J666AYP

|

| posted on 13/11/17 at 02:21 AM |

|

|

Hi Angel,

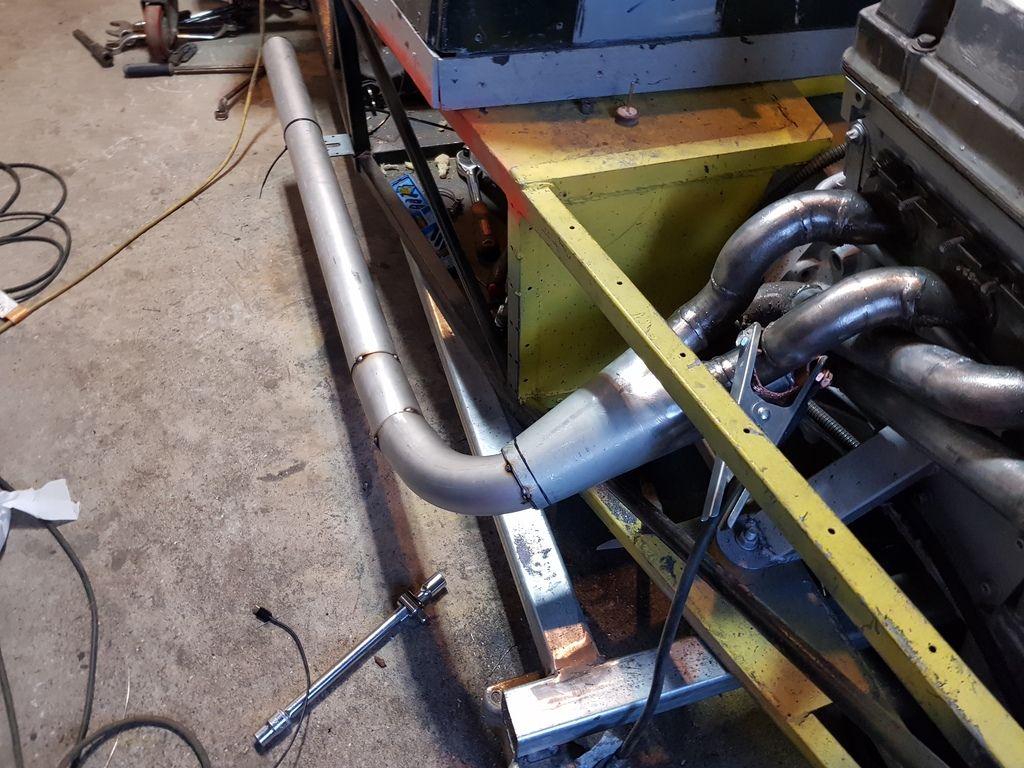

The manifold pipes in the pic are 2mm wall thickness, this is just to make sure it does not crack when it heats up/cools (I'm not experienced in

welding so better to do it once than twice). These lead into a 1.6mm wall merge pipe and then out to the 1.6mm exhaust.

Jay

[Edited on 13/11/17 by J666AYP]

|

|

|

|

|

big_wasa

|

| posted on 13/11/17 at 05:35 PM |

|

|

Not to porky the. Worth thinking about, thanks.

[Edited on 13/11/17 by big_wasa]

|

|

|

scudderfish

|

| posted on 13/11/17 at 06:05 PM |

|

|

quote:

Originally posted by J666AYP

Craigdiver,

Thanks mate! In all honesty I was expecting alot of negative responce for using something abit different. I have had a look at your thread, shes going

to be fun for sure!

Jay

[Edited on 12/11/17 by J666AYP]

This is LCB, not a Caterham owners site

|

|

|

J666AYP

|

| posted on 14/11/17 at 10:22 PM |

|

|

Scudderfish,

Very good point well made.

