ZX9 engined Off road buggy - megasquirt install for turbo

dave_424 - 5/4/13 at 07:42 PM

Hi, I have an off road buggy that started life as a class 9 Autograss chassis, I then decided to fit a ZX9 engine and have some fun last summer as

seen here....

https://www.youtube.com/watch?v=zohqwFvNBak

Now I am progressing at university doing motorsport engineering, I wanted to turbo my engine for some more power and also high performance engine

experience. Now I was thinking of staying with the the stock ignition and carbs, but got fed up of changing jets, needles, needle heights and float

levels when trying to dial in the carbs in NA form.

So I decided to go with Megasquirt, I picked up an assembled DIYautotune MS2 v3.0 from someone local who went with an Omex instead, also got a loom

with it as well.

I couldn't use the existing stick coils from the ZX9 because these are CDI coils and Megasquirt doesn't really like them, so I foind myself

a Gen 1 fiesta coilpack which will do 4 cylinder wasted spark.

A second BIP373 had to be added to the megasquirt board for my second ignition coil driver which was pretty simple to do.

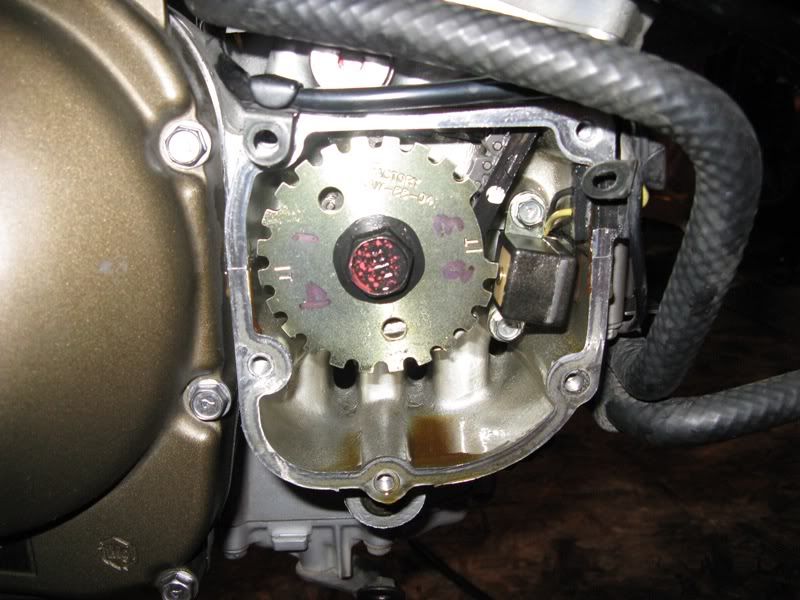

As many of you know Megasquirt usually needs a toothed trigger wheel and VR sensor to know engine speed and position, my stock trigger wheel looks

