Benzine

|

| posted on 2/6/14 at 01:35 PM |

|

|

Welding a pulley

I've made a pulley for my supercharger (Eaton M62). It's from a Merc that used a clutched pulley, so it is splined. Instead of spending

daft money on a custom pulley, I found an air con pump shaft that had the same splines. So I got an alternator pulley from the scrap yard, and turned

the center hole to accept the air con shaft. It slotted in nicely and ran true.

The problem is, as soon as I weld it, it distorts. I welded the whole thing up and when running it's slightly off true.

I've had it in the lathe again and taken it apart and got it running true, is there any way I can weld it so it doesn't end up spinning

all out of kilter? Heat the pulley and shaft up in the oven/blowtorch before welding?

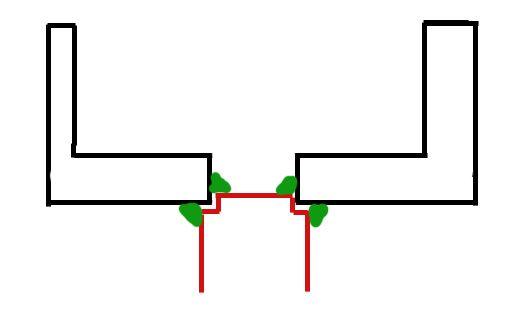

Black - alternator pulley, red - shaft, green - weld. As you can see the shaft doesn't go in very far which isn't helping.

[Edited on 2-6-2014 by Benzine]

|

|

|

|

|

nick205

|

| posted on 2/6/14 at 01:52 PM |

|

|

Could you bolt the pulley to the shaft instead?

Sounds like you have a lathe, so maybe bore/thread a hole in the shaft and bolt it up tight with some thread lock. The splines are doing the locating

and keying part and that way it's removable if you need to in the future.

|

|

|

r1_pete

|

| posted on 2/6/14 at 02:21 PM |

|

|

I can't see your pictures, bloody work proxies, but, if your shaft doesn't go in very far, I fear you will soon get wear and the pulley

running out of true anyway, however you fit it...

|

|

|

dinosaurjuice

|

| posted on 2/6/14 at 02:27 PM |

|

|

how about welding a round plate to the shaft, skimming it up on lathe and then bolting pulley to that?

could even machine a small spigot on to ensure concentricity.

|

|

|

Oddified

|

| posted on 2/6/14 at 04:39 PM |

|

|

Tack weld it in a few places, back in the lathe to check for running true (straighten with a hammer if needed) and then weld it up properly.

Ian

|

|

|

Benzine

|

| posted on 2/6/14 at 05:56 PM |

|

|

Thanks for the input. I think I'll try tacking first. I won't be able to bolt the pulley on as I'm using such a small pulley,

there's no room round the nut that tightens it to the S/C. If the tacking and checking doesn't work I'll start again with a new

shaft and new pulley and make the whole thing much meatier.

|

|

|

mark chandler

|

| posted on 2/6/14 at 07:16 PM |

|

|

It will be pulling 30bhp off the crank, needs to be very strong as also flying over at 11,000 rpm +

|

|

|