Bodywork for CANAMSA

Fred W B - 18/4/06 at 02:30 PM

You guys may have noticed that I have not posted any progress updates on my project for a while. That is because, on top of some domestic projects

getting in the way, significant progress has been made on a desk and in a computer, and not in the garage.

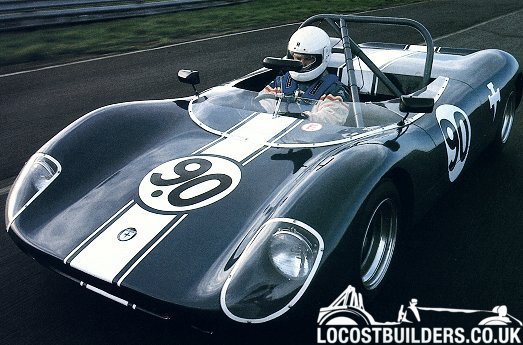

I posted previously (a long time ago) that I had purchased a 1:18 scale model of a Lola T70 Spyder, and that someone had undertook to measure it up

for me on a 3 axis digital machine, "when he gets a chance". Problem is that he never did, so after over a year of waiting I went and got

the model back.

In order to measure it myself, I made up a simple 3 axis measuring jig from alloy channel section and flat, steel rules, a straight edge and a digital

vernier. Then with the aid of a colleague Andrew, I measured the offset of the body surface from the datum base at every point on a 5 mm x 5 mm grid,

and recorded the measurements on a large piece of paper

Andrew then used this data and many reference photo's to draw the body surface in Inventor - One sentence that describes many hours of work.

Now we are using that data to produce drawings of many flat body sections (stations every 100 mm in the length) and some longitudinal stringers to

position them, in DXF file format.

These will then be cut out on a CNC router from 8 mm plywood sheet, in order to start building the body plug. The router can handle 8' x 4'

sheets.

I had promised myself that I would wait until I had pictures of the buck in construction before posting on my body progress, but I wanted something

auspicious to be my 500th post.

Please see photo and screen shots below. The ribs screenshot I show is not yet complete.

Cheers

Fred W B

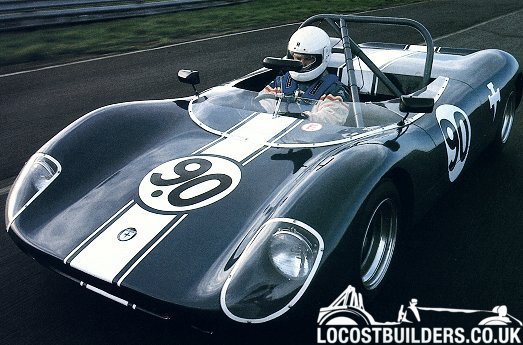

donahue 70

[Edited on 18/4/06 by Fred W B]

Fred W B - 18/4/06 at 02:32 PM

[img][/img]

Fred W B - 18/4/06 at 02:33 PM

body2

Fred W B - 18/4/06 at 02:35 PM

[img][/img]

emsfactory - 18/4/06 at 02:55 PM

That is very cool.

RazMan - 18/4/06 at 03:58 PM

Huge respect to you Fred - the collation of all those measurements must have taken loads of time to do.

Judging from the ribs pic you have been very thorough too

Krismc - 18/4/06 at 06:19 PM

wow good luck with rest of project!

liam.mccaffrey - 18/4/06 at 07:05 PM

muchos repect

jimmyjoebob - 18/4/06 at 08:05 PM

Looks awesome - You have way more patience than me!

As a complete aside, Gardner Douglas are now selling a Lola T70 spyder kit in the UK.

When you have made your own moulds, are you planning to make a few more to sell?

C10CoryM - 18/4/06 at 10:18 PM

Looking good. Ive played with 3D programs so I know how much work that is. When I went to the monterey historics last year I met up with a guy from

another forum who races a 1965 T70. (Yes I sat in it and made vroom vroom noises  )

)

Anyhow, he may be willing to help you on some points. He is pretty busy though so may not be able to.

His website is here:

http://www.pozziracing.com/

Cheers.

Fred W B - 19/4/06 at 11:04 AM

Hi guys, thanks for responses, and in particular C10CoryM for the very useful Link.

At this stage I am not planning to build more than one car, but you never know?

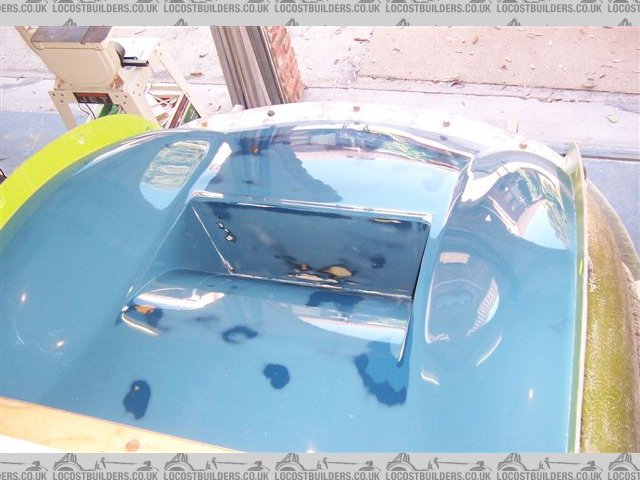

The link has helped explain something that has puzzled us, that being what should the rad exit duct (on top of the nose) and the body shape surronding

the front brake air duct/driving light openings look like. Turns out there were mark 1 and mark 2 versions. The mark 1 has a small square rad exit

duct- see scale model above, with "flat" round brake air duct/driving light openings - see light blue car, while mark 2 had a wider tapered

rad duct, with brake air duct/driving light openings that seem to be more oval, and follow a smoother nose shape than the mark 1 - see mono picture .

The GD replica 70 seems to use a mark 2 style rad duct, with mark 1 style driving light openings - see dark blue car.

Originally I had not intended to attemp an exact replica, to stop any pedantic's telling me I have this and that detail wrong but now that I am

going to all this trouble, it seems a pity not to get it as right as I can.

So which one do I follow? I prefer the mark 1 rad exit duct, and the mark 2 brake air duct/driving light openings. I suppose I could do it that way,

and call the car shape a tribute to a T70 spyder. Then again, presumably the nose was modified because of cooling problems. Currently our model is a

mark 1.

How did people do this sort of thing before the internet??

Regards

Fred W B

[img][/img]

Fred W B - 19/4/06 at 11:08 AM

[img][/img]

Fred W B - 19/4/06 at 11:10 AM

gd 70

jimmyjoebob - 21/4/06 at 07:55 AM

Lola T70 has to be one of my favourite racing cars. What weight will yours be? Power to weight?

Fred W B - 21/4/06 at 11:26 AM

The targets would be 750kg (or less?) and 250 HP (eventually)

Cheers

Fred W B

Browser - 24/4/06 at 10:45 AM

Awestruck at your dedication and cleverness

When ya gonna build a Porsche 917/30 rep?

Or maybe a Chaparral 2E?

sgraber - 25/4/06 at 07:29 PM

Hi Fred, Glad to see someone else taking up the task! Your work looks awesome!

I'm sure you have the process well in hand and therefore my suggestions may seem redundant. I'll post them for the benefit of others just

casually looking in on your project.

If you recall I did the same cross-section thing with my 3D model (except it's my own original design) and then went to cad drawings which were

taped to the wood sheets and cut with a jigsaw. I used 22 ribs along the length and interpolated the curvature. I don't know if you will need as

many ribs as you have shown?

You will want to have as solid a substructure as possible. I have found my 2x4 structure woefully inadequate. And whatever you do, don't use

styrofoam and drywall plaster!

When you get out to the plug surfacing stage and are at a mirror finish, if your substructure is not rock solid,

the mirror surface may appear to 'crawl' and move from day to day depending on humidity and temperature. So try to keep it in a temperature

controlled environment. Specifically at these final stages.

When you get out to the plug surfacing stage and are at a mirror finish, if your substructure is not rock solid,

the mirror surface may appear to 'crawl' and move from day to day depending on humidity and temperature. So try to keep it in a temperature

controlled environment. Specifically at these final stages.

Once again, Incredible progress you have made and I am now even more proud of you!

