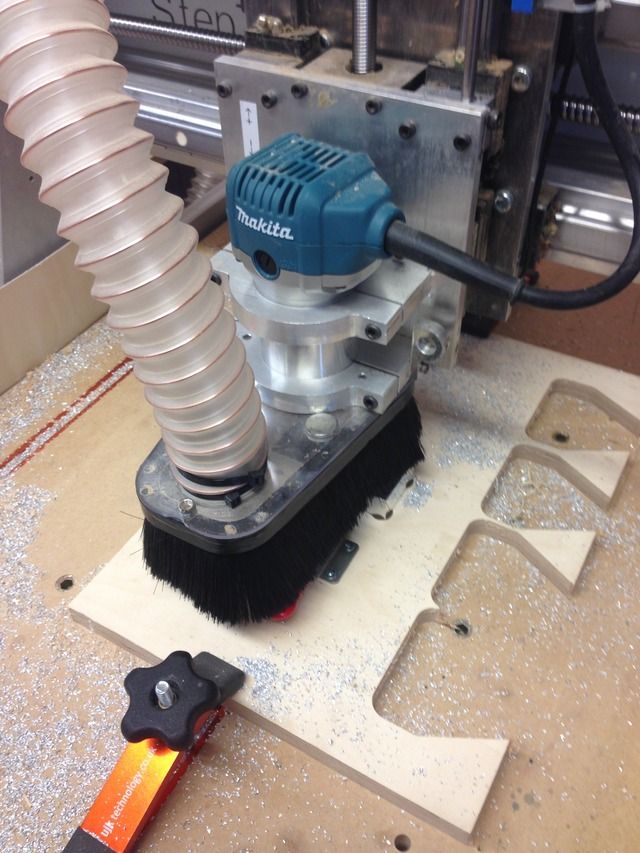

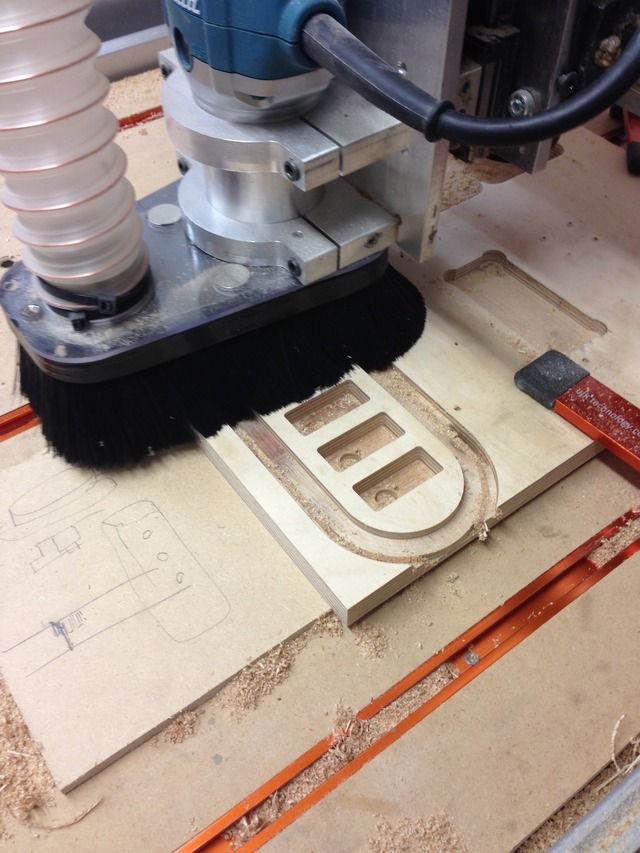

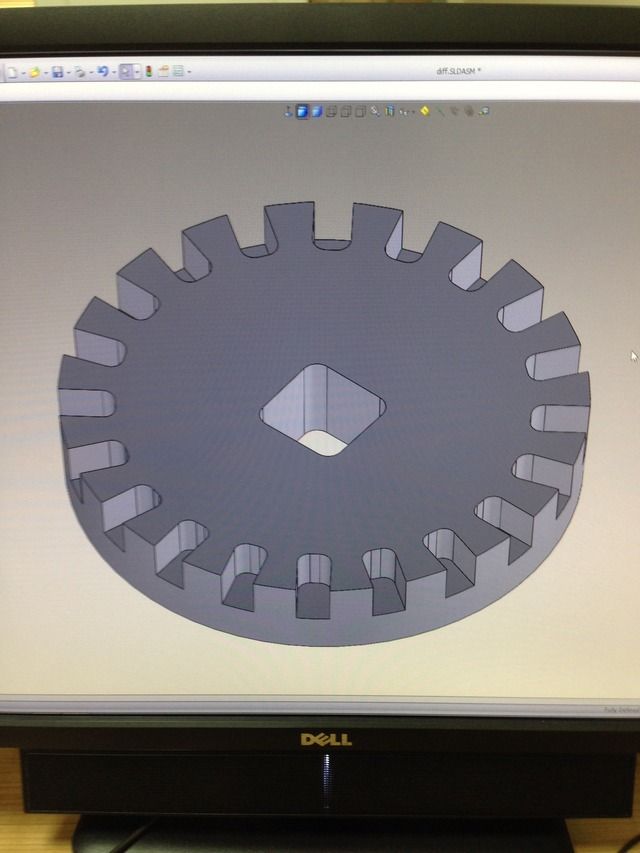

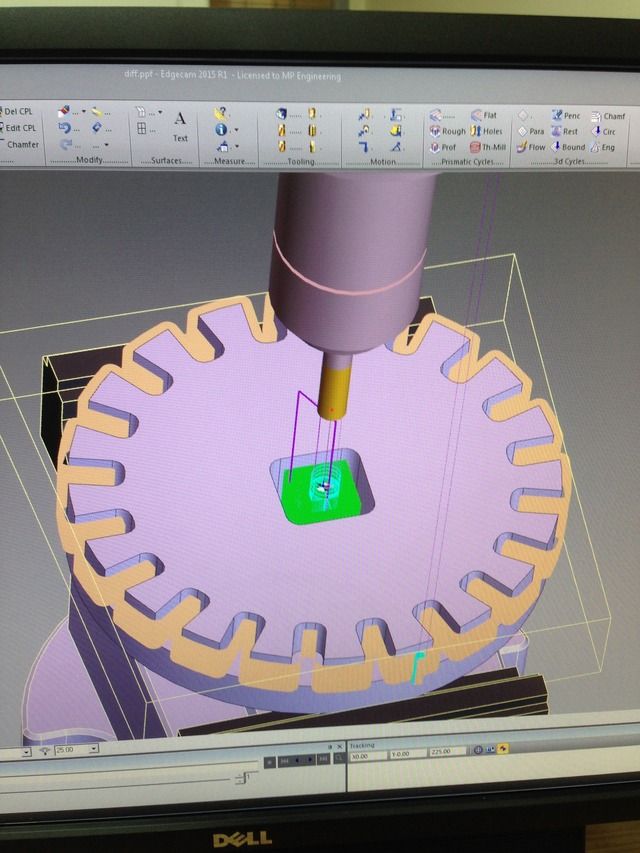

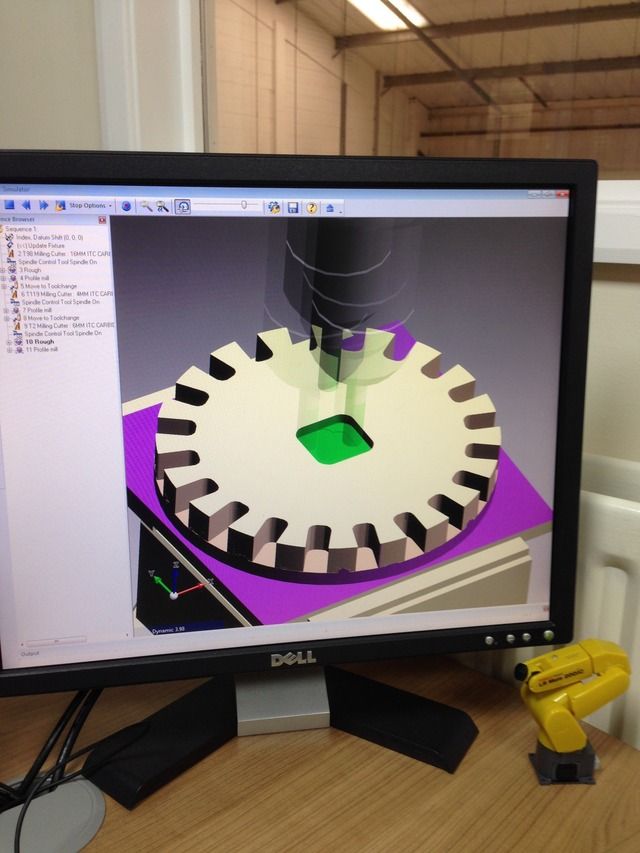

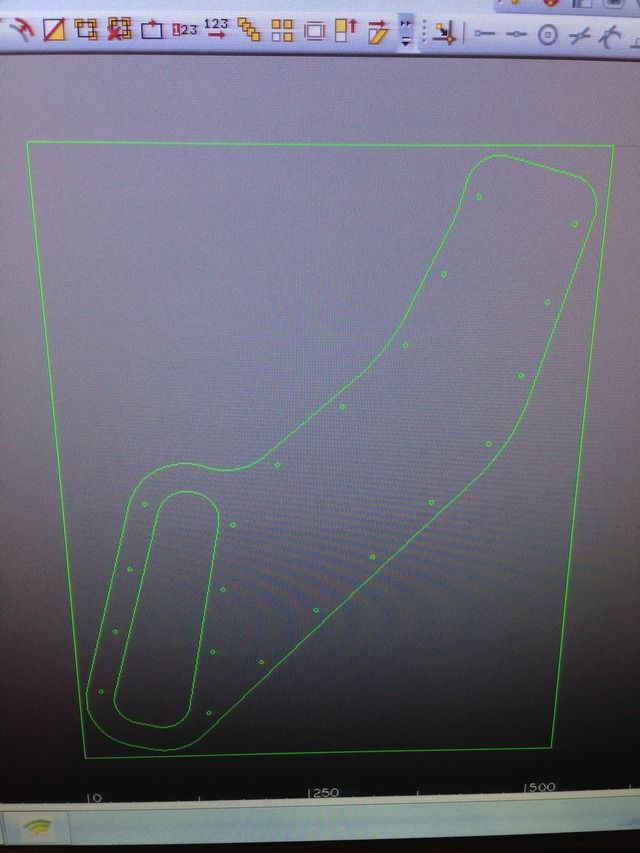

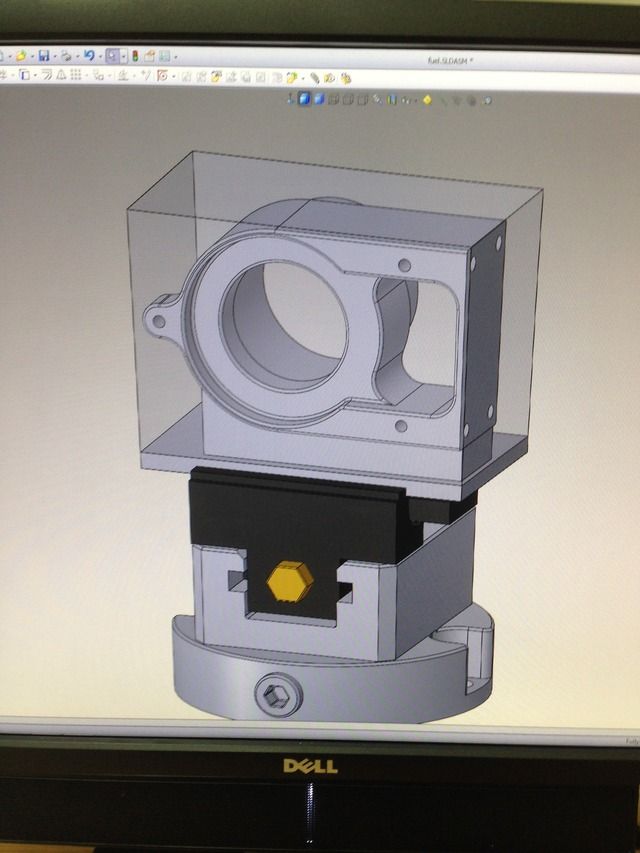

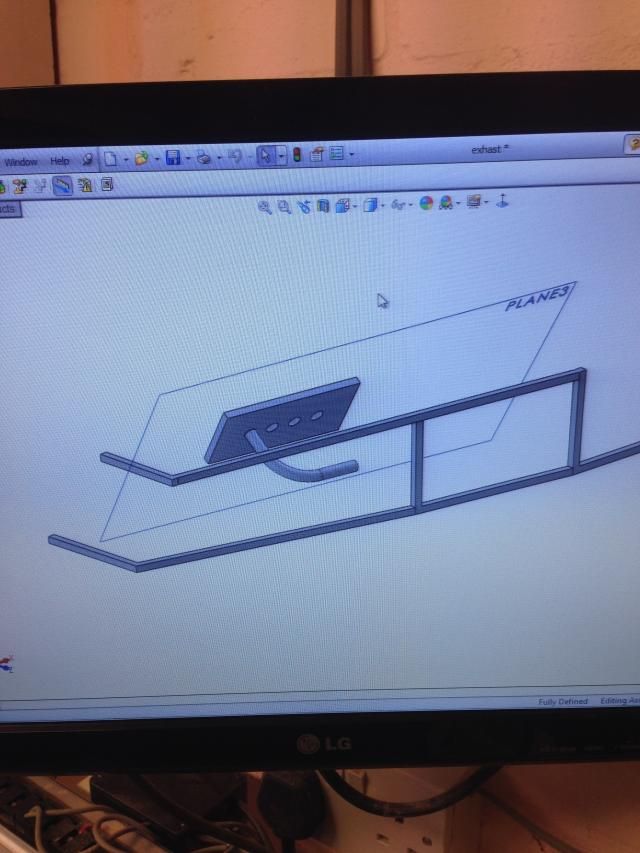

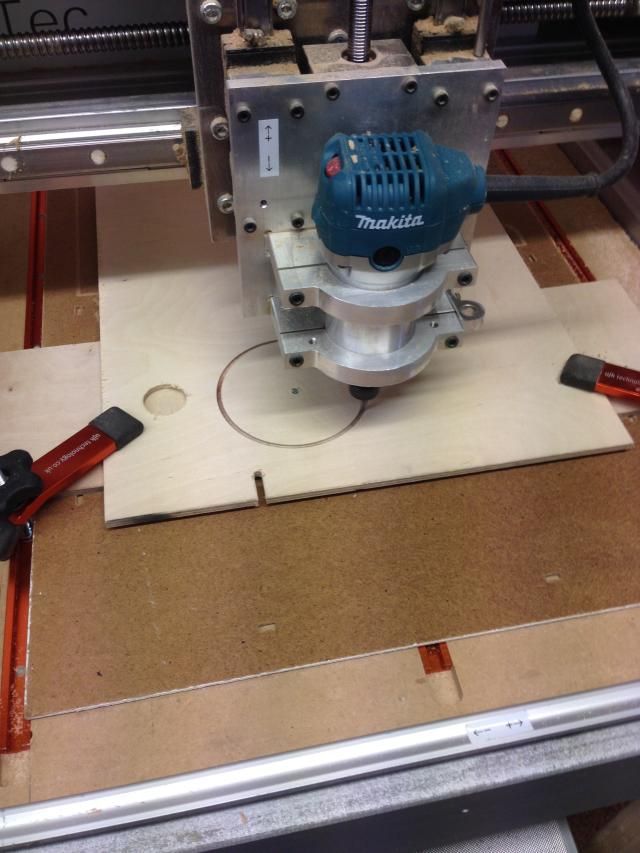

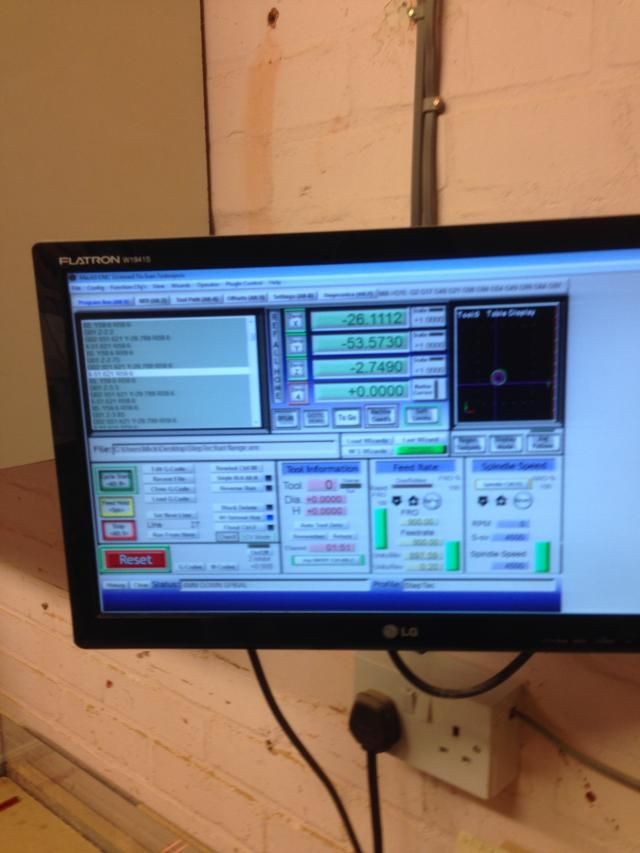

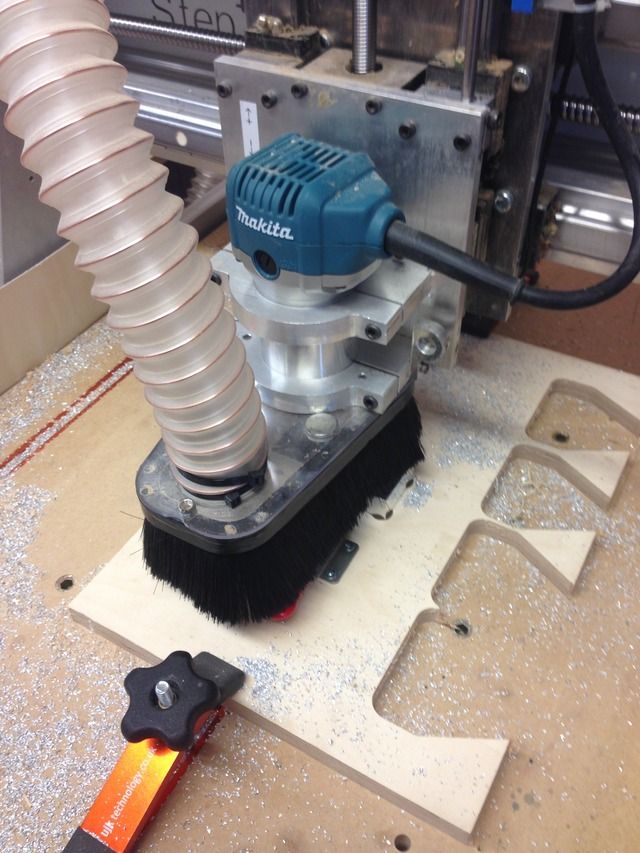

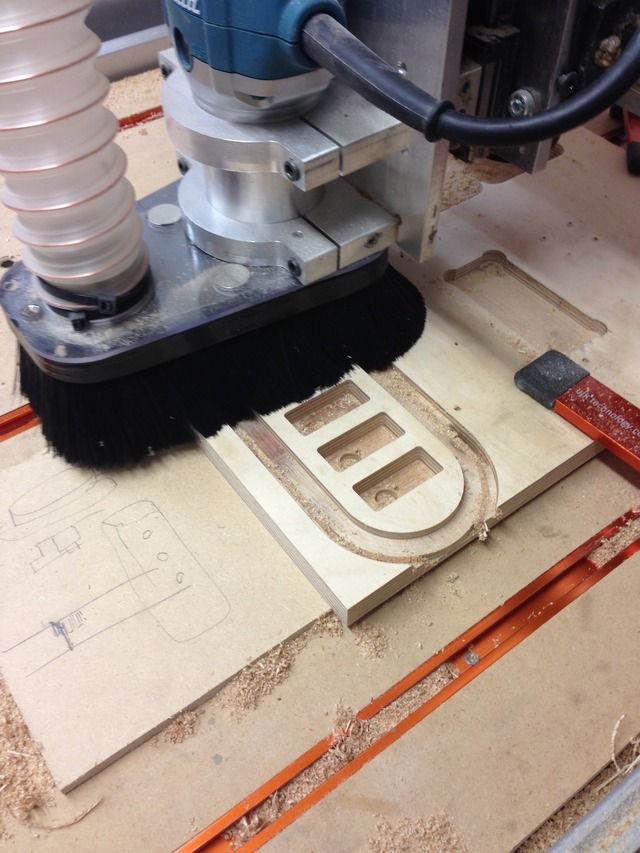

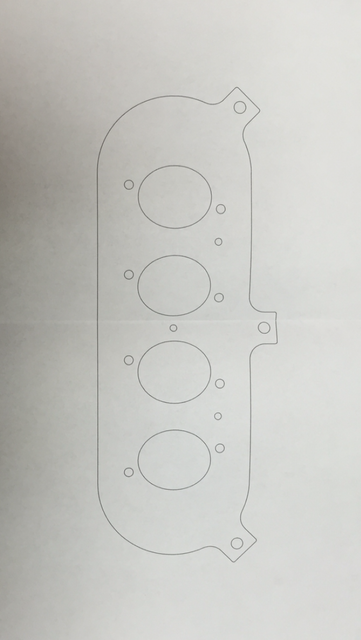

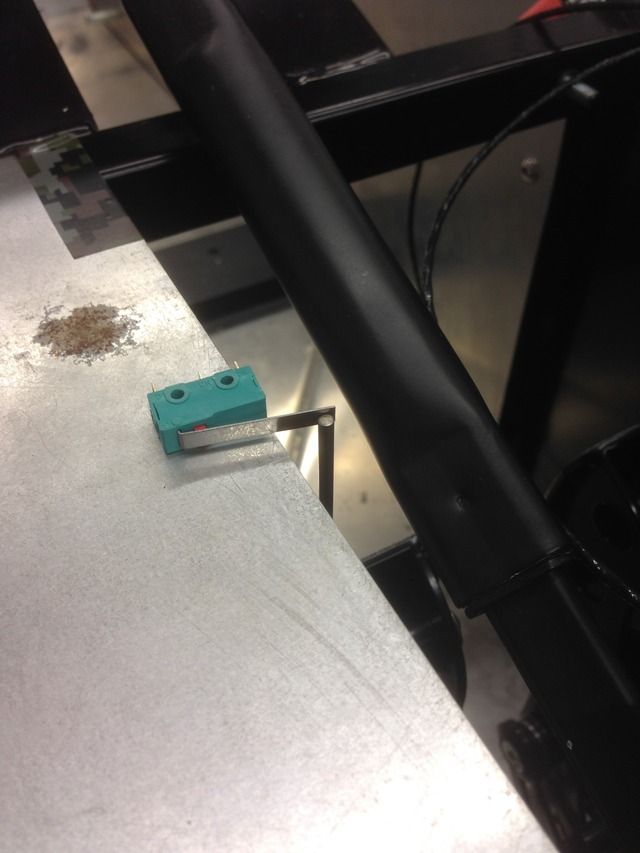

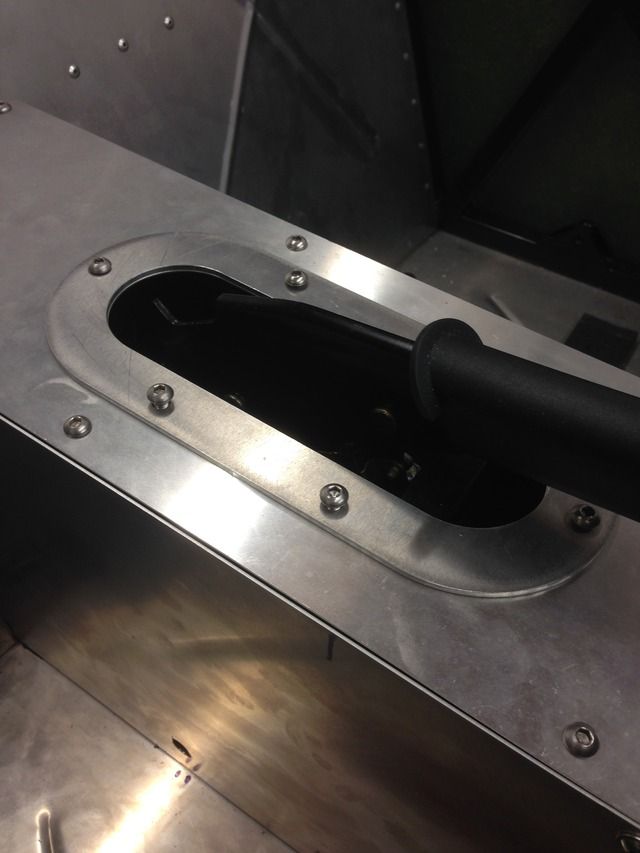

First job today make a dummy exhaust collector so I can mock up my exhaust, luckily my dads built a cnc router!

Then mocked up with four tubes of equal length

Then started to draw it up on the cad to work out my bends

Then made a start on remaking my rear upper wishbones

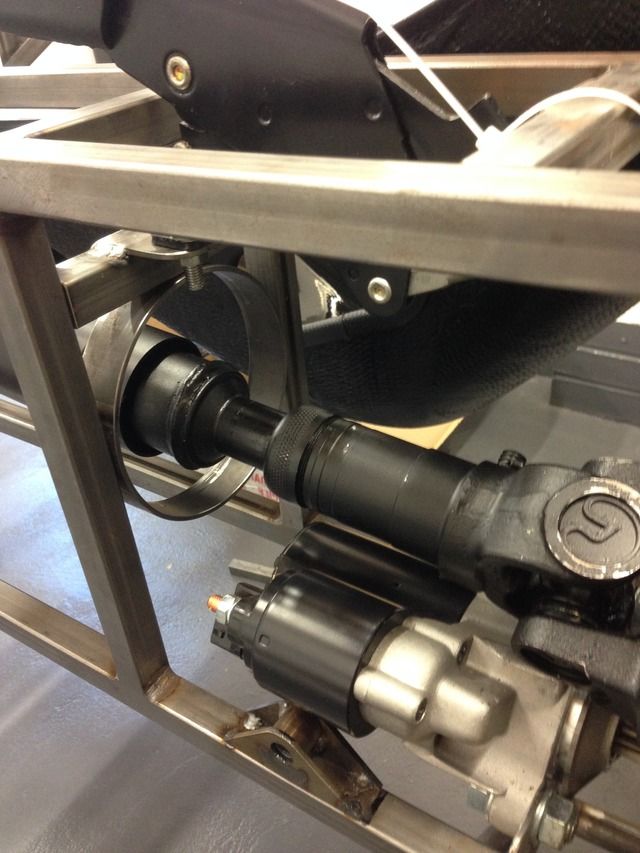

Rosco86 - 24/1/15 at 07:33 PM

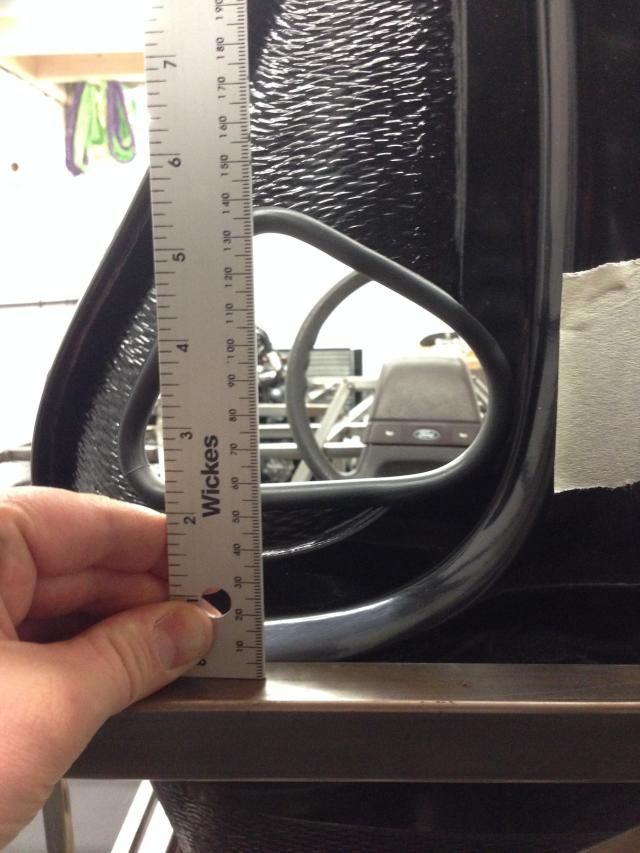

Got my seats from JK Composites this week

Really happy with the quality

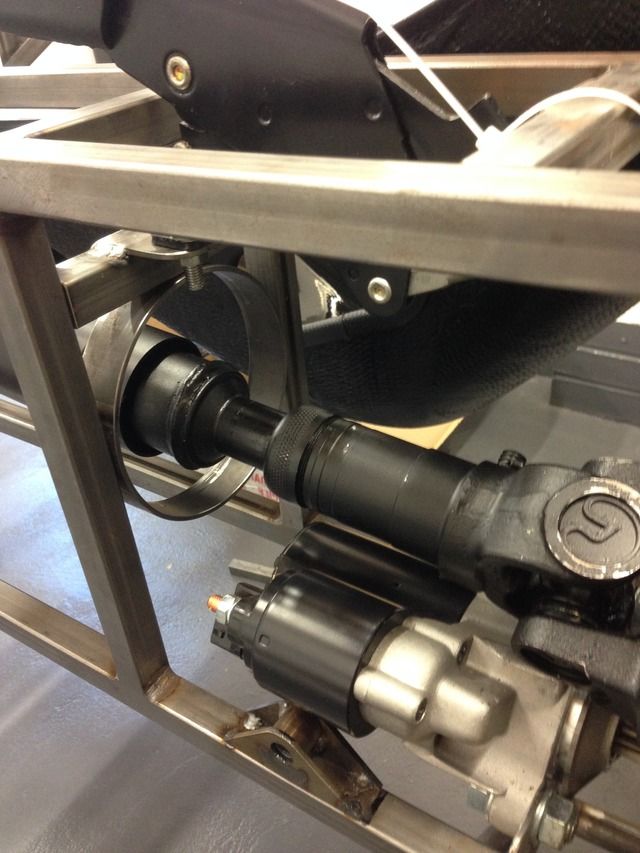

Also got a column and got it mounted

Just need to get a UJ joint that's fits the rack as the one I've got is to big

I've cut the steering lock off and I'm going to get the Ali bit turned town so it's nice a clean looking coming out of the dash

Got my lower engine mount sorted to!

Here's a pic of where my upper harness holes fall, there a bit high up

i

i

I was hoping to have some welded bosses in the top chassis rail like most people do must looks a bit high, I don't really want a cross rail as

I'm going to put

A diagonal across the rear hoop, what options do I have, anyone got any ideas?

rdodger - 24/1/15 at 08:05 PM

Is the seat reclined enough? They look very upright.

[Edited on 24/1/15 by rdodger]

Rosco86 - 24/1/15 at 08:15 PM

Yeah there about the same angle as the back panel of the car, feel pretty nice when sitting in them

rdodger - 24/1/15 at 08:34 PM

I would wait a while before doing anything

I found I reclined my seats a lot more when I had the pedals set to get more under thigh support.

The angle of my seat is also much greater than the rear panel.

[Edited on 24/1/15 by rdodger]

Rosco86 - 24/1/15 at 08:38 PM

quote:

Originally posted by rdodger

I would wait a while before doing anything

I found I reclined my seats a lot more when I had the pedals set to get more under thigh support.

Yeah cheers, think your right, that's my next job on my list, pedal box

CosKev3 - 24/1/15 at 10:22 PM

Looking good,as usual

Looking forward to the exhaust manifold taking shape,are you doing that yourself?

Rosco86 - 25/1/15 at 08:38 PM

quote:

Originally posted by CosKev3

Looking good,as usual

Looking forward to the exhaust manifold taking shape,are you doing that yourself?

Urm hopefully not lol, my mate builds f1 manifolds and hoping he's going to sort me out, just waiting to hear back from him

ste - 25/1/15 at 10:47 PM

Rosco, this has got to be up there with the best builds. Hats off to you.

Are those stainless pipes for the cooling system flared? as I had no end of troubles with silicon elbows slipping off regardless of how tight you get

the clips.

CosKev3 - 26/1/15 at 01:19 AM

A nice small bead of weld will work if they are not flared

quote:

Originally posted by Rosco86

quote:

Originally posted by CosKev3

Looking good,as usual

Looking forward to the exhaust manifold taking shape,are you doing that yourself?

Urm hopefully not lol, my mate builds f1 manifolds and hoping he's going to sort me out, just waiting to hear back from him

That should be a nice piece of work then

Rosco86 - 30/1/15 at 07:22 PM

quote:

Originally posted by ste

Rosco, this has got to be up there with the best builds. Hats off to you.

Are those stainless pipes for the cooling system flared? as I had no end of troubles with silicon elbows slipping off regardless of how tight you get

the clips.

Wow thanks for the complement, yeah there stainless but I'm going to swap for aluminium with beaded ends just to save a bit of weight

Rosco86 - 30/1/15 at 07:45 PM

Got a bit done this week,

Cut the lock etc off and made a stainless tube, still need to secure it

Also made some top hat washers for the column bracket

Got my plates for the footwell back from my fabricators

I've had these cut out of 2mm and a strengthening fold along the bottom where the pedal box bolts in

Also got a couple of front seat rails bent up, these will have nuts welded underneath

And sit somewhere like this, pedal box is next weeks job so then I can work out my seat position

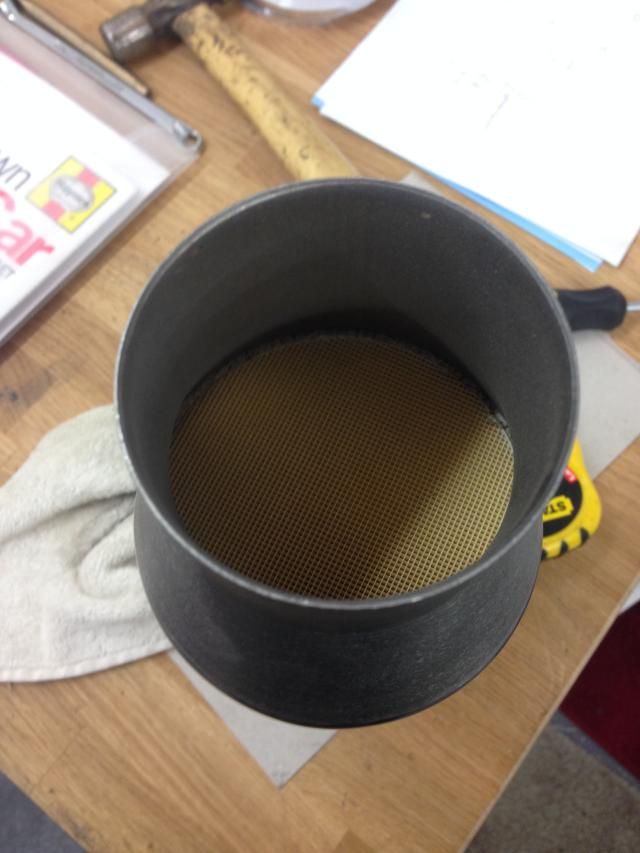

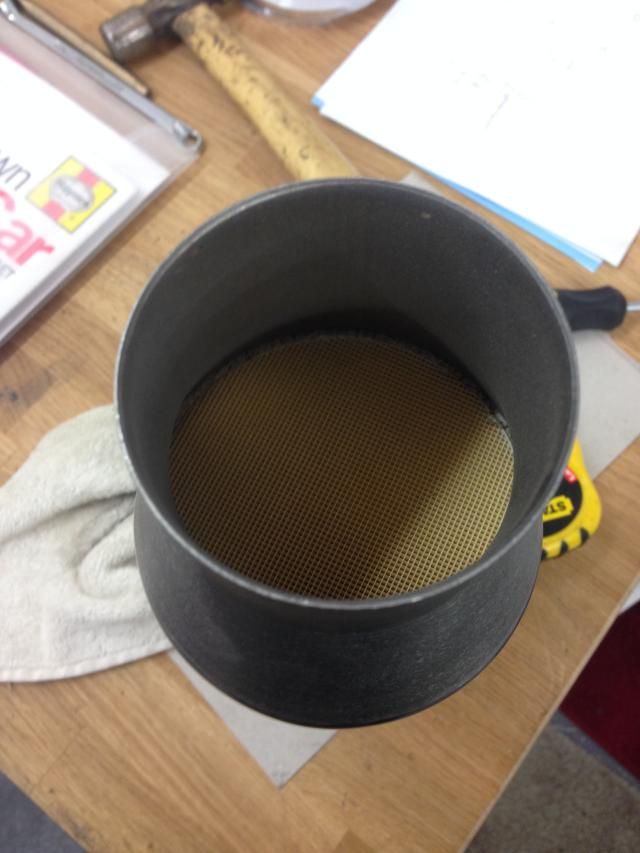

Picked up a cat today to, it's a 400 cel custom chrome one, there only down the road from me, could of got a 200 cell high flow but didn't

want any problem getting through my iva

[Edited on 30/1/15 by Rosco86]

