How hard is it to construct a small say a3 size home cnc and use it to make small parts and engrave stuff

Bear in mind I'm a complete novice I just think it would be a cool toy

[Edited on 13/4/14 by carlknight1982]

Easy! But not all that cheap. All bits available from http://www.worldofcnc.com/collections/cnc-router-packages. Have a look at the Artsoft forum.

Took two years out of my life don't do it:

http://www.alastair-reynolds.pwp.blueyonder.co.uk/milling/

I'm not looking to convert a manual mill

I'm thinking more like these

linky

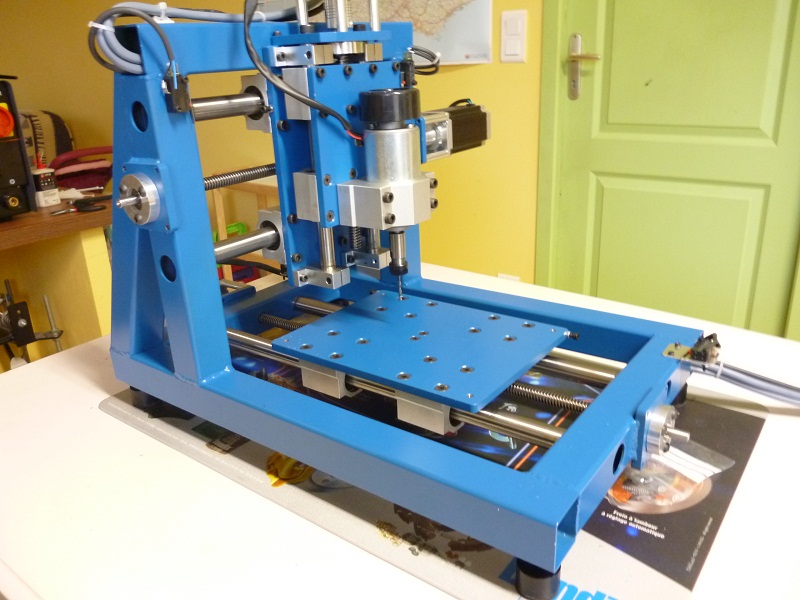

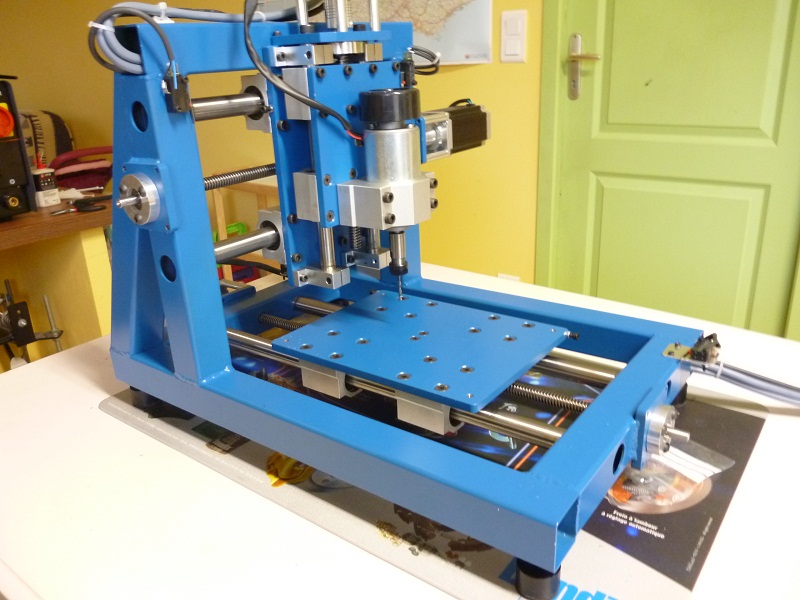

mild steel is cheaper and stronger that ali, mine:

I started to build one 5 years ago then got into building my car

Sold my frame but still got all the motors and built my own controller and pc alonh with it would sell if any one is interested

Rigidity is what you want, not strength.

I'm about 1200 quid into a manual mill conversion because I saw some routers in action, spoke to some machinists and concluded what most do after

a router build - they're only really good for wood and 2.5D.

If you just want to do engraving keep an eye out for old camm 2 machines

or even the early Denford micromill stuff

Atb

Mike

As others have said, the problem with CNC milling is you need a good strong rigid machine. I have converted an X2 type machine to CNC and ended up

making braces, filling columns with concrete etc. The small machines look nice in theory, but when you end up doing things like taking 0.1mm depth

cuts the time taken to machine parts becomes very tedious - often simple parts can end up taking hours. To give an idea of scale I have a Denford

Triac which I rebuilt. My old mill could be picked up by one person, the Denford is over 1/4 ton!

Have you considered 3d printing? Low forces so everything can be much lighter.

[Edited on 14/4/14 by davidimurray]

Hadn't considered that as an option

I've been pondering building a 3d printer myself. Seems to be lots of versions out there.

There is some good info here - http://reprap.org/wiki/Build_A_RepRap

I was considering builidng a prusa of which there is a newer version out - http://reprap.org/wiki/Prusa

3D printer is a good novelty but what would you actually use it for?

Be amazing if you could print in wax and had access to a foundry to turn the printed item into something useful....

quote:

Originally posted by tegwin

3D printer is a good novelty but what would you actually use it for?

Be amazing if you could print in wax and had access to a foundry to turn the printed item into something useful....