Graber

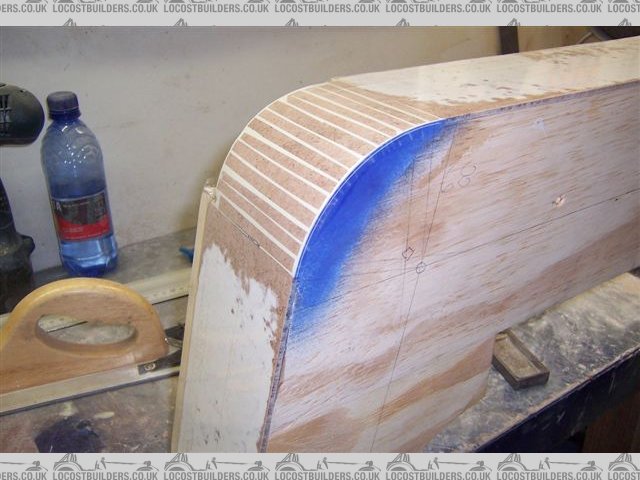

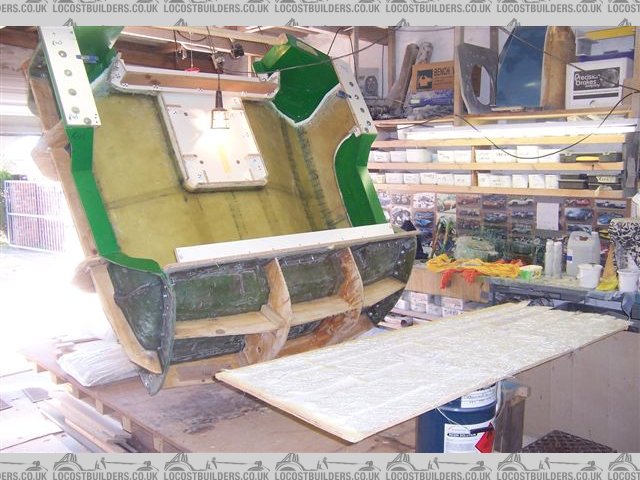

Fred W B - 4/5/06 at 11:19 AM

Hay Steve.

Thanks for the kind words. I have learnt a lot from following your progress.

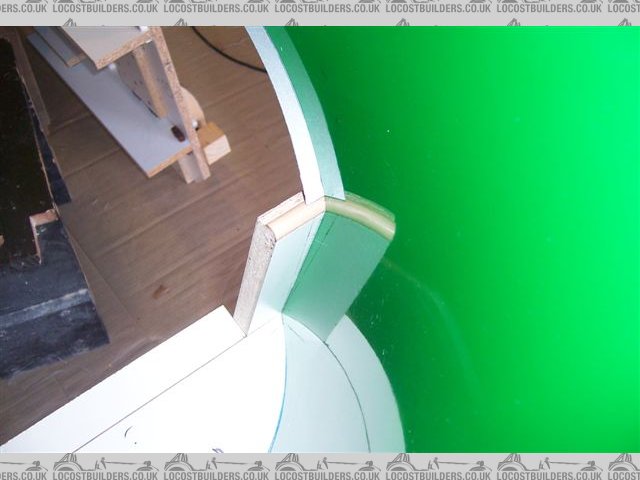

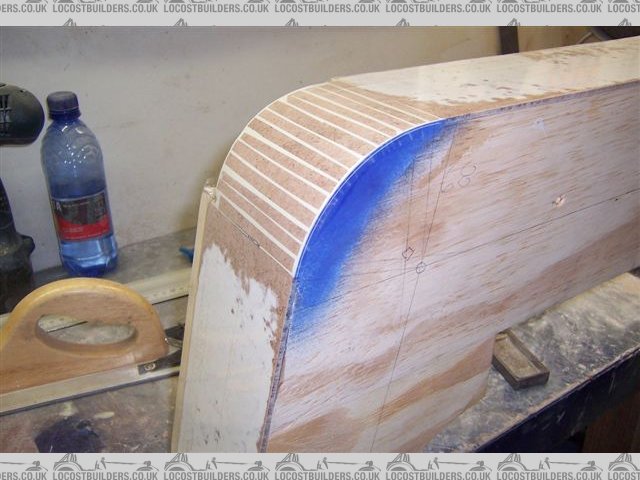

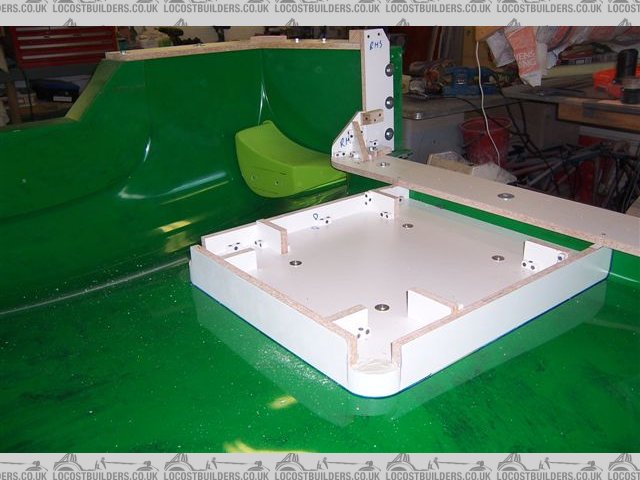

I have had a conversation with the boss of one of my companies GRP suppliers, and he also reccommends gluing and screwing the buck framework together

in order to make it as rigid as possible. As we cut the 8 mm plywood stations and ribs we will include matching groves so they will hopefully slot

together jigsaw fashion. Below is half of the more or less complete set. It does look like a hell of a lot of wood, but I am hoping that going to all

this trouble to produce a good framework with profiles that are exactly what I want will reduce the surfacing pain somewhat. We won't cut all the

wood shown in the cockpit area.

Cheers

Fred W B

GG

[Edited on 4/5/06 by Fred W B]

Fred W B - 12/5/06 at 06:07 AM

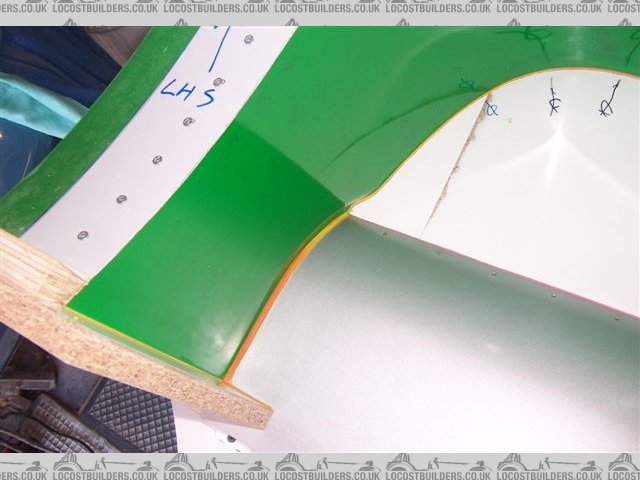

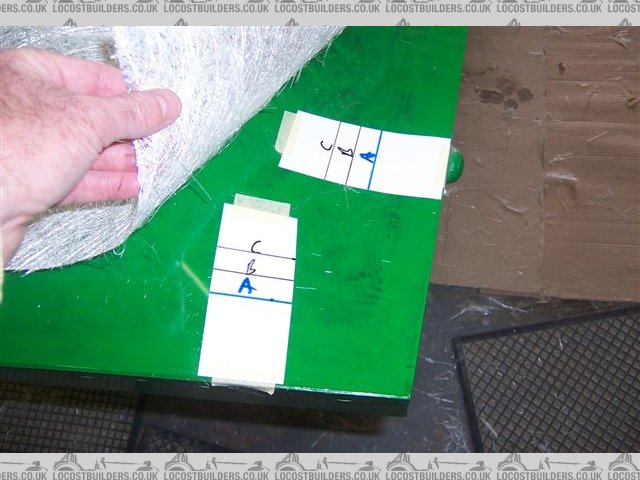

Just had the first trial station panel cut, to see if the CAD program talks to the CNC router okay. Came out pretty much perfect, just got to add a

centre line reference. This is a transverse station on the front axle line, through the front wheel arches and rad duct.

Looks like I'm off to buy a pile of plywood.

Cheers

Fred W B

[img][/img]

Dutchman - 12/5/06 at 11:03 AM

I found a guy in my country that is doing anythig from plexiglass/lexan so if U could not find the headlight covers know that it can be made.

the pics of what is he dooing are here

Fred W B - 30/5/06 at 07:05 PM

90 square meters of 8 mm plywood loaded for delivery to the router guy.

The plywood is recycled from packing crates used to send stuff from GM Brazil to a GM plant here in Port Elizabeth.

Cheers

Fred W B

[img][/img]

Trev D - 30/5/06 at 09:08 PM

Hi Fred I could make you an all aluminium body on the buck you are making. I think the car you have chosen is wonderful it is right up my street.

The best of luck with your build keep us all posted on your progress.