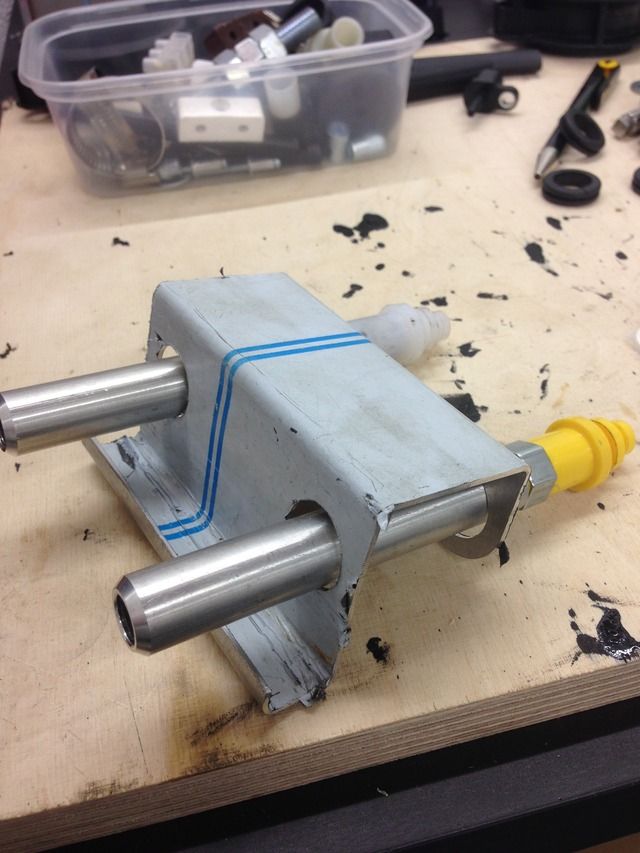

Rosco86 - 1/2/15 at 07:28 PM

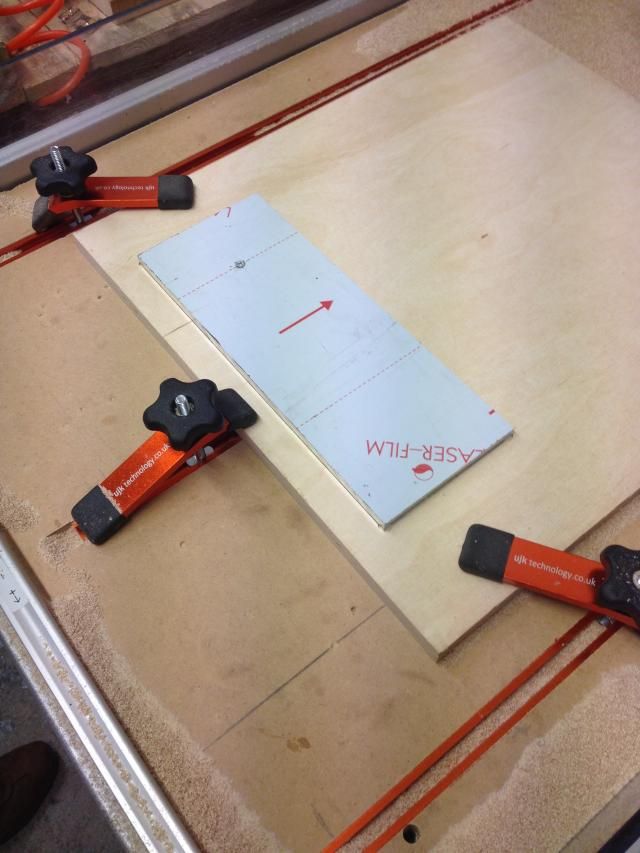

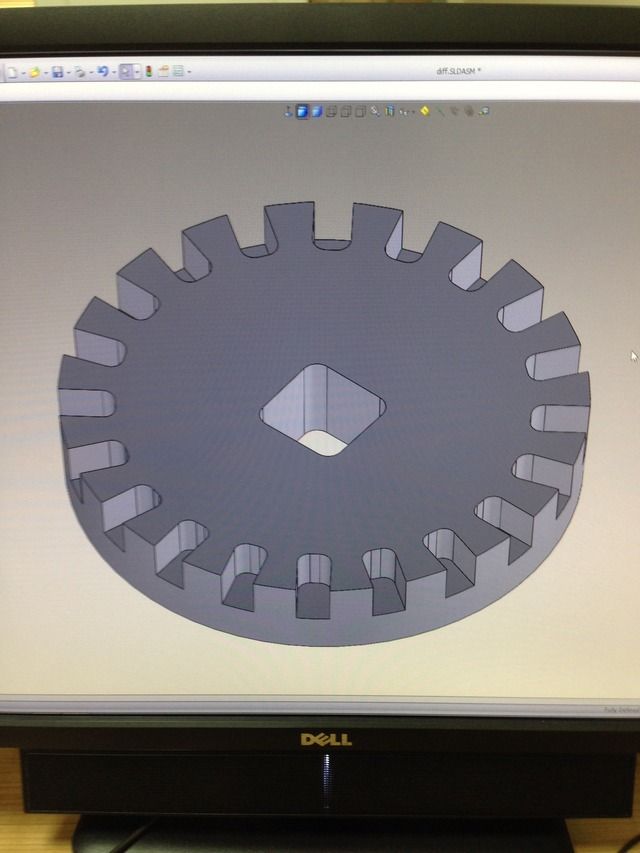

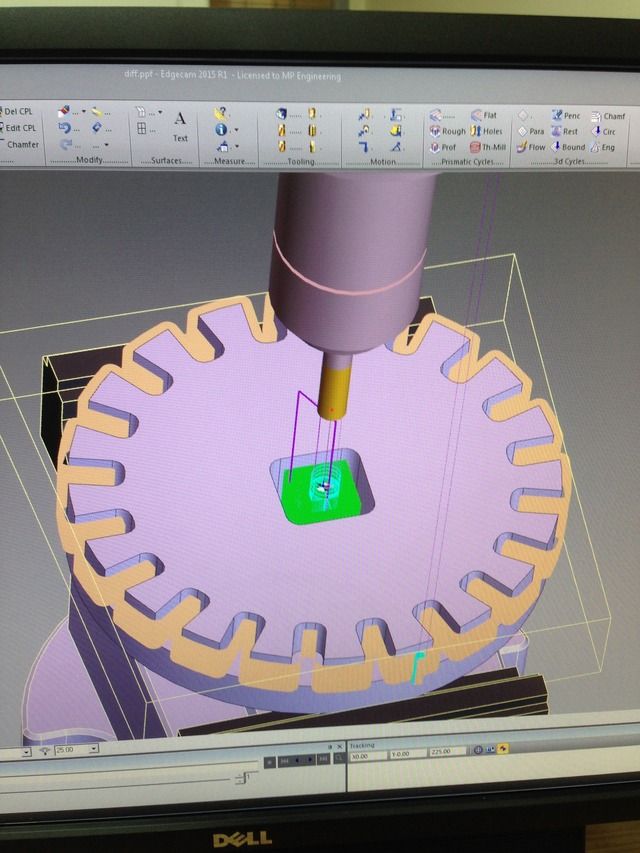

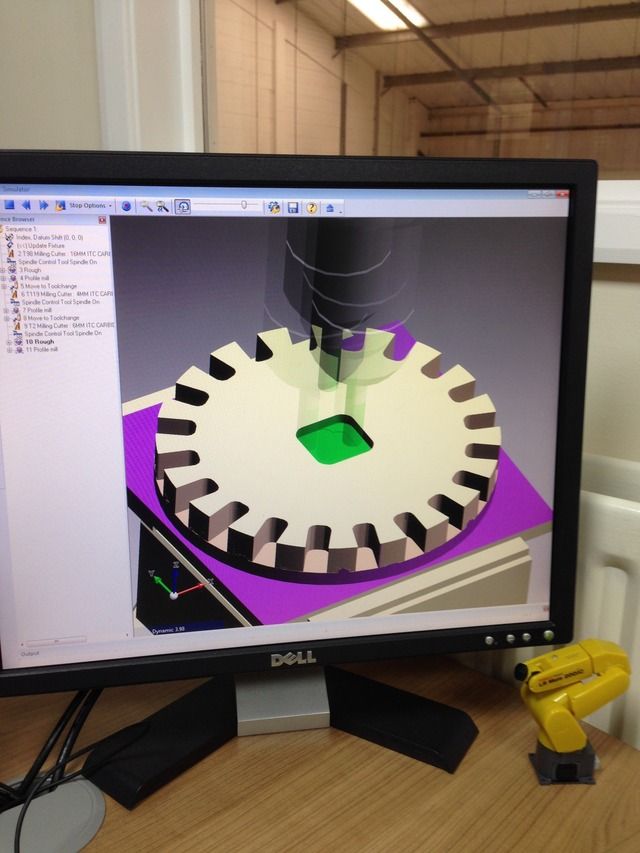

Down my dads all day today, he's built a cnc router, works like a dream

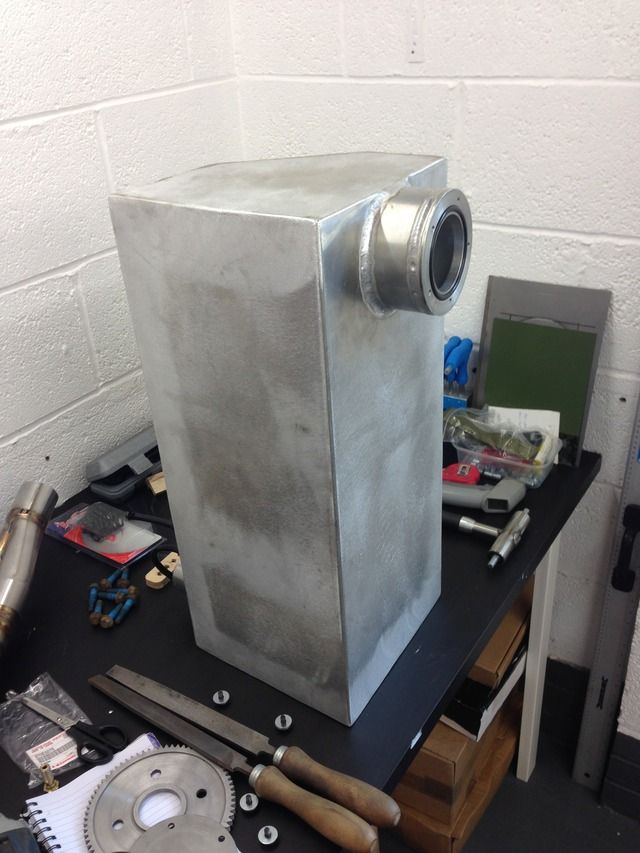

Made a flange for my zx10 fuel pump today, this will be welded to a tube then to the bottom of the tank to make a swirl/ sump

Made a ply one first to check holes and oring grove

10mm Ali plate

Took 25mins to cut this out

Then made a wheel with the correct offset so I can check clearance when we make the exhaust manifold

One side is a 205 tyre the other is a 185 tyre

12mins for this I think, it flys through timber!

Then a mk1 gear lever, just as a starting point

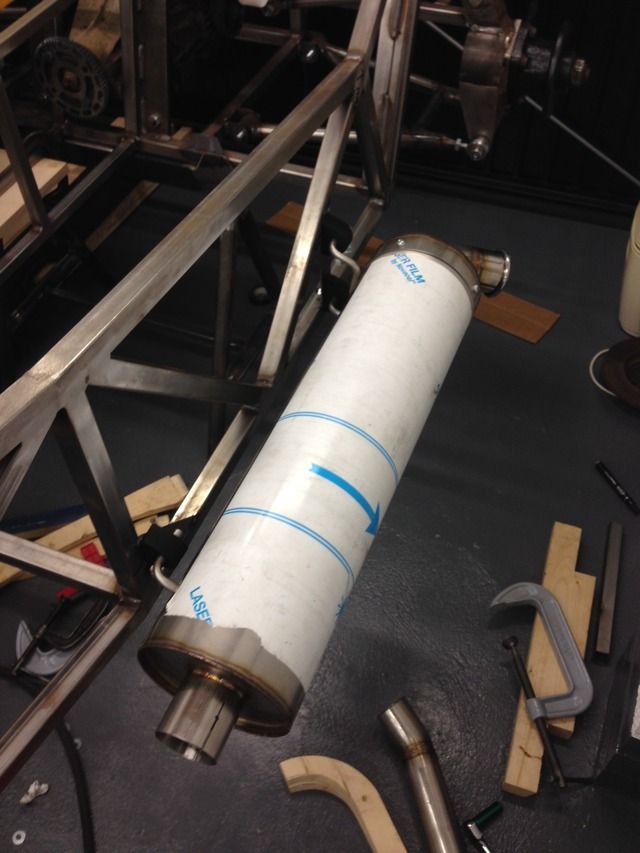

Rosco86 - 2/2/15 at 09:11 PM

Got a bit done tonight, made two hose barbs for my fuel tank

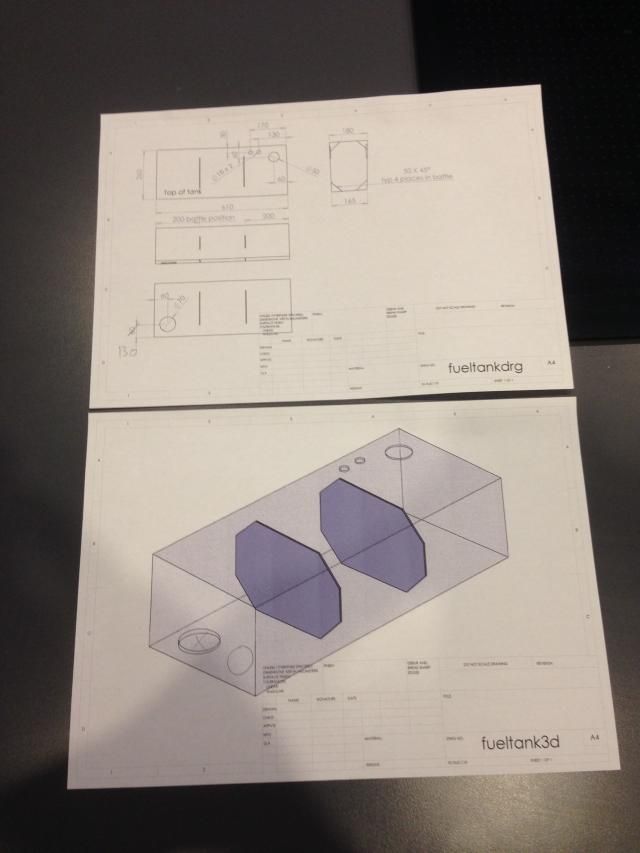

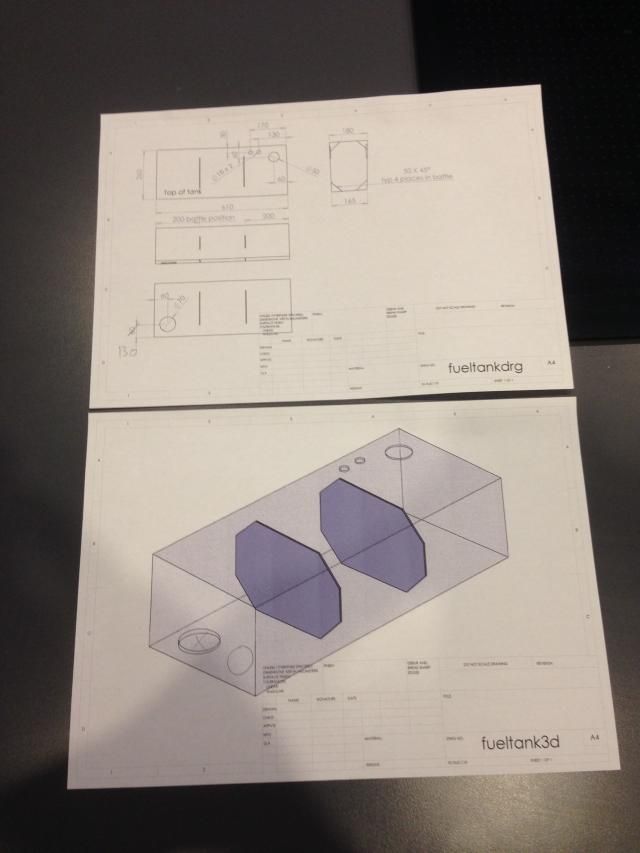

And drew my fuel tank up ready to get it laser cut and folded

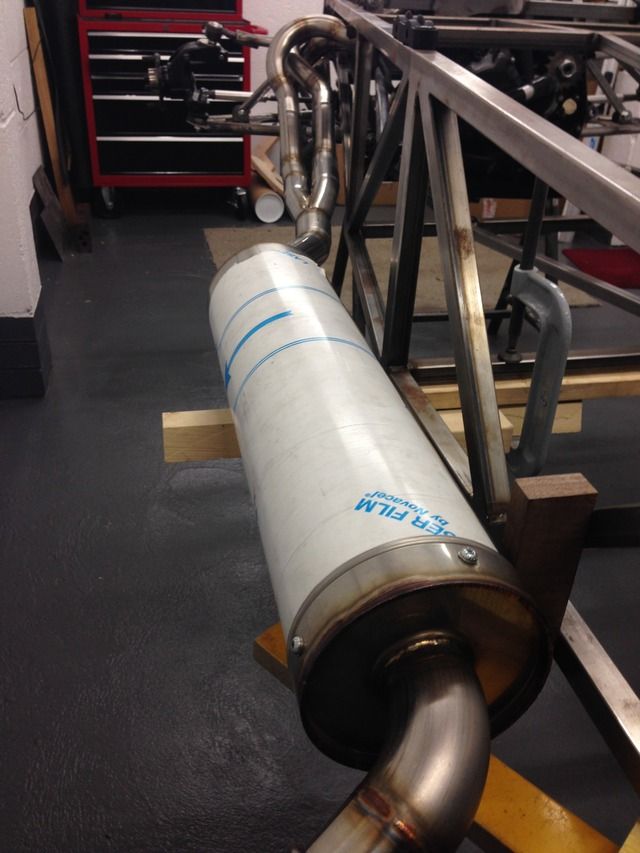

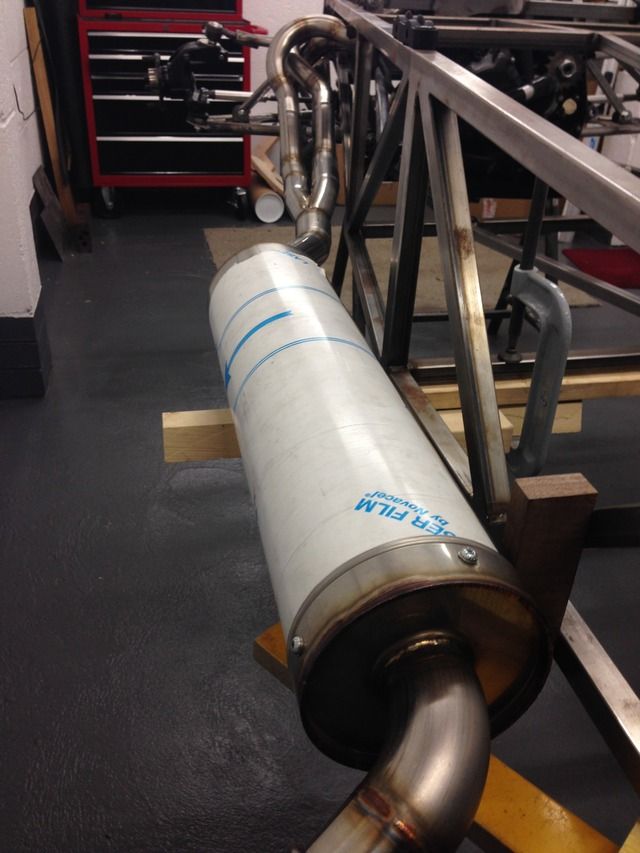

Also my mates started on my silencer, it's repackable

[Edited on 2/2/15 by Rosco86]

ste - 2/2/15 at 11:20 PM

How much for one of those cats?

bart - 3/2/15 at 12:54 AM

I like it !

might sue you over the gear change design handle though ! LOL

Rosco86 - 3/2/15 at 08:28 AM

quote:

Originally posted by ste

How much for one of those cats?

Sent a U2U

Rosco86 - 3/2/15 at 08:31 AM

quote:

Originally posted by bart

I like it !

might sue you over the gear change design handle though ! LOL

Haha, just looked at yours! Mines plywood so im safe!

Rosco86 - 4/2/15 at 07:41 PM

Few hours tonight but was getting cold!

My tube for my fuel tank came today so made a bit for the filler and the larger bit for my swirl pot/ pump houseing, also drilled and tapped the pump

flange

Also Picked up my exhaust flanges and collars tonight ready for making my manifold

[Edited on 4/2/15 by Rosco86]

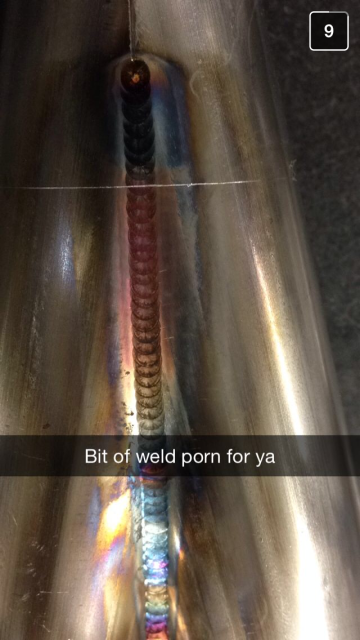

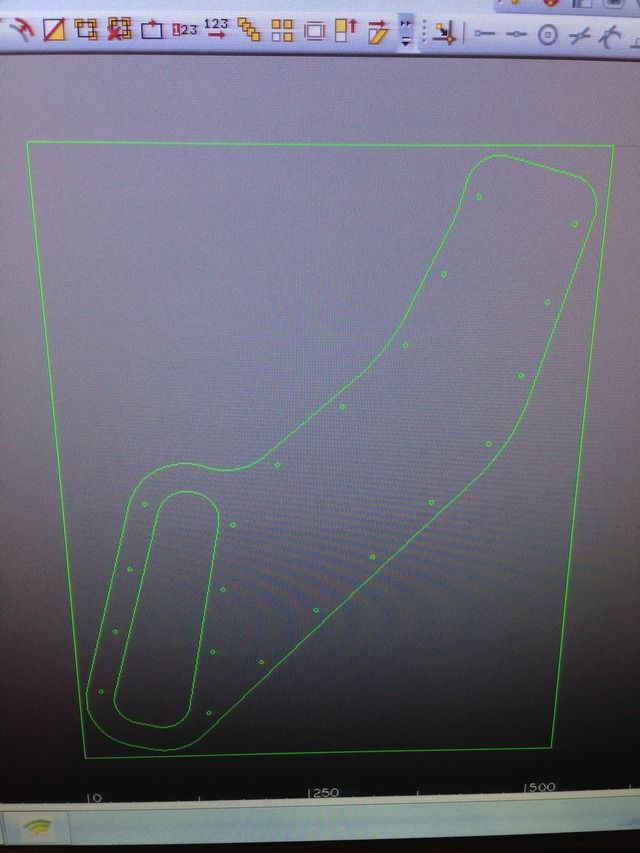

Rosco86 - 15/2/15 at 02:59 PM

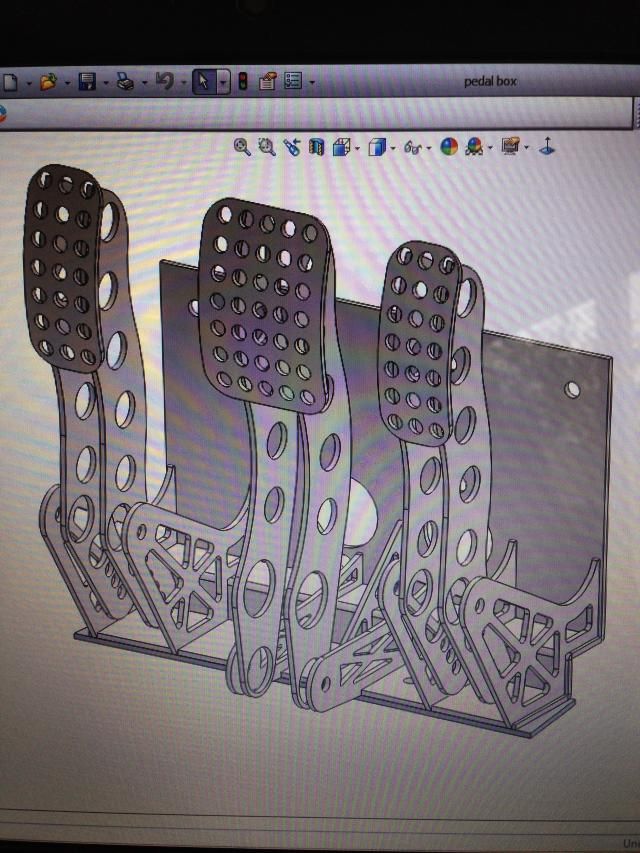

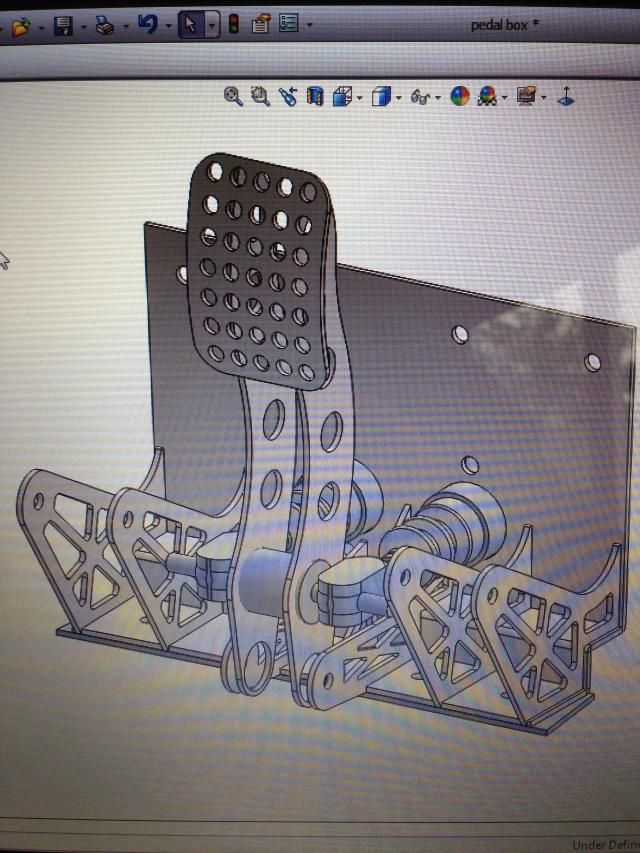

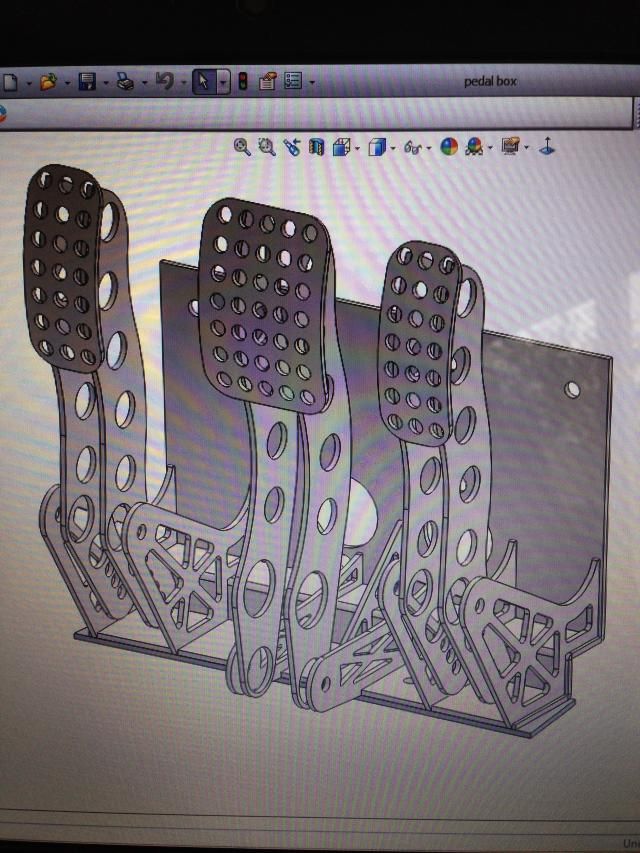

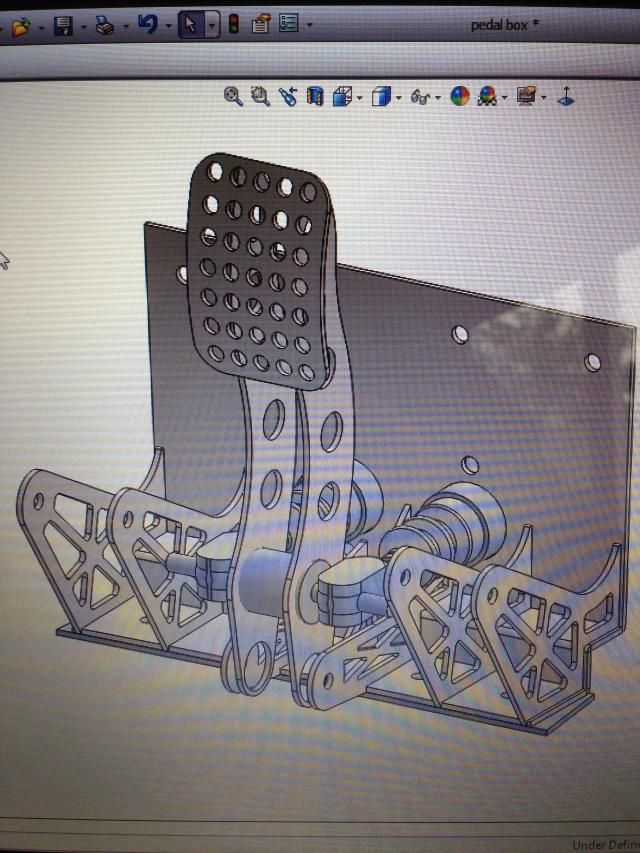

Well I've been doing a few jobs since my last update, my fuel tanks well on its way, I've been drawing up my pedal box for the last few

weeks and

I've spent all day on it today, pretty happy with it, should get it cut out next week, I was going to use Vouchts pedal box design off the haynes

forum

But with the bias bar and different cylinders I just couldn't get it to work, all my ratios have work out as I want them, so all being well it

will be sweet

The pedals will have tubes in between them

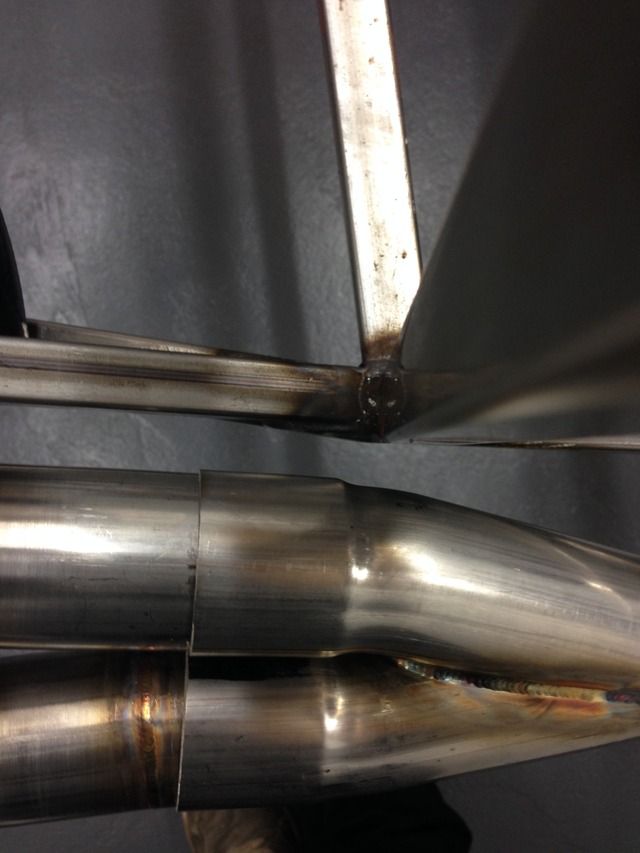

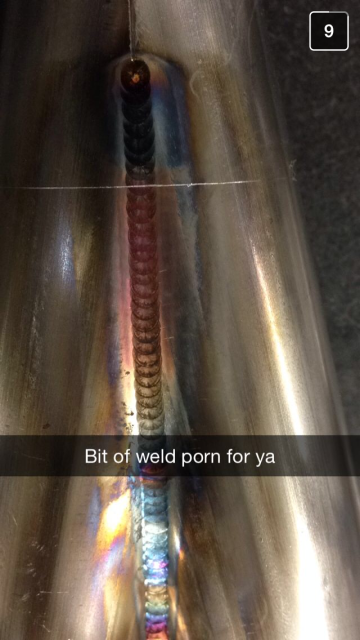

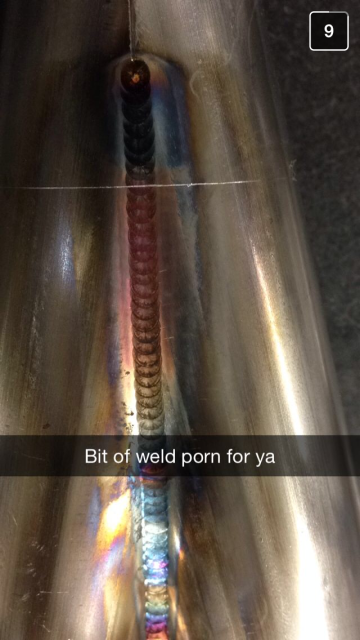

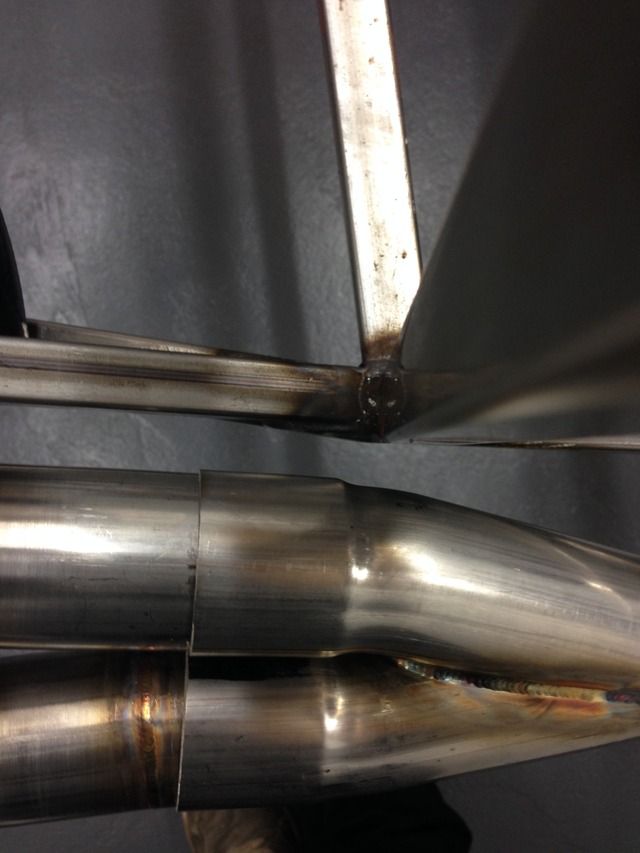

Also my mate sent me a pic of my exhaust collectors, possibly doing my manifold with him next weekend

bart - 15/2/15 at 04:52 PM

I love weld porn

the best type

got to say very professional build lots of care and looks neat

big_wasa - 15/2/15 at 05:08 PM

I would love to be able to weld like that

Rosco86 - 15/2/15 at 06:57 PM

quote:

Originally posted by bart

I love weld porn

the best type

got to say very professional build lots of care and looks neat

Thanks, yours is the same mate! If you ever get selling kits I think I would be interested in one

Rosco86 - 15/2/15 at 06:58 PM

quote:

Originally posted by big_wasa

I would love to be able to weld like that

Me to! Can't wait to see my manifold!

Rosco86 - 15/2/15 at 06:59 PM

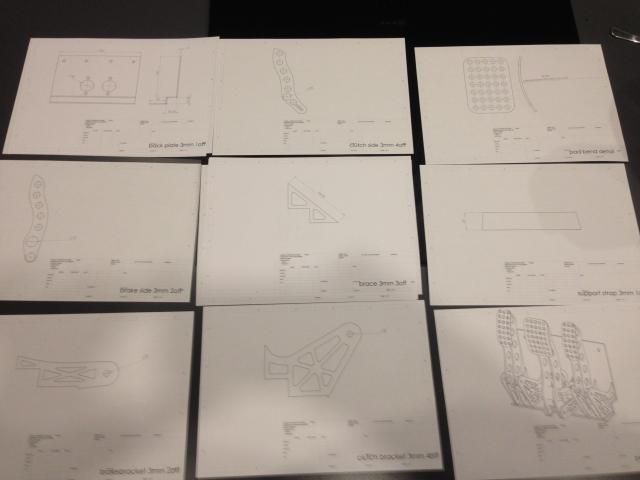

Drawings ready for my laser man

bart - 15/2/15 at 09:13 PM

You probably have but shouldn't the drawings be in a dxf file format without dims and page format . You probably have just checking

Rosco86 - 15/2/15 at 09:30 PM

quote:

Originally posted by bart

You probably have but shouldn't the drawings be in a dxf file format without dims and page format . You probably have just checking

Yeah I've got the dxf's on a USB stick, I do him drawings for folding details and so he knows what needs cutting etc

CosKev3 - 18/2/15 at 09:59 PM

quote:

Originally posted by Rosco86

Also my mate sent me a pic of my exhaust collectors, possibly doing my manifold with him next weekend

Wow

What's the score with the different colours around the weld?

Rosco86 - 21/2/15 at 09:01 PM

Don't no if I'm honest mate, prob as it heats up as you weld along

Rosco86 - 21/2/15 at 09:10 PM

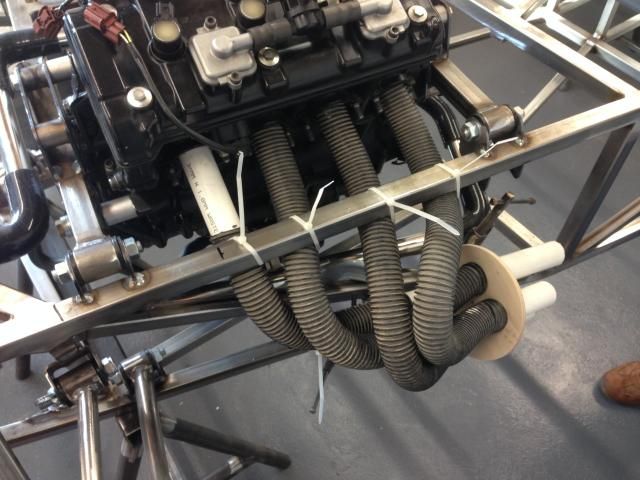

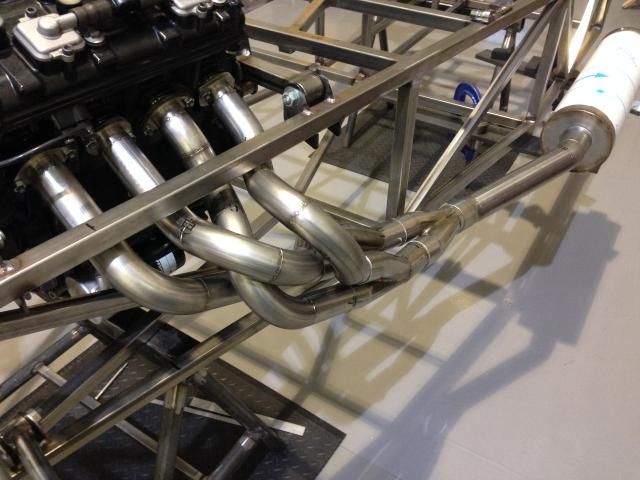

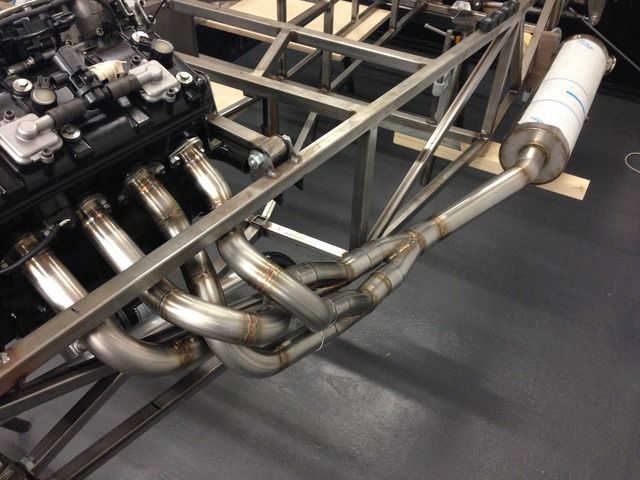

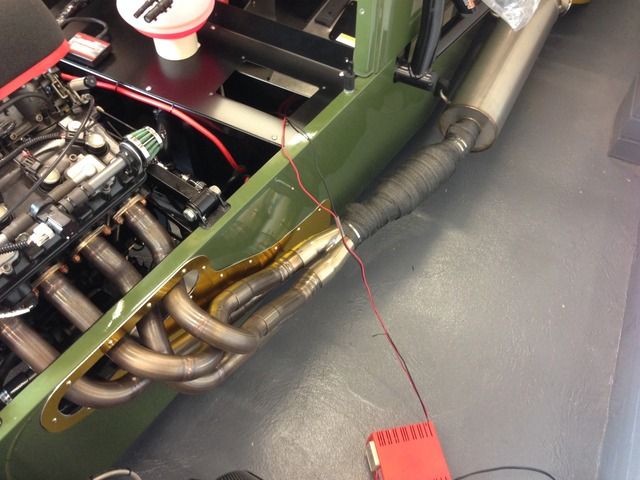

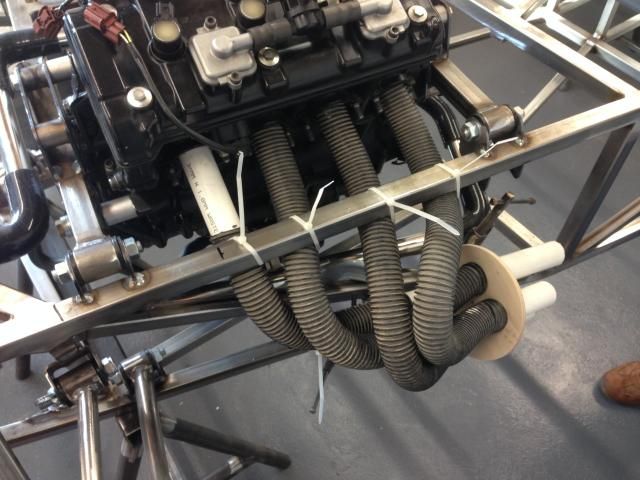

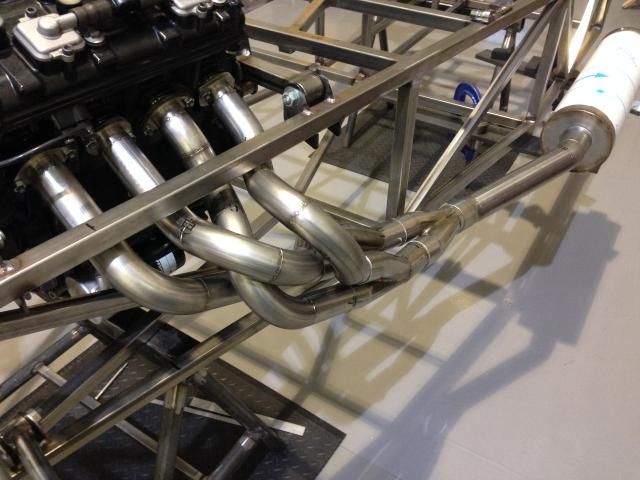

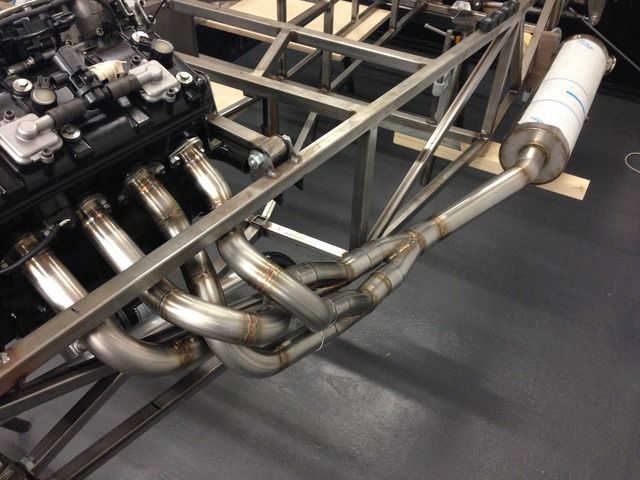

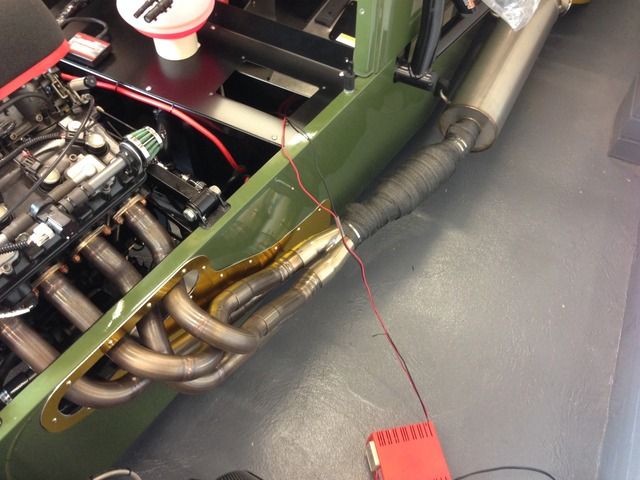

Well had a awesome day today! Been up and seen my mate at Primary Designs in Thame today, was a long day but we got my exhaust all fabricated and

tacked up, he's going to get it finish welded during the week, the primary lengths are all within 5mm! I will let the photos do the talking

bart - 21/2/15 at 09:14 PM

That reminds me

Spaghetti on toast for tea tomorrow

tajgreidotu - 25/2/15 at 06:21 PM

quote:

Originally posted by tajgreidotu

Congratulations for the clean build. I'm just 2 steps behind you, so its nice to see your progress.