Jay

|

|

|

J666AYP

|

| posted on 24/11/17 at 09:13 PM |

|

|

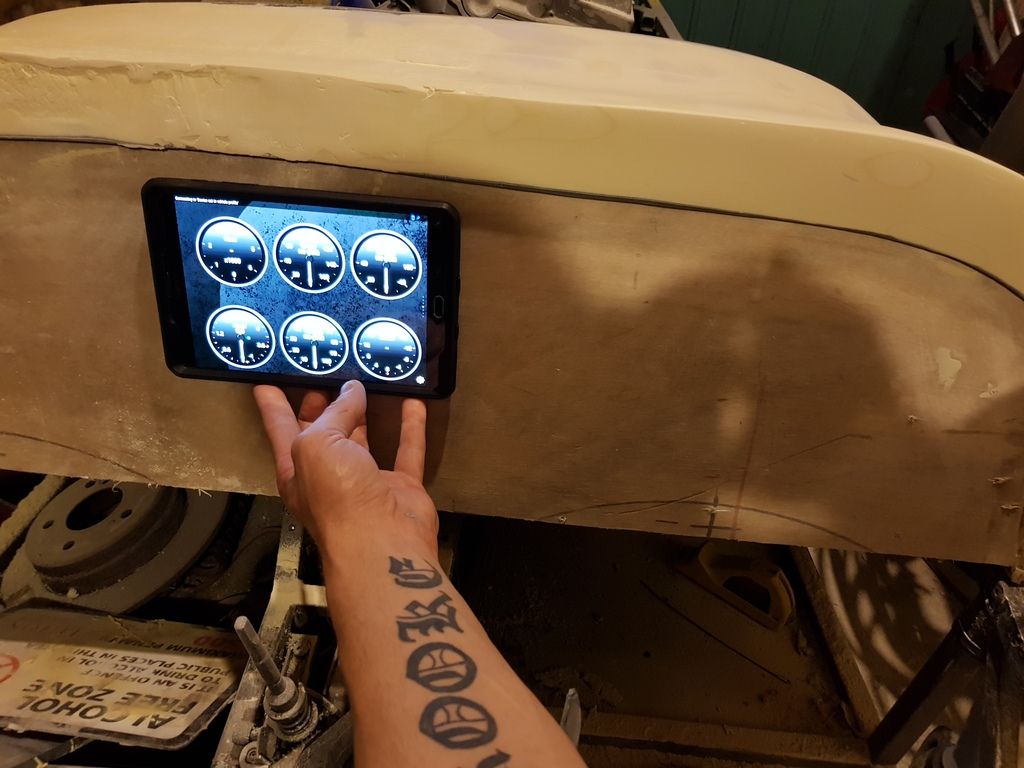

Got bored today so I thought I would do some work on the scuttle that did not fit....

Going to use this to make a fibreglass one.