Regards

Trev

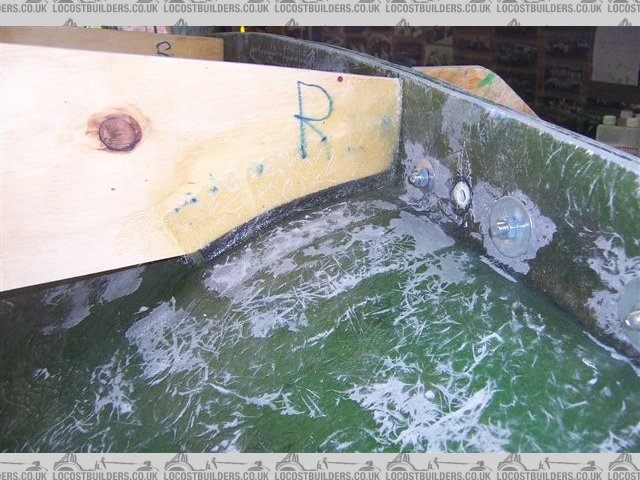

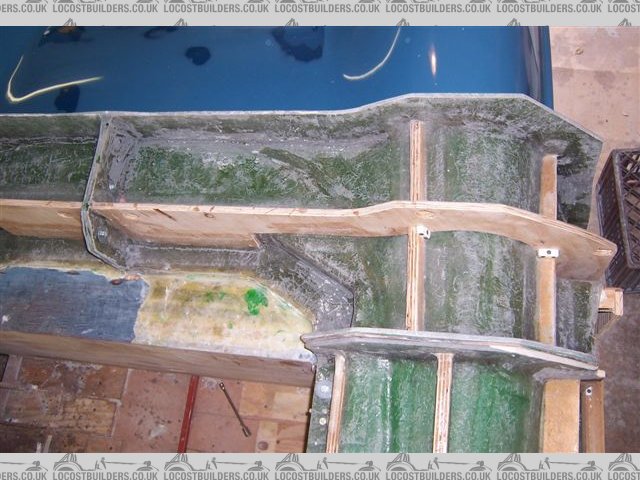

Fred W B - 11/2/07 at 11:44 AM

Believe it or not, some progress to report.

I cleared the decks in the workshop and

screwed a length of tube to the new base board for the centre reference.

buck start

buck table

[Edited on 11/2/07 by Fred W B]

Fred W B - 11/2/07 at 11:53 AM

Set a station that coincided with the end of the table vertical, then contined to position stations at 100 mm centres.

Logitudinal "skewers" planned straight and to size to fit holes cut into stations

Every 5 opening gets a transverse stiffener

buck step 1

[img][/img]

stiffener

[Edited on 11/2/07 by Fred W B]

Fred W B - 11/2/07 at 12:17 PM

Rear section of buck framework almost complete

buck feb 2

buck feb

[Edited on 11/2/07 by Fred W B]

DIY Si - 11/2/07 at 12:18 PM

Bloody hell that looks a bit complex! Good news on the progress front though, I was beginning to wonder if you'd had some major drawback or

problem! How are you planning on doing the first layer of the moulds? Or are you filling all the gaps with something like polystyrene and then going

over that?

Fred W B - 11/2/07 at 12:23 PM

Hi DIY

The hold up was this

WRT skinning the plug, I have had 350 polyurethane foam blocks cut, to glue into the "egg box" spaces to form the surface. These will be

finished to shape and then the whole thing skinned with GRP and filler.

Cheers

Fred W B

[Edited on 11/2/07 by Fred W B]

DIY Si - 11/2/07 at 12:58 PM

Ah, I'd forgotten about that. Fair enough, I would gladly take time out to make such a nice garage/build space. Any guesses as to when the

buck'll be ready? I imagine that'll be a fair sight all on it's own.

RazMan - 11/2/07 at 02:30 PM

I'm following your project with growing interest Fred.

When covering the 'egg box' with GRP are you going to anchor it to the surface with load spreader plates or similar? I was just thinking

that it might need to be bonded in some way to avoid separation when it comes to removing the buck from the mould. Or is it going to be a sacrificial

buck?

sgraber - 11/2/07 at 02:46 PM

Great progress Fred, and forgive me as I take the podium to say that you are doing the right thing by making sure you have a good base to start from.

If I can give any advice to people seeing Fred's complex structure who are considering their own buck/plug/mold construct - Do not skimp on the

understructure. I did, and paid for it over the years of struggle to prevent shifting and cracking.

Now, we could have a whole conversation about CNC milling the plug vs hand shaping.... But this is not the time or the place. Just LOOK at that

amazing wood work! Lovely!

Fred W B - 12/2/07 at 02:56 PM

Hi Guys

Raz, I am hoping that the "skin" of GRP/filler will stay on the plug when I pull the moulds. I hadn't planned on doing anything more

then just relying on the resin to stick the skin to the wood and foam base

Cheers

Fred W B

[Edited on 12/2/07 by Fred W B]

thomas4age - 12/2/07 at 11:22 PM

HolySh*T that is indeed very nice,

makes me kindoff ashamed that I'm being a wuss, saving up for the GD t70 chassis and body.......

if I only had the time and skills to pull that off.

grtz Thomas

DIY Si - 12/2/07 at 11:24 PM

Just do what I might do, and buy a shell off him!

Fred W B - 18/2/07 at 04:10 PM

Made some progress on the front section this weekend.

WRT diy si's comment, would you believe that since I've been posting details of my project on here and on GT40s.com, I've had 5

different guys contact me wanting bodyshells. I tell them I'm not quite ready yet........

Cheers

Fred W B

buck16feb

RazMan - 18/2/07 at 06:13 PM

Hey Fred, it's starting to look like a car now!

Gaz 1977 - 19/2/07 at 09:17 AM

looking good, christ you have put some work into that

gttman - 19/2/07 at 03:05 PM

quote:

Originally posted by Fred W B

Made some progress on the front section this weekend.

WRT diy si's comment, would you believe that since I've been posting details of my project on here and on GT40s.com, I've had 5

different guys contact me wanting bodyshells. I tell them I'm not quite ready yet........

Cheers

Fred W B

I can well beleive it.... I've had people pressure me to provide them a body and I hadn't even designed the rear end at the time.....

nothing stranger than folk.

keep up the good work.

Fred W B - 30/4/07 at 08:22 AM

some process photos

body22

Fred W B - 30/4/07 at 08:24 AM

foam shaping tools

body23

Fred W B - 30/4/07 at 08:27 AM

body 23.5

Fred W B - 30/4/07 at 08:28 AM

body 25

Doug68 - 30/4/07 at 09:25 AM

Awesome work Fred!

How long did it take the router guy to turn that lot out?

iank - 30/4/07 at 10:13 AM

quote:

Originally posted by gttman

quote:

Originally posted by Fred W B

Made some progress on the front section this weekend.

WRT diy si's comment, would you believe that since I've been posting details of my project on here and on GT40s.com, I've had 5

different guys contact me wanting bodyshells. I tell them I'm not quite ready yet........

Cheers

Fred W B

I can well beleive it.... I've had people pressure me to provide them a body and I hadn't even designed the rear end at the time.....

nothing stranger than folk.

keep up the good work.

Most will melt away when the issue of getting paid to make one is raised.

Some things about folk are rather predictable unfortunately.

Looking very good (both of you) wish I had the time, space, money and talent* to make exactly what I want.

* Not necessarily in that order

Fred W B - 30/4/07 at 10:52 AM

Thanks Doug and iank

WRT the routing, the handling time was much more of a factor that the cutting time. The job was done in between real paying jobs, and took 3 or 4

weeks to complete, I think - It was a while ago!

Things I would do different next time would include putting 0.5 mm clearance in the interlocking slots (I made them dead 8 mm wide, to fit over the 8

mm ply and had to hammer the longitudinals in) and I would add some stations at the extreme rear, but fitted perpendicular to the body surface, not

vertical. I would also make the longitudinal ribs thickness stick into the body shape from the actual longitudinal line, and not out as I have done. I

still have to finish off all these edges flush with the eventual body surface.

Best thing I did was have lots of 92 mm wide planks cut, I've used them a lot to get spacing correct at various places, particularly on the base

board. (my stations are at 100 centres, ply is 8 mm)

As for supplying others with bodies, I am under no illusions as to how many people will actually stump up money. Out here we have an expression which

comes to mind whever anyone asks me if I can make them something - "Talk is cheap, money buys the whiskey!"

I want the wheel arches to look like this car. Over the years the wheel arch lips on original 70's seem to have varied quite a bit.

wa 2

[Edited on 30/4/07 by Fred W B]

[Edited on 30/4/07 by Fred W B]

Fred W B - 30/4/07 at 10:54 AM

body 30

Fred W B - 30/4/07 at 10:55 AM

body 32

Fred W B - 30/4/07 at 10:57 AM

body 36

Fred W B - 30/4/07 at 10:59 AM

I think I have to start getting the hard skin on before I can get this any better.

body 38

Fred W B - 30/4/07 at 11:01 AM

body 40

Fred W B - 30/4/07 at 11:04 AM

I am now trying to get to grips with the air intake "nostrils" and complete the cockpit edges.

Cheers

Fred W B

body 42

Fred W B - 30/4/07 at 11:05 AM

body 44

violentblue - 30/4/07 at 02:27 PM

My next project is going to be a 4'x8" cnc router table.

Nice job so far. I've built lots of plugs in my day (boats) and a solid understructure makes a huge difference in the quality of your final

mould, I've seen many try and cut corners to get done quicker or cheaper, and it either cost them more in the end, or quality was lacking.

But you are on the right track for a blug you's be able to pull miltiple moulds off of, if you were planning to go into production.

Schrodinger - 14/5/07 at 09:30 AM

I've been watching this progress and am very impressed with the project.

Any progress Fred?