Just to clarify, in this picture the tube RS15 should go on the opposite side. Did you do it on purpose?

I forgot to weld it while doing the box, im afraid maybe is too late

Have fun!

Hi mate,

great build you are doing!!

Did you manage to solve the RS15 issue somehow?

Keep pushing!

Rosco86 - 26/2/15 at 10:36 AM

not yet but im just going to put a fillet piece of 3mm plate across the corner where the box section should have gone

Rosco86 - 10/3/15 at 08:35 PM

Right no updates for a few weeks, still waiting on laser cutting and to get my exhaust back so I've got a little side project to keep me busy

Ive been after this for about a year as it's been sitting in a blokes yard, he finally sold it me last Saturday afternoon

I borrowed a trailer to get it home on, but it weighs about a ton so we had to strip it to get it up the garden!

The bed took 4 of us to lift and so did the stand

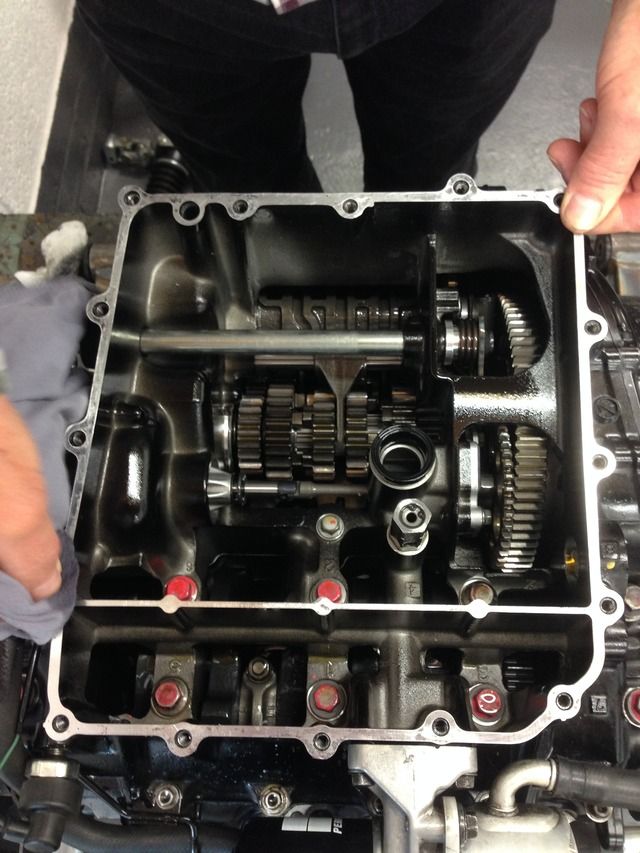

Gearbox was mint

Loads of bits to clean up

Base and bed ready for paint

Clean parts bin filling up

Covers and parts ready for paint

Parts painted by my dad while I've been at work

And that's where it's up to, cheers for looking

CosKev3 - 10/3/15 at 09:32 PM

Will look mint when back together!

Manifold looks great, but there's not much room for bodywork between chassis and manifold in collector area?

Rosco86 - 10/3/15 at 09:48 PM

quote:

Originally posted by CosKev3

Will look mint when back together!

Manifold looks great, but there's not much room for bodywork between chassis and manifold in collector area?

Yeah I've been thinking the same to be honest, will have to have a look when I get it back, can always be tweaked out or altered I guess

bart - 11/3/15 at 01:48 AM

Nice lathe

Make a good job of the slides and nuts and it will out live you

Consider covers ion to quick change tool post. Worth it in the long run

Rosco86 - 20/3/15 at 07:26 PM

quote:

Originally posted by bart

Nice lathe

Make a good job of the slides and nuts and it will out live you

Consider covers ion to quick change tool post. Worth it in the long run

Cheers pal, yeah it's on my never ending list!

Rosco86 - 20/3/15 at 07:36 PM

Well the lathes almost there, new motor fitted, just a bit of wiring up to do

Also I've got my exhaust back all welded up

Going to use these rubber mounts I think

I'm a little worried about the clearance between the exhaust and my grp side panel, the gaps 15mm at the min

I'm happy with the silencer position though

Can anyone comment on my clearance issue?

bart - 20/3/15 at 07:51 PM

Nice lathe

Nice exhaust

Looking good

big_wasa - 20/3/15 at 08:34 PM

Lathe looks great.

Rosco86 - 24/3/15 at 10:22 PM

Cheers guys

Rosco86 - 30/3/15 at 07:53 PM

A bit of an update tonight, I was looking on speedhunters today like I do most days, and they decided to do a little wright up with some pictures I

sent in

http://www.speedhunters.com/2015/03/iamthespeedhunter-your-bike-powered-builds/

It's about half way down

Next on the list, the lathes all finished

Also I'm back on my pedal box, should get it all tacked up this week

Clamping the sides up square

Pedals

Flange bearings for the pivots

All the tubes will be tig welded in

And that's it for now

Andybarbet - 30/3/15 at 08:07 PM

Oooooh - I like that a lot :-)

rdodger - 30/3/15 at 08:56 PM

Very nice!

Rosco86 - 1/4/15 at 09:18 PM

A bit more done tonight, I made some exhaust hangers at the weekend and my rubber mounts came today so got it all mounted and tacked up

Pretty happy with how it's worked out, sits where I want it to which in good

[Edited on 1/4/15 by Rosco86]

Rosco86 - 6/4/15 at 04:10 PM

Had a good few days on the car this weekend, got a bit done

Pedal box tacked up and in the car, there's still a bit to do on it but at least I no where my seats going

Front seat rails done, I've raised the front of the seat to lower the harness holes at the rear

Nuts welded underneath

Harness mounting bosses made

Rear diagonal done

A shot from the rear, also a bit of artwork put up!

Also I've set my self a date of Easter next year to be Iva'ed and on the road

Rosco86 - 12/4/15 at 12:46 PM

This weeks progress

I started working out where my lower harness mounts were going according to the msa blue book

I've changed the book design a little, tacked in

Centre two

Upper seat brackets done, I no the top edge doesn't need a radius behind the seat, but it looks neater I think

Just need some side to side spacers sorting and some correct length bolts

Next throttle cable sorted and temp return spring and the studding through the top is a temp forward stop

Full throttle

Clutch cable

Full clutch

I made two tubes to hold the outer cables

Next job, the rest of the roll cage, I've decided to mount the front hoop on the outside, as bashing my leg on it all the time not my idea of

fun

I mocked up the scuttle panel, and worked out a mounting plate

The tube will mount to a bit of tube on end with two more bolts so it meats msa spec, once the front hoops in place I will sort my roof bars and door

bars out

[Edited on 12/4/15 by Rosco86]

davidimurray - 12/4/15 at 02:25 PM

Be careful with those upper seat belt mounts. I can't remember if you're going for IVA, but if the belts touch the seats they will fail.

Mine are on a cross bar on the roll hoop about 4 inches higher and it was just right for IVA.

Cheers

Dave

Rosco86 - 12/4/15 at 05:10 PM

quote:

Originally posted by davidimurray

Be careful with those upper seat belt mounts. I can't remember if you're going for IVA, but if the belts touch the seats they will fail.

Mine are on a cross bar on the roll hoop about 4 inches higher and it was just right for IVA.

Cheers

Dave

Yeah im going for iva, ive tilted the seat back a bit and the mounts are going to have a spacer ontop to bring the mounts up a little, they dont need

a lot

Rosco86 - 13/4/15 at 07:03 PM

Just been looking at my front roll bar hoop, I think I'm going to mount it on the outside i think and welded on, I've had a quick draw up of

it, but I'm going to mock it up with plastic pipe while I'm sat in the car

CosKev3 - 14/4/15 at 09:16 PM

Nice.

Have you planned for a stop on your clutch pedal?

As you can pull bike clutches too far when using a pedal.

Rosco86 - 14/4/15 at 09:44 PM

quote:

Originally posted by CosKev3

Nice.

Have you planned for a stop on your clutch pedal?

As you can pull bike clutches too far when using a pedal.

Cheers, yeah I'm going to have an adjuster in the backplate on the clutch and throttle, and forward stops,

Does anyone no if you need a forward stop on your brake?

Also when I put the engine in first gear the output shaft obviously is turning the engine instead of spinning but when I dip the clutch it

doesn't spin

Rosco86 - 26/4/15 at 05:33 PM

Good progress the last few weeks, pedal box and pedals are getting finish welded and then off for powder coat

Front hoop in position, roof bar in plastic

Side mounts

Door bar mocked up

Exhaust altered and posted back to my mate to tig weld

Door and roof bars fitted, notching the door bars what a bit tricky to get them both the same!

Rear diagonal redone in 45mm cds

Rosco86 - 9/5/15 at 08:22 PM

Bit of an update, didn't have much to do last week, I went stonleigh and brought all my lights,

Made these threaded slugs

Drilled and fitted here

Rear spoiler held in position

More slugs made

Stays made

All done

I no some people won't like it, but I got the spoiler for nothing, it's only for a mess about, that's why I've done it to bolt on

and off easily

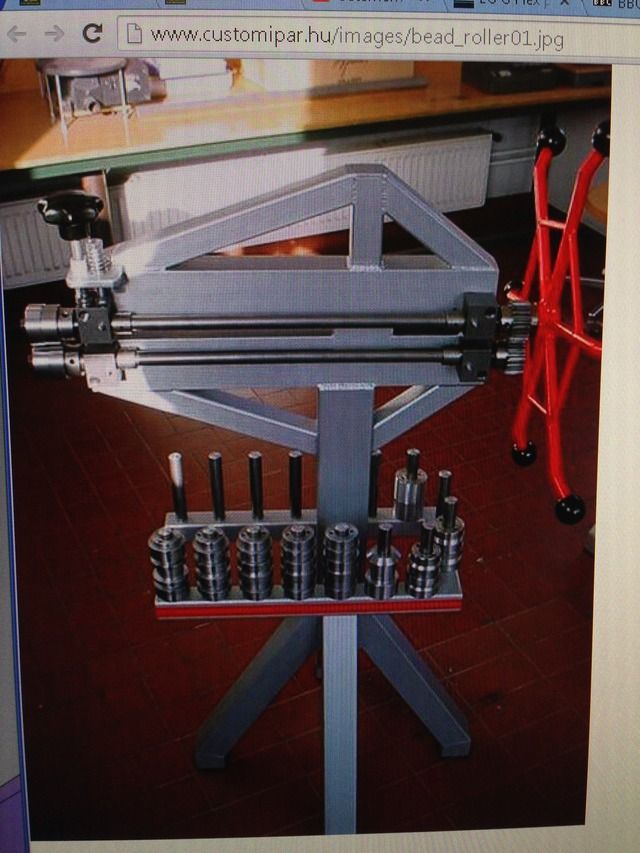

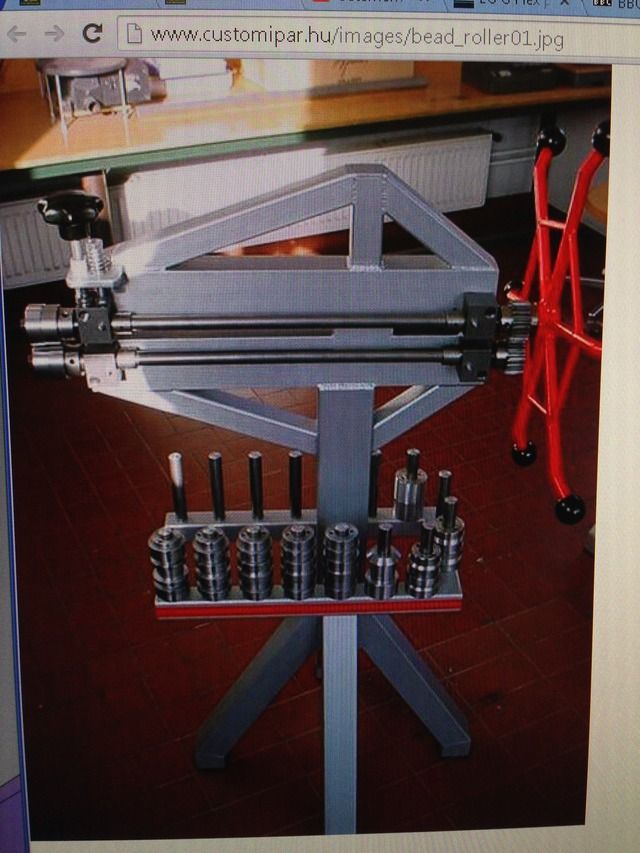

Today's job was to start making a bead roller like below

Bits required

Machining the blocks to house the bearings on my dad's home built cnc

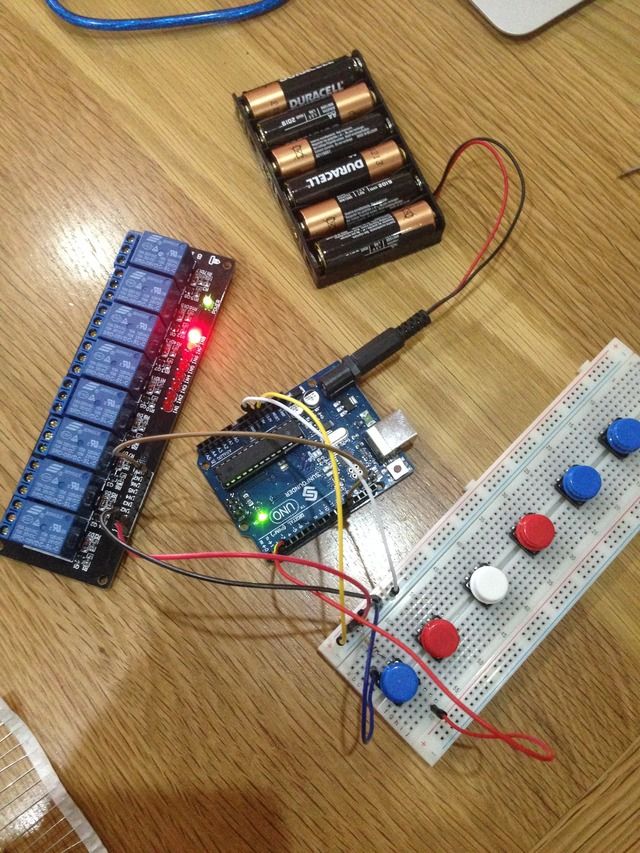

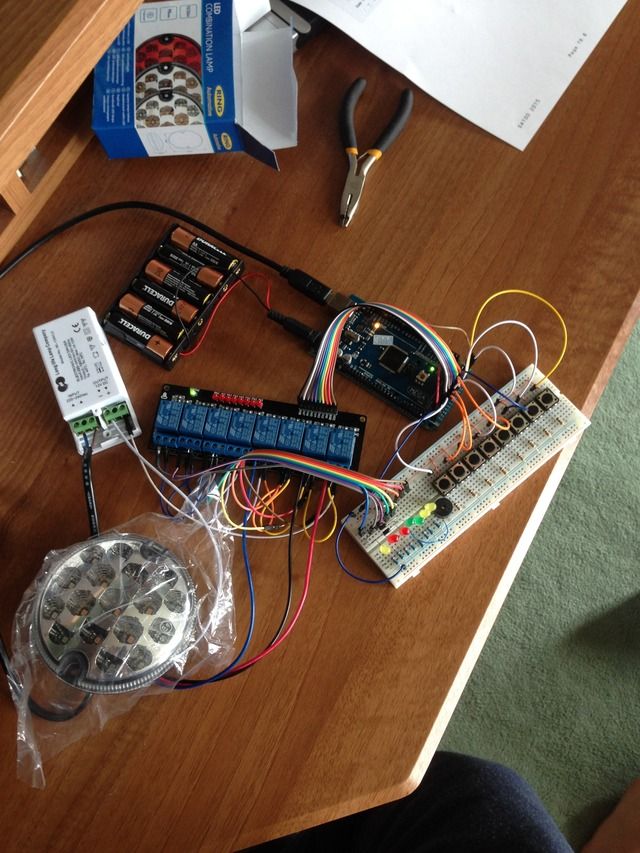

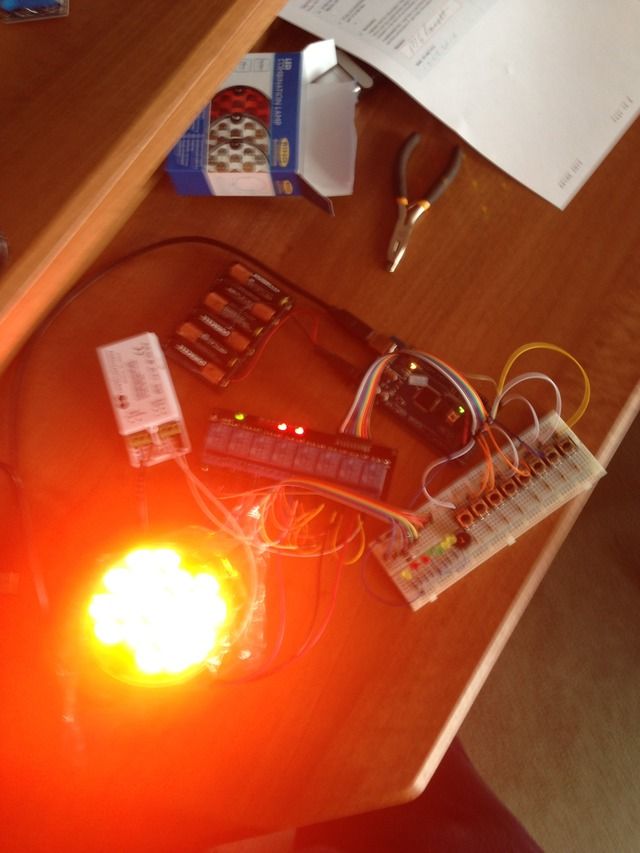

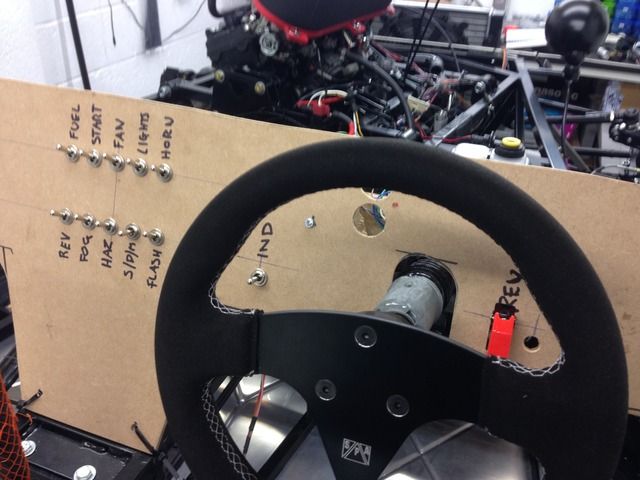

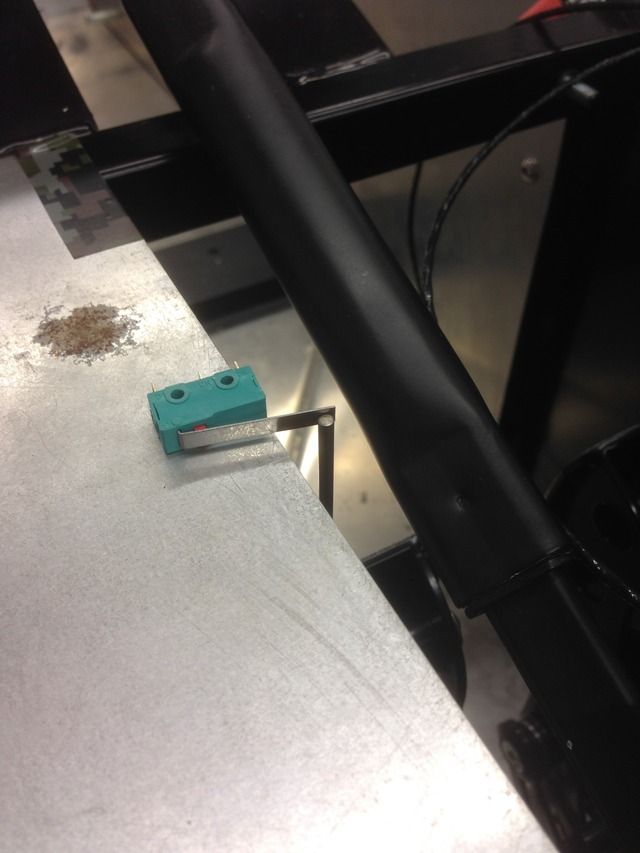

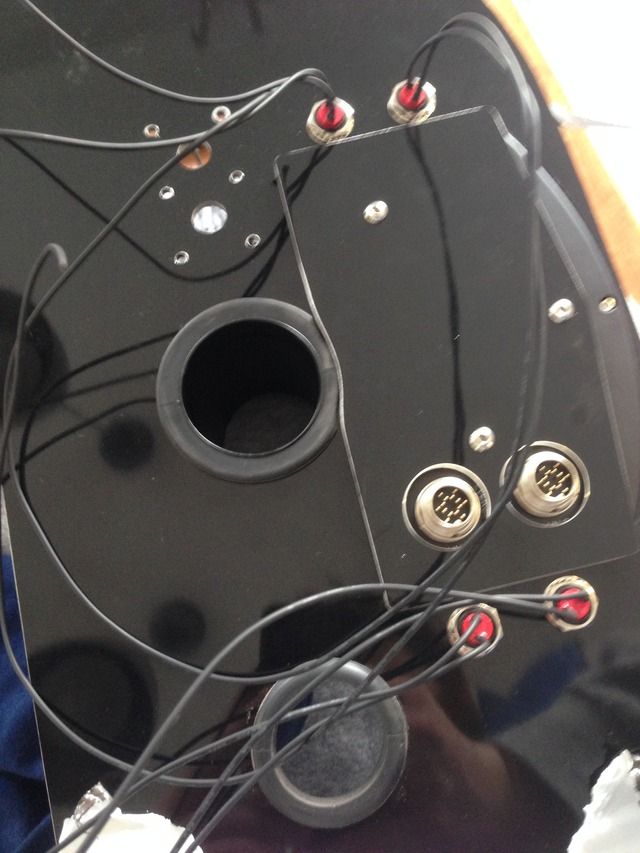

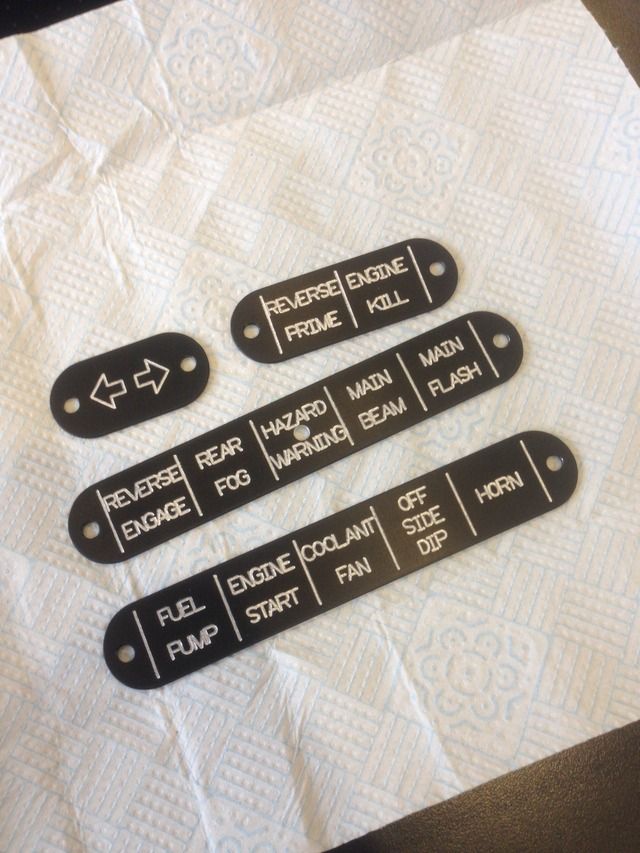

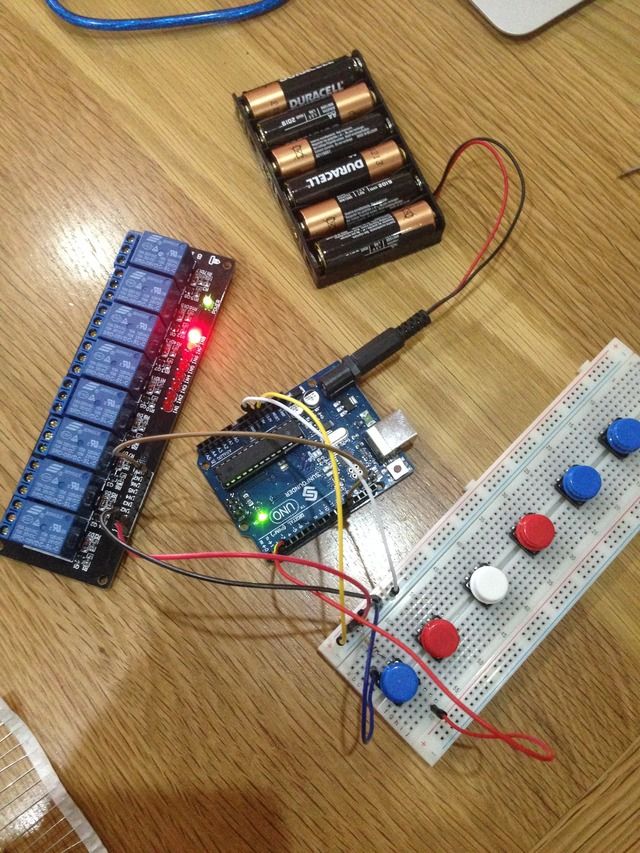

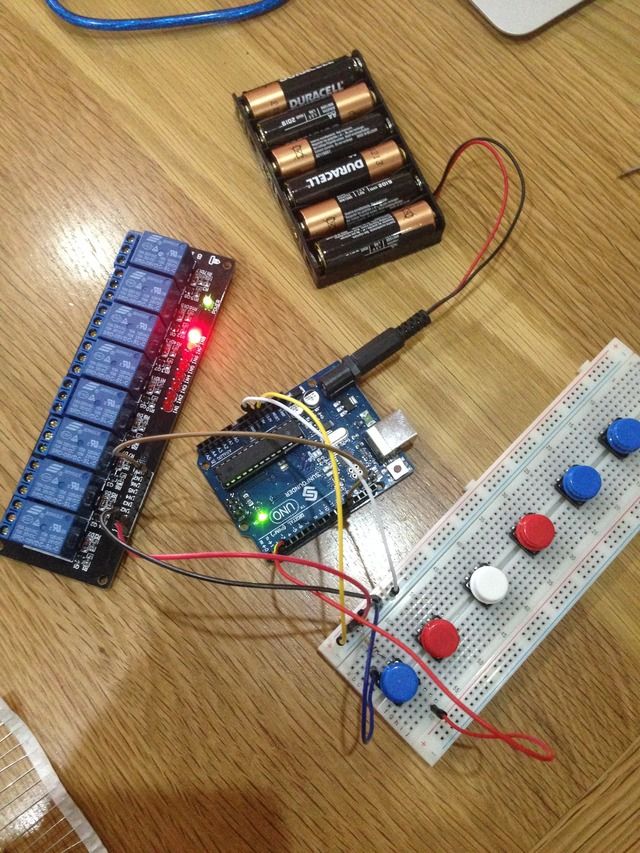

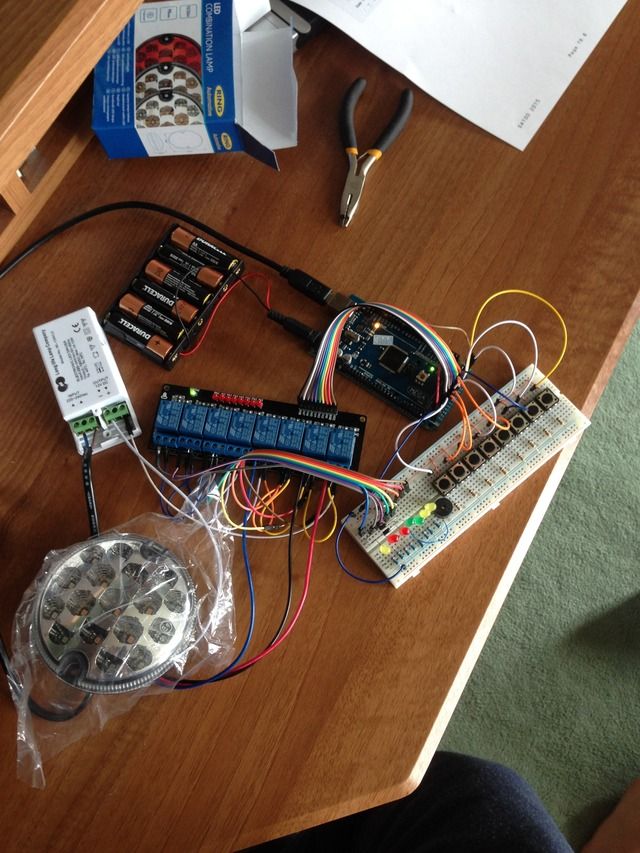

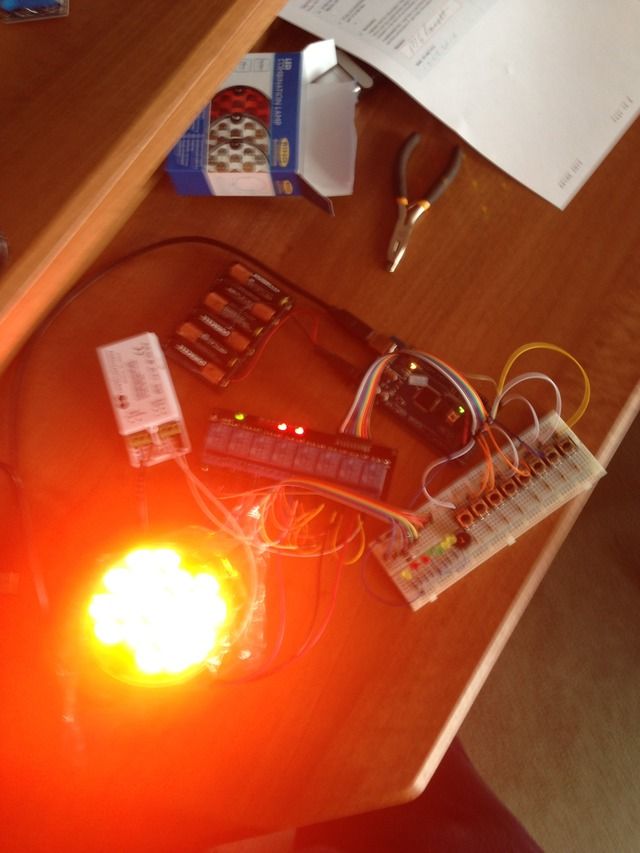

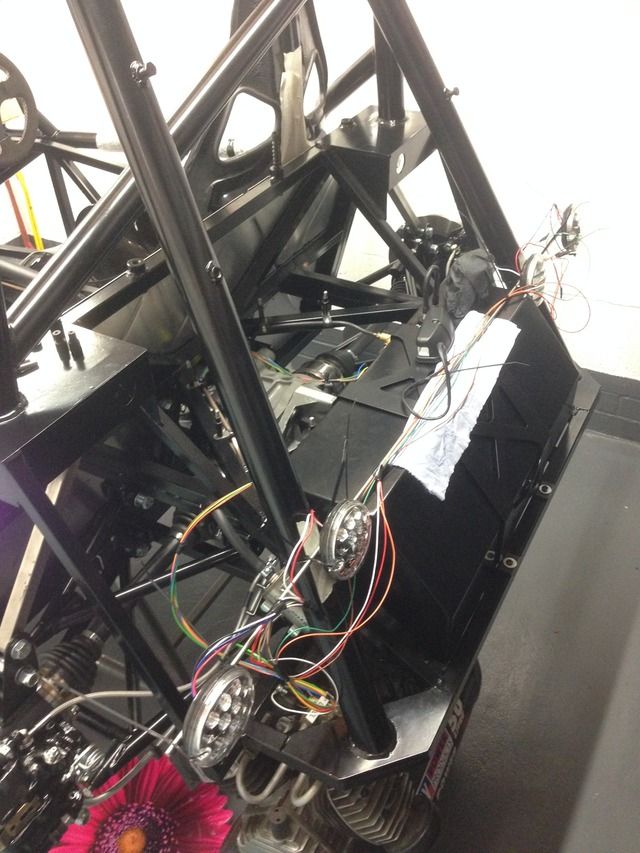

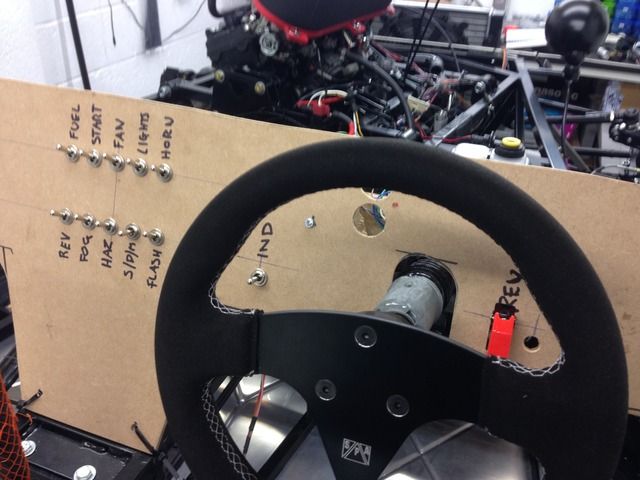

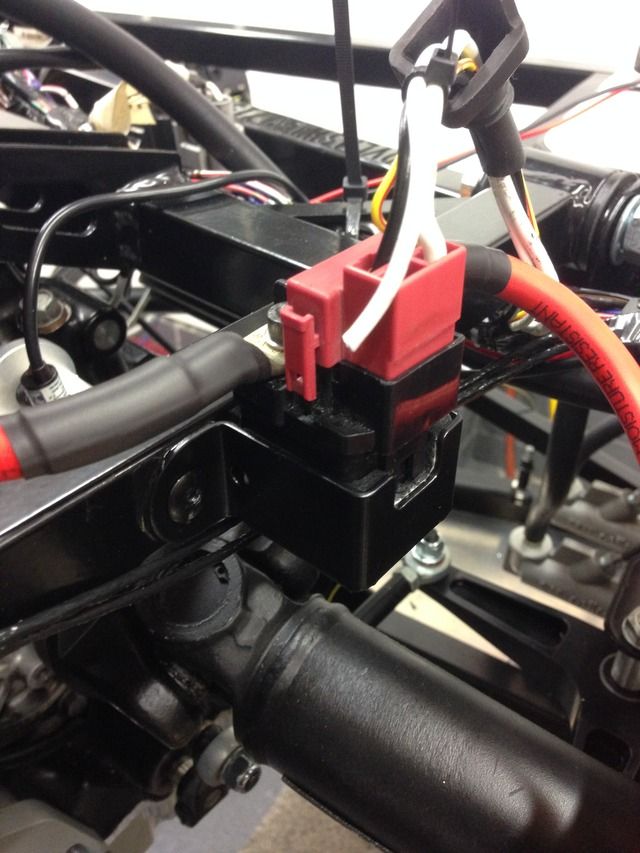

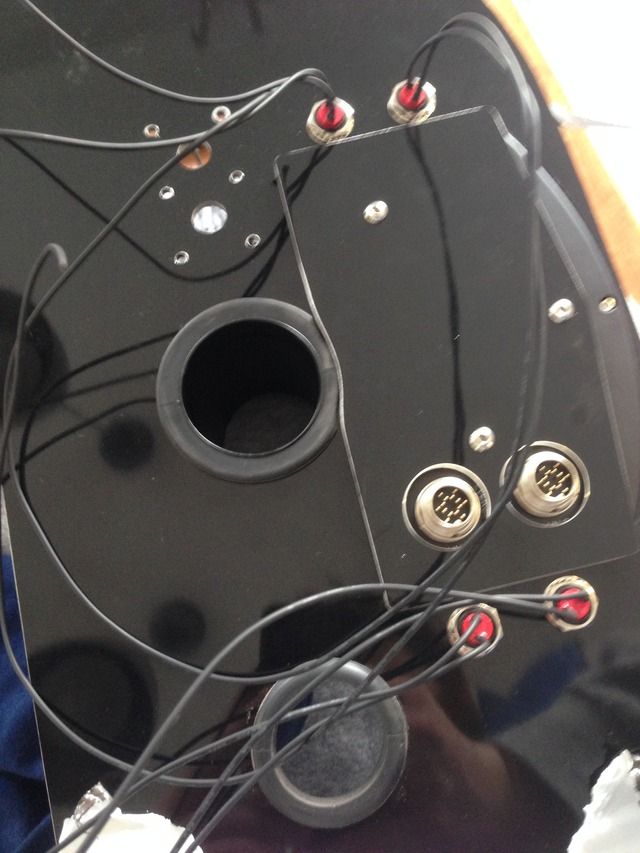

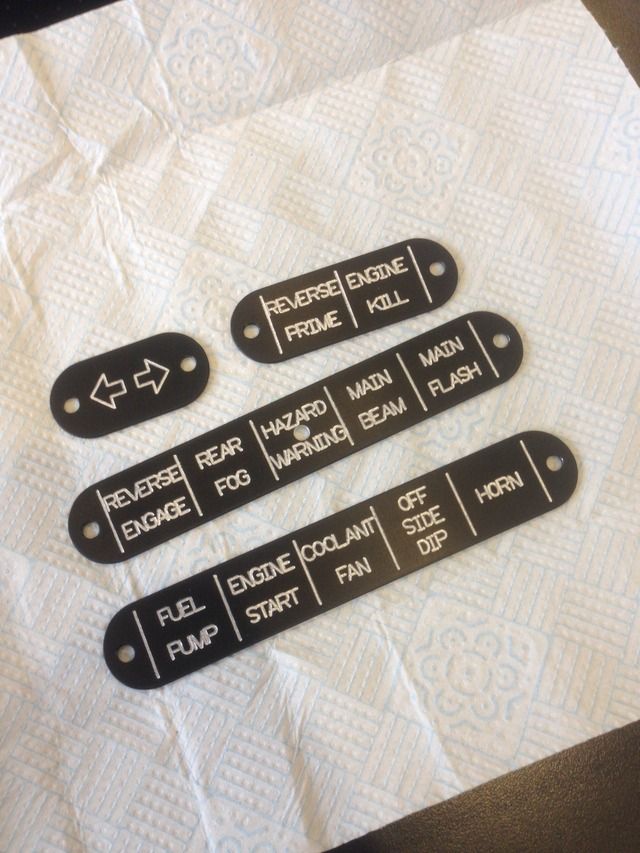

Last up my dads started on my dash buttons, we're having a go using an ARDUINO, it's a programable chip with ins and out, they can be used

with switches, sensors, relays just have a look on ebay to see what's available, the boards are about £8 and everything else like switches are

pence, it's programmed from a PC through USB, so things like indicator flashing can be programmed, if it works out ok it will all be soldered and

put in a little project box

dubzter - 10/5/15 at 08:41 AM

quote:

Originally posted by Rosco86

Last up my dads started on my dash buttons, we're having a go using an ARDUINO, it's a programable chip with ins and out, they can be used

with switches, sensors, relays just have a look on ebay to see what's available, the boards are about £8 and everything else like switches are

pence, it's programmed from a PC through USB, so things like indicator flashing can be programmed, if it works out ok it will all be soldered and

put in a little project box

Awesome work, not sure about the spoiler but it will be good to see it once there is some bodywork in place.