like this and not suitable for Megasquirt

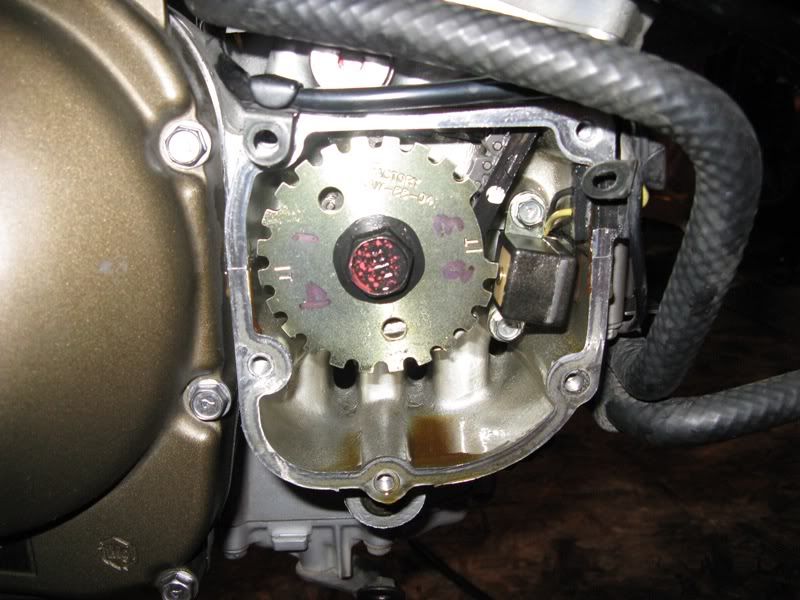

I found out that the later ZX9's and the z1000 (just a bored out ZX9) have a 24-2 trigger wheel which looks like this

This fitted straight onto my crank, and Megasquirt was giving me a nice looking tooth log using the standard VR sensor.

After a few hours of stripping out the old modified bike loom, making sure to keep the voltage regulator that deals with the stator/alternator so that

I would get it charging, I was ready to push the big red button.

I had guessed the number 1 tooth position to be at 135 degrees, since I didn't have a timing light I was just going to wing it, set it to 10

degrees fixed advance in TunerStudio. This 135 degrees and a few degrees around it gave me backfires through the carbs and partial ignitions that

would stop the cranking of the engine, this meant it was too advanced. I then increased my tooth angle until things started to sound better and at 270

degrees she fired right up.

Just missing a high pressure fuel pump and then I can get rid of the carbs and go full injection.

Stay tuned......

[Edited on 5/4/13 by dave_424]

matt_gsxr - 5/4/13 at 07:48 PM

Nice work. Finding an appropriate trigger wheel was genius.

There is some code and a circuit diagram on the MSextra site to deal with your long-tooth wheel, but I ended up making a 32-1 wheel from the 2-inch

and a stock wheel using a lathe.

I'll be interested to hear how your mapping goes. Having explored this it seems that you have to take TPS as well as MAP into account.

dave_424 - 5/4/13 at 08:00 PM

I was worried that I was going to have to have a toothed ring made that would press over my existing one once machined down, luckily I found out about

the later model wheels.

Once I can get it idling and free standing revving correctly, it will be going straight to Bailey Performance for mapping.

I currently haven't for any sensors other than VR sensor wired in at the moment, hence the fixed 10 degrees.

I can use hybrid alpha-n but I'm not too sure how that works with the tables

What I could do is use table switching, have one 16x16 table from 0-100KPA and then another 16x16 table from 100-250KPA, and have the tables switch at

100KPA, this would give me great tuning resolution in both on and off boost.

Dave

matt_gsxr - 6/4/13 at 11:34 AM

I have both a MAP and a TPS table and it multiplies. Seems to do a decent job but the autotune can't adjust them simultaneously so I have to

keep switching between then and allow it to iterate. It works reasonably. I couldn't get the wall wetting algorithm to work for me though and I

tried really quite hard on that.

Regarding sorting out mapping with multiply tables, the suggestion (from Dale) was to wedge open the wastegate, then map the TPS. Then after that map

the boost. Not sure whether he has tried that yet on ITB's which seem tricky to map. As far as I am aware there are only a small number of cars

that run Turbo and ITB as stock (Skyline, Pulsar are two) and I think they use MAF.

I don't have a rolling road (just a road) so it took me a while to get a decent tune. Still more I can do with ignition timing, but wary of

detonation.

Matt

dave_424 - 6/4/13 at 11:44 AM

How have you been finding the autotune in general? does is do what is says on the tin?

Tuning the fuel tables seems pretty simple to me, I just don't really know what to do with the spark tables, I know that there is a certain

general rule of thumb to retard x timing per psi of boost, but it seems like a rolling road is needed to tune ignition maps.

Since I have an external wastegate I can just unbolt it from the manifold, or remove the spring from inside it which should stop me boosting, I plan

on having just a 3 inch 45 degree pipe coming from the turbo dumping out the side of the engine, also a straight dump pipe from the 38mm wastegate,

hope it won't be too loud for where Dale is located