Hadders

|

| posted on 4/2/13 at 07:00 PM |

|

|

Bell crank for gearchange - construction question

I'm about to make one and I'm wondering:

1. what's the thinnest sheet successfully used for a bell crank (i have some 3mm and 10mm ali kicking around)

2. did you find there is an optimum size (e.g bigger to allow multiple mounting points to experiment with sensitivity/feel of gearchange)

What lessons did you learn? Any info to speed up the process would be most appreciated.

Many thanks

Ben

|

|

|

|

|

Andy B

|

| posted on 4/2/13 at 07:30 PM |

|

|

Hi Ben

think I have several lying around the unit from old projects - you are more than welcome to them - doesnt really shed light on the construction but

might save you time - i think one is off a Westy

regards

Andy

|

|

|

Hadders

|

| posted on 4/2/13 at 07:48 PM |

|

|

Cheers Andy. That's very good of you. I'll send you a U2U in a second.

|

|

|

adithorp

|

| posted on 4/2/13 at 08:00 PM |

|

|

Mine is made from 5mm steel. I found the important thing was stiffness of all the components. Any flex in the bell crank, rods or pivot and the

gearchange isn't good.

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|

Hadders

|

| posted on 4/2/13 at 08:11 PM |

|

|

Thanks Adithorp.

What size is your bell crank?

|

|

|

adithorp

|

| posted on 4/2/13 at 09:37 PM |

|

|

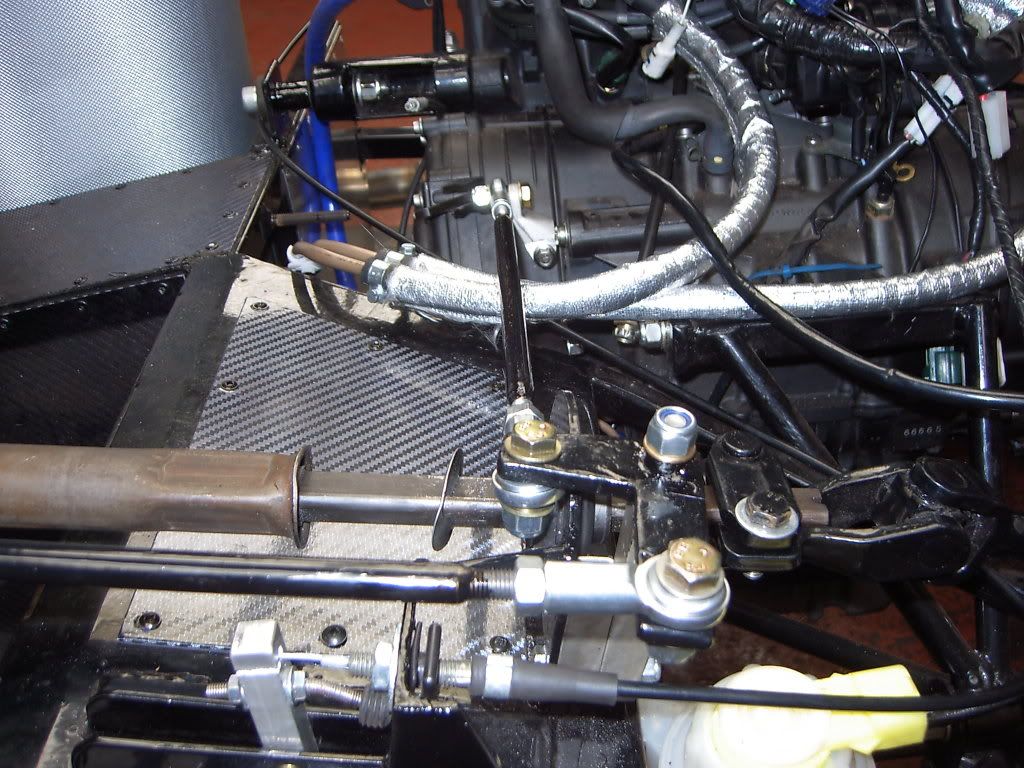

Best picture I could find...

"A witty saying proves nothing" Voltaire

http://jpsc.org.uk/forum/

|

|

|