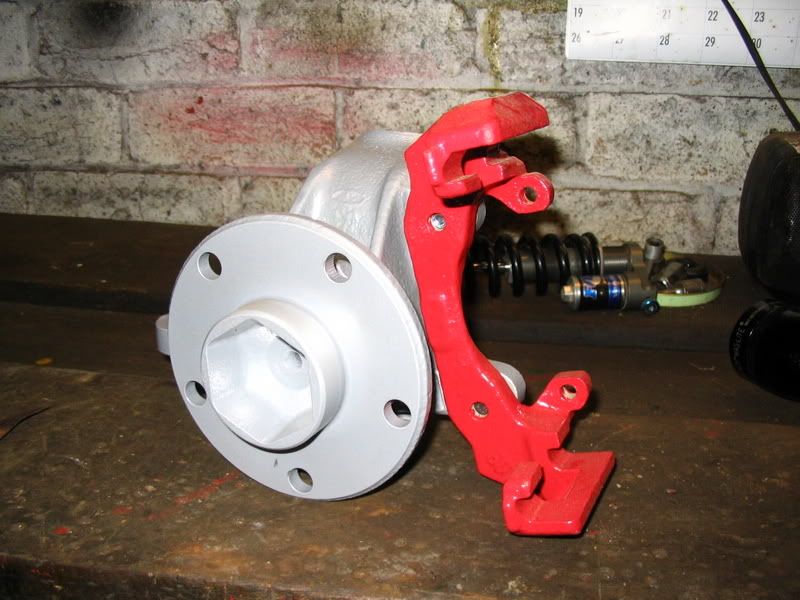

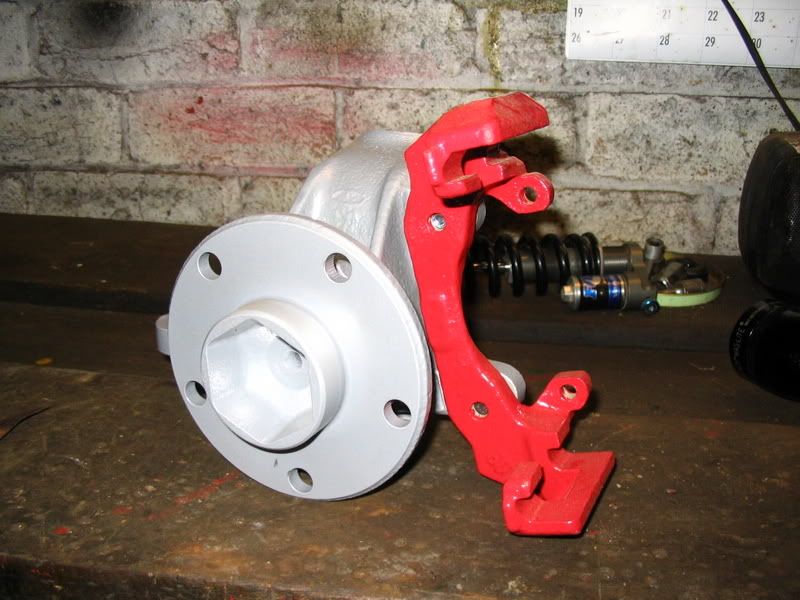

painting my uprights

mrwibble - 29/7/10 at 05:24 PM

Another day another question.

Here are my uprights before

after electrolysis + wire brush + power file.

any who after a bit more polishing, i'm going to paint them with rustoleum, i'm just wondering whether to paint the spinny bit with the

bolts on (hub carrier?), obviously i dont want to create any friction between the spinny bit and the meaty bit, and/or affect the mating surface onto

which the disc sits.

regards Ed.

graememk - 29/7/10 at 05:49 PM

have them chromed for extra bling

mcerd1 - 29/7/10 at 05:56 PM

I powder coated mine  but I stripped them down first and rebuilt with new bearings

but I stripped them down first and rebuilt with new bearings

omega0684 - 29/7/10 at 06:42 PM

from experience get them done in Black! they won't stay silver for long i can tell you!