I've been looking at Arduino for building a boost type gauge for my other car, should be a nice cheap control unit for what you are planning if

it works out.

Lew The Machine - 14/5/15 at 09:49 PM

looking really good dude! I'd keep the wing, looks awesome! although i think the stays could do with a few tweeks!

I've just finished Uni for the summer so hoping to make some decent progress on mine over the next few months!

Pedal box looks INSANE... pretty sure you could sell those all day long!

Keep it up!

Rosco86 - 15/5/15 at 06:39 PM

quote:

Originally posted by dubzter

I've been looking at Arduino for building a boost type gauge for my other car, should be a nice cheap control unit for what you are planning if

it works out.

Yeah that should be doable, I'm sure you could get a pressure sensor linked up, I've got my dad on it so see how he gets on

Rosco86 - 15/5/15 at 06:40 PM

quote:

Originally posted by Lew The Machine

looking really good dude! I'd keep the wing, looks awesome! although i think the stays could do with a few tweeks!

I've just finished Uni for the summer so hoping to make some decent progress on mine over the next few months!

Pedal box looks INSANE... pretty sure you could sell those all day long!

Keep it up!

Cheers pal, what do you think needs doing to the stays then?

Cool, get cracking then!

Lew The Machine - 15/5/15 at 09:30 PM

quote:

Originally posted by Rosco86

quote:

Originally posted by Lew The Machine

looking really good dude! I'd keep the wing, looks awesome! although i think the stays could do with a few tweeks!

I've just finished Uni for the summer so hoping to make some decent progress on mine over the next few months!

Pedal box looks INSANE... pretty sure you could sell those all day long!

Keep it up!

Cheers pal, what do you think needs doing to the stays then?

Cool, get cracking then!

The angles of the stays look like they're "triangulated" the wrong way?

I can see why you need the distance between the top stay and the bolt as the acuteness of the angle would stop the bolt coming out, but the bottom one

could be much nearer the bolt head?

It just "looks wrong" and as most of the guys at work tell me... If it looks wrong it usually is!

It's a minor detail though and the whole build is beyond awesome!

I'm doing my best to play catch up... But I'm being side tracked by real life, buying a house! Solicitors don't appreciate that I need

time in the shed haha!

Rosco86 - 16/5/15 at 07:59 PM

Yeah I see what your saying, it's because that's how long the tube was that I used lol, I didn't want to buy any as it's only for

a mess around, I'm going to put some fancy laser cut gussets in it I think

Rosco86 - 16/5/15 at 08:08 PM

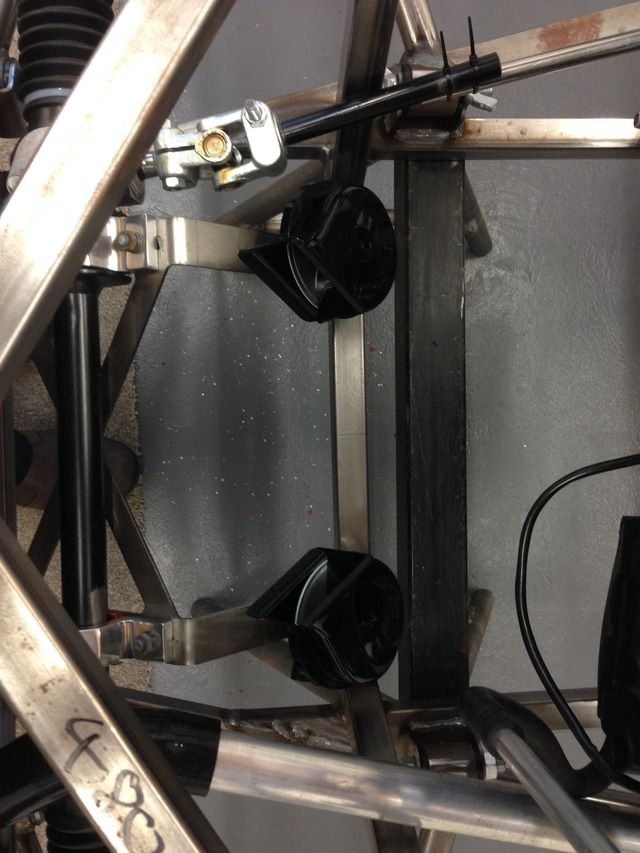

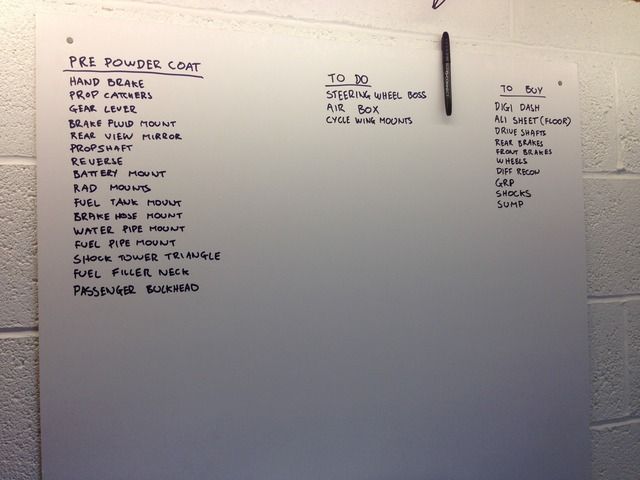

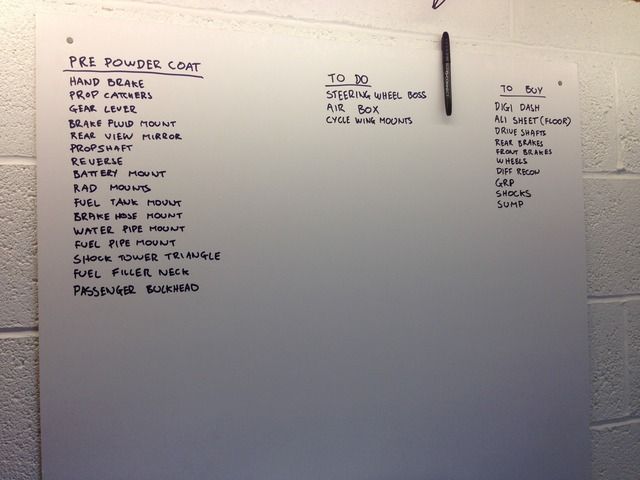

Steady progress this week I think

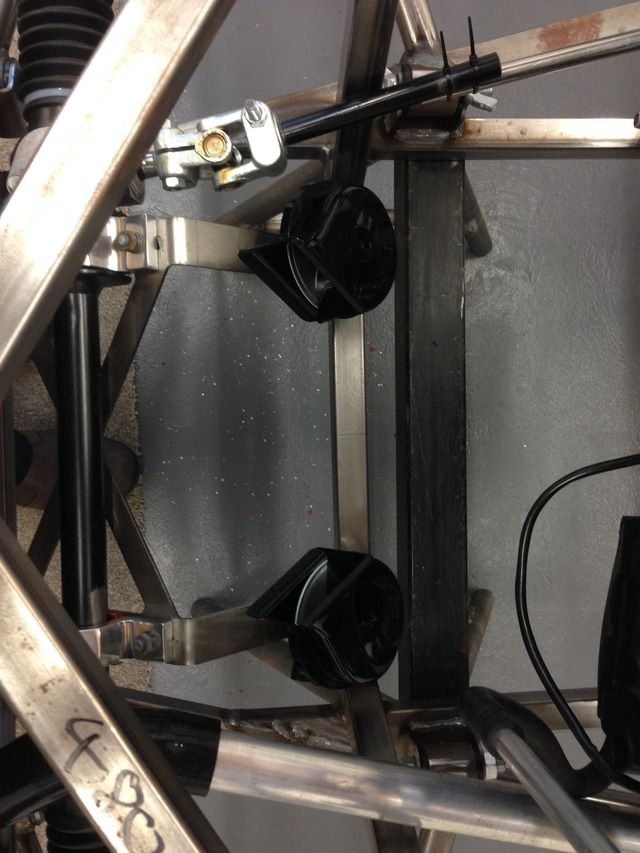

Horns mounted

Headlight mounts made

I stripped the whole chassis down so I could lift it outside, I needed to cut the front shock mounts off as I had got them in the wrong place, to far

back by about 10mm

My garage from outside while it's empty

Headlights on

Lower engine mounts tacked on

Next up I made some threaded bosses for my wing mirrors

Also made myself a list, my main aim is to get the chassis ready for powder coating

big_wasa - 16/5/15 at 08:54 PM

looking good

Rosco86 - 17/5/15 at 04:50 PM

Cheers, my dad's made good progress on the dash circuit, if you click the picture below its a video

There's still a bit to do but I think he's sorted the hardest bits of code

Also I've sorted my steering shaft out with some thick walled tube, I heated it up to get the shaft in, just needs tiging around the ends and

possibly a few pins

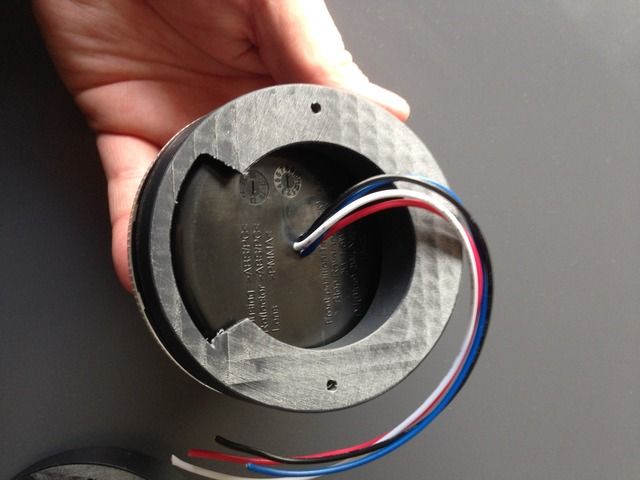

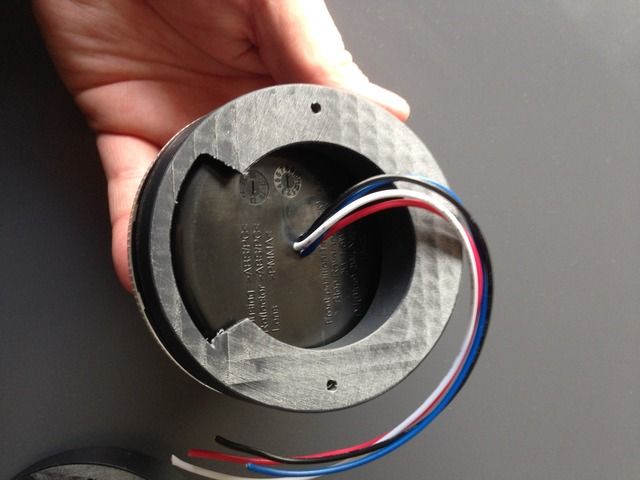

Rosco86 - 24/5/15 at 06:55 PM

Got my stearing wheel last week, but needed a boss to mount it so turned one up on my lathe and milled the hex in on my dads cnc, also needed to drill

the wheel so marked it on his cnc so I new it was right, real happy with this as it not like you can buy them off the shelf

I copied the tapered hexigan from the standard sierra wheel

A stainless cover tube to hide the column, still not 100 percent how I'm finishing this bit yet

Then looked at the wiring loom and got it plugged in and the ignition on ready for a start up when I get my fuel tank

tilly819 - 25/5/15 at 07:31 AM

Great looking build, before you paint/coat the chassis it is worth putting a single diagonal or full cross into the front frame. There are quite high

torsional loads at that point of the chassis and there is a distinct lack of any proper bulkhead in the original design.

This is mine for reference.

Cheers Tilly

[Edited on 25/5/15 by tilly819]

[Edited on 25/5/15 by tilly819]

Rosco86 - 26/5/15 at 07:02 PM

Cheers mate, added to my list, looks like your right to as there's not much in strength in that part of the chassis

Rosco86 - 26/5/15 at 07:09 PM

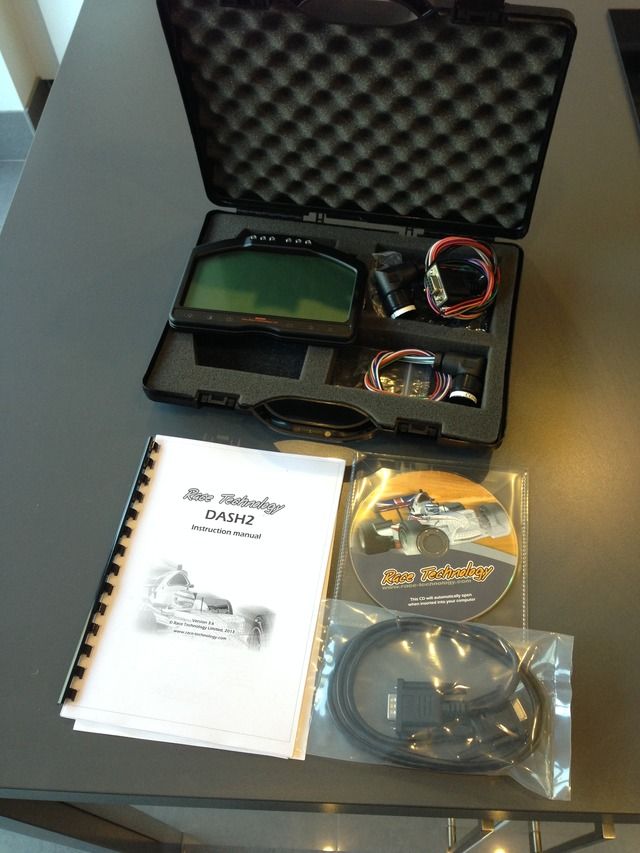

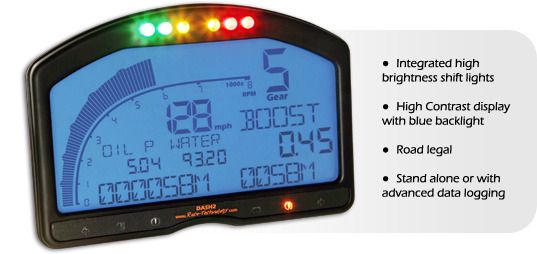

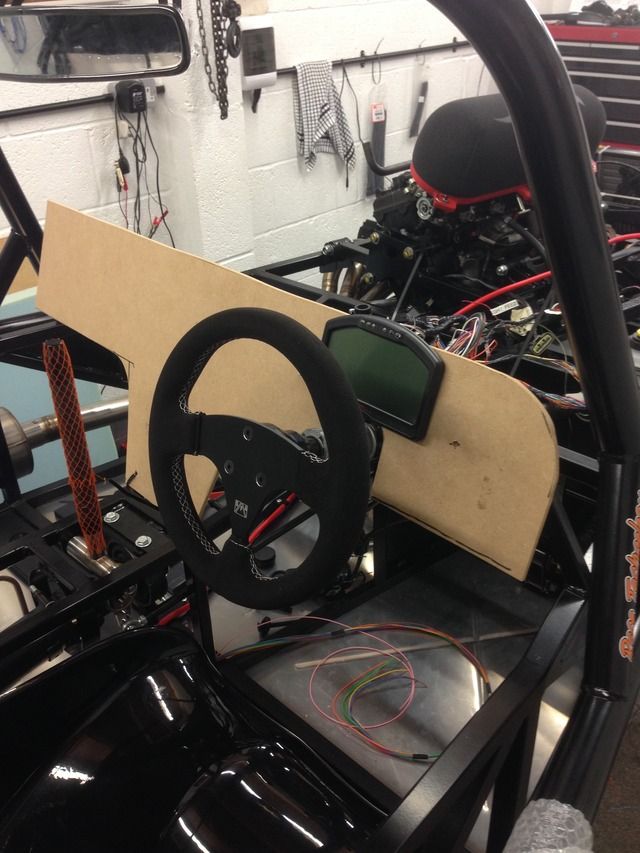

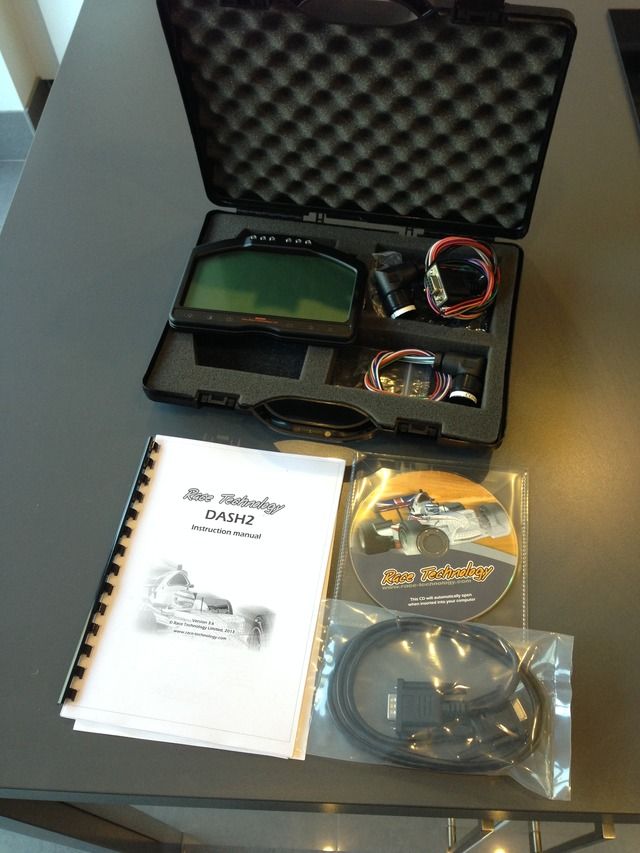

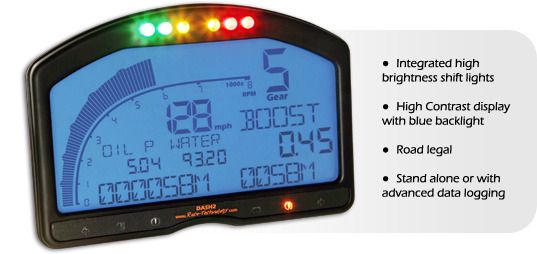

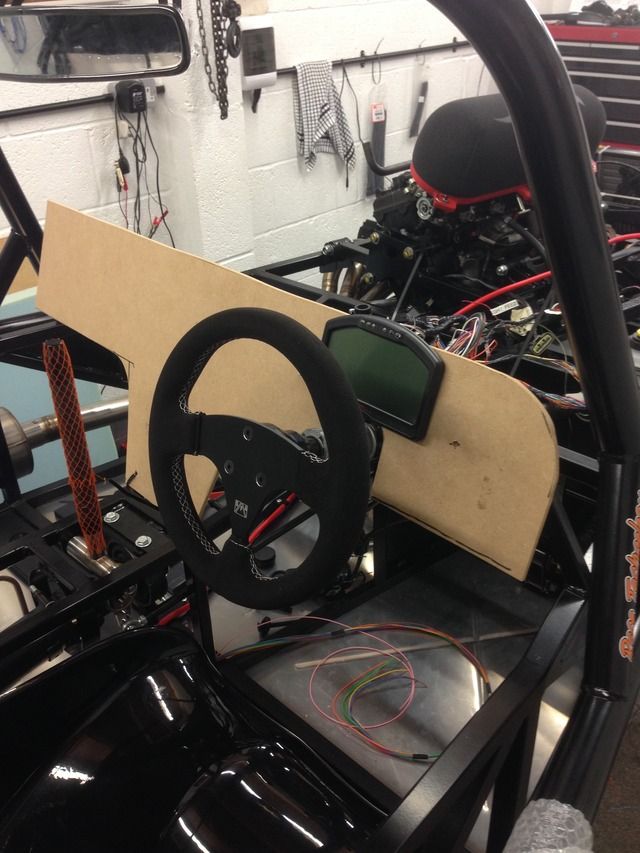

Went off up to Race Technology today to pick up my Dash2, really nice chap who owns it and he couldn't be more helpful,

To say I love it would be an understatement, even before I've wired it up, I've always wanted a digi dash on one of my cars, so hopefully I

might make a start on wiring it up at the weekend.

Here's a pic of them lit up for those that are interested

matt5964 - 26/5/15 at 07:25 PM

You will love it, I got the ecu interface with mine as it makes it so simple to set up and leaves you analogue inputs free for other sensors. They do

them for most excuse, only thing I need to do is set up the fuel level indicator.

big_wasa - 26/5/15 at 08:59 PM

Very nice

bart - 26/5/15 at 09:35 PM

Very very very nice

Class build

Rosco86 - 31/5/15 at 02:40 PM

quote:

Originally posted by matt5964

You will love it, I got the ecu interface with mine as it makes it so simple to set up and leaves you analogue inputs free for other sensors. They do

them for most excuse, only thing I need to do is set up the fuel level indicator.

Yeah I did ask, but they don't do one for bikes excuse

Cheers for the comments

matt5964 - 31/5/15 at 02:50 PM

quote:

Originally posted by Rosco86

quote:

Originally posted by matt5964

You will love it, I got the ecu interface with mine as it makes it so simple to set up and leaves you analogue inputs free for other sensors. They do

them for most excuse, only thing I need to do is set up the fuel level indicator.

Yeah I did ask, but they don't do one for bikes excuse

Cheers for the comments

Bummer 😔

Rosco86 - 31/5/15 at 02:51 PM

Not much to get on with this week as I'm waiting on my prop shaft, but some switches turned up from china so decided to make a prototype panel,

it's no way near the finished design and the large outer plate sort of represents the dash, I've recessed the switches as they would have

stuck out a bit to far otherwise I think

The fished housing will be out of aluminium or plastic I think

Also got my bead roller finished and did a test panel

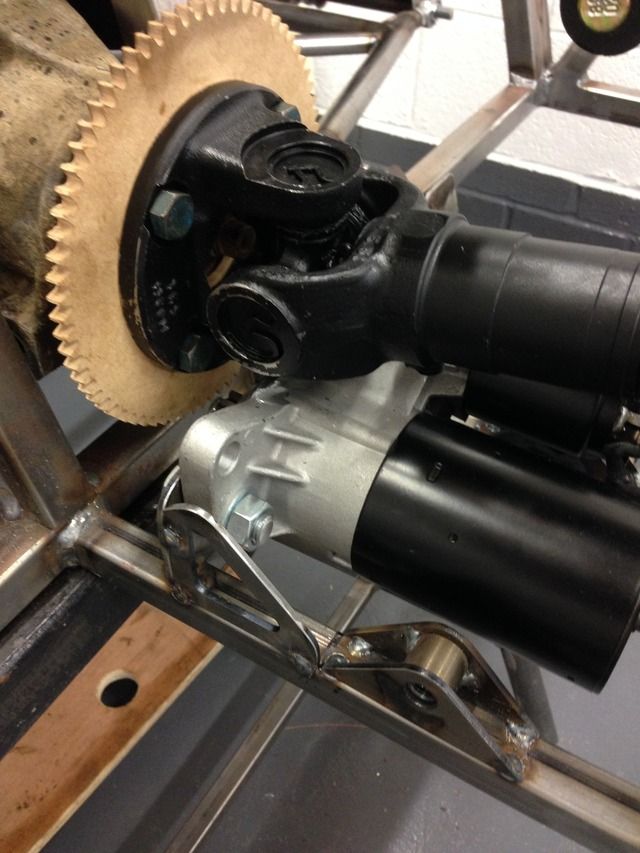

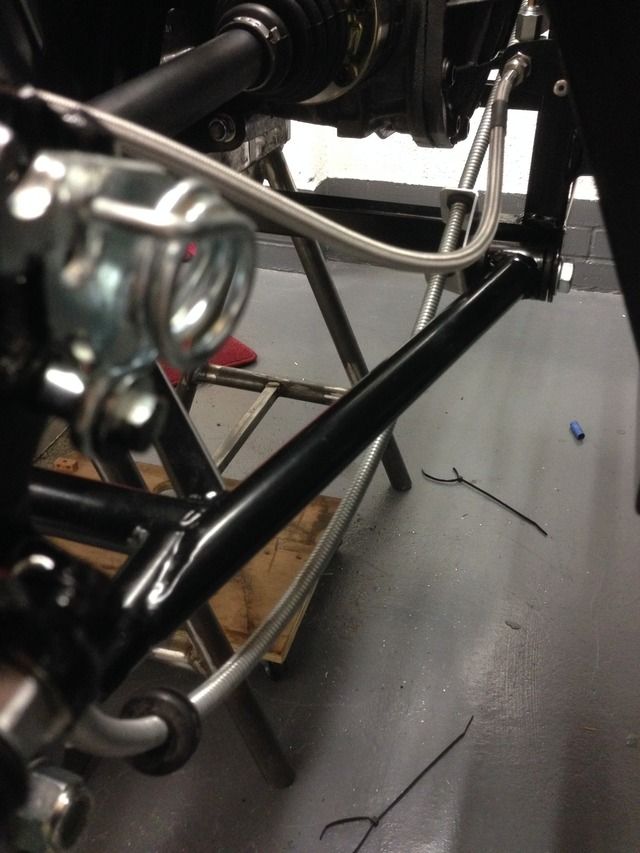

Rosco86 - 7/6/15 at 08:25 PM

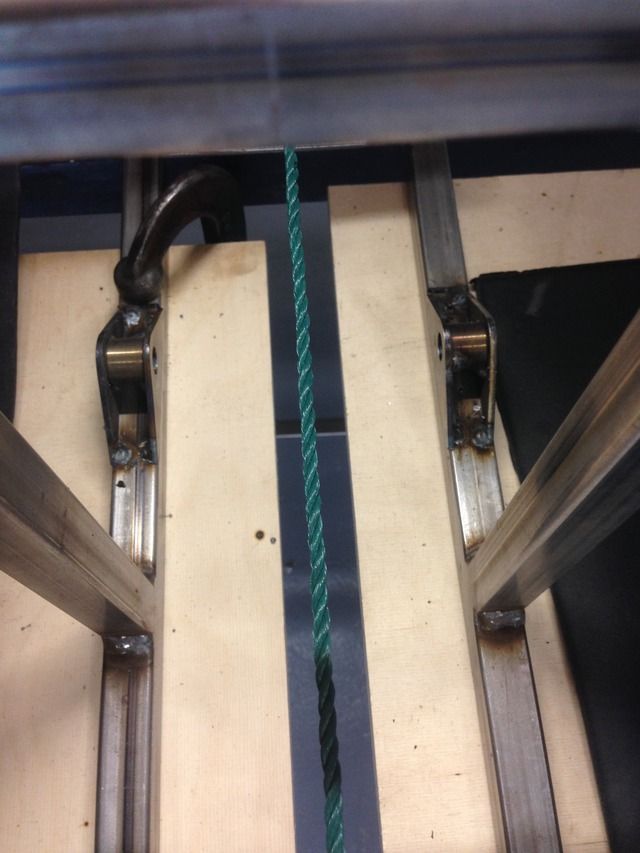

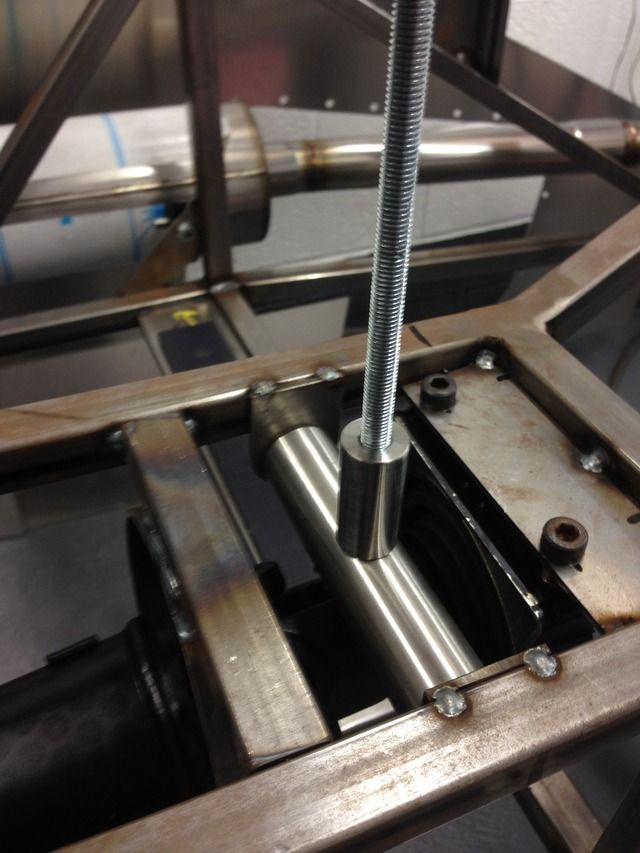

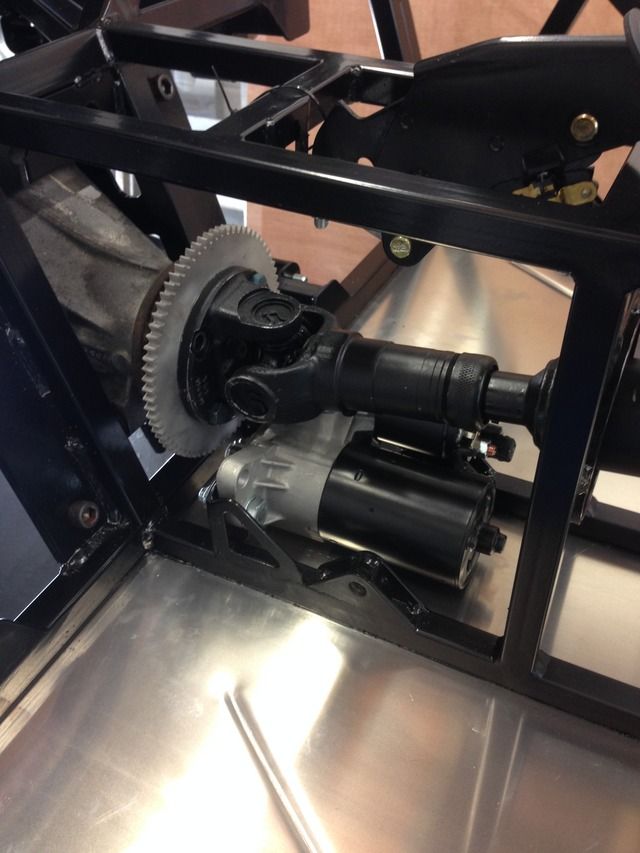

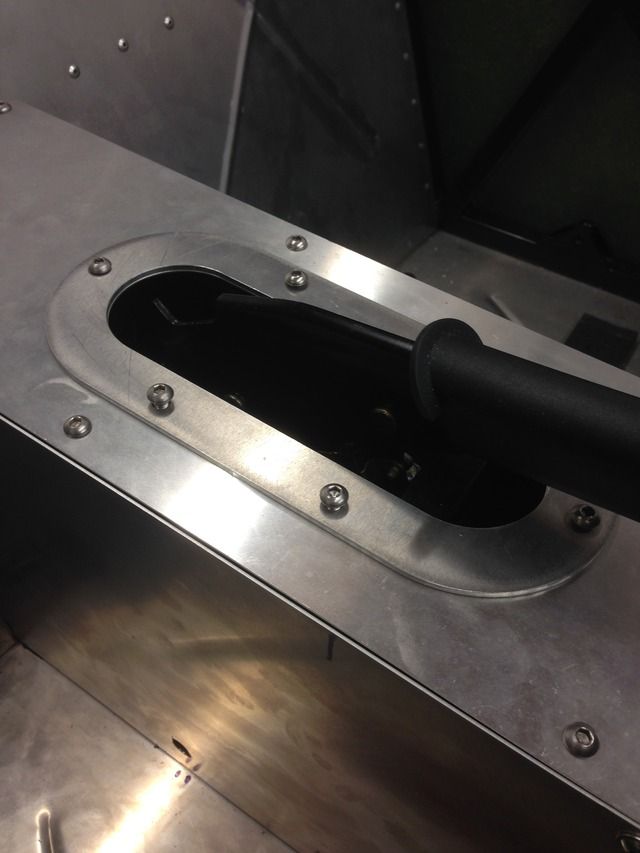

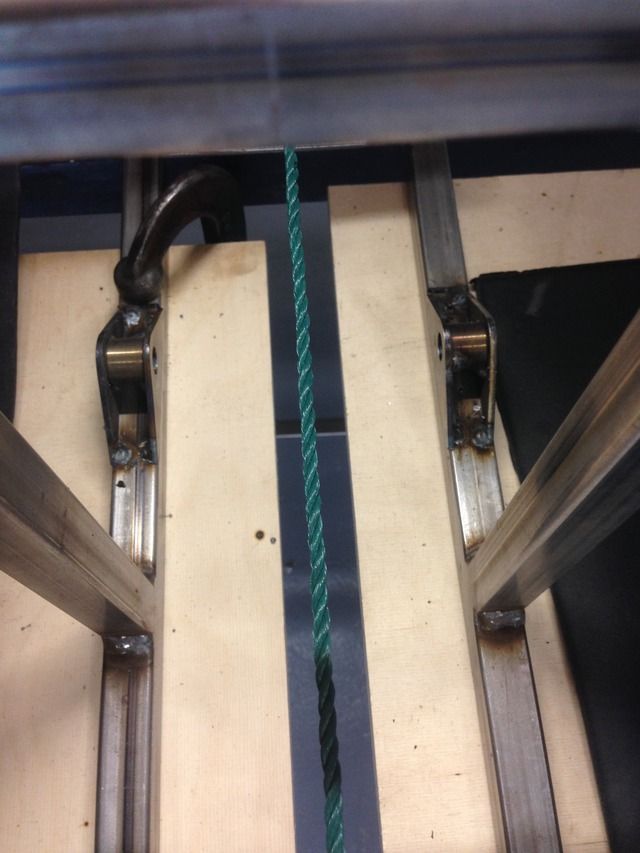

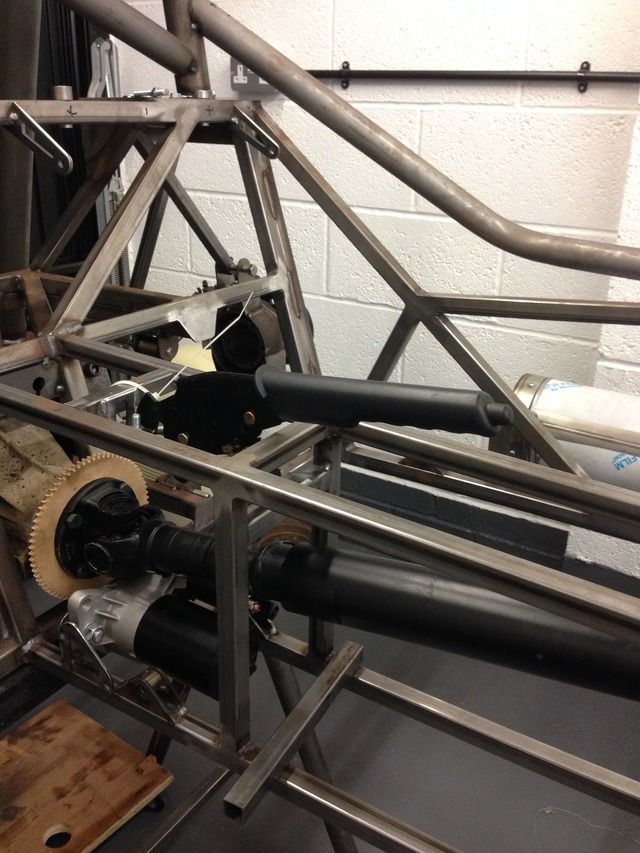

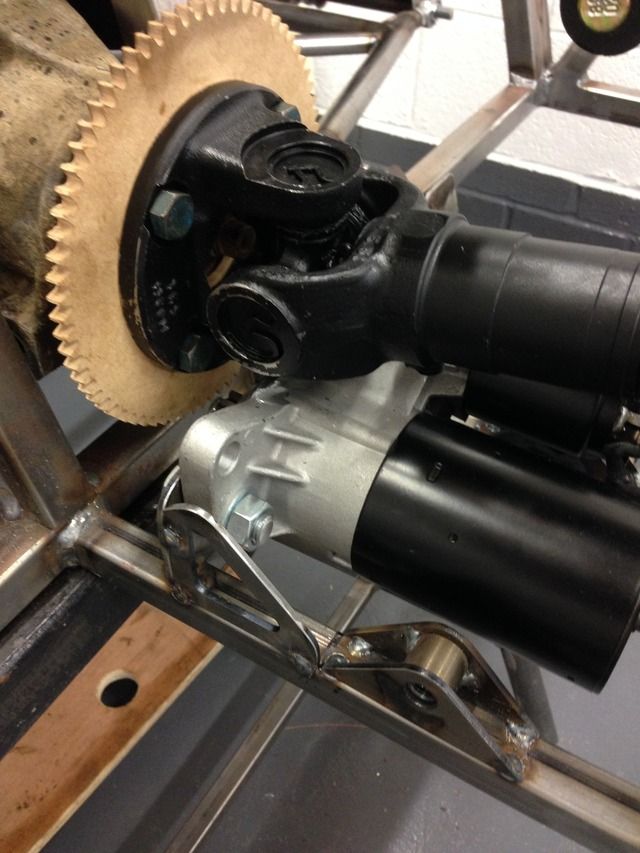

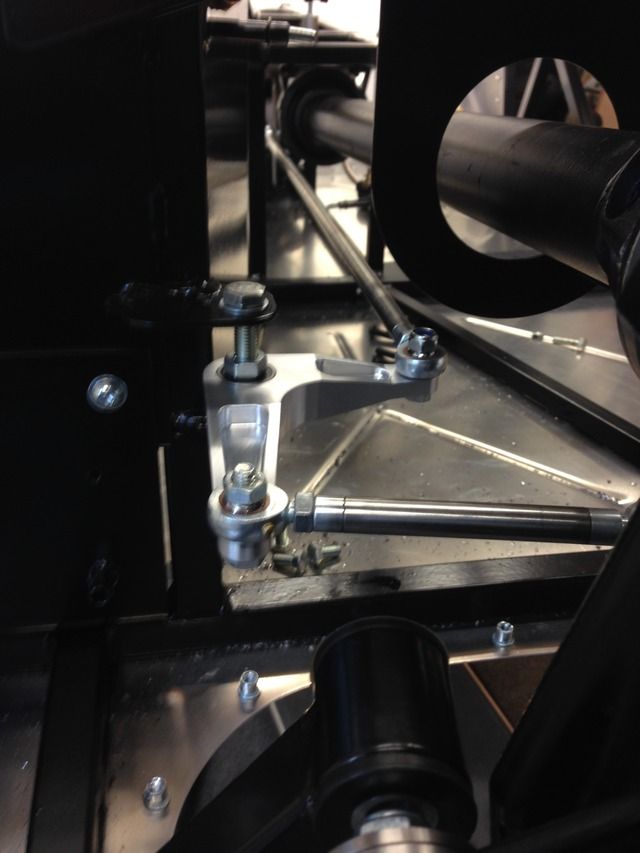

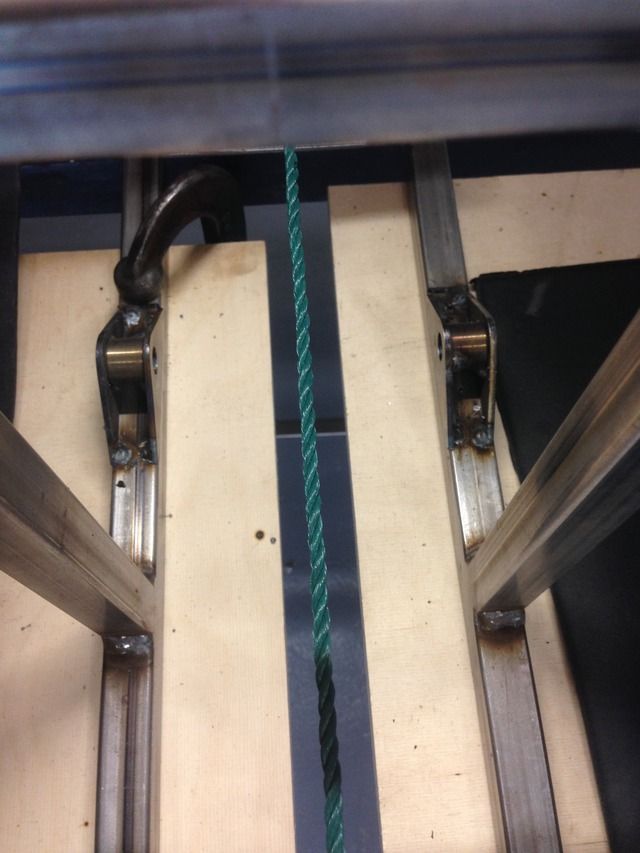

Prop shaft turned up from dunning and fairbank on Friday so lots of jobs to be done

