its early in the morn....im still sleepy...

will edit...

[Edited on 5/5/10 by boggle]

hi everyone...

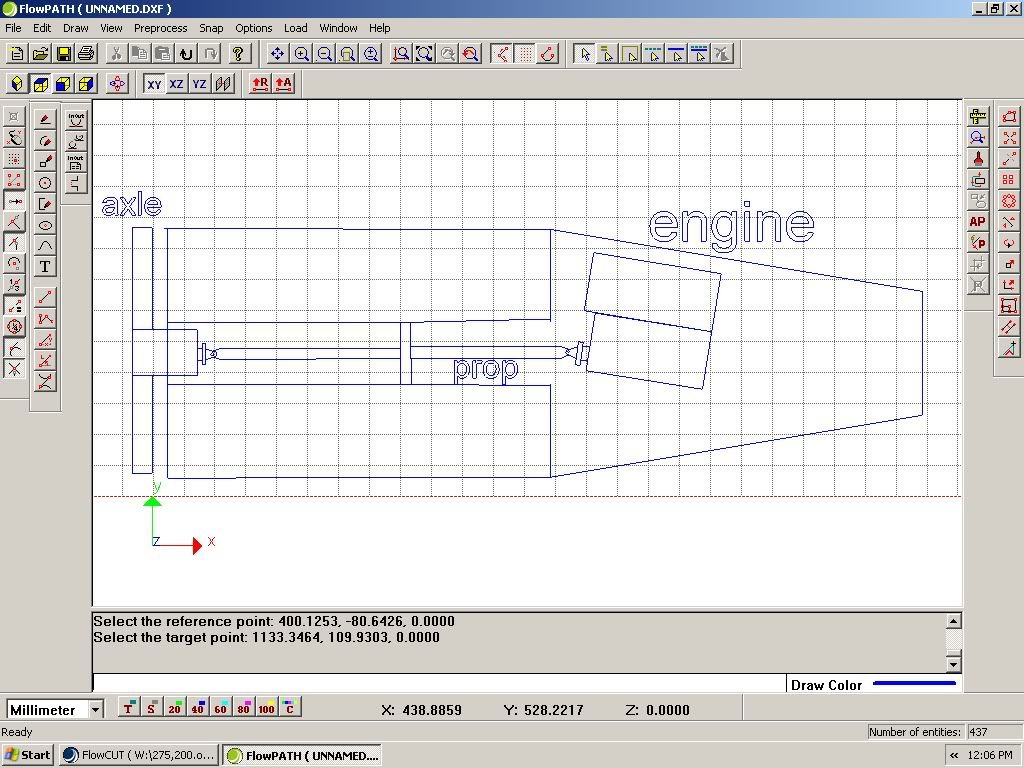

started to locate my blade engine in my locost last night and wasnt too sure what position it should sit at???

should the prop adaptor look as though it is in line with the tunnel or should it look like the prop will run out at an angle?

any pics of engine position would be awesome...

also how much should the sump be showing under the chassis ???

many thanks

barry

[Edited on 5/5/10 by boggle]

Sorry.. can't help on this one Barry, but I have to ask... what's a 'balde' engine?

haha....

its early in the morn....im still sleepy...

will edit...

[Edited on 5/5/10 by boggle]

Boggle, here's a few pics of a Blade motor in a Stuart Taylor chassis.

The prop here runs straight but I was looking at one of the MK chassis' at stoney

and that had the engine parallel with the front chassis rail and the prop at an angle.

Not a bad idea as it avoids the front being so close to the top rail.

Blade install 3

Blade install1

Blade install 2

[Edited on 5/5/10 by NigeEss]

[Edited on 5/5/10 by NigeEss]

Just a thought, i also saw the MK one and saw the prop at an angle. Surely you would loose a vast amount of power having it at an angle? Maybe im

wrong, but my guess is if you can, to mount it in line!

Ed

the engine seems to fit better at an angle, and i cant see how you would loose power from the prop being mounted irregular.....the uj should keep it

all good???

please give me your theory edd???

Just would have thought that the UJ would reduce the power. Maybe this is a very little amount and not worth trying to mount it straight... As i said, probably wrong!

Most are mounted as close to the scuttle as possible (for better weight distribution, front mid-engined and all that) and at an angle simply because of the necessary clearance with the side frame rail, and of course the exaust downpipes (unless you are having bespoke pipes made.

i agree with you to a point, just trying to work out if it would cause a problem....i will have 3 other ujs in the prop setup and a slider, so now im

thinking that these may also drain some of the power??

aren't they supposed to be on a slight angle?

do a search her on brinnel on here, and you will see why people don't run straight prop-shafts.

I don't think that these is an appreciable power loss as the UJ's are well lubed and don't get hot.

Matt

Not a blade (R1) but not a lot of difference. We tried to keep the weight down by not adding too much of a cradle for the engine and bolted it

straight to the chassis. This sits square (leaving the prop output at 90 degrees to the prop) although there's an angle in the vertical plane to

the fixed diff.

Rescued attachment header tank install.JPG

With universal joints the faces of the prop flanges should be as parallel as possible, but slightly out of alignment so the rollers are kept

moving.

If they aren't parallel it can cause vibration and premature wear, but if its only a slight angle it will be negligible. Mine's a couple of

degress out to give extra clearance on the top rail.

at the mo it looks something like this

Ideally, the propshaft flanges of the diff and the engine will be parallel in both planes, and slightly offset so that there's a slight angle on each UJ as they don't like being run straight. Personally I try to keep the propshaft angles as small as possible, but I don't think there's really an issue which larger angles such as those used on the MK installation.