Fred W B - 14/5/07 at 11:18 AM

Hi Keith - Thanks for your interest.

Progress seems very slow, but I do feel that I am steadily getting somewhere.

I have now got the radiator exit duct and the cockpit edges finished (except at the nostrils), and am fitting foam blocks to the nose and LHS of the

car.

I will post some more photos soon. I prefer to post several pictures when I feel that I have made some significant progress, rather then one picture

every week, as then it looks like I'm just bringing the post to the top again and again.

Cheers

Fred W B

[Edited on 14/5/07 by Fred W B]

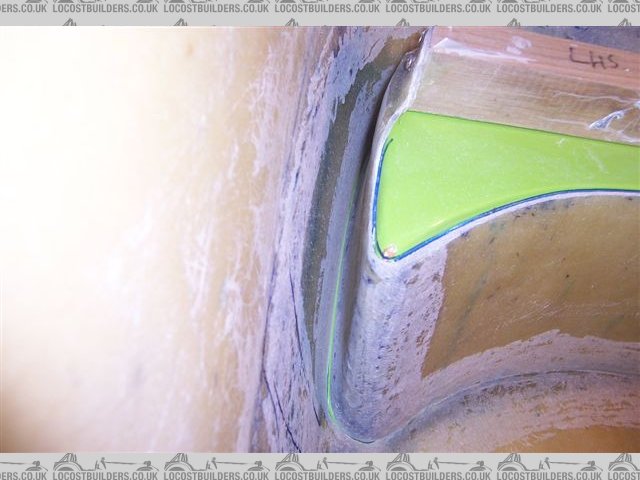

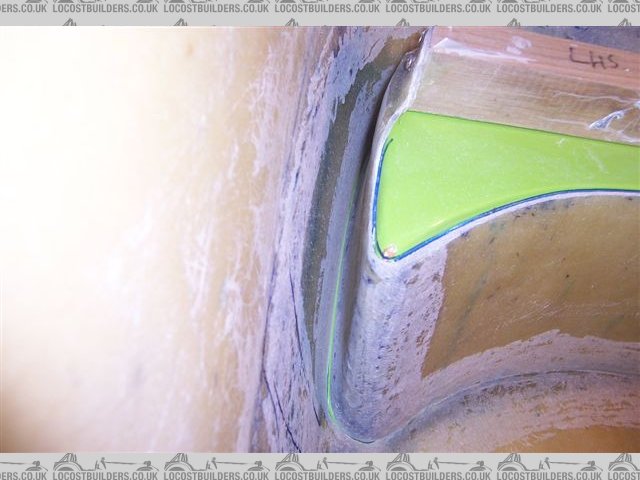

Fred W B - 8/7/07 at 04:13 PM

Still plugging along, and have finally managed to wrestle the shape of the rear air intake ducts into submission. This has been the worst bit to get

right so far, and one I have been working on a bit, leaving to do something else, and then going back to. We didn't get this area right in our

computer model, so I had to go back to old fashioned first principles, shaping by eye from the model and photo references, and using wood and

cardboard templates to get the left and right sides to match. It's still not quite finished, still pending the application of the hard skin.

Trust you will find the attached photos self explanatory. I bent the conduit to shape by hand in a vice and with lots of trial and error.

Cheers

Fred W B

nos1

Fred W B - 8/7/07 at 04:16 PM

nos2

Fred W B - 8/7/07 at 04:17 PM

nos3

Fred W B - 8/7/07 at 04:18 PM

nos 4

Fred W B - 8/7/07 at 04:18 PM

nos5

Fred W B - 8/7/07 at 04:19 PM

nos6

Fred W B - 8/7/07 at 04:20 PM

nos7

Fred W B - 8/7/07 at 04:21 PM

nos8

Fred W B - 8/7/07 at 04:22 PM

nos 9

sgraber - 8/7/07 at 05:02 PM

I trust you will have room to save this 'intermediate' work of art once you have used it to create your mould! It's beautifully

crafted.

Taking your time and spending the money/effort to make this phase as good as possible will save you so much money/time/hassle later on. (Said as

someone with painful experience behind me.  )

)

I can't wait to get started on my next one.

not.

gttman - 10/7/07 at 07:29 PM

quote:

Originally posted by sgraber

I trust you will have room to save this 'intermediate' work of art once you have used it to create your mould! It's beautifully

crafted.

Taking your time and spending the money/effort to make this phase as good as possible will save you so much money/time/hassle later on. (Said as

someone with painful experience behind me.  )

)

I can't wait to get started on my next one.

not.

Ahhh the words of pure wisdom.... shame I'm making all the mistakes you did lol.

What rates do you charge for consultancy? I think I need some!

Fred W B - 18/8/07 at 06:05 PM

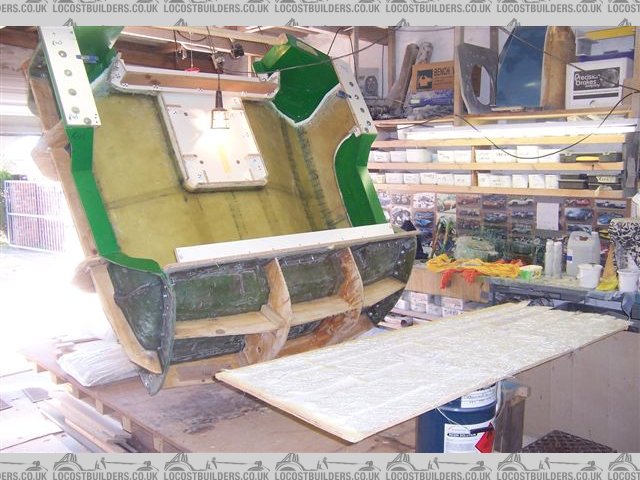

So back to the business at hand....

I have now got pretty much the whole of the body pattern framework covered in foam, and the hard edges such as the cockpit edges etc made up.

Won't be starting with the hard skinning for a while yet though, as I am currently working on the extreme rear of the body and the front 250mm of

the nose still has to be done. I am also not happy with the contours we did along the top of the doors, into the top of the front wheel arches, so I

have some reworking to do there.

I want to get rid of most of the foam dust before I get the sticky stuff into the workshop.

Cheers

Fred W B

[img][/img]

Fred W B - 18/8/07 at 06:08 PM

[img][/img]

Fred W B - 18/8/07 at 06:14 PM

[img][/img]

Peteff - 18/8/07 at 06:30 PM

That next to last picture looks like a flight deck.

[Edited on 18/8/07 by Peteff]

thomas4age - 19/8/07 at 05:26 AM

@ peteff, that's because it kinda is, suprized me how long the tail is when I was in a GD t70 first, the rear is longer that my strikers

bonnet....

@ Fred

Once again BIG THUMBS UP!!!

permission to speak freely, SIR?

the problem with the doors to nosesection is that it looks like the door is a section and the wheelarch is a section beause of the angle of the

upwards curve at the section where the wheelarch begins, the flat piece of the door suddenly takes of as you move your eyes towards the arch.

maybe it would be an idea to make the doors and arch look like one piece

I can imagine that when you take a picture of the side of the car it looks like the car has three sections

front to arch, arch to rollbar, rollbar to rear.

you can try to make that 2 sections nose to rollbar, rollbar to rear.

more like this, I don't know about originality but it looks good

disclaimer: I may very well be that I talking a pile of poo that didn't even come from where it should.....

grtz Thomas

[Edited on 19/8/07 by thomas4age]

Fred W B - 19/8/07 at 08:16 AM

You are quite right thomas, that area does have to be reworked. Not difficult, but everthing takes ages.

Thanks for the support

Cheers

Fred W B

Fred W B - 31/8/07 at 11:26 AM

Whoa Ė Minor setback.

Spot the difference between this model photo (similar to the one we measured for the computer model) and the real car?

I mean beside the modified rear wheelarch on the model.

Some reworking to start this weekend!

Cheers

Fred W B

bymodel

byreal

donahue 70

[Edited on 31/8/07 by Fred W B]

neilj37 - 31/8/07 at 11:49 AM

Only things I can spot different is the rear wing and the shape of the rear wheel arch.

Fred W B - 31/8/07 at 11:49 AM

Beside the wheel arch and the wing?

Once you see it you can't imagine how you missed it, and I have been looking at T70 pictures for literally years

bmodel

[img][/img]

7070

[Edited on 31/8/07 by Fred W B]

[Edited on 31/8/07 by Fred W B]

[Edited on 31/8/07 by Fred W B]

RazMan - 31/8/07 at 12:13 PM

Got me stumped

Delinquent - 31/8/07 at 12:57 PM

front splitter differs on most of the pics?

Dale - 31/8/07 at 01:11 PM

Gentle curve downward on the door?

Dale

sgraber - 31/8/07 at 01:42 PM

c'mon - tell us already !

Fred W B - 31/8/07 at 02:13 PM

All right - look at the length of the tail of the body aft of the rear wheel arch. It's most apparent if you look backwards along in line with

the top of the rear tyre.

I could not understand that no matter what I did with the blend of the rear lower section into the rear panel with the holes I could not get it to

look right.