So got the prop bolted in and mounted my rear view mirror

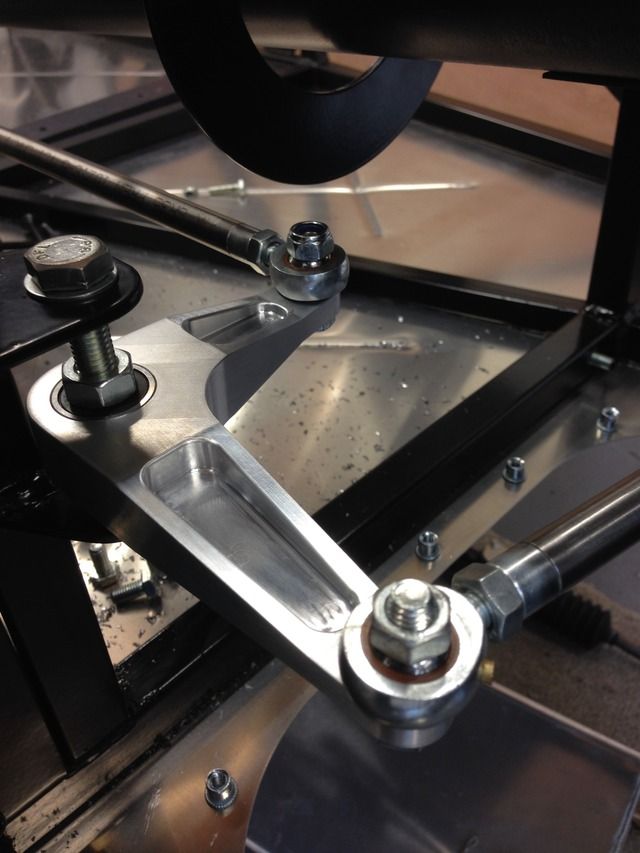

Gear linkage mocked up

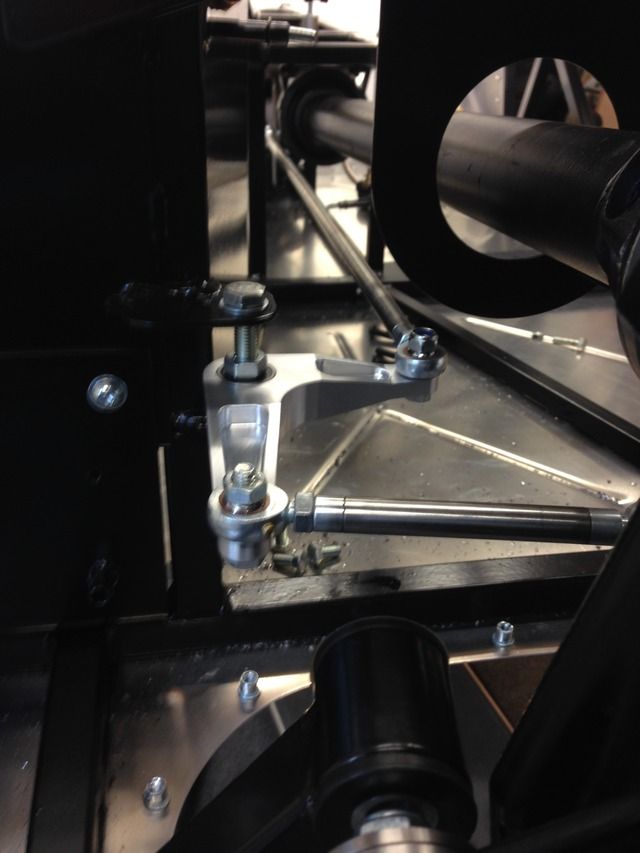

Mounts for bel crank

Plate for centre bearing sorted and mounts for gear lever done

Not overly happy about the handbrake lever position but it's not in the way when sat in the seat and it's the best position for the cable

Front cross brace done

Water pipe mounts, will have rubber grommets in

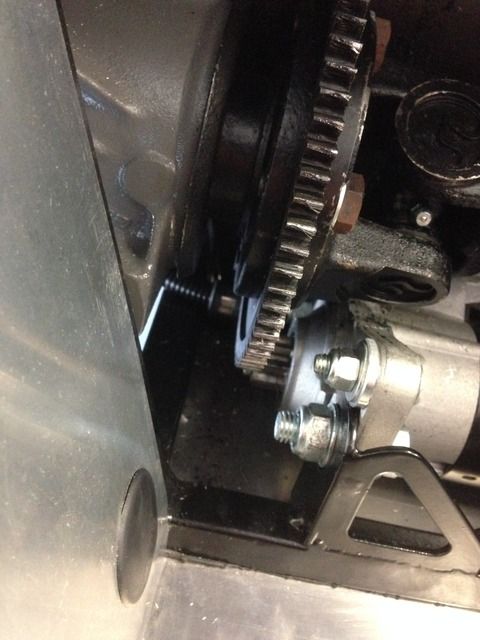

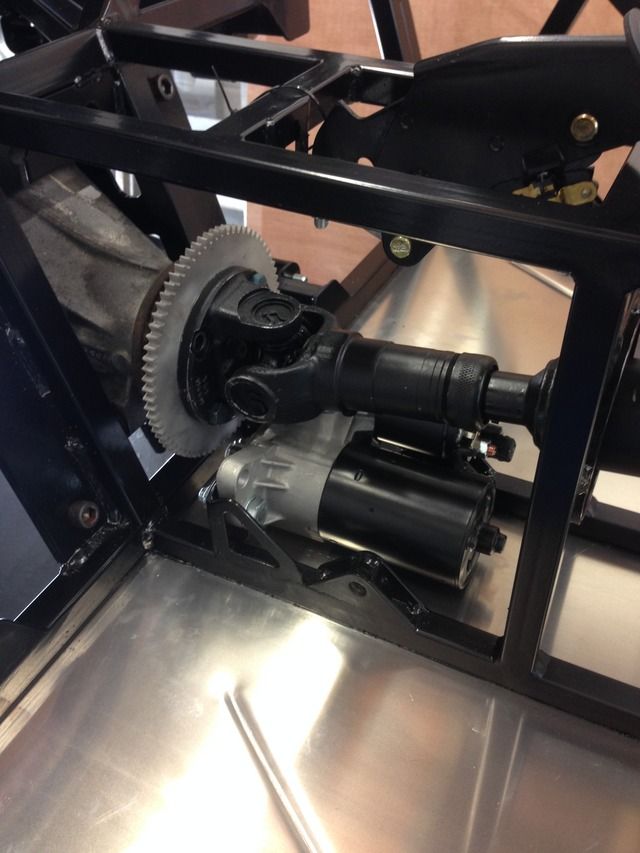

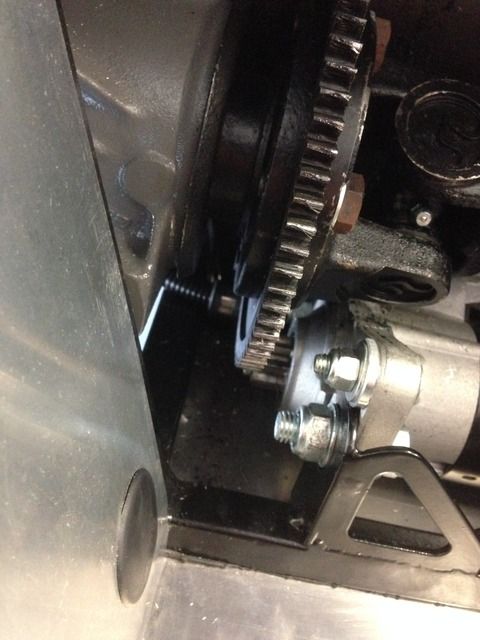

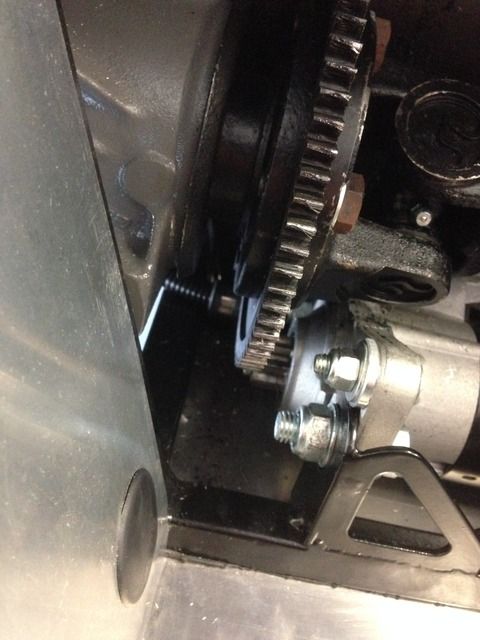

My dad cut me a bigger gear out of mdf on his cnc as a test, as the normal 140mm that people use was way to small, the motor needed to much grinding

out

We went for 160mm and the motor only needed a little bit out in a few places, I'm really happy as the motor doesn't sit through the bottom

of the car

I will get a steel gear laser cut out now, we powered it up on the mdf and it worked a treat

Also got the handbrake mounted

bart - 7/6/15 at 08:48 PM

once again looking terrific

top quality work

you need to make your own body panels so we can compete fairly !!!

Rosco86 - 7/6/15 at 09:30 PM

quote:

Originally posted by bart

once again looking terrific

top quality work

you need to make your own body panels so we can compete fairly !!!

Haha sounds like a chalenge, maybe one day but not on this build i dont think, im aiming to be on the road ready for next summer!

Rosco86 - 9/6/15 at 08:43 PM

Got a couple of prop catchers done tonight, these two will be welded on, I'm going to make a front one that bolts on else I will never get the

prop in and out

The tube was a bit of rear hub tube I had left over and it's a perfect fit in between the tunnel

Rossmcleod - 9/6/15 at 09:24 PM

Epic build mate stunning

Badger_McLetcher - 9/6/15 at 09:53 PM

I can't get over how CLEAN your build is! My build just gets covered with shite, no matter how much I try to keep it clean.

Cunning handbrake mount as well

Rosco86 - 10/6/15 at 02:50 PM

quote:

Originally posted by Rossmcleod

Epic build mate stunning

thanks pal

Rosco86 - 10/6/15 at 02:50 PM

quote:

Originally posted by Badger_McLetcher

I can't get over how CLEAN your build is! My build just gets covered with shite, no matter how much I try to keep it clean.

Cunning handbrake mount as well

haha cheers, that's helped by having the car in my garage and my tools in my workshop!

Rosco86 - 22/6/15 at 07:55 PM

Quick update, just tacking the last few bits onto the chassis, my vin number came today, just need to make a plate and sort some earth points then

ready for powder coat

Passenger bulkhead bead rolled and fitted

Gear lever taking shape

The black smudge is where I'm going to weld my vin number

Vmax1974 - 23/6/15 at 09:30 PM

Seriously impressive build following with interest

Rosco86 - 27/6/15 at 07:22 PM

Well stripped my car down this week and my mate has finished welded it, just a bit of weld splatter to get off then everything's off for

sandblasting and powdercoat

The vin number my dad milled for me

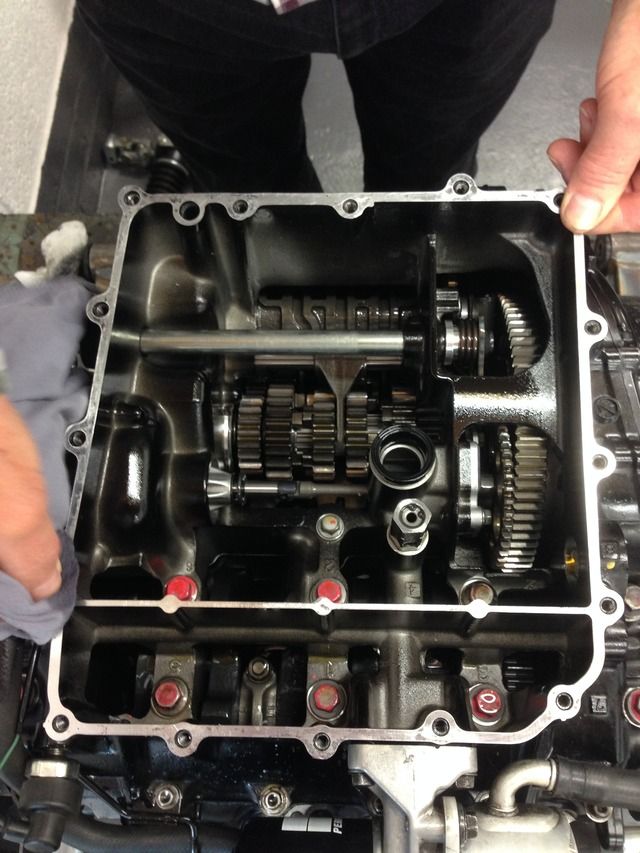

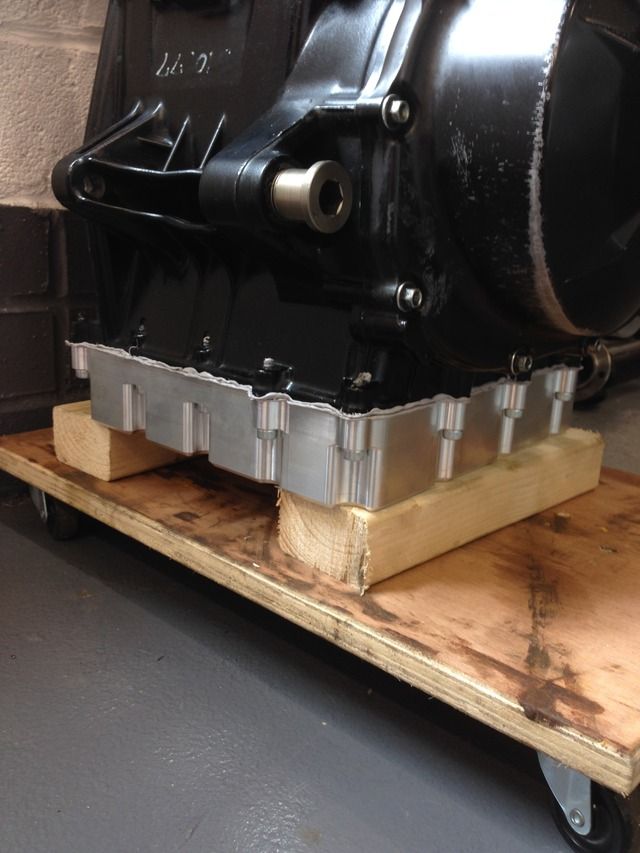

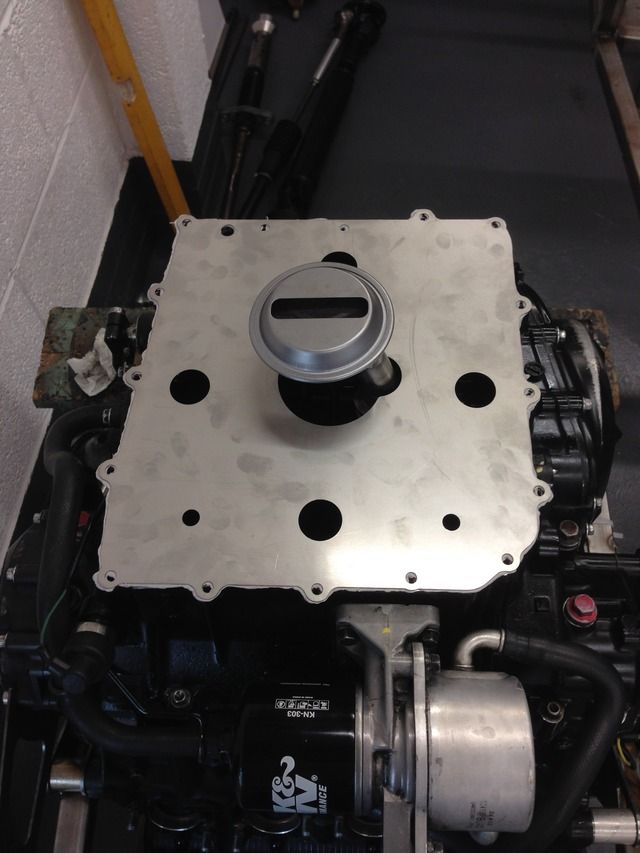

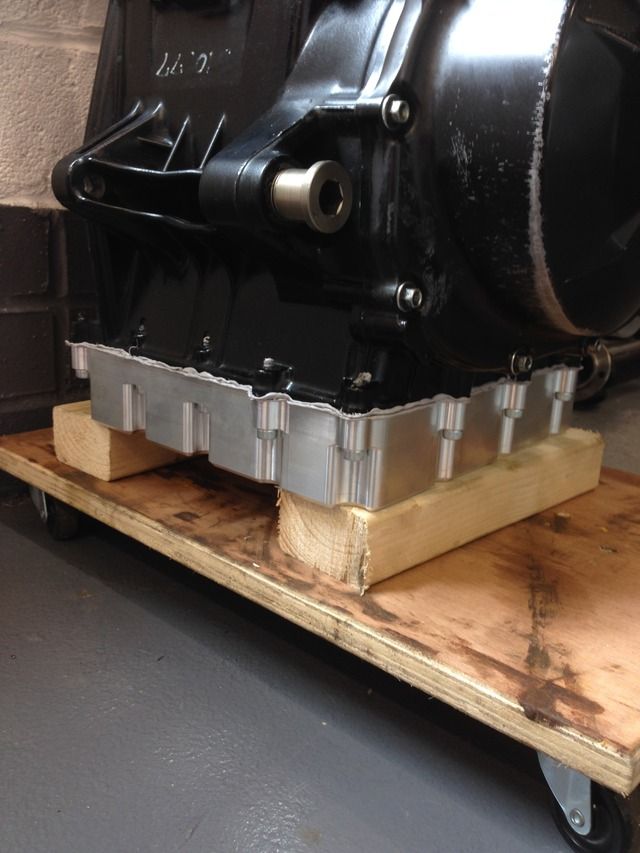

Ordered a billet sump and HD clutch springs from AB Performance

Baffle plate and new oil pickup

Clutch springs

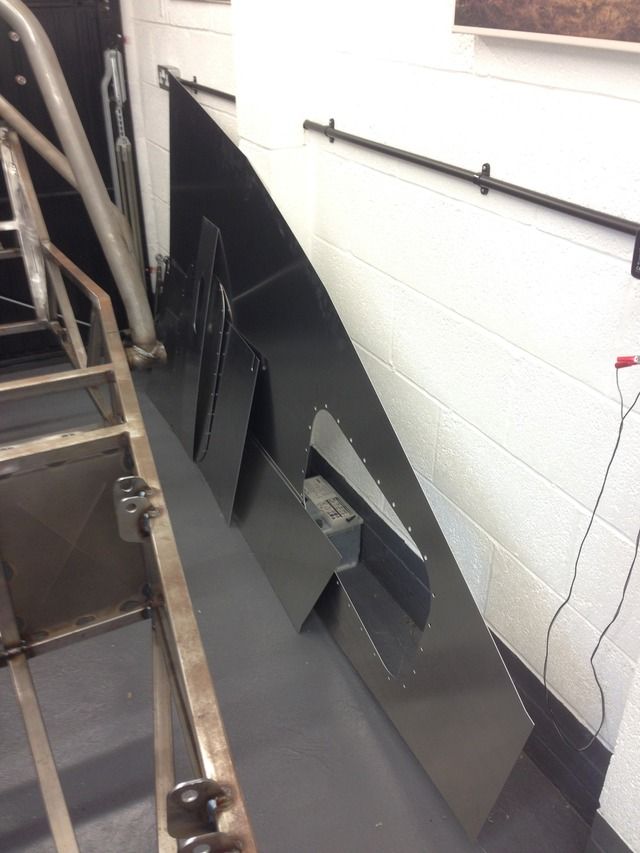

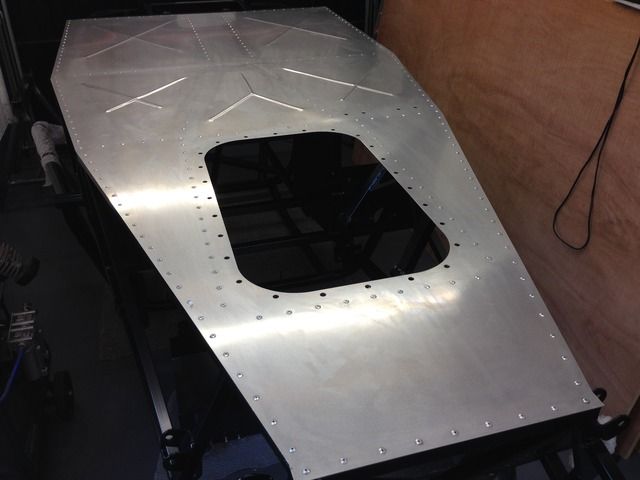

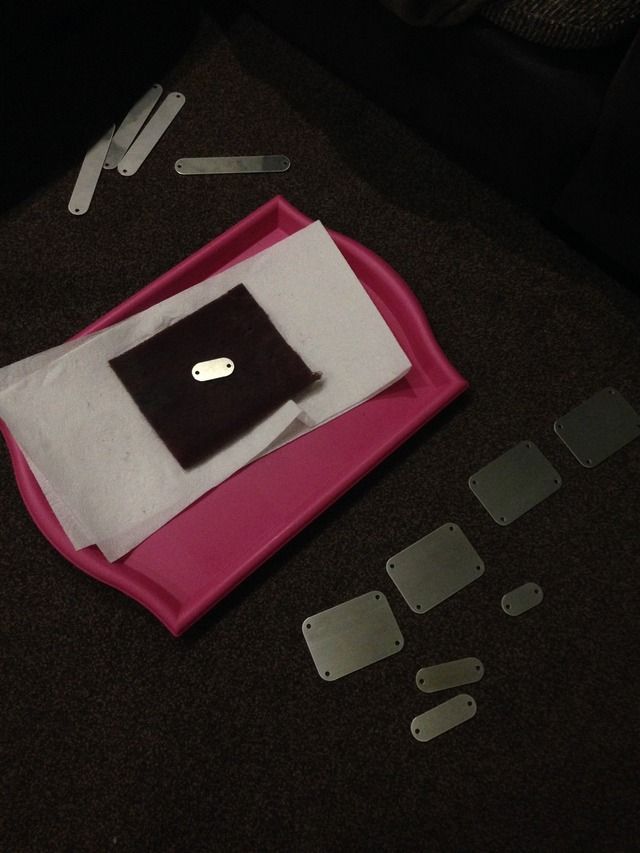

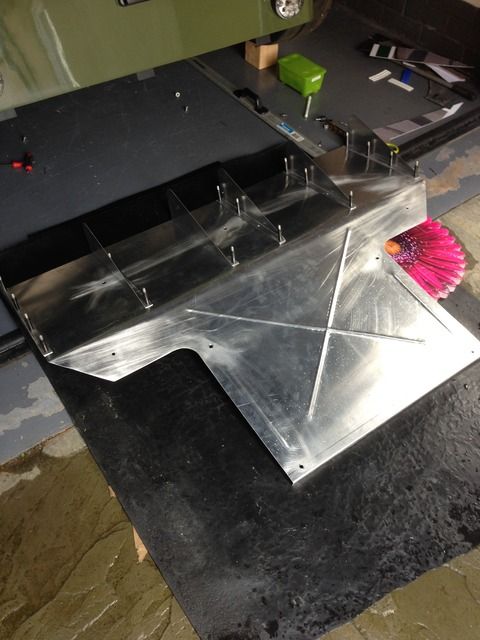

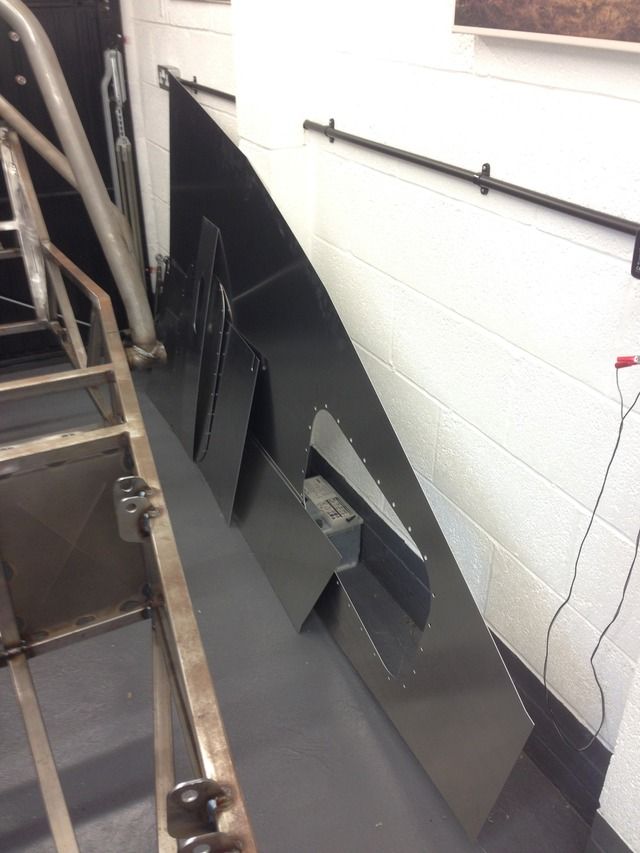

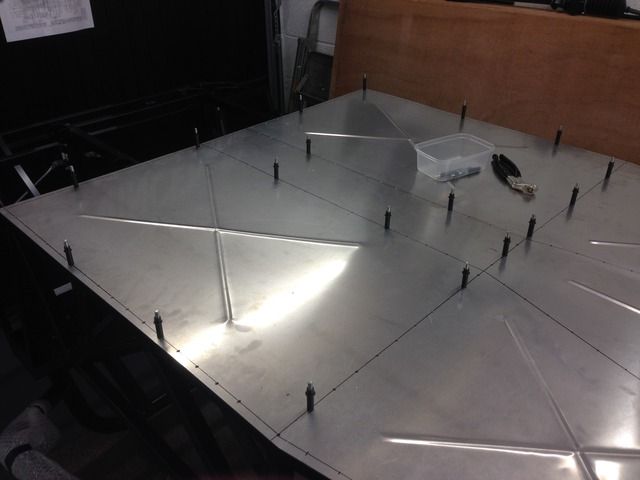

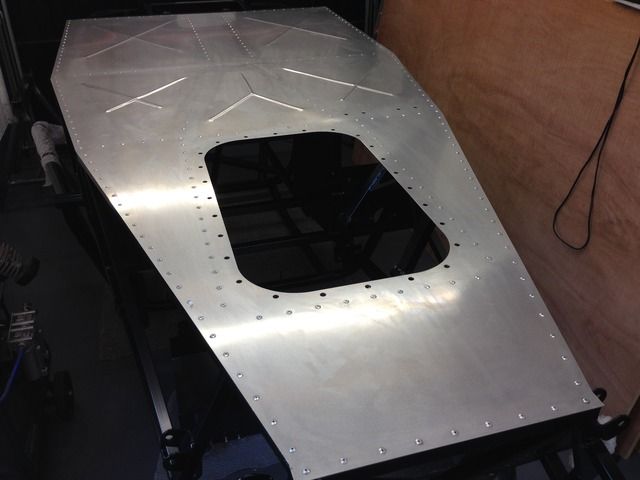

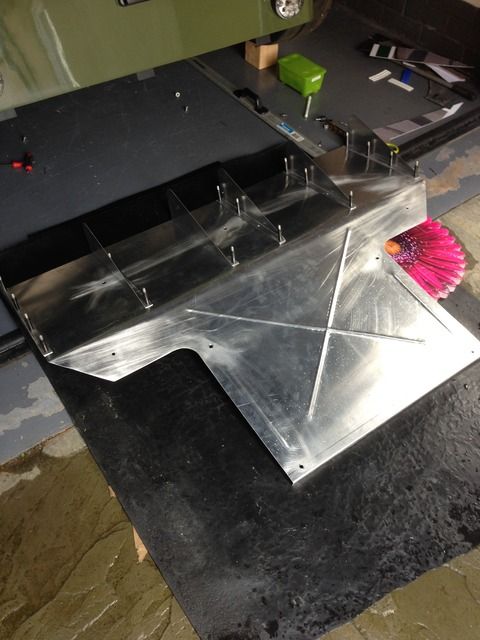

Also got my aluminium panels lazer cut instead of getting the jigsaw out, the floors 1.5mm and the rest 1.2mm, all 5251 sheet

The big hole will sit under the engine, this will have rivnuts fitted and a removable section bolted on

Rosco86 - 28/6/15 at 07:35 PM

Got my sump fitted today, engine looks like brand new inside, the new pickup was a little tricky to locate, but got it on in the end

Rosco86 - 7/7/15 at 08:25 PM

Got my carbon fibre tube that I've been waiting for today so did a bit more on my gear lever

To say I'm happy with how it looks is an understatement, well happy with it! I'm going to get all the aluminium bits anodised to

Digimon - 9/7/15 at 01:35 PM

Your build is on speedhunters.com

http://www.speedhunters.com/2015/03/iamthespeedhunter-your-bike-p

owered-builds/

Rosco86 - 9/7/15 at 03:16 PM

quote:

Originally posted by Digimon

Your build is on speedhunters.com

http://www.speedhunters.com/2015/03/iamthespeedhunter-your-bike-p

owered-builds/

haha yeah i no, i sent some pics in a while back when they were doing bike engine week, then one day i was reading through and there was my build,

hopefully i will get a full right up on there when its finished!

Rosco86 - 12/7/15 at 07:08 PM

Needed a tool to strip my diffs down so drew one up and made it at work quick, 30mins total

Fitted perfect, I had to use the air good and heat to get them out though, was a hot sweaty oily job so no pics I'm afraid

Offered my floor up to see how well it fit, perfect, was well happy, as my chassis that I built with a tape measure matches a laser cut panel

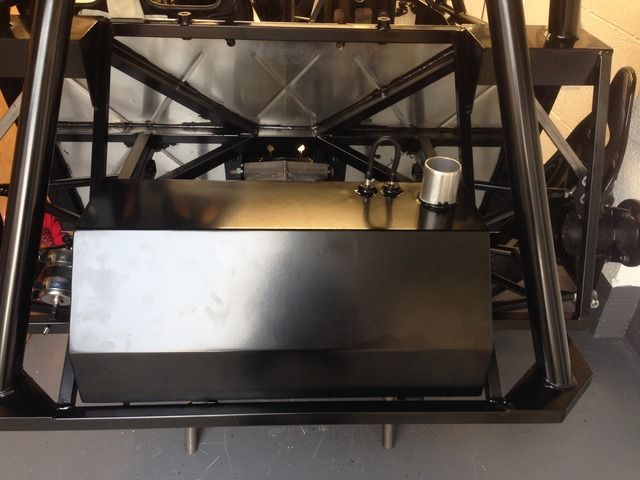

All my small parts blasted ready for powder coat next weekend

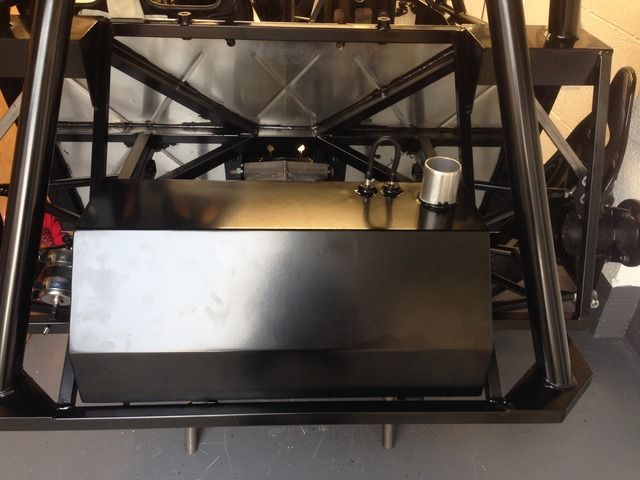

Got my fuel tank

Testing for leaks

Only thing is my mate who made the tank has dressed the welds and sanded the tank so I think I'm going to get it powder coated

Rear seat panel

Tunnel sides

DRM Black7 - 12/7/15 at 09:48 PM

Absolutely stunning build, just spent the evening reading the thread. Amazing detail and some really lovely touches. Superb!!!

Rosco86 - 13/7/15 at 06:19 PM

quote:

Originally posted by DRM Black7

Absolutely stunning build, just spent the evening reading the thread. Amazing detail and some really lovely touches. Superb!!!

Cheers, just trying to keep on top on my updates, will be good to read it all back when it's finished

Rosco86 - 13/7/15 at 06:24 PM

Made a few modifications to my bead roller, welded a handle on to apply the roller pressure and swapped the bottom wheel for a plastic one as the

metal one was a bit heavy on the aluminium

Engine hatch marked out

Finished panel, I was a bit worried about ruining it, but it's turned out perfect, tomorrow night I'm doing the big floor panel

Rosco86 - 14/7/15 at 06:57 PM

Got my floor beaded tonight with the help of my dad, could of done with another set of hands really as it's quite a big sheet

Turned out quite well, one bits a little dodgy but I will give it a little tap before I rivet it on

What it looks like from the inside

Rosco86 - 19/7/15 at 04:29 PM

Dropped my chassis and everything off at the powder coaters yesterday morning and collected it this morning, well happy with it! I feel like the ends

now in site!

Rosco86 - 20/7/15 at 09:21 PM

Got the car spun over tonight and got on with marking the rivet holes out, I've gone for 4mm rivets at 45mm spacing, I'm bonding it on

to!

I marked the rail centres on first then used a set of dividers to mark the spacing, wasn't as bad as I thought it was going to be and 45mm worked

out nicely everywhere which was good for my OCD!

I started drilling a few holes at the back and worked up to the next cross rail, I had brought some cleco pins and glad I did there perfect for the

job

Because I had bead rolled the panel it wasn't as flat as a plain sheet, but it pulled flat as I worked my way along

20 cleco pins fitted

Then I drilled all the holes In between, I will get on the next section tomorrow hopefully

[Edited on 20/7/15 by Rosco86]

Rosco86 - 22/7/15 at 07:35 PM

Well got the rest of the holes drilled last night and debured

I used Wurth Bond and Seal to bond it on, just put a small bead down the middle of all the rails covering all the holes, it was just enough as I was

still covered in it!

My mate let me use his air rivet gun! It's a good job as there's no way I would of done it by hand

Digimon - 22/7/15 at 08:41 PM

looking good mate

Rosco86 - 23/7/15 at 06:55 PM

Made myself a rivnut tool tonight

Then fitted the rivnuts round the hatch opening

Then spun her over

I love how the bead rolling has turned out

Just the right amount of sealant, this is down to my dad as I wanted to put more on but I resisted

Rosco86 - 26/7/15 at 08:35 PM

Two full days of updates tonight

Made some stainless spacers from some tube for my pedal box

Then went down my local bolt shop

Pedal box assembled and fitted

Then painted a few little bits that couldn't be powder coated

Steering rack because I had to cut a bit off

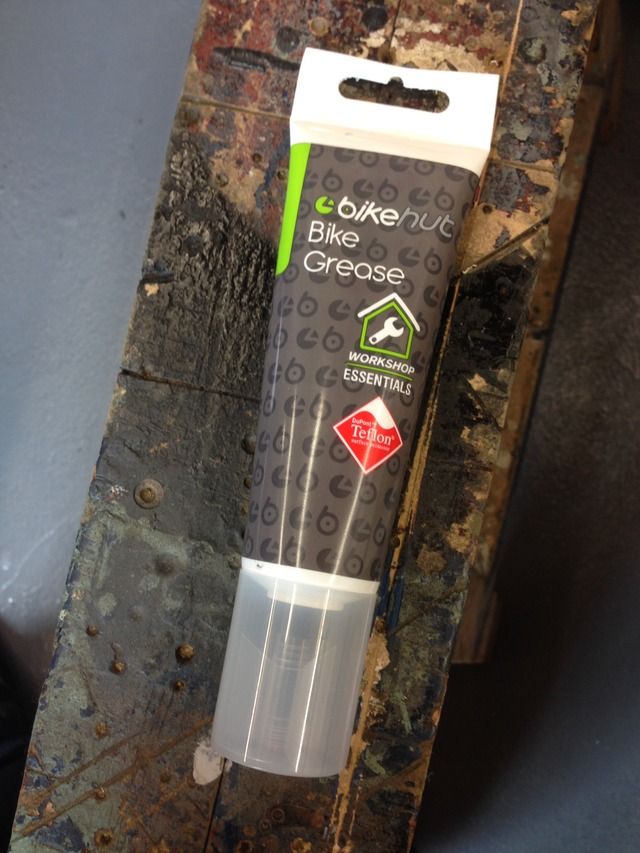

Got some Teflon grease for my poly bushes

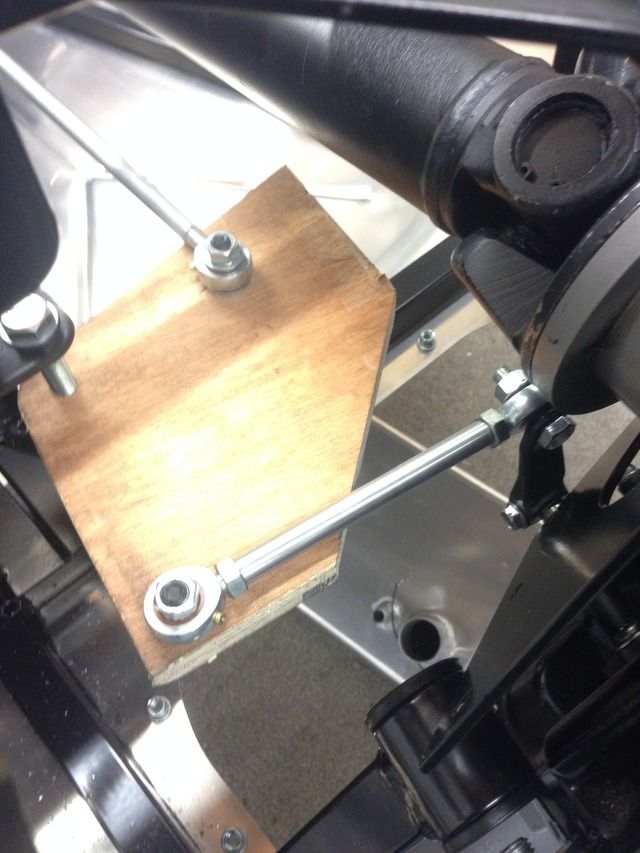

Wishbones fitted

Few other bits fitted

Today's job was to get the seat panel fitted, my dad gave me a hand as it was quite tight and didn't want to scratch everything

The panel fit really well from the laser cutters and only needed a little trim on the tunnel top, then the top and bottom needed bending

We clamped the bottom Inbetween two bits of box section and the top between timber with a bevel on the back

It folded real nice

We both decided it needed bead rolling to match the rest

All sealed and riveted

I decided to gob the backside with the sealer to stop any water or dirt getting trapped anywhere, not the neatest but does the job

Rosco86 - 18/8/15 at 09:18 PM

Right I'm back on the updates now, I've not got much done really, I've brought a Bridgeport mill so I've been sorting that out

over the last few weeks

Back to the car, my dad made me some radiater brackets and a brake fluid bracket

These will all be powder coated then riveted on

Engines back in to with stronger clutch springs

Gear linkage next, just working out the size of the bell crank to be made

Down arm added to gear lever, this will be shortened once I've decided the holes in the right place

Lastly put some skateboard grip tape on my pedals, also a clue as to what sort of colour scheme I'm going with

CosKev3 - 19/8/15 at 06:57 AM

Spot on job!