|

|

|

J666AYP

|

| posted on 1/12/17 at 05:43 PM |

|

|

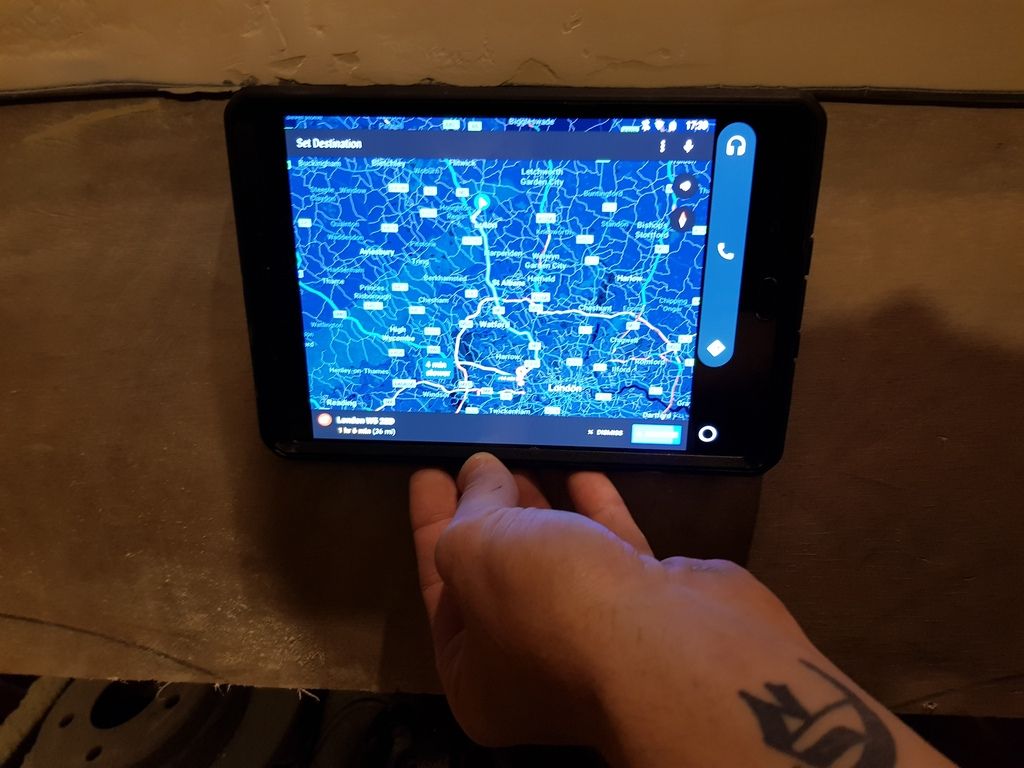

This could work... Satnav, basic data logging, on the go faul reading and bluetooth connection to the gopro! will still use a normal digi dash for

speed to keep Mr IVA tester happy.

[Edited on 1/12/17 by J666AYP]

|

|

|

scudderfish

|

| posted on 1/12/17 at 06:01 PM |

|

|

Make sure you can read it in direct sunlight.

|

|

|

J666AYP

|

| posted on 1/12/17 at 06:12 PM |

|

|

It has a sort of matt plastic cover over the screen to reduce sun glare, going to recess it abit aswel so it should work.

Plus the sun only comes out for two days on the average UK summer lol.

|

|

|

J666AYP

|

| posted on 1/4/18 at 08:03 PM |

|

|

Its been a busy winter at work so not much has been done. I have stitch welded the entire chassis joint by joint and started working out a few other

bits. (welding done the other day after these pics were taken).

Jay

[Edited on 1/4/18 by J666AYP]

|

|

|

Ian2812

|

| posted on 2/4/18 at 12:44 AM |

|

|

Very interested in this build...

Looks like you are hard at work creating a beast of a car here...

How long do reckon this will take to complete, and are you getting it road legal or track car?

Can't wait to see this one progress and see it when completed.

Good luck!

|

|

|

J666AYP

|

| posted on 2/4/18 at 03:00 PM |

|

|

Thanks mate! has been alot of hard work so far.

I'm hoping to have it road legal for summertime 2020, having it done sooner would be nice but im too busy at work to get much time in the garage

Plus trying to hide money from the mrs with a wedding to pay for is proving difficult lol.

Jay

|

|

|

Ian2812

|

| posted on 2/4/18 at 05:50 PM |

|

|

Haha! I hear you with the wedding...

You haven't do too badly money wise up to now though, (with the costs you've advertised,) but its time that's more of an issue

isn't it when building.

Keep the pics coming...

|

|

|

J666AYP

|

| posted on 2/4/18 at 07:32 PM |

|

|

Yeah she seems to think dresses are more important than cars.... I will educate her!

And so far it owes me about 1k all in so not doing too bad.

And tell me about it, as soon as you change one bit that creates three more bits that need to be made or moved  must have had that engine out

atleast 10 times by now. must have had that engine out

atleast 10 times by now.

Jay

|

|

|

J666AYP

|

| posted on 3/4/18 at 05:08 PM |

|

|

Todays efforts...

|

|

|

froggy

|

| posted on 3/4/18 at 05:31 PM |

|

|

Where is the throttle situated ? The Merc used a big pwm operated bypass to stop any damage caused by shutting the throttle from high boost

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

J666AYP

|

| posted on 3/4/18 at 06:10 PM |

|

|

I have ditched the standard electronic bypass/recirculation system.

Im using a dumpvalve and redirecting the excess charged air back into the induction system. Pretty basic but a whole lot less agro than trying to run

merc electronic systems off aftermarket management.

Jay

|

|

|

froggy

|

| posted on 3/4/18 at 07:03 PM |

|

|

So the throttle is after the blower and intercooler?

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

bi22le

|

| posted on 3/4/18 at 08:01 PM |

|

|

quote:

Originally posted by J666AYP

I have ditched the standard electronic bypass/recirculation system.

Im using a dumpvalve and redirecting the excess charged air back into the induction system. Pretty basic but a whole lot less agro than trying to run

merc electronic systems off aftermarket management.