As far as I can tell from scaling photo's I have to shorten my plug behind the rear arch by about 160 to 170 mm

Cheers

Fred W B

[Edited on 31/8/07 by Fred W B]

RazMan - 31/8/07 at 02:36 PM

Ahhh I see it now - the tail section is noticeably shorter now that you mention it.

A bit of cut'n'shut needed then Fred?

sgraber - 31/8/07 at 03:31 PM

yes, I see it now too. Very subtle indeed.

adithorp - 31/8/07 at 08:10 PM

So why would the models be wrong?

There wasn't a special body work for some events was there? Not sure about now but endurence race cars ran different bodywork for Le-Mans due to

the sustained high speeds down the strieght, back in the '80s when I used to follow it.

adrian

Fred W B - 9/10/07 at 06:46 PM

So the tail used to look like this

[img][/img]

Fred W B - 9/10/07 at 06:48 PM

Now it looks like this

[img][/img]

Fred W B - 9/10/07 at 06:57 PM

The rear transom panel turned into a real mission

buck 47

sgraber - 9/10/07 at 06:59 PM

WOW. again - WOW.

Lovin it.

Fred W B - 9/10/07 at 07:00 PM

But it's now pretty much done, just a few holes to fill and edges to straighten

Note the foam dust lying like snow on the floor along the wall. I blow it away with an airline, it's easier than sweeping up all the time.

Cheers

Fred W B

buck 48 003

[Edited on 9/10/07 by Fred W B]

Fred W B - 9/10/07 at 07:01 PM

Thanks Steve, you got in just as I was posting the last picture

Cheers

Fred W B

Delinquent - 9/10/07 at 09:47 PM

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

gttman - 10/10/07 at 12:57 PM

quote:

Originally posted by Delinquent

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

But doing it in CAD would drive me barmy.

Delinquent - 10/10/07 at 01:01 PM

quote:

Originally posted by gttman

quote:

Originally posted by Delinquent

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

But doing it in CAD would drive me barmy.

well yes, that's true as well - with CAD though, a mistake means usually tweaking a few spline co-ordinates and examining the difference,

it's the fact Fred's taken the entire back end off again and re-sculpted it - would be heartbreaking having put so much effort in the first

time!

gttman - 10/10/07 at 07:00 PM

quote:

Originally posted by Delinquent

quote:

Originally posted by gttman

quote:

Originally posted by Delinquent

Have to say Fred, Hats off to you, really no way I could cope with all that manual input, would drive me barmy!

But doing it in CAD would drive me barmy.

well yes, that's true as well - with CAD though, a mistake means usually tweaking a few spline co-ordinates and examining the difference,

it's the fact Fred's taken the entire back end off again and re-sculpted it - would be heartbreaking having put so much effort in the first

time!

yep pretty much what I do..... but by doing it in the flesh we can also see the change in the flesh.

Also the satisfaction when you have put it right is quite nice.... I almost forget the pain of doing it for the 4th time.

BTW Fred, top job... keep up the good work.

Fred W B - 17/11/07 at 05:45 PM

Thanks for the comments guys.

Some more progress to report. I am now happy the rear panel is ready for skinning. All the openings have 1 degree slope returns and the edges are all

radiused.

[img][/img]

Fred W B - 17/11/07 at 05:47 PM

Moving to the mid section, I have mocked up a windscreen template in hardboard in order to establish the angle of the windscreen recess.

screen

Fred W B - 17/11/07 at 05:49 PM

Having reworked the LHS, I am now much happier with the blend into the top of the front wheel arch and the profile of the top of the door. Still have

to finish off and do the RHS.

side rework

door mod

sideeeeeeeee

[Edited on 17/11/07 by Fred W B]

Fred W B - 17/11/07 at 06:02 PM

We have been discussing the merits of CAD verses old fashioned trial and error following the rework I did to shorten the tail. Here we see the other

approach.

Andrew volunteered to do some more work on the nose of the car. This is the refined front view drawing, which was used to generate a tool path to cut

the front 250 mm of the nose on his home made 3 axis CNC router. The part was cut in 3 sections which were glued together.

model fv

nose cut

nose cut 2

[Edited on 17/11/07 by Fred W B]

[Edited on 17/11/07 by Fred W B]

Fred W B - 17/11/07 at 06:08 PM

And today I glued the nose on. I am now looking forward to adding the remaining foam and blending it in once the glue dries.

Cheers

Fred WB

[img][/img]

RazMan - 17/11/07 at 06:10 PM

That 3D router certainly does a nice job Fred - what material is it working with?

Fred W B - 17/11/07 at 06:49 PM

Hi Raz.

The material you see there is polyurethane foam, with a density of about 32 kg/m2. That density is not ideal, heavier would be better.

Cheers

Fred W B

[Edited on 17/11/07 by Fred W B]

jrevillug - 17/11/07 at 11:52 PM

Stunning work there. Lots of effort- and it shows.

The modified door looks spot on to me.

James

sgraber - 18/11/07 at 01:48 AM

I'm not going to say wow again...

.

.

.

.

.

WOW

DAMMIT!!! That just blurted right out!

Love the fact that you are blending old world techniques with new world ones.

Delinquent - 19/11/07 at 12:40 PM

excellent combo of the disciplines there Fred! Really is coming on beautifully.

Fred W B - 2/12/07 at 04:13 PM

This weekends work......

nose 02 dec 2

[Edited on 2/12/07 by Fred W B]

Fred W B - 2/12/07 at 04:16 PM

[img][/img]

Fred W B - 2/12/07 at 04:17 PM

side 02 dec

Cheers

Fred W B

violentblue - 4/12/07 at 06:36 PM

so when are we going to see it in primer?

Fred W B - 5/12/07 at 06:03 AM

Still quite a bit of work to do before I get to the surfacing stage. Still need to complete the reworks on the RHS. and touch up a few other areas

I am now happy with most the shape, just want to do a bit more work on the rear air intakes, I now think they need to be a bit smaller and lean back

less. I think I have cut them too far back into the rear wings, so they are much bigger than they should be. I also want to add a bit more

"bulge" to the inside side of the front wheel arch bulges, above the tops of the front wheels

I have still not yet personally seen a real (or replica) T70 spyder in the flesh and trying to get the proportions and some of the details more or

less right from photographs has been driving me crazy, not helped by the fact that the model I started with, the original 60's built cars in

period (and now), the Lola Heritage continuation series cars, the GD / RCR narrow shell replicas etc are all slightly different in certain areas to

each other.

I have had a lot of help from some of the Lola owning guys on gt40s.com who have sent me photographs and measured dimensions from original cars and

bodywork that they own.

www.gt40s.com

Cheers

Fred W B

[Edited on 5/12/07 by Fred W B]

Ivan - 8/12/07 at 06:32 AM

Fred - I am extremely impressed with the quality of work and effort you are putting into this project.

Seeing the nose done on the 3D router gives rise to the question:

If one where contemplating a similar project on some other car would it be worthwhile getting the shape cut on a 3D router using high density foam or

doing it in frames as you did?

One advantage would be that re-designs would be a lot easier to implement.

thomas4age - 8/12/07 at 03:34 PM

Hey Fred

home made portal type CNC router, that sound very tasty!

@Ivan, that's a way of doing it,

but acces to a big cnc portal type milling machine isnt very easy, I know at least one who did it like that, the body plug was milled at a shipping

yard on a 3d portal CNC mill, that normaly is used to make plug's for hulls of 100K+ costing sailing yachts, the total cost for tooling the

bodyplug was somewhere in the region of 15.000euro's

so unless your neighbour has something like that standing in the workshop and likes lots of beer tokens.... it wouldn't be very locost.

grtz Thomas

Fred W B - 8/12/07 at 03:34 PM

HI Ivan

If you have access to CAD and CNC machinery at the right price, it will be MUCH easier to get the shell drawn completely in CAD, and then CNC cut in

one piece (or sections) in foam. Nowadays, they cut the foam a few mill undersize, then apply the surfacing filler and recut the plug final size, so

then just have to wax and take moulds.

If the CNC you have access to is a router with limited Z height I would suggest rather than cut thin ribs and fill between than manually, have foam

sections cut in say 30 mm slices, glue then together and then blend the contours together.

With any task that is new to you, you only really know how to do it properly once you are finished! If I was doing this again, I would spend more time

getting the CAD model to be exactly what I want, by comparing it at all angles with photos of actual cars. If you are doing an original body that will

not be a problem.

Cheers

Fred W B

Delinquent - 8/12/07 at 08:34 PM

quote:

Originally posted by thomas4age

Hey Fred

home made portal type CNC router, that sound very tasty!