Best build quality and pics I've seen on any thread for a kit car build.

One question, and a suggestion

Why have you gone with the propshaft the opposite way around to manufacturers/any other build?

Grip tape is not required for IVA on throttle pedal, and will make driving the car smoothly a pain in the arse!

Rosco86 - 19/8/15 at 07:11 AM

quote:

Originally posted by CosKev3

Spot on job!

Best build quality and pics I've seen on any thread for a kit car build.

One question, and a suggestion

Why have you gone with the propshaft the opposite way around to manufacturers/any other build?

Grip tape is not required for IVA on throttle pedal, and will make driving the car smoothly a pain in the arse!

cheers! im doing the thread as a record of the build really, im hoping to print it all off when im done as a bit of a keep sake

re the prop shaft i discussed it with d&f at length who made my prop, and they didn't have an issue with it, it just made the two sections

similar in length instead of having one quite a bit longer that the other, also it worked out that the angles of the prop were smaller

also this form suggestions both ways round, mine is the same as option 1

http://baileymorris.co.uk/pdf/KIT_CAR_2_PIECE_SHAFT.pdf

as for the throttle pedal, now you mention it all pictures i have seen have a smooth throttle pedals (that would explain why), i best peal it off

before i cant get my arm down there!

Cheers for the input!

Rosco86 - 19/8/15 at 06:52 PM

On the lathe tonight, I made some countersunk washers for my seats to spread the load a little

Everything aluminium will be going for anodising at some point

Rosco86 - 20/8/15 at 09:05 PM

Bit more done tonight, I made three more washers, a bit smaller this time for my pedal box

Washed my fuel tank out and mounted the fuel pump

Foam padding stuck to chassis

Tank in place

Fuel filter mounted

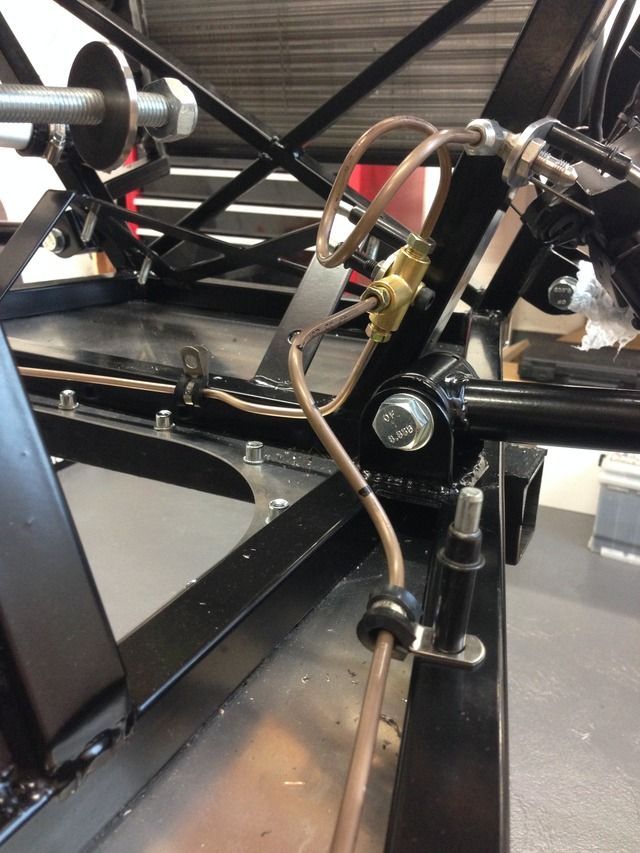

Rosco86 - 23/8/15 at 08:29 PM

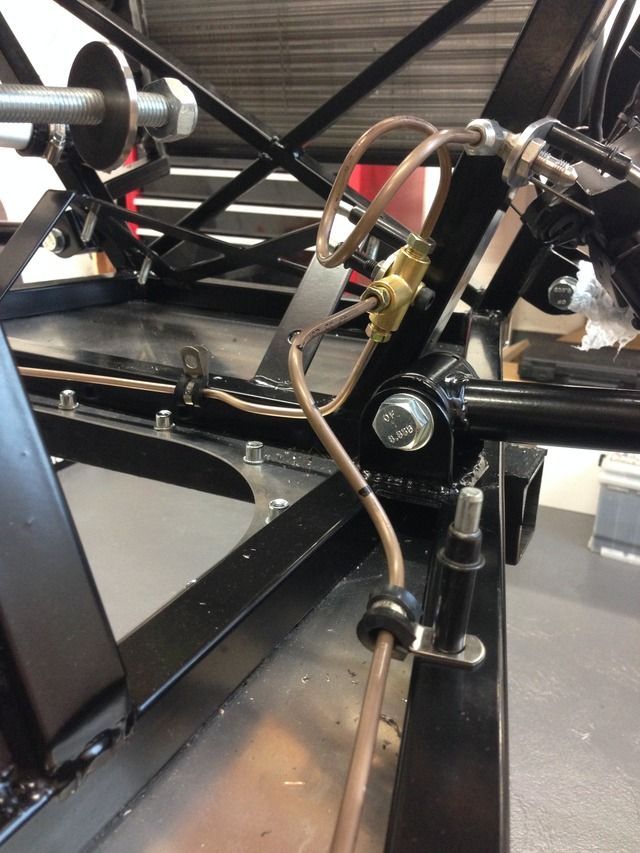

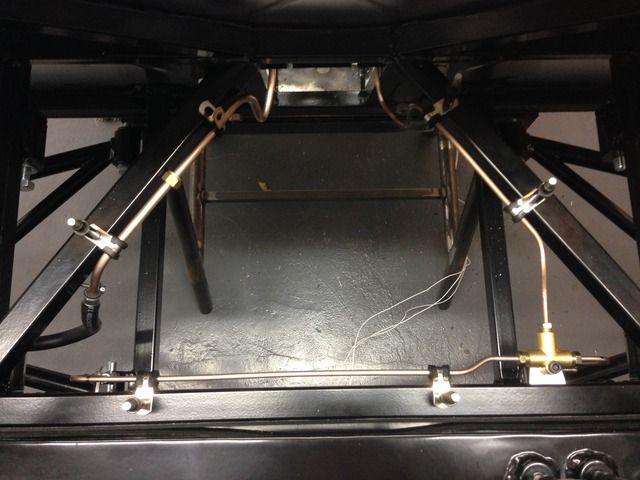

Update for the weekend, my gear link bars were 10mm Ali tube with a 6mm bore, drilled and taped m8 in the ends but I didn't feel they were strong

enough so made some with 12x1mm stainless tube with threaded slugs in the end, these just need tigging in

Then onto my fuel pipe, 8mm cupro, drilled a bit of plastic to straighten the tube with, worked great

The routing was a bit rubbish due to the electric reverse but it turned out a lot better than I thought in the end

Rear

Front

also once bent it was a bit tricky to get in position, but I just managed it, I had a go at the main brake pipe but wasn't happy so will have

another attempt one night in the week

40inches - 23/8/15 at 08:37 PM

Far too neat! Obviously CGI.

Rosco86 - 25/8/15 at 08:08 PM

Haha thanks, it's mirrors

Rosco86 - 25/8/15 at 08:12 PM

Well ordered some brake pipe brackets off my dad last night, he had done them before I got home from work today!

I've polished all my aluminium parts up ready for anodizing

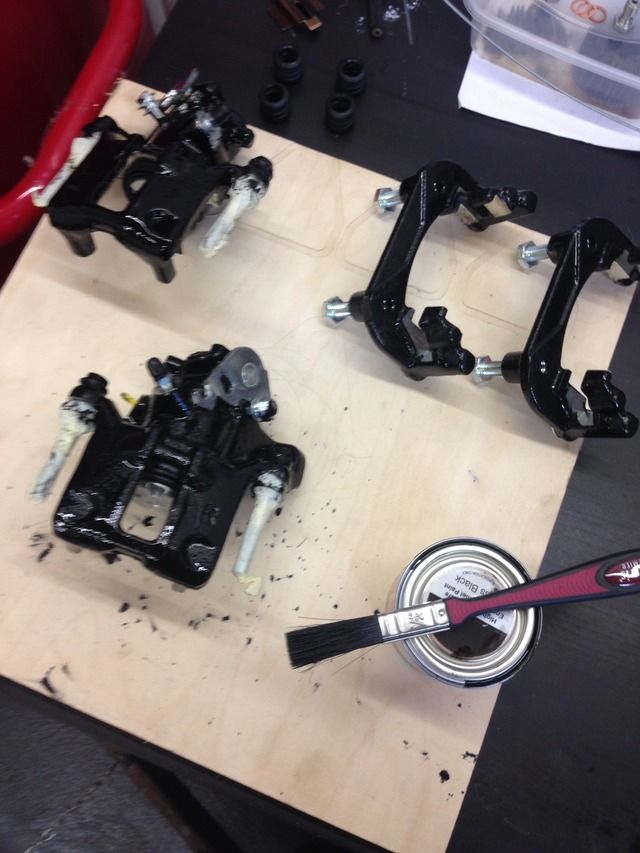

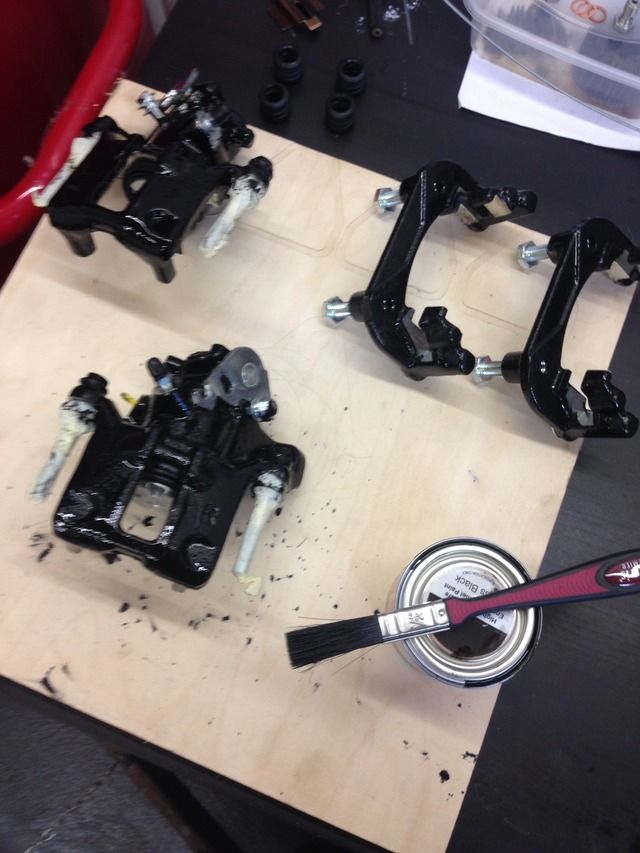

And my rear calipers turned up today to!

Next job is to get all my brake pipes sorted!

Rosco86 - 28/8/15 at 05:50 PM

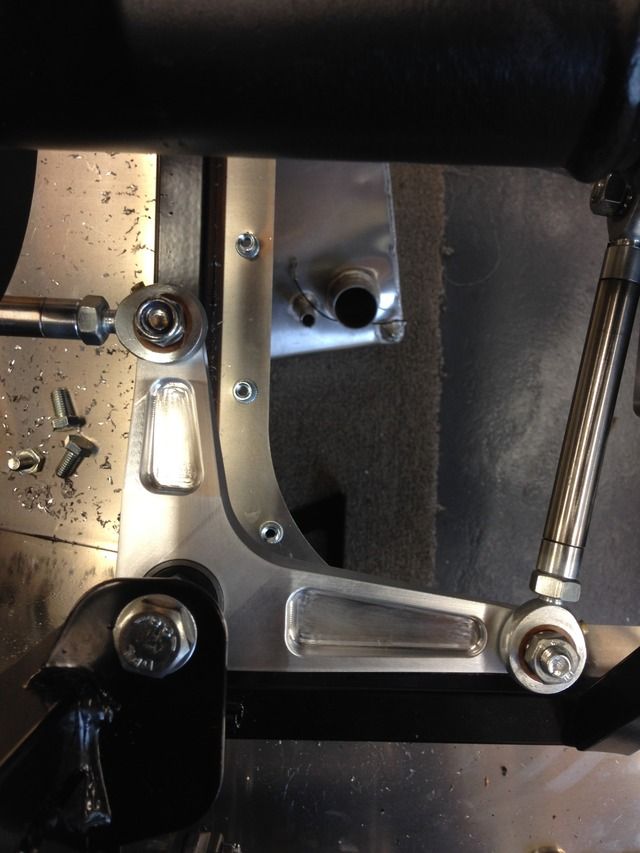

Made my bellcrank for my gear change after work tonight

CosKev3 - 28/8/15 at 07:02 PM

Awesome

You should sell those on E-Bay.

What's ratio like?

Adamirish - 28/8/15 at 07:13 PM

Epic, just epic! I wish I had the time, knowledge and skill to even think about a build like that. Well done mate, a real credit to you!

Rosco86 - 28/8/15 at 08:16 PM

quote:

Originally posted by CosKev3

Awesome

You should sell those on E-Bay.

What's ratio like?

Haha if I had my own cnc I would!

Ratio wise, I'm not totally sure, I've just blagged it really

Rosco86 - 28/8/15 at 08:17 PM

quote:

Originally posted by Adamirish

Epic, just epic! I wish I had the time, knowledge and skill to even think about a build like that. Well done mate, a real credit to you!

Wow thanks for that, but I'm just working my way through bit by bit

Rosco86 - 29/8/15 at 06:36 PM

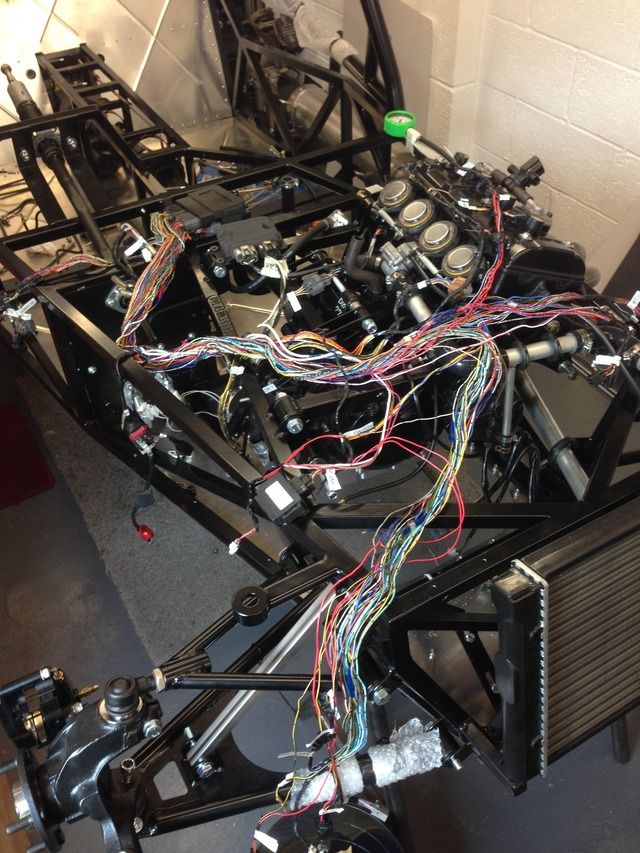

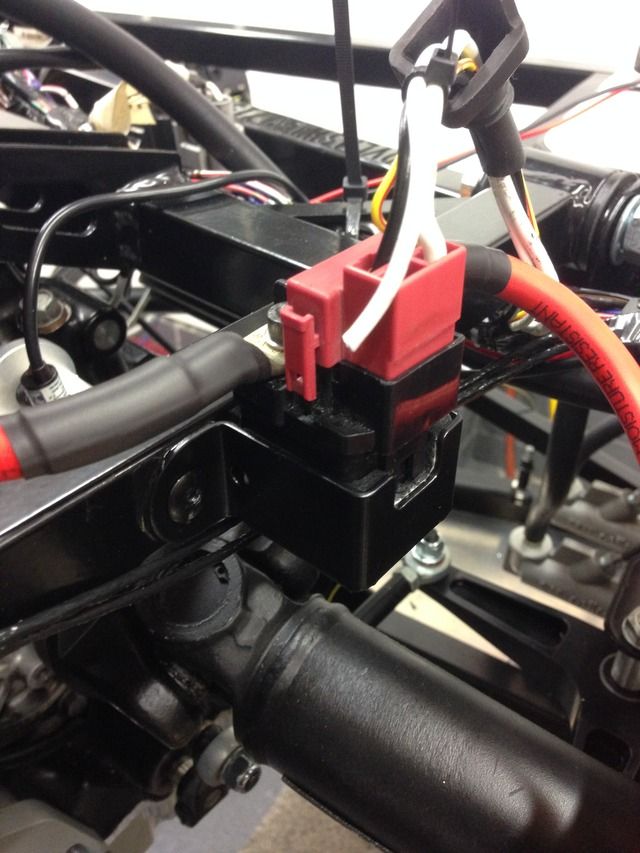

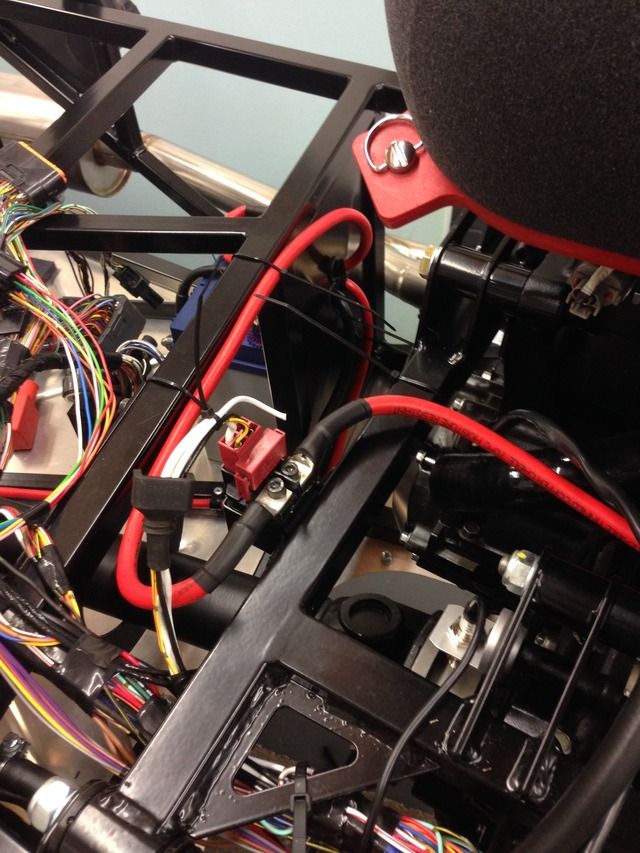

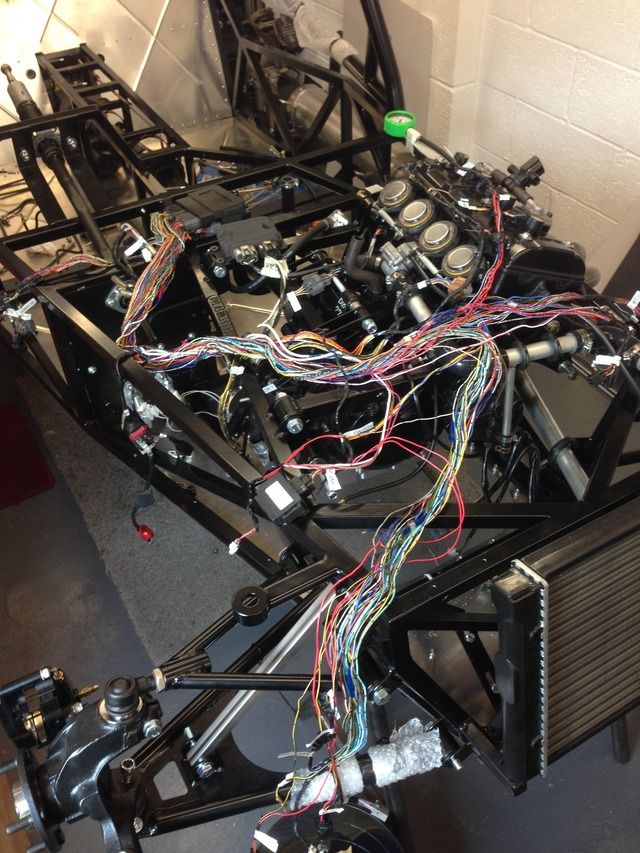

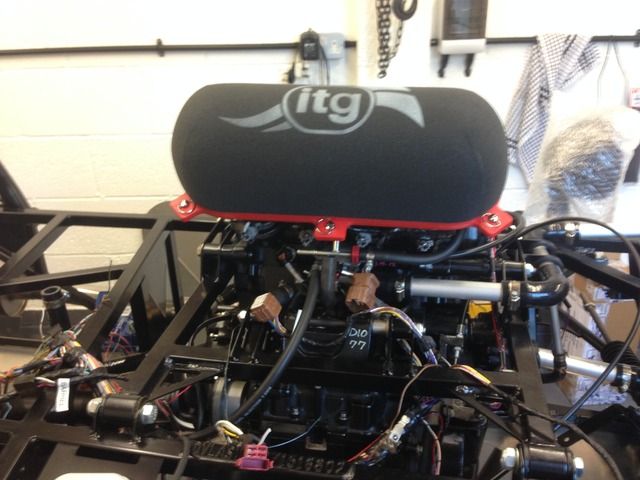

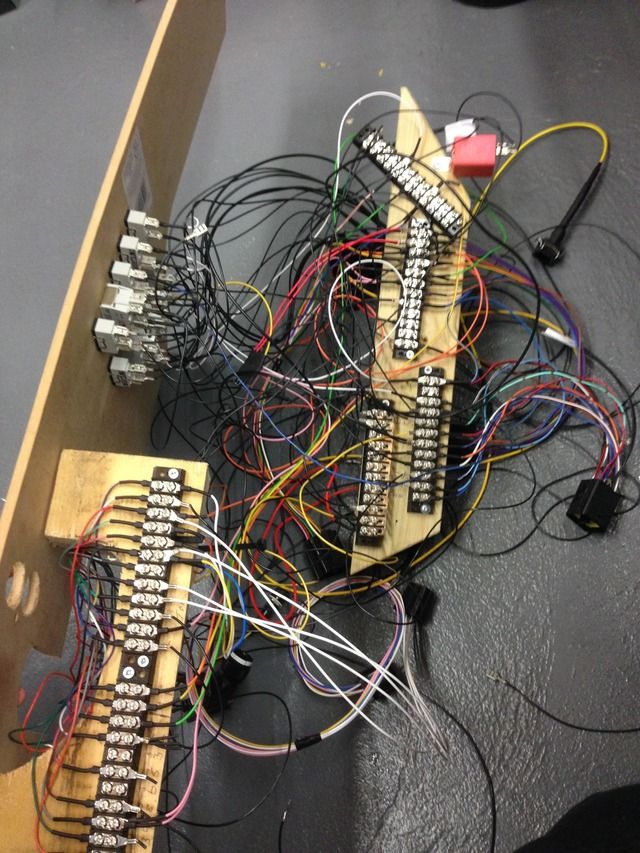

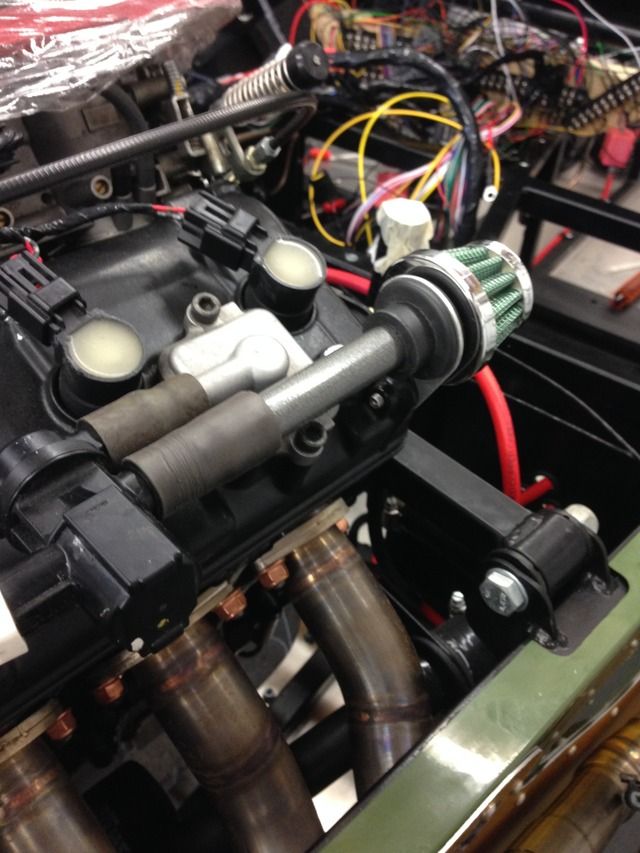

What a day! Got the engine running today! cranked the engine with the plugs out to get some oil pressure, it took a min but cracked the oil filter off

and that sorted it, primed the fuel through and she started up! I was well chuffed! Sounds so good!

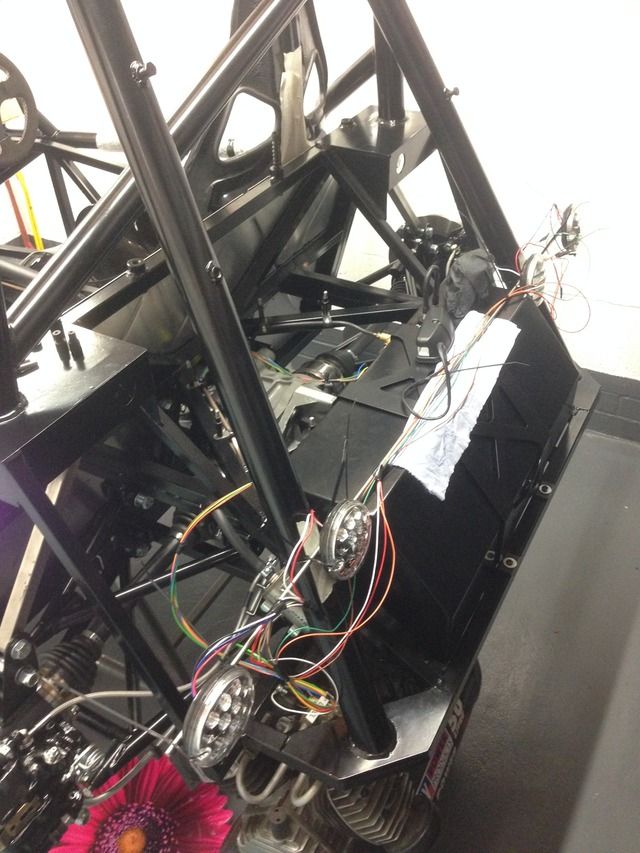

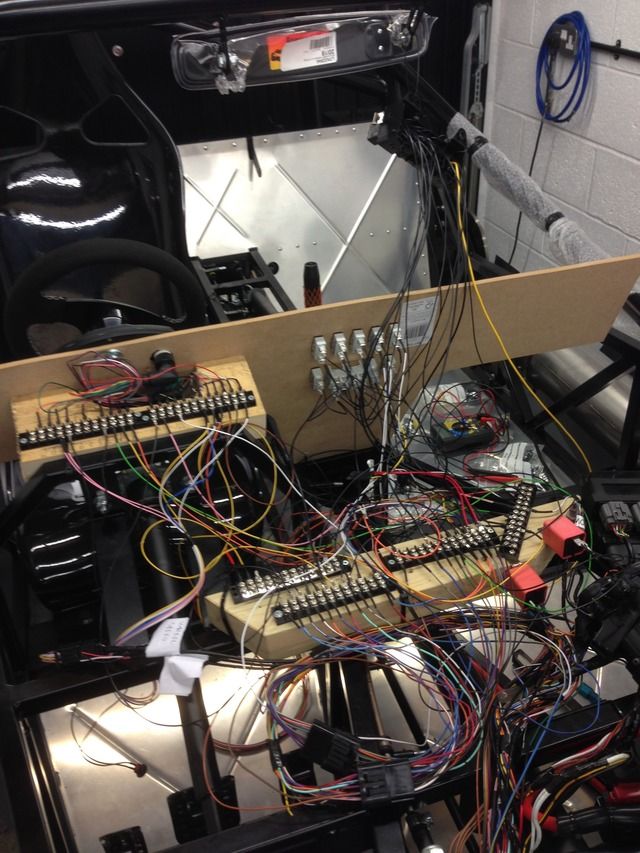

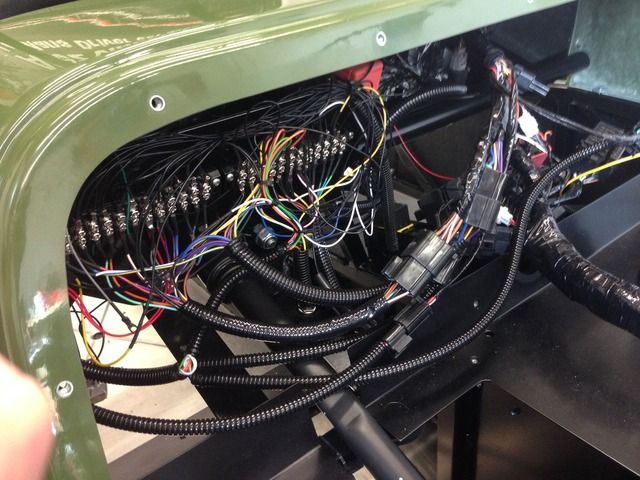

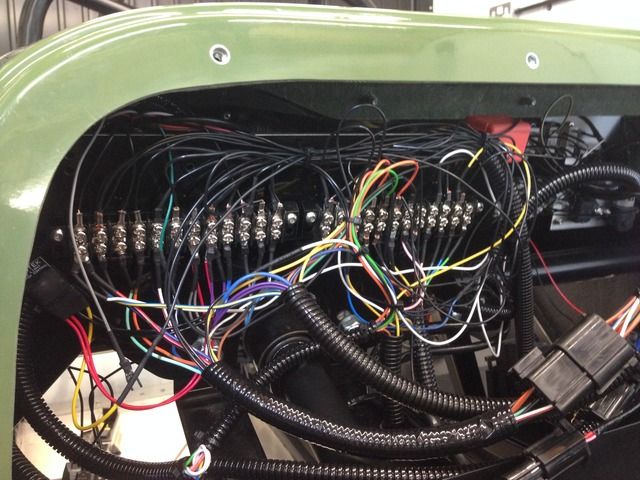

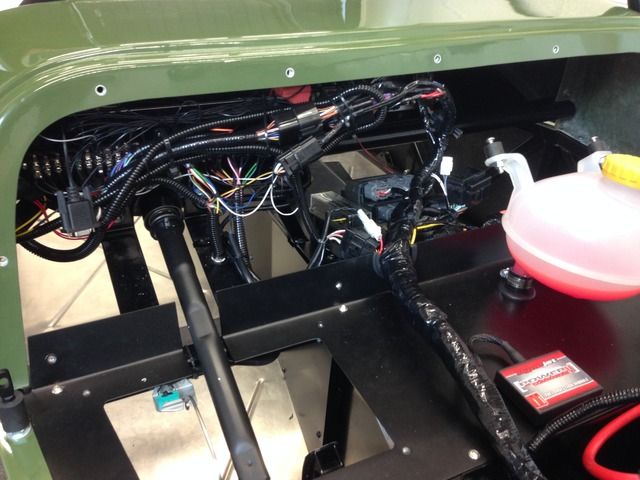

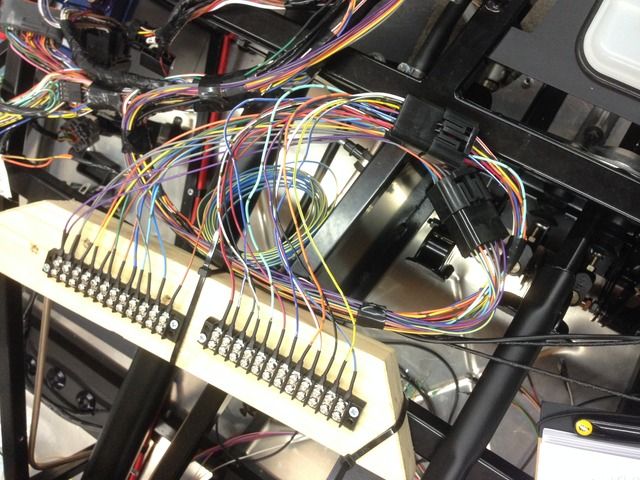

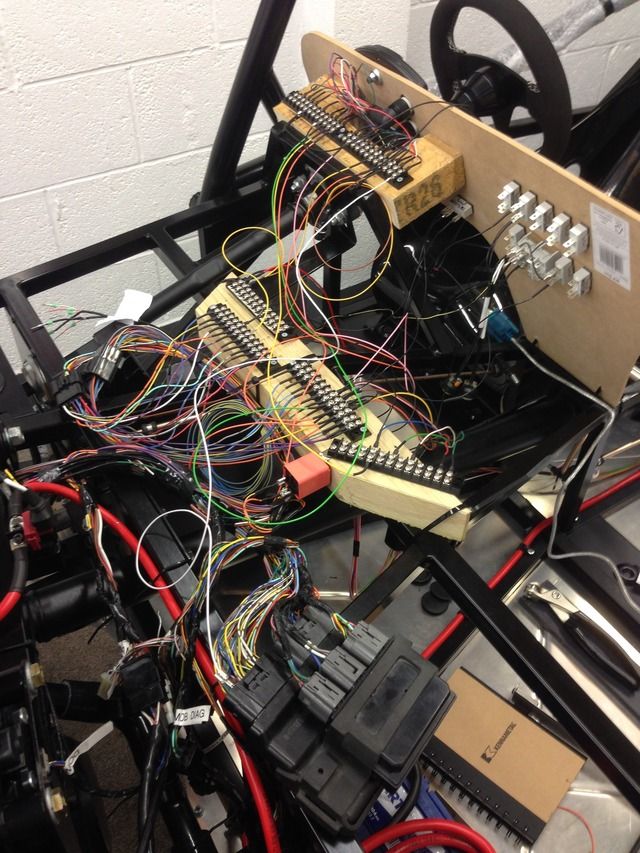

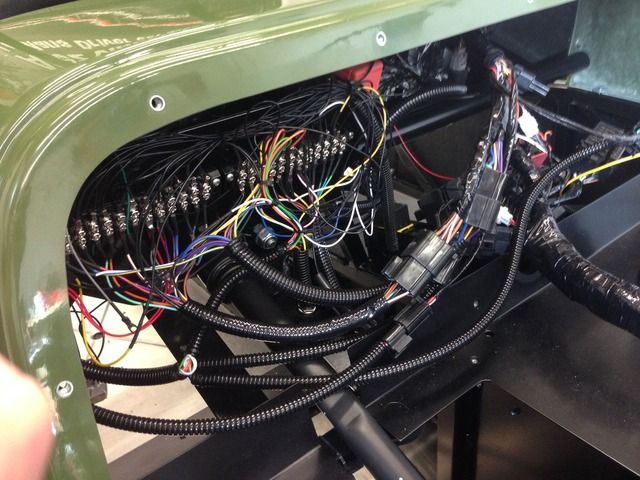

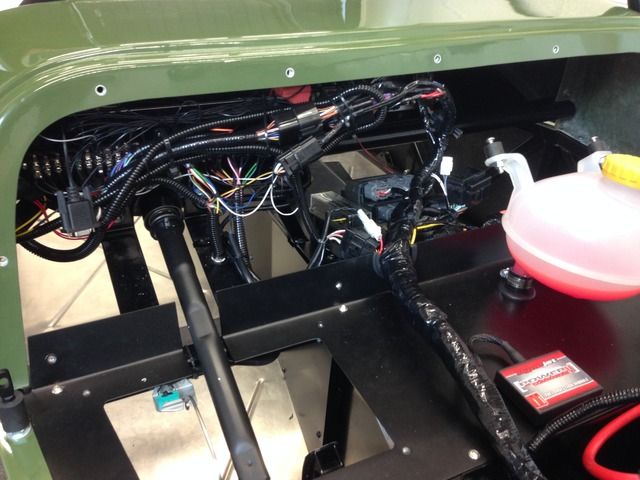

The rats nest that needs sorting!

scutter - 29/8/15 at 08:57 PM

Outstanding, Well done.

ATB Dan.

CosKev3 - 29/8/15 at 10:55 PM

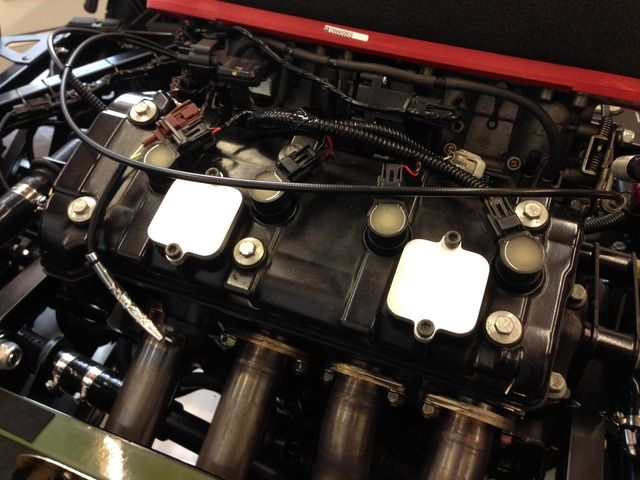

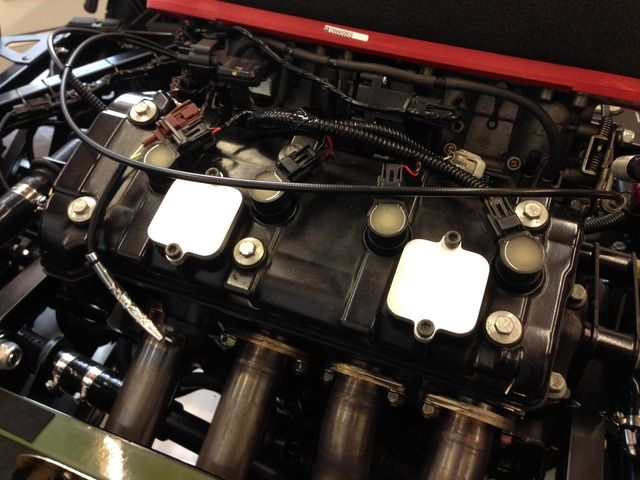

Are those injectors on the top of air box a secondary set,or are they the only injectors?