Jay

When (if ever!!) I get around the SC my 4age I was going to use this sort of thing for my M62. My plan was to run the correct ratio pullies to get the

SC spinning fast enough to produce about 2 bar boost at about 6K. I believe 2bar is as good as these chargers can do before they become really

inefficient. The bonus with this set up is that it can hit 2 bar earlier than max revs, providing more low down power and torque. Also as these are

positive displacement chargers it wont 'waste' as much energy because its not putting more effort in as the revs increase (pressure is

staying at 2bar). My final thought is that the M62 is large for my 1.6l engine and therefore it wont have to spin that hard to displace the air

required to create the pressure, again improving efficiency.

https://www.ebay.co.uk/itm/Forge-Splitter-Recirculation-Blow-Off-Dump-Valve-FMDVSPLTR-1-8-Turbo-BLACK-/121868713362?clk_rvr_id=1488294637192&utm_m

edium=cpc&utm_source=twenga&utm_campaign=twenga&utm_param=eyJlcyI6MCwicyI6OTcyMDIzNywiY2kiOiIwMzM1MzNhNDU1NTkxNjZlYzM1ZDIwYTBlN2MwNjdjMCIs

ImkiOiIxMjE4Njg3MTMzNjIiLCJ0cyI6MTUyMjc4NTAwMCwidiI6Mywic28iOjE1MDAsImMiOjEwNzA2M30%3D&rmvSB=true

Dial in the spring preload to 2 bar, dump the hot air out and away from the intake to improve air density.

Broom broom.

Track days ARE the best thing since sliced bread, until I get a supercharger that is!

Please read my ring story:

http://www.locostbuilders.co.uk/forum/13/viewthread.php?tid=139152&page=1

Me doing a sub 56sec lap around Brands Indy. I need a geo set up! http://www.youtube.com/watch?v=EHksfvIGB3I

|

|

|

froggy

|

| posted on 3/4/18 at 09:01 PM |

|

|

quote:

Originally posted by J666AYP

I have ditched the standard electronic bypass/recirculation system.

Im using a dumpvalve and redirecting the excess charged air back into the induction system. Pretty basic but a whole lot less agro than trying to run

merc electronic systems off aftermarket management.

Jay

The electronic valve is there to catch the spike in pressure as the throttle shuts . With the throttle post charger there will be a delay from boost

to vacuum which puts pressure on the bearings in the charger , I ran twin throttles as some mx5 conversions do or use a large diameter bov to help

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

J666AYP

|

| posted on 3/4/18 at 09:18 PM |

|

|

Froggy,

"The electronic valve is there to catch the spike in pressure as the throttle shuts . With the throttle post charger there will be a delay from

boost to vacuum which puts pressure on the bearings in the charger , I ran twin throttles as some mx5 conversions do or use a large diameter bov to

help"

I dont think im on the same wavelength mate....

Even the standard merc setup uses the electric throttle type thing after the charger? As far as I understand it all it does is dump excess boost back

into the airbox to reduce pressure drops? would a DV not do the same thing if routed into the airbox?

Also would it not make sence to mount this after the intercooler so im blowing cold air back into the inlet instead of hot air?

Confused.com

Jay

[Edited on 3/4/18 by J666AYP]

[Edited on 3/4/18 by J666AYP]

|

|

|

J666AYP

|

| posted on 3/4/18 at 09:23 PM |

|

|

|

|

|

froggy

|

| posted on 3/4/18 at 09:44 PM |

|

|

Itís a by pass and being electronic it will open before the throttle shuts where a vac operated valve will need enough vac to pull the bypass open .

Itís a mechanical pump at the end of the day so pumping against a shut throttle will put load onto the bearings in the charger . Youíll need a valve

around the same size as the original

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

J666AYP

|

| posted on 3/4/18 at 09:52 PM |

|

|

Hmmm okay.... that makes sence. So in theroy a large dump valve could do near enough the same thing with out all of the electrical nightmares as long

as it has the correct spring for the boost levels?

If that idea fails how would one go about rigging a 2nd mechanical throttle to open when needed? or is the only real way round it to go electric?

Jay

|

|

|

froggy

|

| posted on 3/4/18 at 10:08 PM |

|

|

Throttle pre charger will stop any issues , the little Mini Cooper bypass valves are only £30 and plenty big enough if you run a throttle in front of

the charger

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

J666AYP

|

| posted on 3/4/18 at 10:51 PM |

|

|

Are those mini ones vac operated?

Heres a pic I got off google (sorry if its anyones).

So the flanged end would have a MAP/MAF sensor and then the cone filter?

[IMG]http://i1237.photobucket.com/albums/ff462/jayxr2zetec/ysSv0IY7.jpg[/IM

G]

Jay

[Edited on 3/4/18 by J666AYP]

|

|

|