@Ivan, that's a way of doing it,

but acces to a big cnc portal type milling machine isnt very easy, I know at least one who did it like that, the body plug was milled at a shipping

yard on a 3d portal CNC mill, that normaly is used to make plug's for hulls of 100K+ costing sailing yachts, the total cost for tooling the

bodyplug was somewhere in the region of 15.000euro's

so unless your neighbour has something like that standing in the workshop and likes lots of beer tokens.... it wouldn't be very locost.

grtz Thomas

My plans at the moment are for a home made CNC mill roughly the same size as the workshop (the workshop is having parts built in specifically for the

CNC machine)

Chances of success - 50/50 I reckon, it'll either work or it won't

Ivan - 9/12/07 at 05:34 AM

quote:

Originally posted by thomas4age

Hey Fred

home made portal type CNC router, that sound very tasty!

@Ivan, that's a way of doing it,

but acces to a big cnc portal type milling machine isnt very easy, I know at least one who did it like that, the body plug was milled at a shipping

yard on a 3d portal CNC mill, that normaly is used to make plug's for hulls of 100K+ costing sailing yachts, the total cost for tooling the

bodyplug was somewhere in the region of 15.000euro's

so unless your neighbour has something like that standing in the workshop and likes lots of beer tokens.... it wouldn't be very locost.

grtz Thomas

To pay or do it yourself raises an interesting conundrum when you're retired. the conundrum being whether to work as consultant or at something

that you're realy good at and pays well for a fraction of the time that it would take you to do the job and employ an expert to do the building

- the alternative being to do it yourself that could be a real shlep and take years instead of months to do.

One of our local glass fibre firms for example makes some of the most beautiful car bodies for the racing and advertising industry from scratch at a

cost for buck and moulds for what would take me around 4 months of Consulting to earn.

Bodies he has made recently include a Porsche 917, Audi LMP, Mustang, Formula 1 Clone etc.

Why I'm interested is I would love to do a Porsche 904 or 906 or Renault Alpine a110 replica and am puzzling out the best way to go about it.

Fred W B - 9/12/07 at 06:45 AM

quote:

One of our local glass fibre firms for example makes some of the most beautiful car bodies for the racing and advertising industry from scratch at a

cost for buck and moulds for what would take me around 4 months of Consulting to earn.

No brainer then Ivan, by the time I have a set of moulds I recon I will have spent at least R15 000 on materials, and that includes getting the CAD,

Router, and CNC time and the foam material for FREE, not to mention the maybe 500 hours I have spent on the pattern already.

Some sources quote 1000 hours for a car body pattern done the old fashioned way, and I can believe it

Cheers

Fred W B

Ivan - 9/12/07 at 07:38 AM

^^^ Thats what I thought Fred - although doing it yourself has a lot of appeal.

Next time I'm in PE I would love to see what you are doing.

Fred W B - 9/12/07 at 12:48 PM

quote:

Next time I'm in PE I would love to see what you are doing.

Sure thing Ivan, be glad to show you.

Cheers

Fred W B

Fred W B - 23/12/07 at 06:17 PM

Meanwhile, back in the garage...

I am now much happier with the "hip nostril" shape and size

[img][/img]

Fred W B - 23/12/07 at 06:19 PM

[img][/img]

Fred W B - 23/12/07 at 06:21 PM

And I'm making some progress with the rework to the inside of the front wheel arch contours

[img][/img]

Fred W B - 23/12/07 at 06:23 PM

[img][/img]

Fred W B - 23/12/07 at 06:26 PM

[img][/img]

Fred W B - 23/12/07 at 06:27 PM

[img][/img]

Fred W B - 7/1/08 at 06:20 PM

I have taken advantage of some leave over the holiday season to get some quality time in the garage, between family commitments and eating!

[img][/img]

Fred W B - 7/1/08 at 06:21 PM

I have been working on the RHS, to get it the same as the reworked LHS. Where I have deviated from the original routed stations, I have to make

templates to check symmetry of the profile on the LH and RH sides.

bb 0200

[img][/img]

Fred W B - 7/1/08 at 06:22 PM

You have to be sure to keep the template vertical when checking, particularly where the body slope is steep, hence the spirit level attached to this

template.

[img][/img]

Fred W B - 7/1/08 at 06:23 PM

In order to keep the body as symmetrical and "square" as possible, I check everything back to a horizontal reference plane I have across the

back of the cockpit. Have to be careful you don't loose the centerline on the pattern!

[img][/img]

Fred W B - 7/1/08 at 06:23 PM

Here you can see that at this point I determined that I had had to bring the highest point of the RHS front wheel arch hump up another 3 mm.

[img][/img]

Fred W B - 7/1/08 at 06:24 PM

Have now started adding a bit more "fat" to the rear wheel arch humps towards the center of the rear deck.

Finally starting to feel I have now broken the back of most the body shaping.

Cheers

Fred W B

bb 0290

bb 0300

[Edited on 7/1/08 by Fred W B]

Ivan - 7/1/08 at 08:54 PM

Fred - watching your progress amazes me - you are certainly going for perfection and getting there.

It reminds me of an old work colleage (a surveyor believe it or not) who's favourite expression was "we are not grinding crankshafts

here" as an excuse for mediocre quality work or taking shortcuts, and in many cases it was valid. However that definitely doesn't apply to

what you are doing and I am sure that your "grinding of the crankshaft" will show in the end result.

Keep up the good work - you are an insperation to many of us.

Fred W B - 9/1/08 at 07:17 PM

thanks Ivan

I use the expression "this is not a space shuttle" quite a bit

Cheers

Fred W B

violentblue - 10/1/08 at 03:38 AM

WOW, i check for updates on your project every time i visit these forums. I'm always impressed.

sgraber - 10/1/08 at 05:22 AM

That is cracking me up! I use the phrase "we aren't sending a man to the moon" all the time!

But seriously Fred, you are really going the extra mile. And I just know you are having a great time doing it! Fun! Hard, but fun.

quote:

Originally posted by Fred W B

thanks Ivan

I use the expression "this is not a space shuttle" quite a bit

Cheers

Fred W B

Dom9 - 10/1/08 at 09:53 AM

Hi Fred, I have hovered on this forum for quite a while but have spent the last few years working away from home. So I never signed up here or indeed

had the space to work on my own project.

I was offered a Group C Jaguar XJR-9 body in GRP a few years back, but I had to move house and so couldn't commit to the project and I also

remember in one of the UK kit car mags a few years ago, another Group C/ Le Mans style body in GRP being sold for only £600 if memory serves

correct...

I haven't seen anything (except maybe the Ultima) like that for a long time and so I have been thinking a lot about getting a nice, authentic

die-cast model in say 1/10th scale and having it drawn up in AutoCAD (my missus, Lou, is a CAD draughy) and make the plug exactly as you have done in

the garage.

I would really love to design the whole car, from spaceframe and suspension through to bodywork and own my own Group C/ Le Mans/ IMSA GTP replica!

This thread is a real inspiration as is Andygtt's work, which I have followed (quietly) on Pistonheads since he first posted there. The only

thing that scares me is the cost and the time involved... Despite being an engineer in the oil and gas industry, having previously worked for Lotus

and Ferrari, I would still be worried about trying to build a body from scratch.

If we are ever in town, and I have promised Lou we will go to SA soon as my grandparents were from Cape Town, I would love to come and see the work

you have done.

Hopefully I will have the time and passion to do what you and Andy have done, over the next few years.

Fred W B - 10/1/08 at 06:27 PM

HI Dom

Thanks for your post. I would be very pleased to show you what I am doing, if you ever end up in Port Elizabeth. If you are planning a trip to SA,

driving by road from PE to Cape Town (or visa versa), via Kynsna is reccomended.

Anything is possible, if you persevere. As an engineer you already have the problem solving skills required. Before I started this, I had no practical

experience in any car designing or composite building skills.

As I said in another post a while ago, once I've decided what I want to do I:

Find out how to do it - books, internet, speak to people.

Get what I need to do it - tools, materials.

Start doing it!

Solve one problem at a time.

If you get stuck do something else for a while, then go back to it.

So just go for it

Cheers

Fred W B

[Edited on 10/1/08 by Fred W B]

Fred W B - 10/1/08 at 06:34 PM

[img][/img]

TheGecko - 11/1/08 at 03:31 AM

quote:

Originally posted by Fred W B

Anything is possible, if you persevere. As an engineer you already have the problem solving skills required.

This brings to mind the quote attributed to Nevil Shute who, as well as being a notable author,

was firstly an aeronautical engineer. He said:

"An engineer is a man who can make something for five bob that any bloody fool can make for a quid!"

I agree wholeheartedly with Fred's thoughts here. Knowledge of the technical details of building a car are less important than the mindset

necessary to enable you to acquire that knowledge.

I suspect that some people enjoy the problem solving aspect as much as (or maybe even more than) driving the finished product.

Dominic

Peteff - 11/1/08 at 11:17 AM

I like Monty Burns' saying in the Simpsons " Good grief man,this is brain surgery, it's not rocket science " You'll see the

shape more when it's all one colour but it looks good so far.