Do you need to keep air box with this engine,if not how do you go about getting those injectors mounted with a foam filter etc?

Rosco86 - 31/8/15 at 05:25 PM

quote:

Originally posted by CosKev3

Are those injectors on the top of air box a secondary set,or are they the only injectors?

Do you need to keep air box with this engine,if not how do you go about getting those injectors mounted with a foam filter etc?

Yeah there secondary's, yeah I'm going to make a new air box and remount the injector rail, easier said then done haha

Rosco86 - 31/8/15 at 05:25 PM

quote:

Originally posted by CosKev3

Are those injectors on the top of air box a secondary set,or are they the only injectors?

Do you need to keep air box with this engine,if not how do you go about getting those injectors mounted with a foam filter etc?

Thanks

Rosco86 - 31/8/15 at 06:19 PM

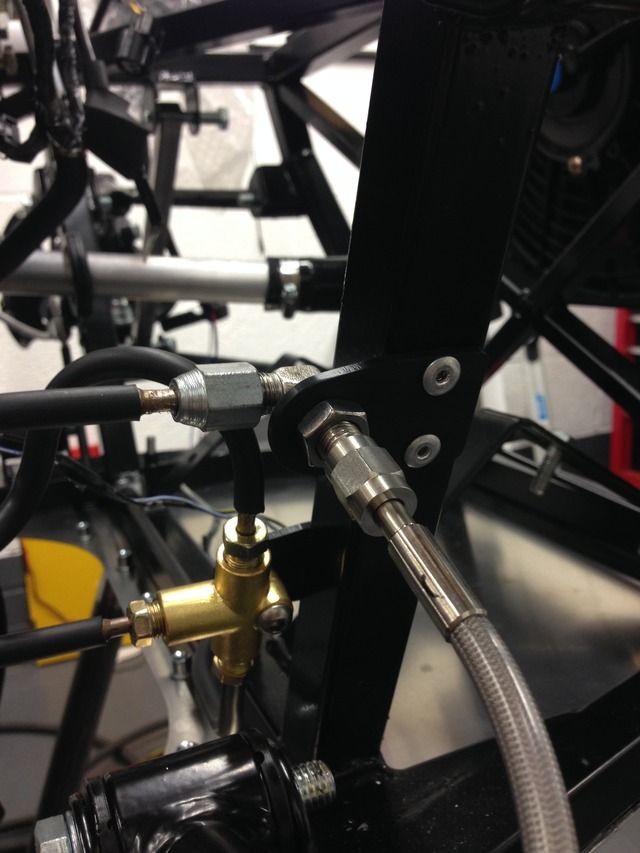

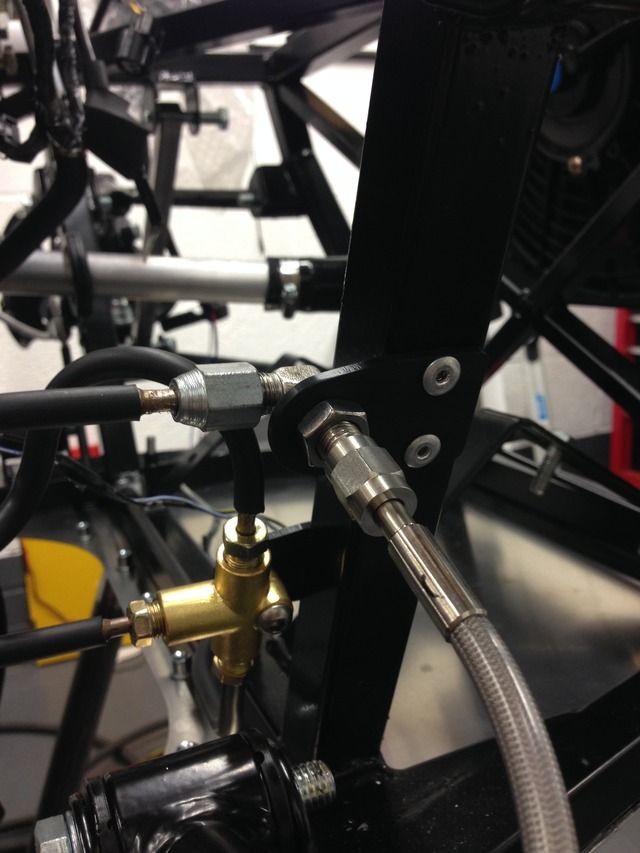

Today's job was brake pipes, had to go my motor spares shop 3 times as the fittings I had ordered weren't going to work out right, this

meant I didn't get going till about 11:30

I'm happy how they have all turned out but I did find it a bit of a faf about, the fittings I brought from various places are all different, also

you read about sae and din flares etc, in the end I did test flares in all my fitting types to check they seated properly and the back edge

wasn't damaged by the fitting, also when I tighten them up I'm going to undo them and check the flares have seated correctly, I'm going

to get my brake flex's made up tomorrow to all being well!

CosKev3 - 31/8/15 at 09:00 PM

Nice and neat.

Your not making up your own flexies?

Rosco86 - 1/9/15 at 08:36 PM

quote:

Originally posted by CosKev3

Nice and neat.

Your not making up your own flexies?

No mate, having them properly crimped, next post!

Rosco86 - 1/9/15 at 08:41 PM

Right, got my brake lines done today, I no you can make them up your self but these are properly crimped and look a bit more factory I felt,

Also got a coat of black on the rear calipers so they match the fronts

prawnabie - 1/9/15 at 08:55 PM

Hoses made with compression fittings will fail an MOT anyway now - not sure about IVA

Rosco86 - 2/9/15 at 06:54 PM

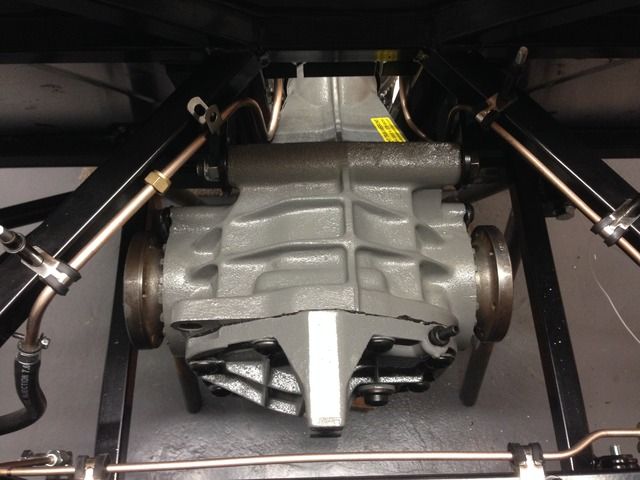

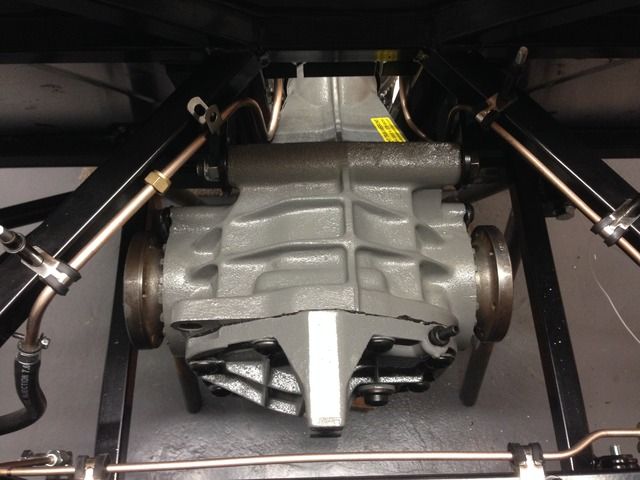

Well i sent David Rae my diff last thursday and i got it back today, well happy, so got it fitted tonight

CosKev3 - 2/9/15 at 07:00 PM

quote:

Originally posted by Rosco86

quote:

Originally posted by CosKev3

Nice and neat.

Your not making up your own flexies?

No mate, having them properly crimped, next post!

look good, as above pretty sure making your own will fail iva,hence why I asked

What ratio is your diff?

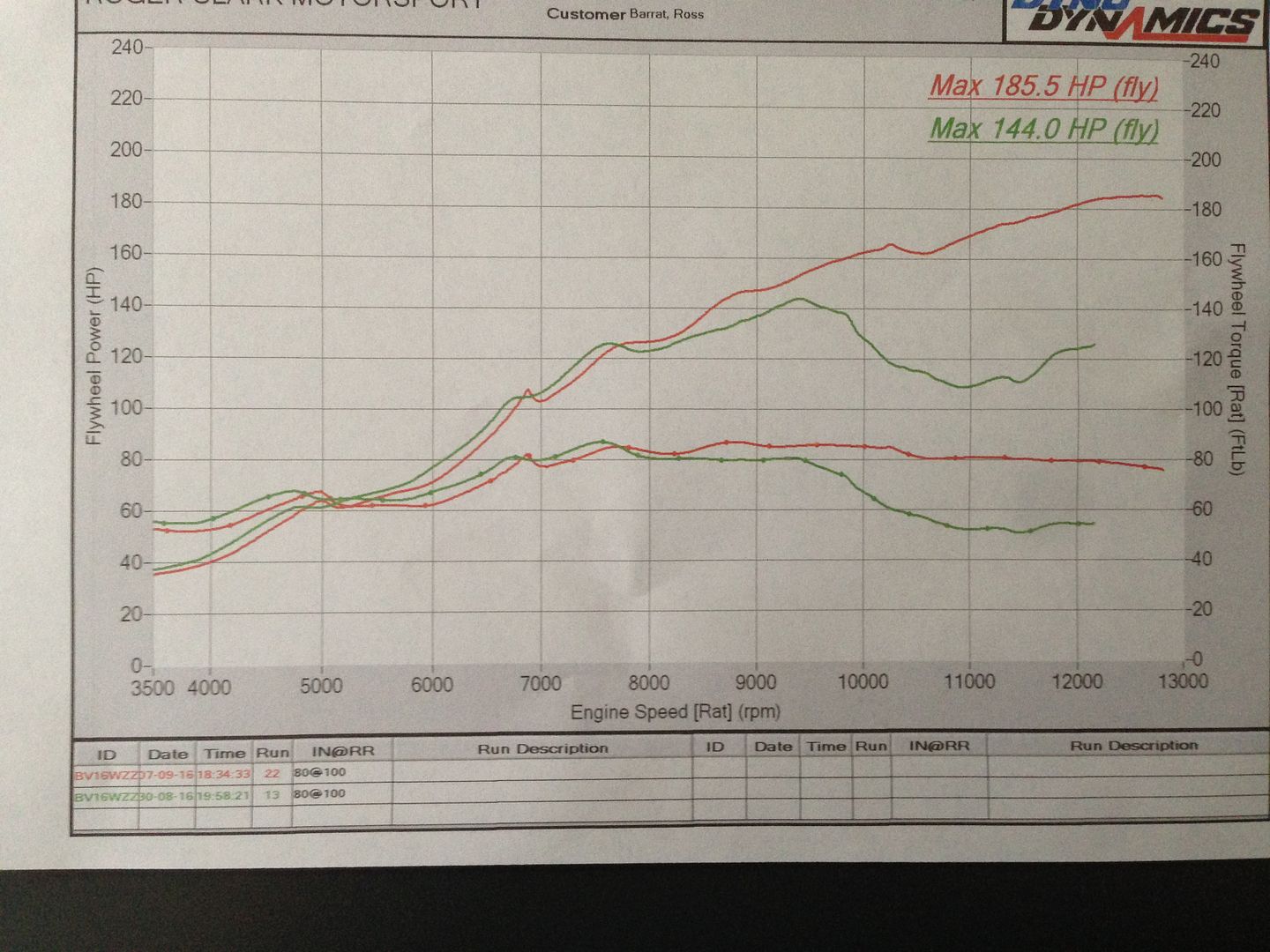

Only ask as I've had mine converted to a 3.38 for my R1, as 3.62 was too low for road use imo.

Topped out at 120mph on the limiter in sixth on rolling road, and was circa 7000rpm cruising at 70mph so was too busy!

Rosco86 - 2/9/15 at 07:47 PM

quote:

Originally posted by CosKev3

quote:

Originally posted by Rosco86

quote:

Originally posted by CosKev3

Nice and neat.

Your not making up your own flexies?

No mate, having them properly crimped, next post!

look good, as above pretty sure making your own will fail iva,hence why I asked

What ratio is your diff?

Only ask as I've had mine converted to a 3.38 for my R1, as 3.62 was too low for road use imo.

Topped out at 120mph on the limiter in sixth on rolling road, and was circa 7000rpm cruising at 70mph so was too busy!

Ah ok, to be honist i didnt no you could make your own flexies

Yeah ive gone for 3.38 i strugled to get it but its turned out ok in the end, ive got a viscus lsd in there to, i think the zx10 gear boxes are a

little worse In top gear but i think it will be ok

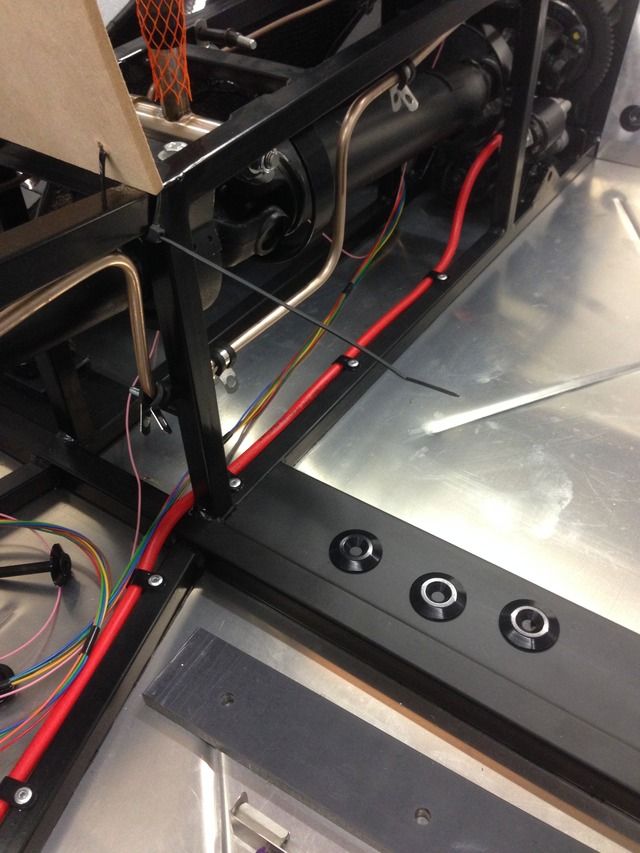

Rosco86 - 3/9/15 at 08:02 PM

Good bit done tonight, I decided my brake pipes looked a bit bodge in copper colour so put some heat shrink over them, was a right pain in the butt,

would of been loads easier before I flared the fittings on the end but turned out ok in the end

Also my dad had cut my fuel tank strap out for me today, just needed to bend it up! It came out sweet, I will get it powder coated I think

Just need to trim the ends to length and sort the holes out

sdh2903 - 3/9/15 at 08:08 PM

That tank strap is a work of art. I love the attention to detail with your build, very impressive. Neat idea with the brake pipes too.

Rosco86 - 6/9/15 at 04:56 PM

quote:

Originally posted by sdh2903

That tank strap is a work of art. I love the attention to detail with your build, very impressive. Neat idea with the brake pipes too.

Cheers, yeah it does look cool but it's still simply two straps like everyone else, as for heat shrink, it's great, makes stuff look so

neat!

Rosco86 - 6/9/15 at 05:14 PM

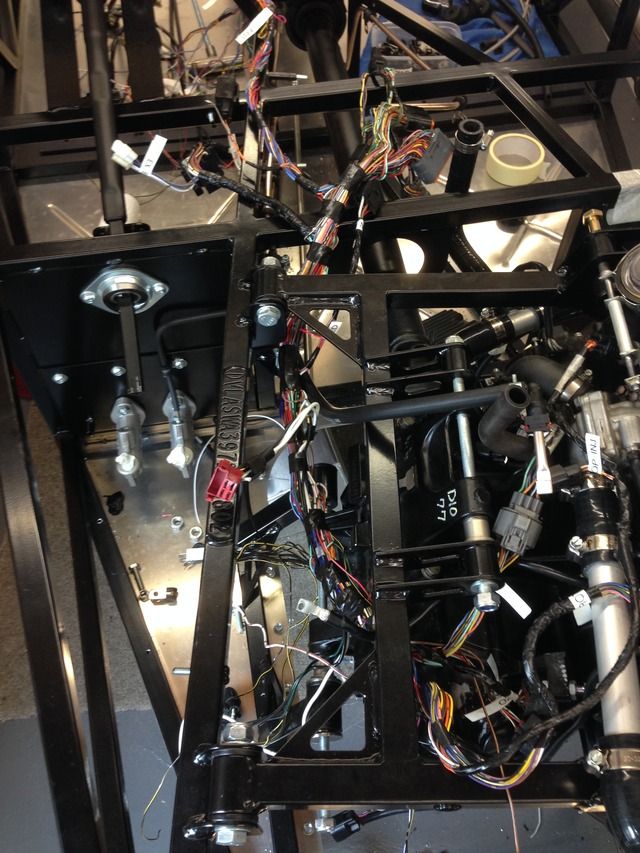

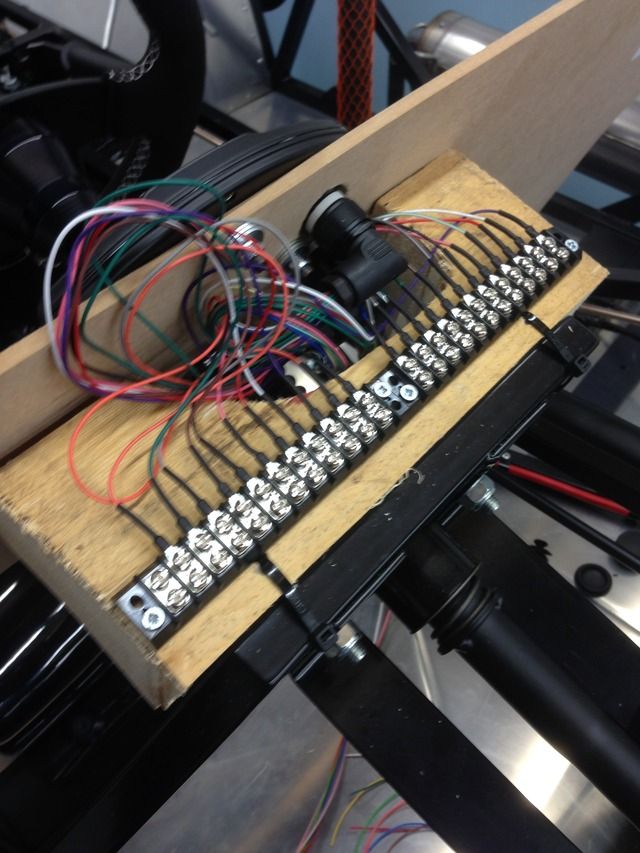

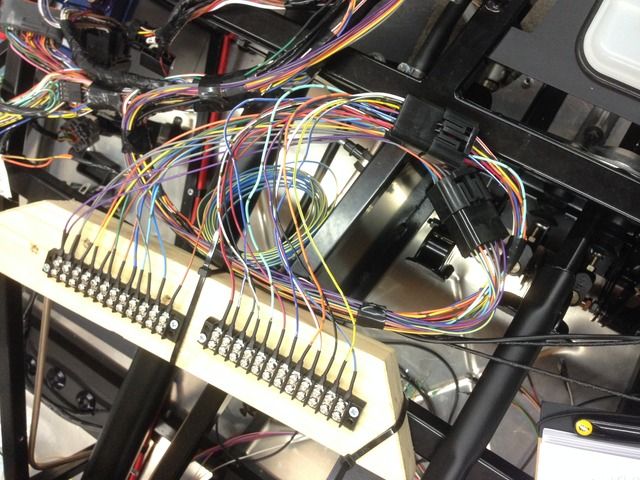

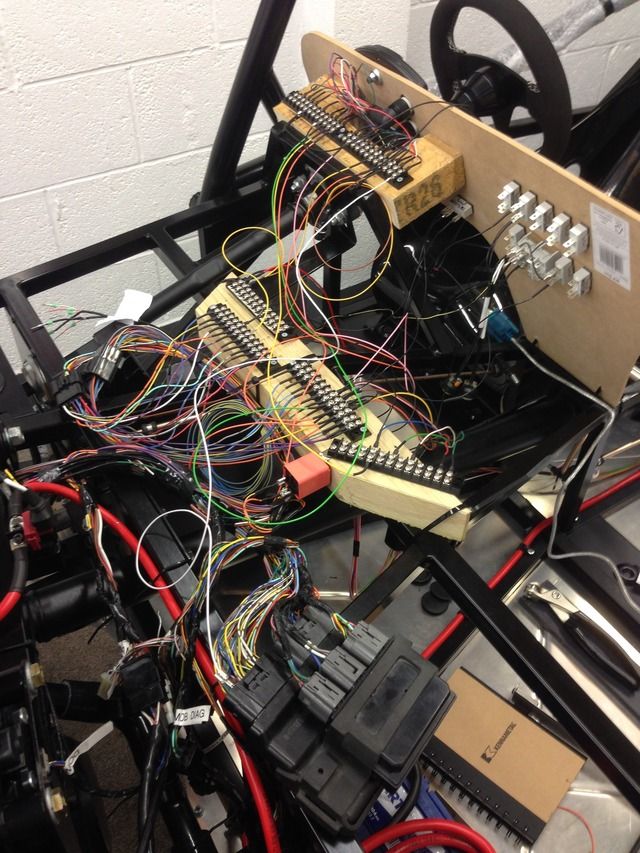

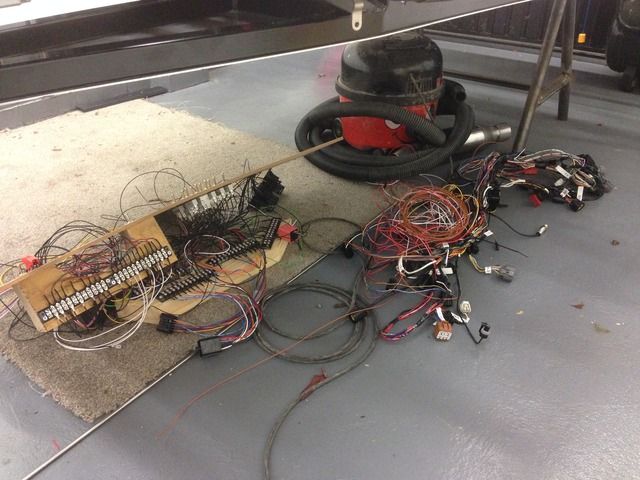

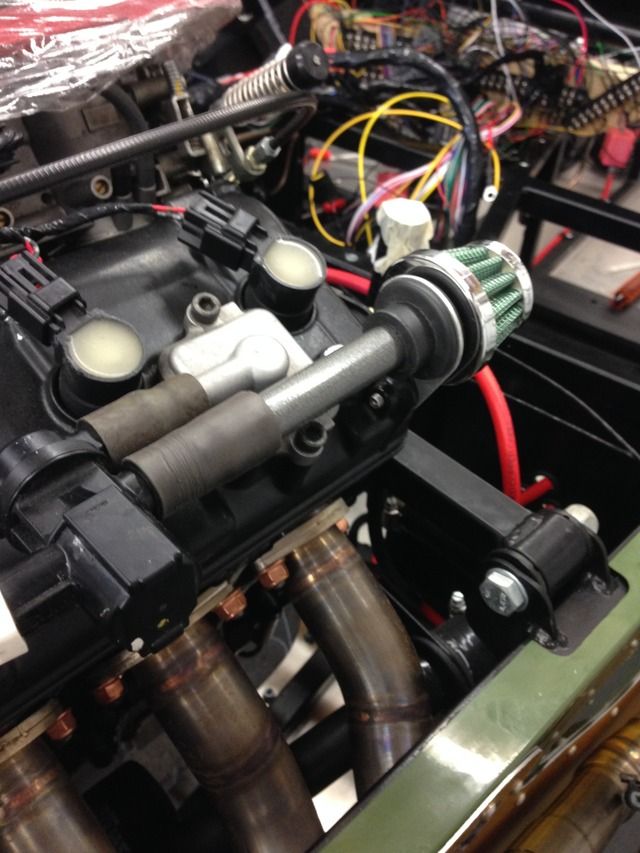

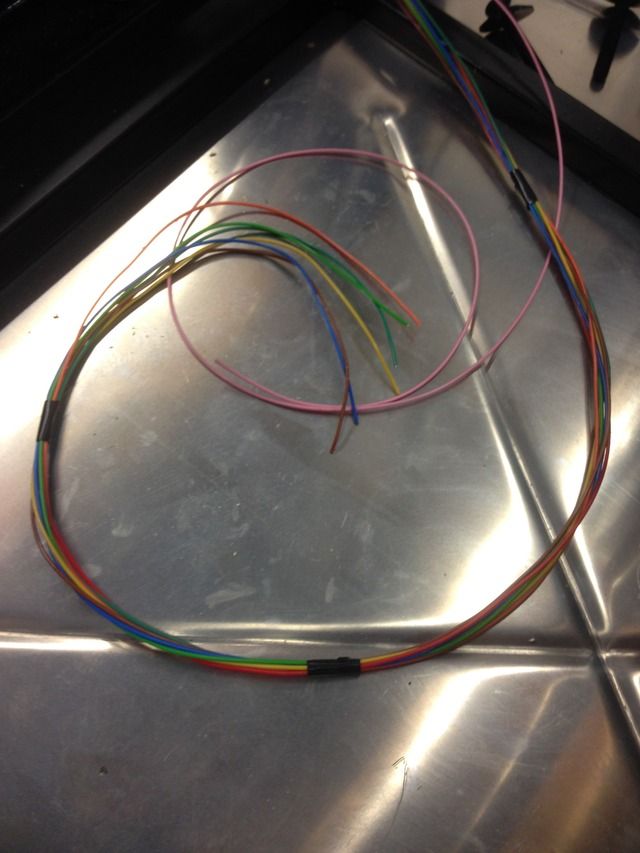

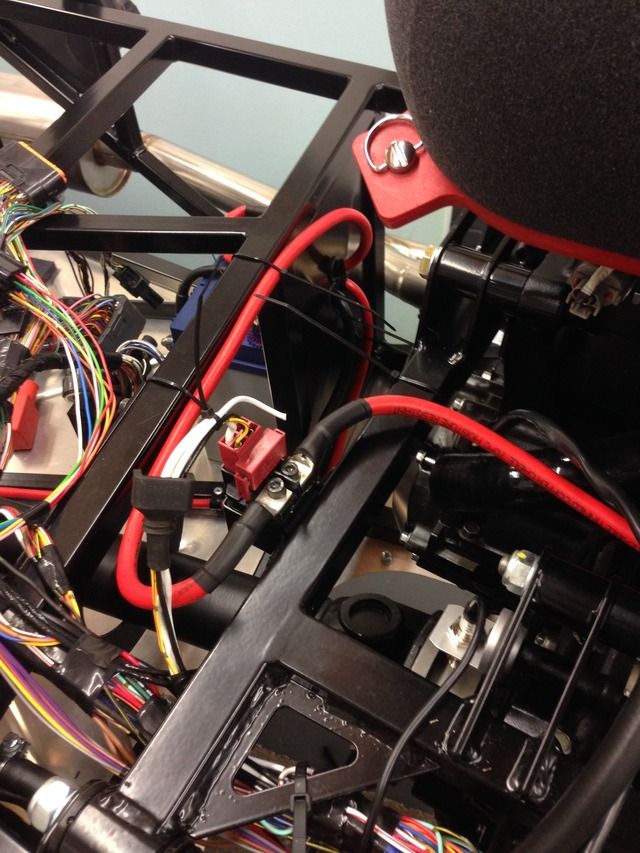

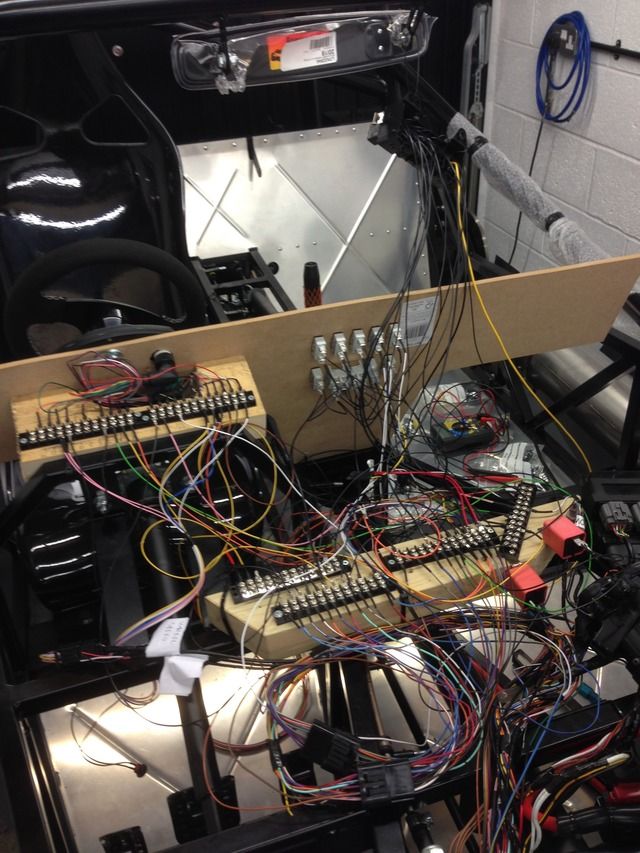

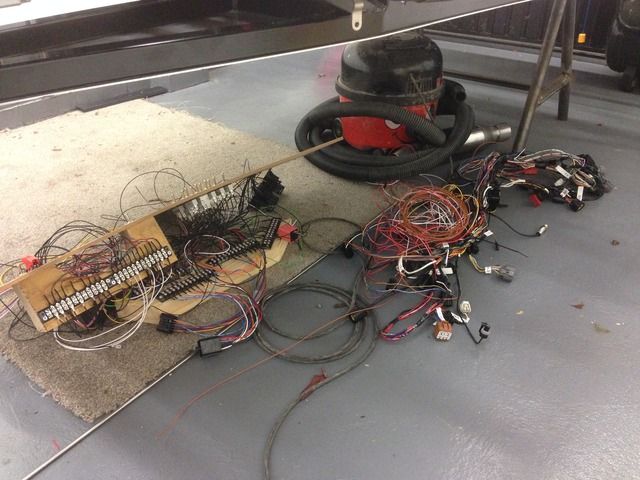

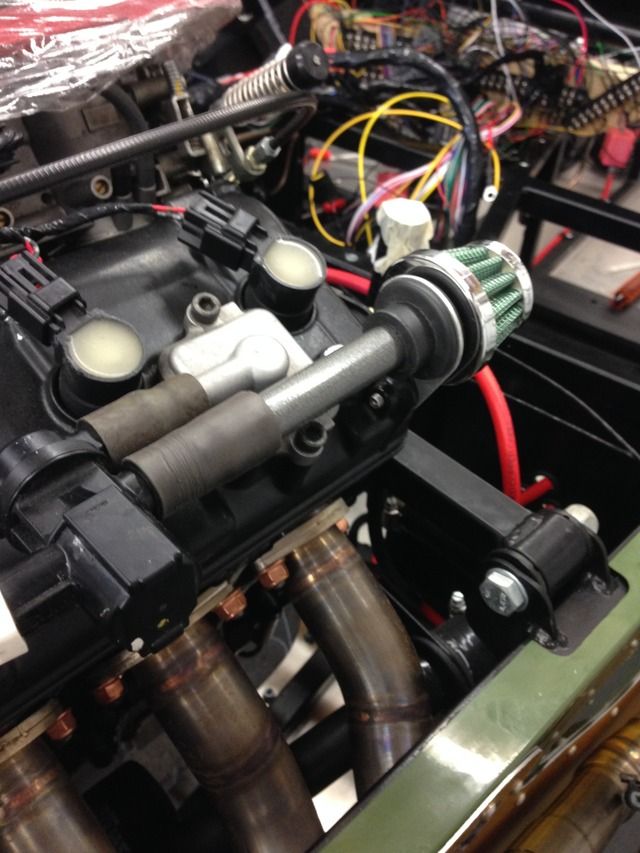

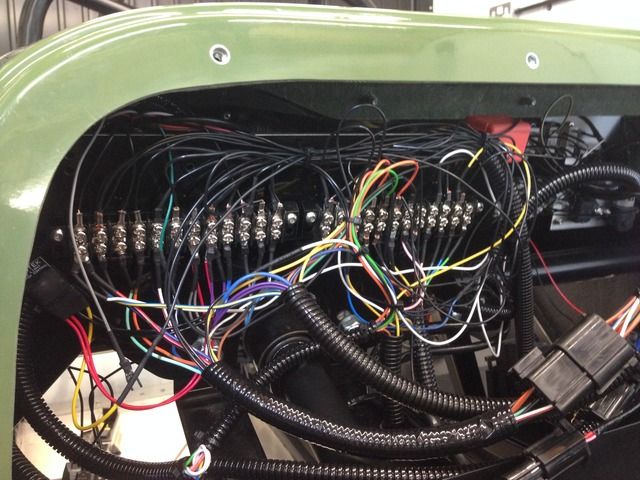

A full day of sticky wiring on Saturday, me and my dad unwrapped the entire loom and relocated everything into position and everything into the

cockpit etc, to be fair it wasn't anywhere near as bad as I thought it would be, also we removed things not required like stop watch buttons,

sidestand etc, we stripped the lighting back so we just have the feeds coming out of the fuse box, next job is get the lights and dash bits roughly in

place and get wiried up

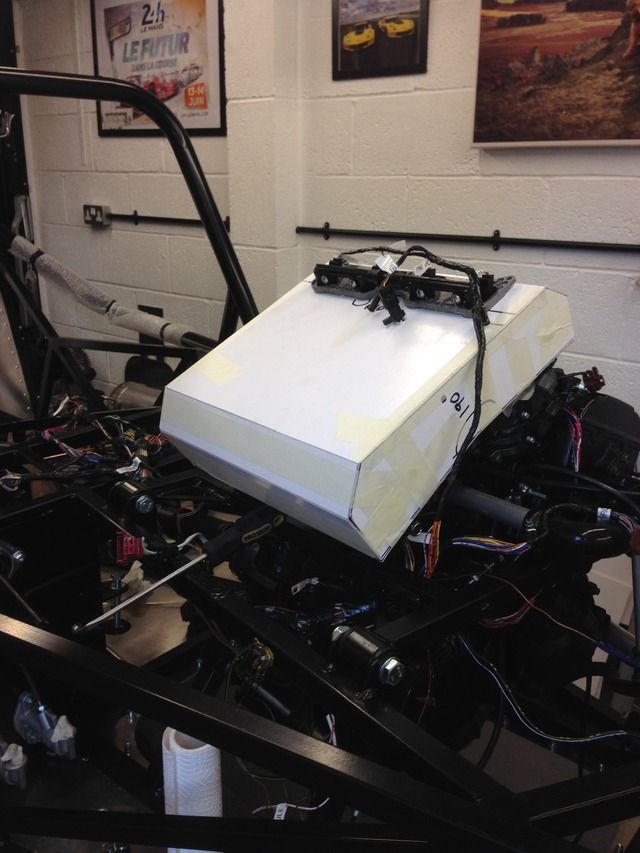

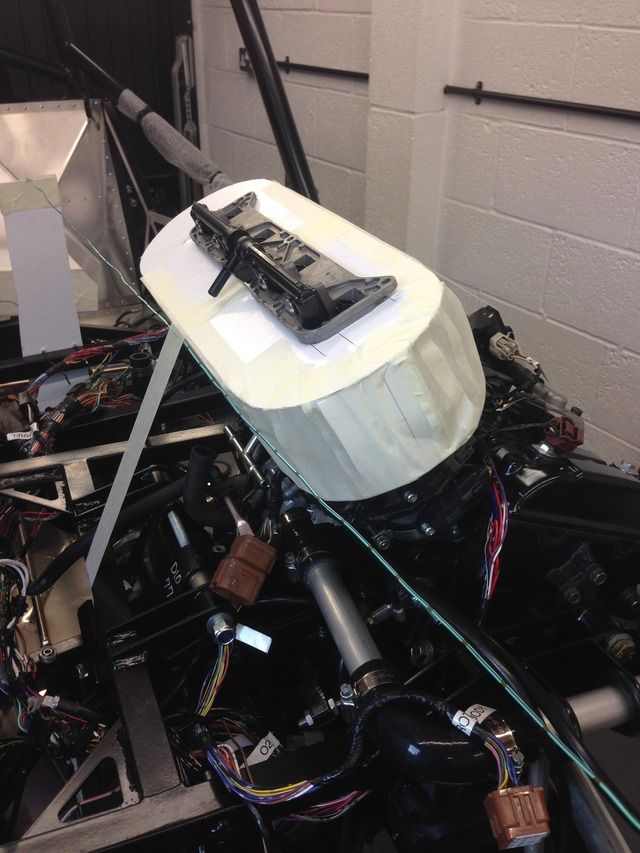

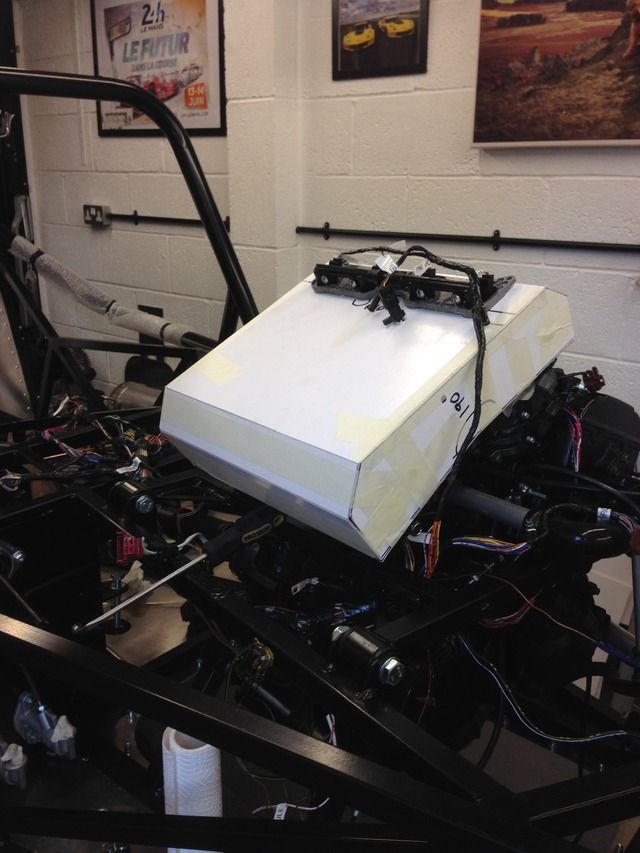

This morning we mocked up a new air box in card, I'm aiming to fab it up in aluminium, the problem is the top injectors, the std box is to high

and out to the side, the new idea is a bit lower but not out to the side, I think if I did it as is I would need a bulge/scoop around 100mm high on

the bonnet, I'm open to any ideas if anyone has any,

Also I'm thinking of using a cone filter with a cold feed, mounted on the front like others have done

OliilO - 6/9/15 at 06:39 PM

Still looking great.

I know Mac1 made an airbox for zx10 engines, so may be worth searching for some pictures of them; not sure if they were for engines with secondary

injectors or not though.

What thickness steel did you used for the panel your lower steering column bearing is bolted to? That's something I want to change in my car over

winter, so it's got a bearing rather than just a bush.

Rosco86 - 6/9/15 at 06:53 PM

quote:

Originally posted by OliilO

Still looking great.