mrwibble - 29/7/10 at 06:44 PM

best not to give me too many ideas. but you've proved i can paint the hub. replacing the bearings sounds like a good idea... how do u get inside?

mcerd1 - 29/7/10 at 07:02 PM

^^ nothing to difficult and its all in the haynes book:

dust cap comes off the back (try to save it - you might find it hard to get new ones)

then there is a big nylock nut

one side is left hand threaded, the other side right hand - make sure these go back on the correct sides of the car or they could undo themself as you

drive

(you get new nuts with the new bearing kits)

there is a ridge in the midle of the upright so each outer bearing race comes out from its own side (you'll need a punch to persuade them)

best to press the new outer races into place if you can

you'll need a big torque wrench to tighten them (310-350Nm from memory)

and some high temp lithium grease to pack the bearing with

[Edited on 29/7/2010 by mcerd1]

omega 24 v6 - 29/7/10 at 08:44 PM

The wheel mounting face should NOT be painted/coated at all.

RichardK - 29/7/10 at 09:37 PM

Maybe worth drilling them and tapping them for the second method of mushroom inset fixing before you paint them, again not good engineering practice

to paint any faces, I would also repe the bearing whilst they are out and apart.

Just my 2 penneth well deposited.

Cheers

Rich

RichardK - 30/7/10 at 10:57 AM

u2u replied but so others can see what I have described.

Hole drilled through side of upright and either into or all the way through mushroom.

Tapped out the upright

Job done!

mrwibble - 30/7/10 at 12:46 PM

i understand what your saying, but ford engineered these to be secured by a pinch bolt, does anyone have a story about that failing?

interestedparty - 30/7/10 at 12:54 PM

there's a tongue on the strut on the Sierra I suppose the idea is to stop the mushroom turning and comilg loose that way

James - 30/7/10 at 01:42 PM

quote:

Originally posted by omega 24 v6

The wheel mounting face should NOT be painted/coated at all.

Agreed. Unevenness in the paint threw my brake discs out enough that they caused a wobble and were rubbing on the brake pad and stopping the wheel

turning properly.

Cheers,

James

James - 30/7/10 at 01:45 PM

quote:

Originally posted by mrwibble

i understand what your saying, but ford engineered these to be secured by a pinch bolt, does anyone have a story about that failing?

I've not heard of anyone's failing.

But the point, is that a fair few people have failed IVA over this. So depending on your inspector, it's worth doing to save failing the test

for!

Cheers,

James

mrwibble - 31/7/10 at 08:35 AM

ah i see. but for a fury i need not worry, bgh supply a machined ring, which the ball joint is threaded into, this cap has a tongue as used by ford. i

did not see(read look) in RichardK's pics that he was missing this.

Lippoman - 31/7/10 at 08:52 AM

quote:

Originally posted by mrwibble

i understand what your saying, but ford engineered these to be secured by a pinch bolt, does anyone have a story about that failing?

Ford engineered them for a strut, not a double A-arm. With a strut there is "always" force pushing the strut into the upright ...

Also the lower joint is in a completely different load case than in the original application. Usually you get away with it in a locost as less

weight=less load.

mrwibble - 31/7/10 at 09:28 AM

i see. fortunately jeremy phillips seems to have thought of this already.

Lippoman - 31/7/10 at 11:12 AM

Sorry, didn't notice you seem to be building a Fury(?), the loads in that one are similar to original application.

I assumed your front to be similar as the one pictured earlier in thread, where the upright is "hanging" from the lower arm (spring/shock

attached to lower arm). These need a lower joint designed for the application.

mrwibble - 31/7/10 at 11:51 AM

fury suspension. note the use of the pinch bolt through a machined ring, with a tongue, to cap where the strut would go.

but I stripped them down first and rebuilt with new bearings

but I stripped them down first and rebuilt with new bearings