Fred W B - 10/2/08 at 11:08 AM

So now we have bigger hips...........

feb 006

feb 008

[Edited on 10/2/08 by Fred W B]

Fred W B - 10/2/08 at 11:14 AM

Here you can see how much material I added when reworking the nostrils.

feb 001

Now just need the edge radii formed

feb 022

[Edited on 10/2/08 by Fred W B]

Fred W B - 10/2/08 at 11:17 AM

As always the devil is in the detail and the smallest things always seem to take forever. Here I am forming the windscreen recess

feb 108

feb 024

feb 025

[Edited on 10/2/08 by Fred W B]

Fred W B - 10/2/08 at 11:23 AM

Looking back up the thread I see I have been reworking for 7 months now. But finally I am happy with the major details of the shape

Cheers

Fred W B

feb 012

feb 013

[Edited on 10/2/08 by Fred W B]

RK - 10/2/08 at 03:01 PM

How much is 5 bob?

Kaspa - 10/2/08 at 06:44 PM

1 quid = 1 pound. or 20 shillings in old pre decimal curreny

5 bob = 5 shillings

not a lot

Kaspa

Fred W B - 14/3/08 at 11:30 AM

Struggling with my motivation a bit at the moment, and have had a few other things to do. Haven't touched the car in a month.......

Cheers

Fred W B

Delinquent - 14/3/08 at 11:46 AM

quote:

Originally posted by Fred W B

Struggling with my motivation a bit at the moment, and have had a few other things to do. Haven't touched the car in a month.......

Cheers

Fred W B

Think there must be a bug going around - virtually everyone I know that has a project running at the moment seems to be down on enthusiasm!

Fred W B - 13/4/08 at 09:30 AM

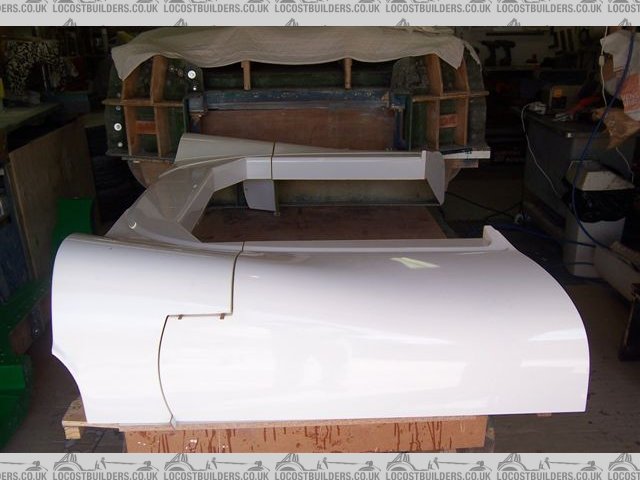

Enough! Foam and preskinning filler work finally finished. Just completed shaping the front lower edges of the front wheel arches and the surface

under the nose. Working overhead while lying on your back is not fun!

Now just radiusing a last few edges and then I can start with laying on the grp skin and the real surfacing.

Cheers

Fred W B

nose 55

nose 049

nose 50

nose 51

[Edited on 13/4/08 by Fred W B]

Delinquent - 13/4/08 at 12:17 PM

Congrats Fred, a milestone reached - and a bloody good looking one at that

autohausdolby - 14/4/08 at 08:19 PM

Awesome thread

ghetto_eddie - 16/4/08 at 03:28 PM

Fred,

I am building a body in a very similar way to you... even down to the little KD (modesty/whatever you call them) blocks holding the ply together..

But one big question... how the hell did you secure yours together? i started to assemble my buck the other day and realised my drill is too big and

hence doesnt fit in enough for me to sink the final screw (of the 3) in the blocks!

My only solution so far is a 90degree drill adapter... but would be interested to see how you got on with this!

Regards

Edd

Fred W B - 16/4/08 at 03:42 PM

Hi Eddie

I made sure that I worked from the first station outwards, so you were always working away from the previous panel. Secure that panel, then move onto

the next. You have to think the assembly process through to ensure you can get in where necessary. Put all the joiners on a panel before you add it to

the buck where possible for example.

Where I sometimes had to go back in, I had to cut away the second panel back enough to get a short battery operated pistol grip style screwdriver in.

Or some times I could use a very long adaptor made up from 1/4" drive socket set bits, through access holes drilled in the stations etc etc.

Use a large "spade" drill

All the best with your project

Cheers

Fred W B

[Edited on 16/4/08 by Fred W B]

[Edited on 16/4/08 by Fred W B]

ghetto_eddie - 16/4/08 at 04:11 PM

Thankyou Fred for the quick and helpful reply!

I shall see tonight if my 90 degree adaptor idea will fit in... if not i shall procede with the method you outlined above!

All the consideration i put into this build... and i overlook the smallest of things!

Edd

Fred W B - 16/4/08 at 04:52 PM

I left out my "trick" , which was to put the longitudinal stringers 200 mm, far enough apart to fit in the pistol grip driver.

I put the connector blocks (with the two screws) on the transverse stations first, as I build up the framework longitudinally, then when the stringers

went in I just had to put the third screw into the stringers

I am sure the right angle drill will work too, though just mayby a bit difficult to "muscle" . I stopped counting once I went past 1000

blocks x 3 screws each!

Cheers

Fred W B

[Edited on 16/4/08 by Fred W B]

ghetto_eddie - 17/4/08 at 08:00 AM

Fred,

I developed a similar method to what you mentioned, assembling the blocks on the "stiffeners" first, and now just to assemble... but

unfortunately my sections are 175mm apart! shot myself in the foot there!

ime currently on 400 blocks pre-assembled onto my stiffeners! FUN

I bought my right angle drill adapter last night... shoddy piece of Cr*p but it may just work!

Sorry for clogging up your thread!