I know Mac1 made an airbox for zx10 engines, so may be worth searching for some pictures of them; not sure if they were for engines with secondary

injectors or not though.

What thickness steel did you used for the panel your lower steering column bearing is bolted to? That's something I want to change in my car over

winter, so it's got a bearing rather than just a bush.

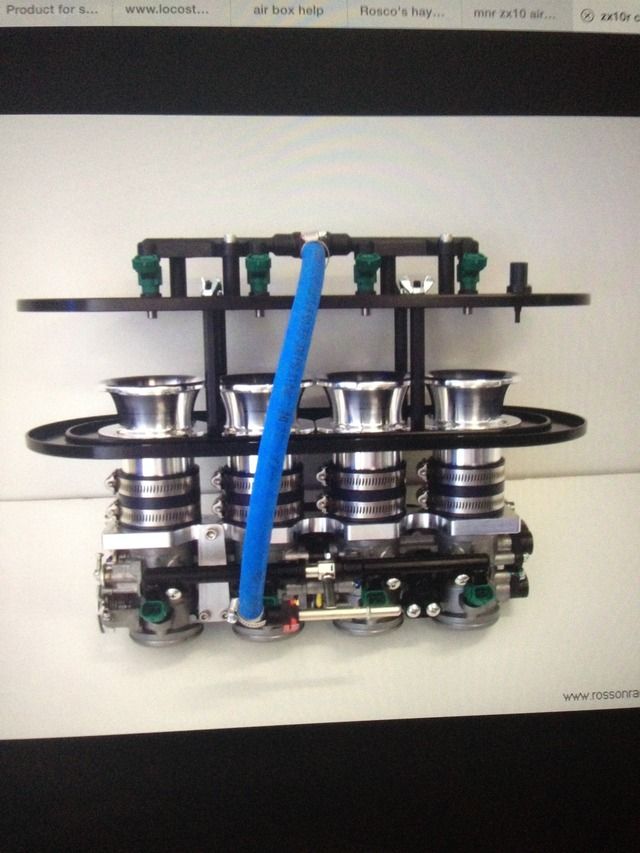

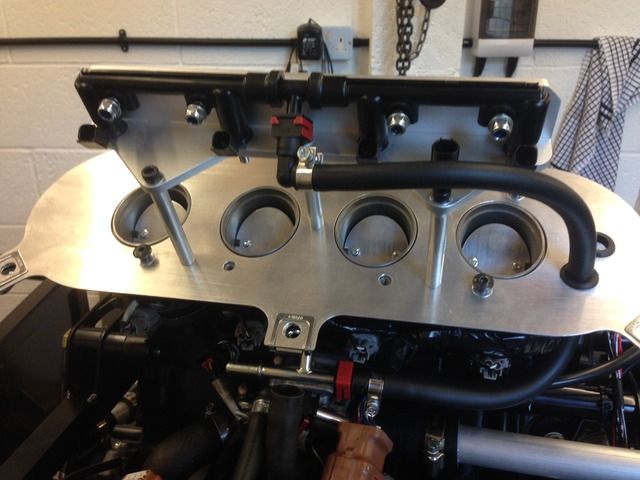

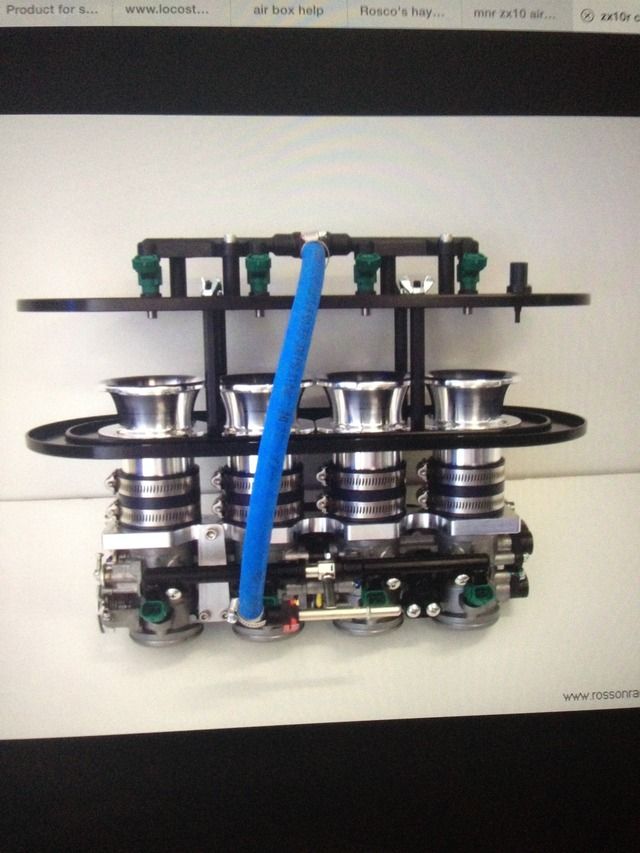

Yeah that's what I've sort of copied, this is Big Macs

I used 2mm but I did also put a short fold in it right on the lower edge to stiffen it up for the pedal box

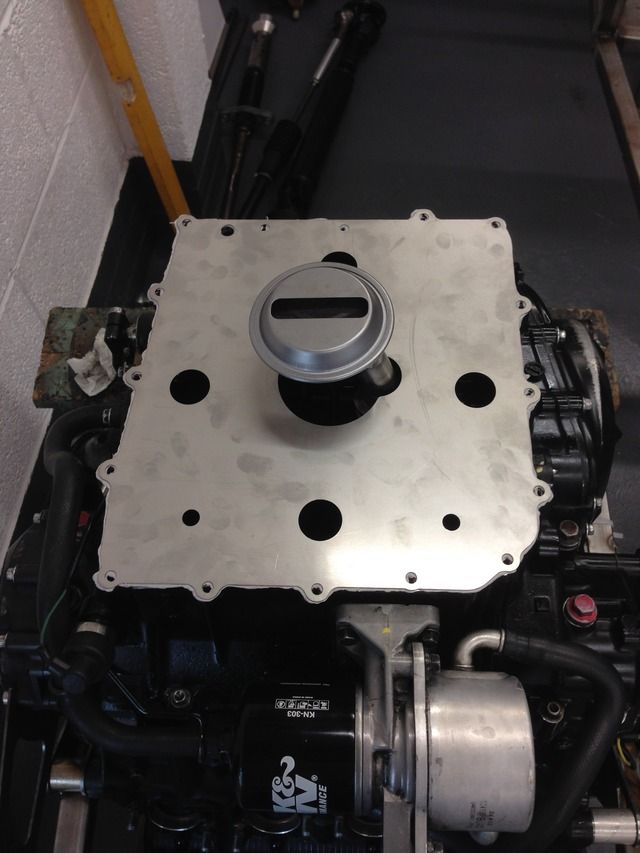

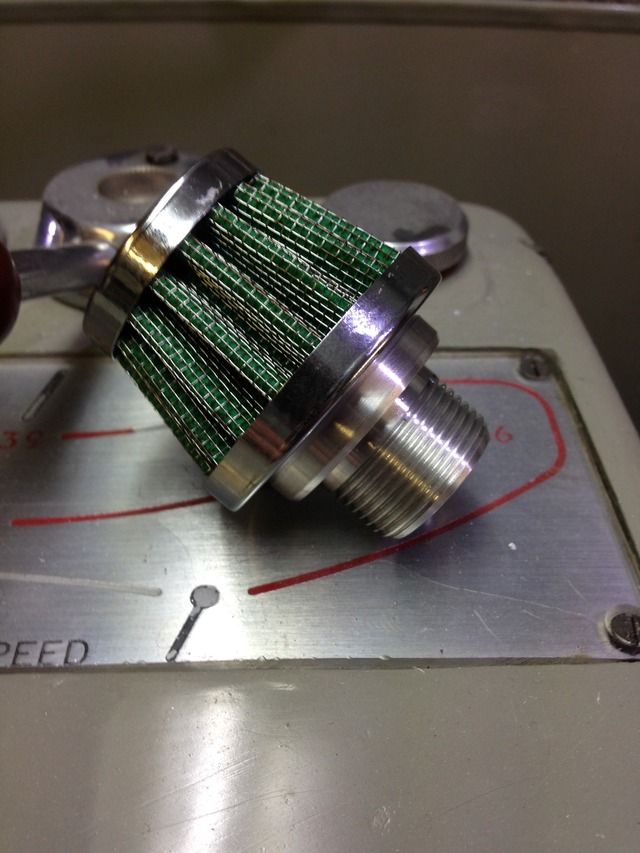

Rosco86 - 6/9/15 at 07:29 PM

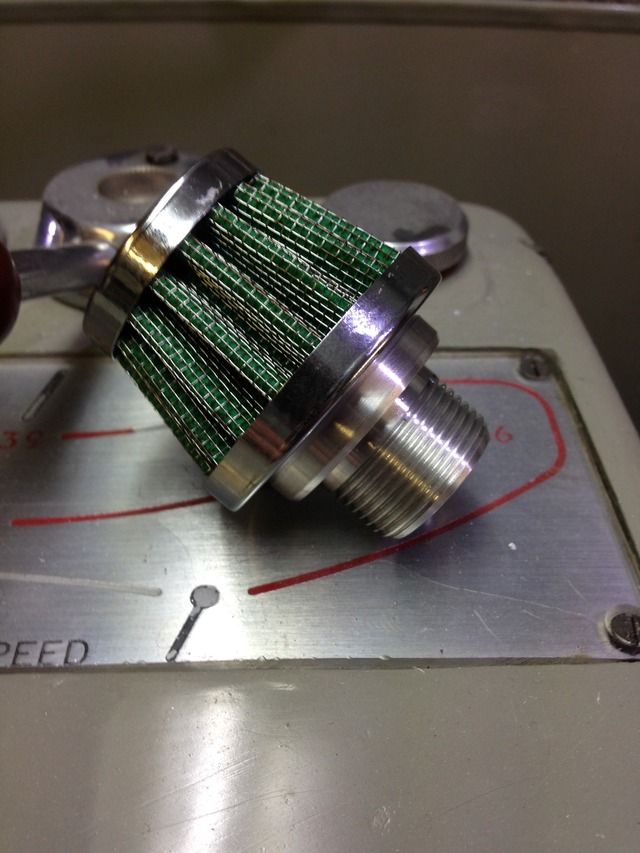

Change of plan haha I've just seen this idea, it clamps a foam/k&n filter between the two plates

Also the injector height could easily altered to keep it as low as possible and altered if it causes a bhp drop,

perksy - 6/9/15 at 10:25 PM

Excellent build, well done

Some great photos and info being shared, thanks

Rosco86 - 7/9/15 at 06:12 PM

Cheers

Rosco86 - 7/9/15 at 06:20 PM

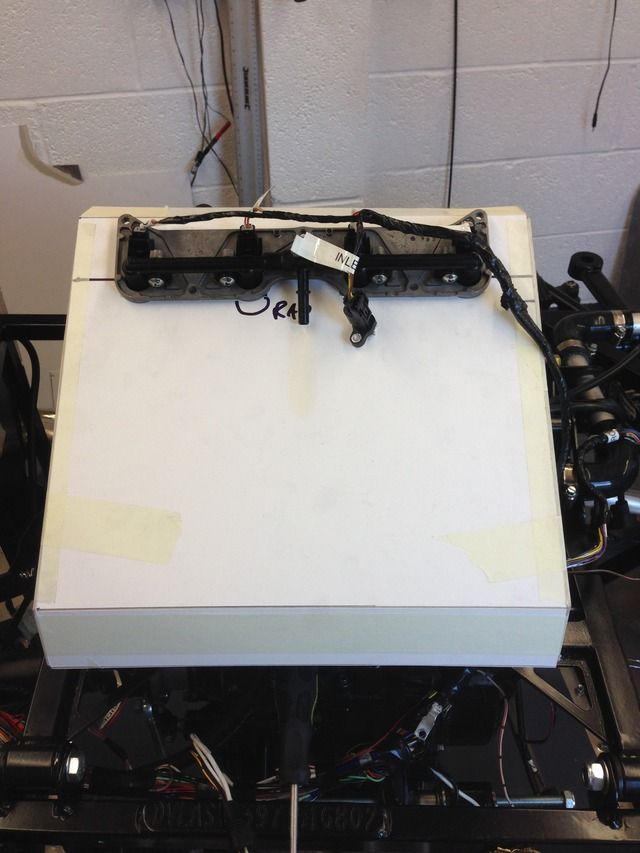

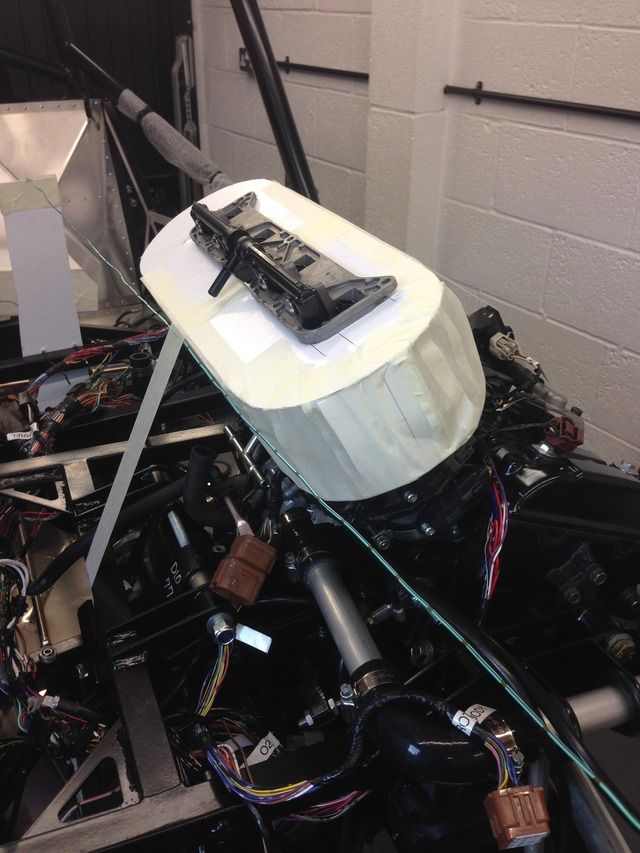

Right well I've mocked up air box idea number two just to get an idea of size, looks ok, I've mocked up a bit of wire to represent the

bonnet line roughly, also I'm a bit worried about induction noise with this method as it's got to be less than 99db at 3/4 throttle!!! Is

there anyway of getting this rpm dropped, maybe a new power graph showing peak power at 8000 rpm say??

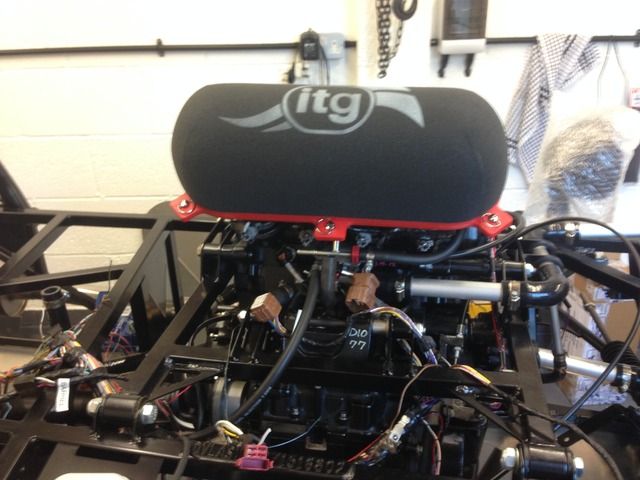

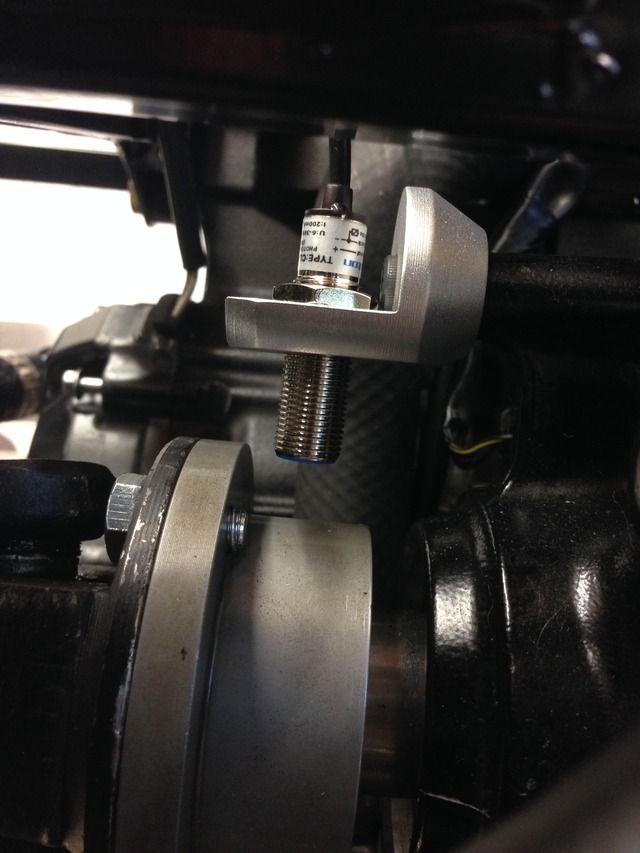

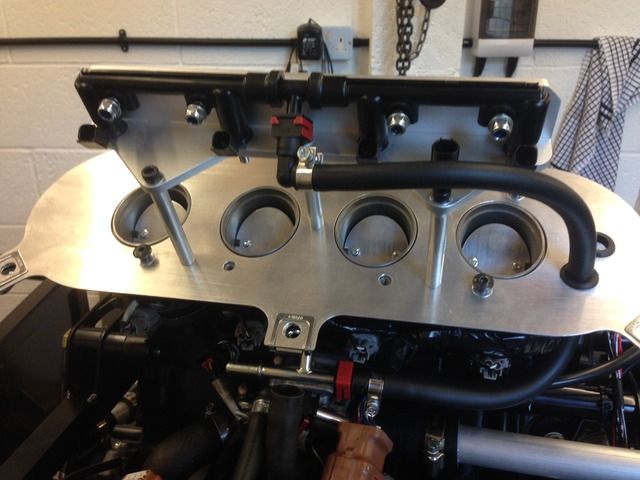

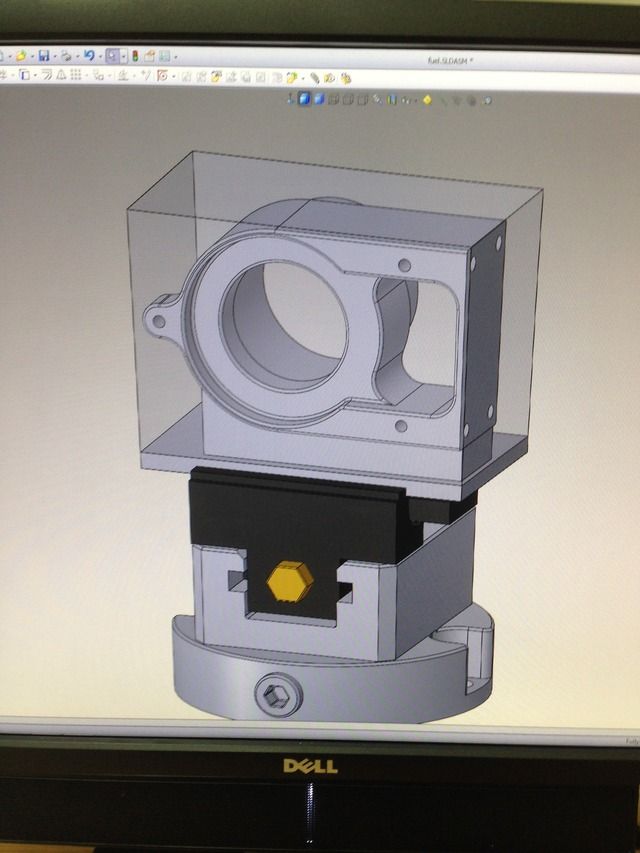

Rosco86 - 14/9/15 at 07:02 PM

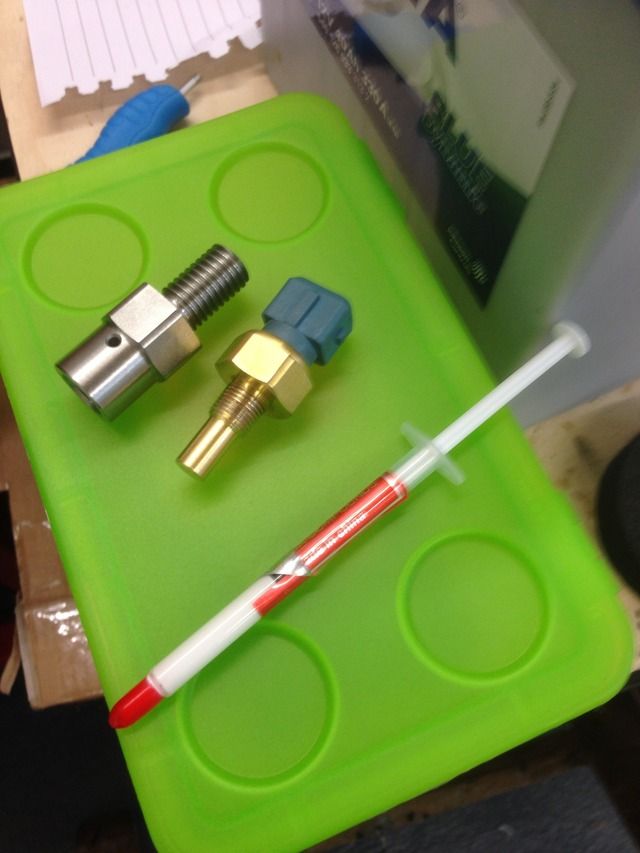

Not many photos tonight but it doesn't mean I've not been busy, got my driveshafts from j&r on eBay greased, built up and fitted

Got a type 054 battery, think it's going in the passenger footwell behind a foot rest, so made the foot rest fit and made a strap out of

stainless

This will bolt through the floor from underneath, all bits need a bit of padding here and there

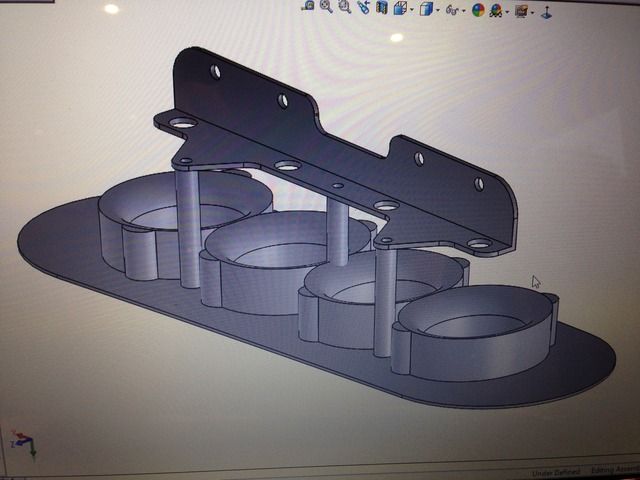

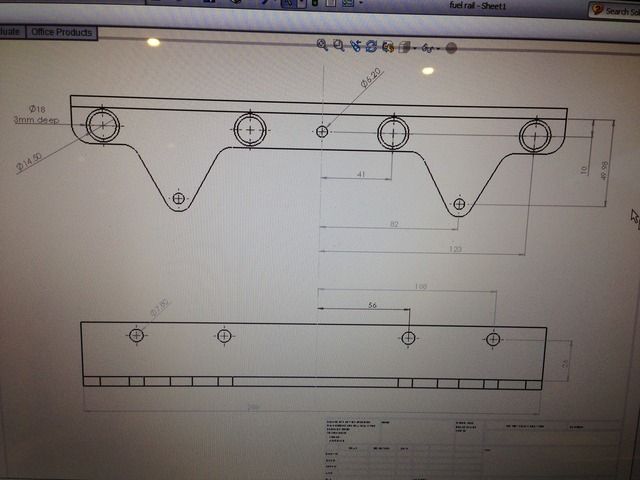

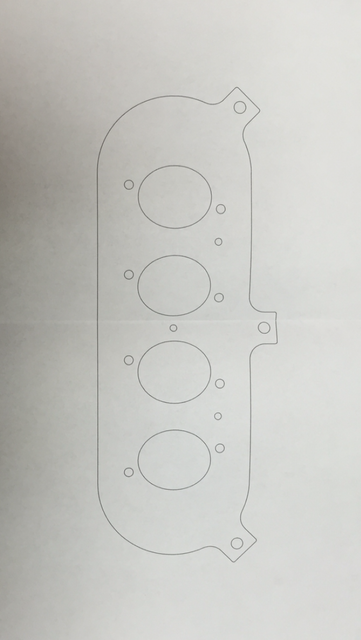

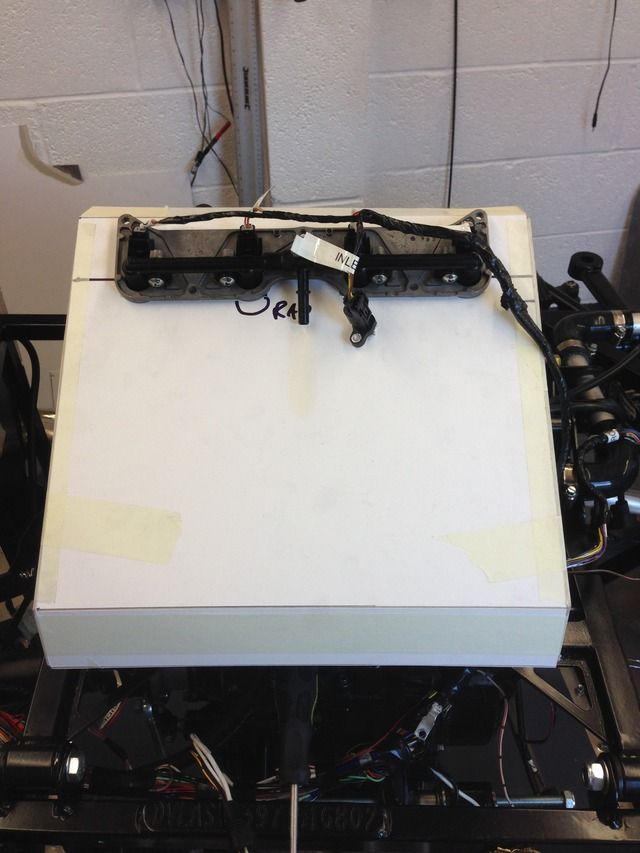

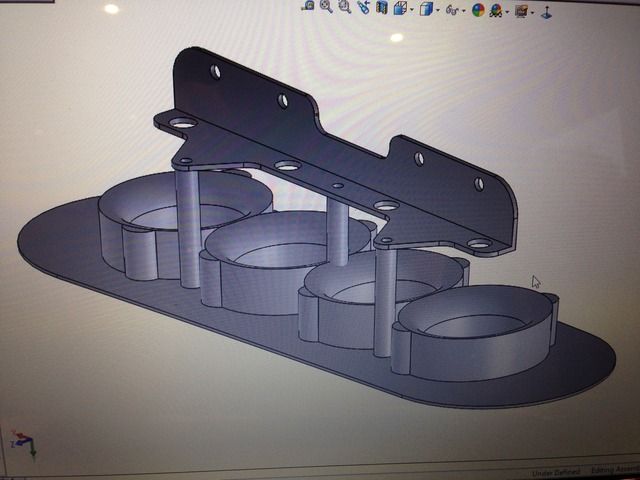

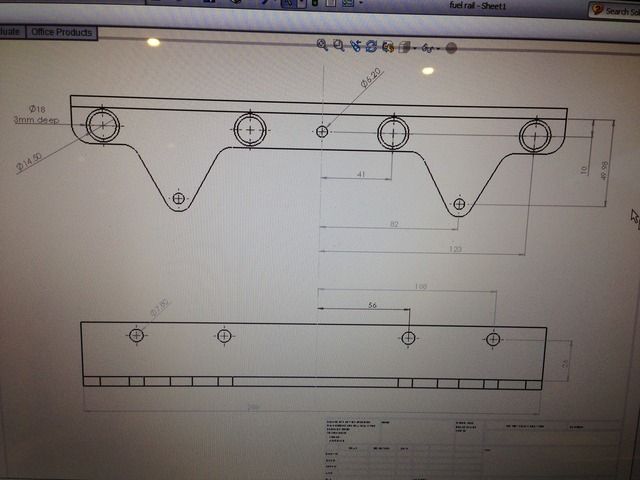

Then spent most of Sunday drawing and deciding how to do my air filter

First try was with a k&n filter but looks to big,

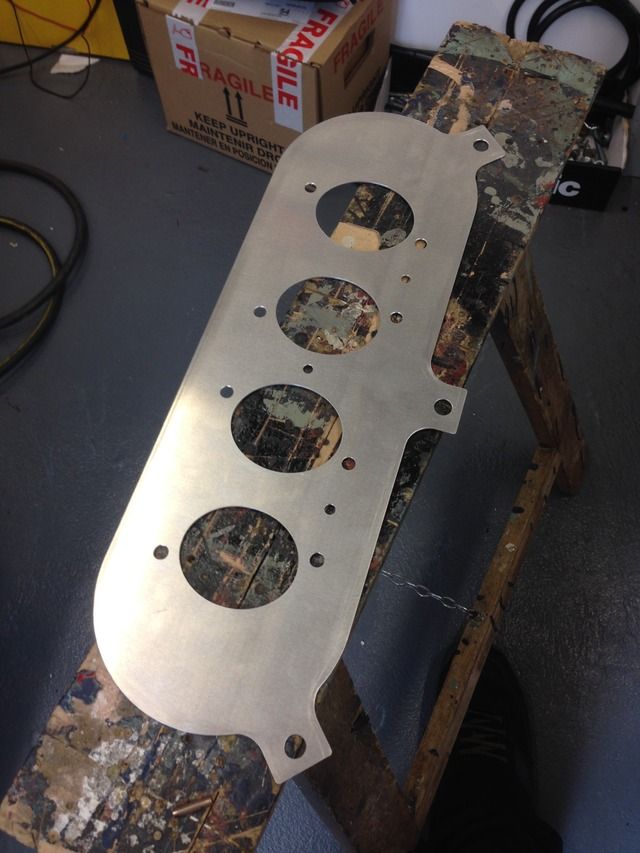

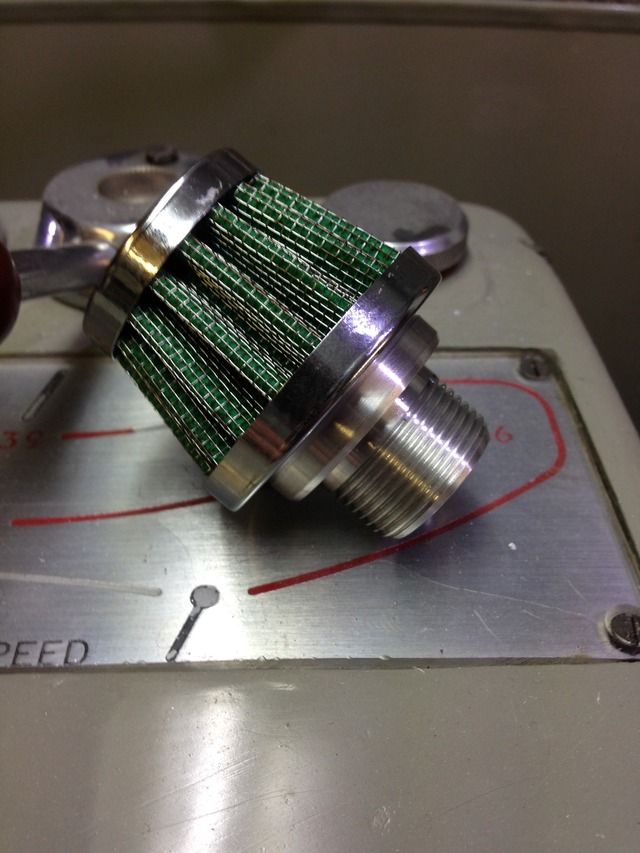

Next is to suit an itg sausage filter over the top, this is what I'm going to do, I've got to make a new fuel rail and a base plate

Std injectors which will fit in the new rail/bracket

This method seems the simplest, easy to make, most compact and uses an off the shelf air filter

Rosco86 - 16/9/15 at 07:51 PM

Well got all my anodizing back today, looks sweet

Gear shifter

Roll cage bungs, I admit I got carried away with these, but I do love it! Made a bit of a logo with my initials

Brake tags bonded and riveted on (I spoke to the tech iva man at the dvla about this and he said it's fine as long as there secure) also got all

my brake pipes back on tonight, I just need to rivet the p clips on

Rad brackets fixed on and fan fitted

Brake res fitted

My air trumpets turned up yesterday so now I have 4 short ones

Started the fuel rail bracket

Back plate drawn up

Just need to order one of these filters

Neilwilson - 16/9/15 at 08:06 PM

The effort that you have/are putting in is outstanding, definitely reflected in the quality of your build.

Really like the personal emblem, I can imagine at some point you will have a badge on the bonnet much the same

Rosco86 - 16/9/15 at 08:11 PM

quote:

Originally posted by Neilwilson

The effort that you have/are putting in is outstanding, definitely reflected in the quality of your build.

Really like the personal emblem, I can imagine at some point you will have a badge on the bonnet much the same

Thanks mate, it means a lot, it's hard to keep it up week in week out but if I don't I won't be happy

As for the badge, I may already have made it

Digimon - 17/9/15 at 08:11 AM

I take my hat off to you sir the attention to detail in each part is amazing!

Adamirish - 17/9/15 at 03:55 PM

As everyone else has said, the attention to detail is incredible in your build, I can't wait to it finished and used in anger. When do you hope

it will be on the road? Are you not worried when you finish?

Rosco86 - 17/9/15 at 07:45 PM

Wow thanks guys,

As for finish date it's done when's it done but I am spending all my spare time on it as I want it finished, I would like to be somewhere

near in the start of next year

Rosco86 - 17/9/15 at 07:54 PM

Well finished my fuel rail bracket off tonight, just got to make a few bosses for it

Then onto the handbrake cables, I thought this would be an easy job but it wasn't, the cables weren't really long enough and not sitting

nicely, I was ready to leave it for tonight then I thought about making some exstention tubes

The cables are a snug fit in the tubes and locate on 50mm also it stops them from rubbing on the diff

I just need to make a couple of brackets to hold the cables in place off the wishbone bolts

I've removed the adjuster from the cable but I will still have adjustment on the cable end fitting as it has grub screws in

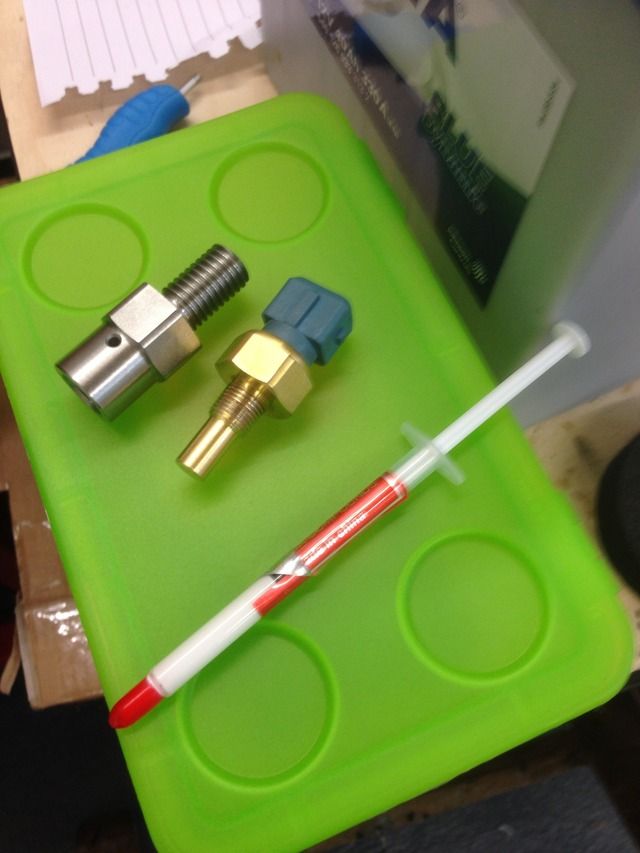

Rosco86 - 19/9/15 at 05:08 PM

Well more done today, made some little crush tubes for the fuel rail, also I've vapour blasted the bracket to make it look at bit more factory

Also I've started making a new gear lever, just the lower bit with the bearings in as its a bit of a bodge lol

Rosco86 - 20/9/15 at 04:56 PM

More done today, loads of bits and bobs to do, got my clutch cable sorted, had to make a bit at the pedal end and solder a bit on the other end, it

wouldn't solder to start with, to hot I think, but got it done in the end.

Also got all my aluminium engine cradle spacers back on and tightened up.

Then went down my dads and made my air filter backplate ready for the itg filter, I got a drawing from ITG for the outside

Came out mint

Pretty much there now, just need a few holes in it for wiring, air temp and the fuel feed, also need some 3mm spacers under the trumpets to replicate

what was there before as it's got orings that seal everything

theduck - 20/9/15 at 07:26 PM

I'm sure it is me missing something, but if you use a JC50 filter won't you end up with the secondary injectors soaking it in petrol?

wylliezx9r - 20/9/15 at 07:53 PM

quote:

Originally posted by theduck

I'm sure it is me missing something, but if you use a JC50 filter won't you end up with the secondary injectors soaking it in petrol?

Don't think so. The secondary injectors and trumpets will sit within the dome of the filter.

theduck - 20/9/15 at 08:14 PM

See. Knew I was missing something!

Rosco86 - 20/9/15 at 08:19 PM

Yeah thats it, the filters going to cover the lot, it seemed like the best way, simple and easiest to make, also hopefully i wont have to cut to much

out of the bonnet, and it will be sucking cool air, im just a bit worried about the induction noise, but i will have just have to see

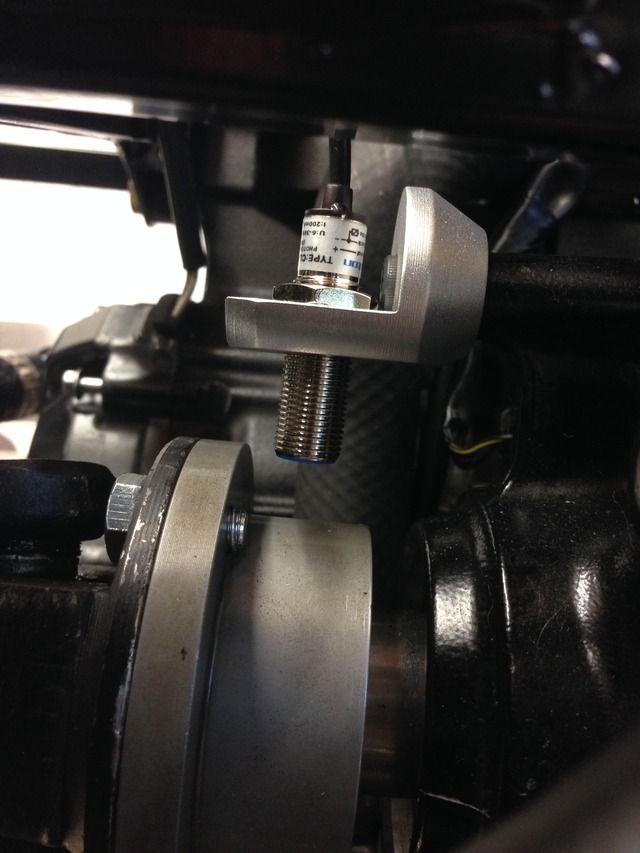

Rosco86 - 26/9/15 at 06:11 PM

Steering rack and track rods re fitted

When I re fitted the steering shaft my break pipe was in the way so I had to make a new one

Rear discs and pads fitted

Done a bit more on my inlet, fuel rail all fitted and fuel piped up

I removed the pins from the injector plugs ready to pass through a grommet but then decided I'm going to cut the lot and put a connector inline

so it's easily removed

Also my air filter came last week and fits sweet!

[Edited on 26/9/15 by Rosco86]

Adamirish - 26/9/15 at 06:27 PM

I know its hard to tell without the scuttle etc fitted but wont the filter stick out too far to see over the top?

Rosco86 - 26/9/15 at 06:47 PM