Edd

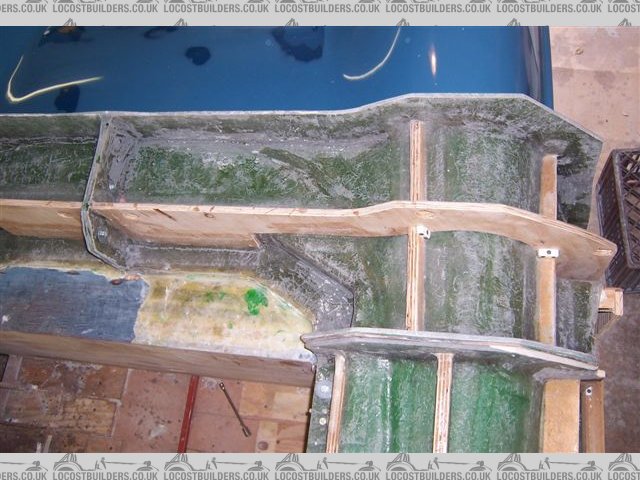

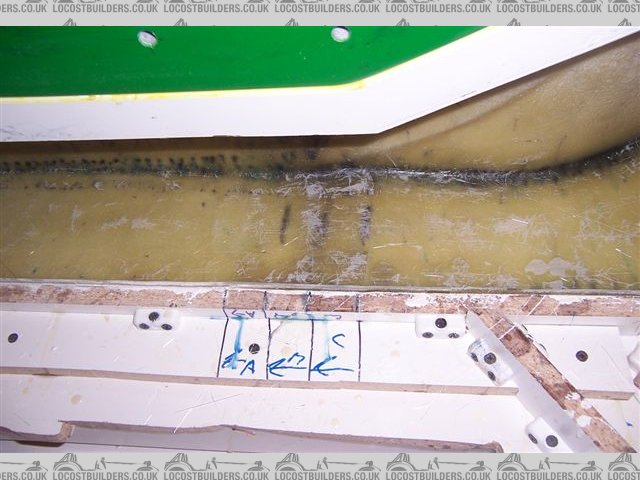

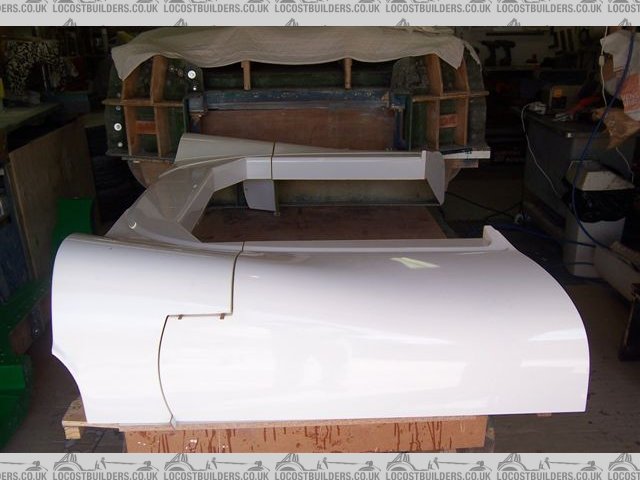

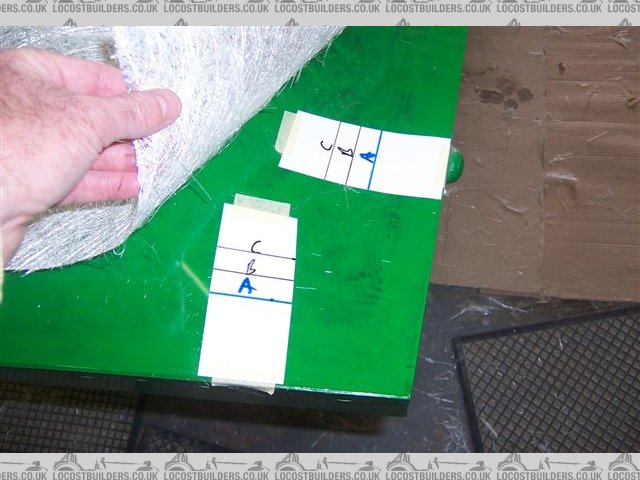

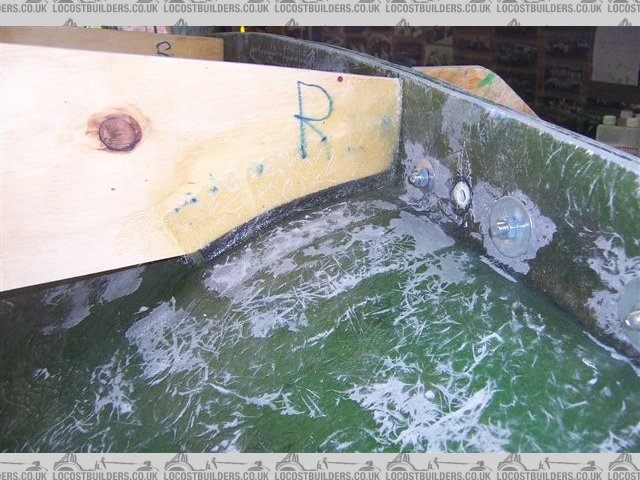

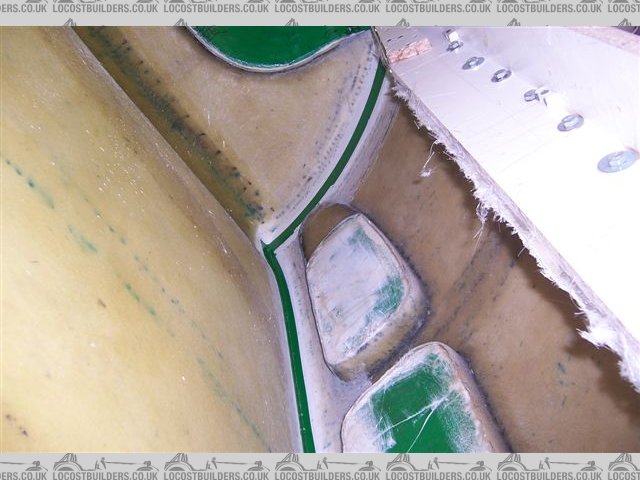

Fred W B - 25/5/08 at 05:51 PM

It's been a while, but I have very busy climbing up the learning curve of laying up and working off fiberglass. Having now consumed the majority

of a 25 kg drum of resin, I have about 80 percent of the pattern covered in a generous layer of resin and CSM.

As I was warned, this is messy, tedious and unpleasant work that definitely requires a "knack" to be acquired. It is the most difficult task

psychologically so far on my project. I am definitely very glad I spent as much time as I did getting the shape to my satisfaction before I started

with the resin.

I attach some detail photos. As always the edges and returns take a lot of time. As you can see the pattern looks a lot worse for a while, before it

starts to look better again. At the moment I am grinding back obvious high spots and overlap joints with a flexback wheel in an angle grinder, and

reworking occasional "soft" spots in the surface, where I caught an airbubble in the layup. I'm looking forward to getting this stage

finished so I can get onto the final smoothing of the surface with a long board etc etc etc

Cheers

Fred W B

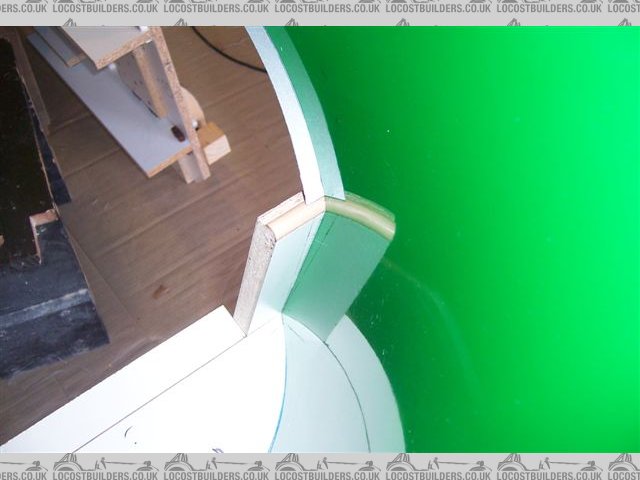

skin 1

Fred W B - 25/5/08 at 05:53 PM

skin 2

The surface of the return is not complete yet in this shot

[Edited on 25/5/08 by Fred W B]

Fred W B - 25/5/08 at 05:54 PM

skin 3

[Edited on 25/5/08 by Fred W B]

Fred W B - 25/5/08 at 05:57 PM

skin 4

Ivan - 26/5/08 at 12:58 PM

Always interested to see your progress Fred

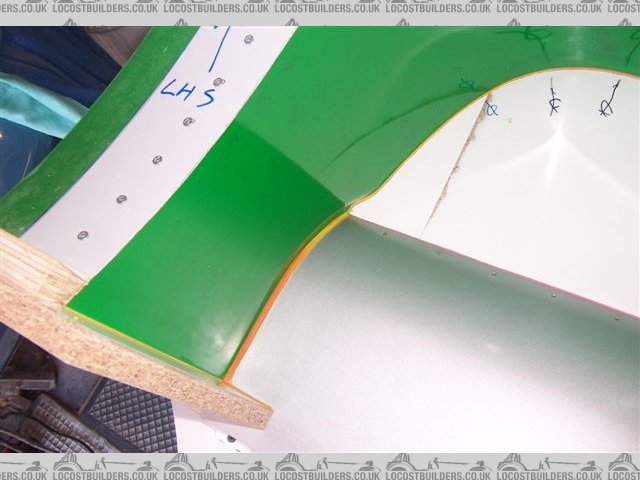

Fred W B - 8/6/08 at 07:57 PM

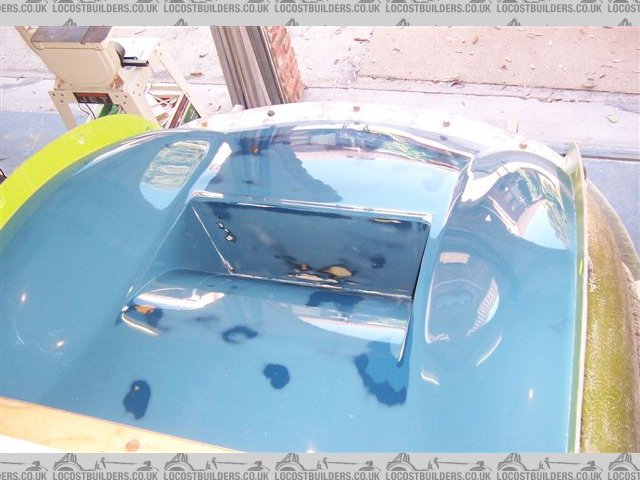

For the last three weekends, and also some weekday evenings, I have pretty much done nothing else than graft in the garage, in order to get the damn

fiberglass skin finished. Now every square centimeter (except under the nose) is covered, some of it worked off fair, and I have actually started

applying some filler - Yay.

I couldn't resist working off the first section of filler I applied and I'm very happy with the way the surface came up. This is after just

one application of filler.

Cheers

Fred W B

[img][/img]

Fred W B - 8/6/08 at 08:04 PM

In this shot the camera maybe makes it look like the lower line of the side pod/door is bowing inwards a bit in the centre, but checking with a

straight edge it is dead flat in the longitudinal direction, except for where you see the guide coat.

Cheers

Fred W B

filler 2

[Edited on 8/6/08 by Fred W B]

02GF74 - 9/6/08 at 07:26 AM

excellent.

has it been asked before - but with all that sanding going on, how do you manage to keep the garage so tidy?

Fred W B - 9/6/08 at 08:07 AM

Thanks 02. I keep an airline handy and blow the dust away periodically. It piles up on the floor against the walls like snow

And of course it goes everywhere. Across the yard, on the cars, on the dogs etc etc. I'm surprised the neighbours haven't complained.

Cheers

Fred W B

[Edited on 9/6/08 by Fred W B]

violentblue - 15/7/08 at 04:44 AM

so whats the status?

looking forward to seeing it in one color

(primer?)

Fred W B - 15/7/08 at 06:11 AM

HI Blue

Have now got a layer of filler worked off over almost the entire pattern. Not much to see though, just how many pictures of sanded filler can you all

stand?

I haven't been able to devote much time to the project over the last few weeks, but I hope to get the first layer of surfacer primer on in a

month or two.

Cheers

Fred W B

[Edited on 15/7/08 by Fred W B]

Delinquent - 16/7/08 at 11:14 AM

quote:

Originally posted by Fred W B

just how many pictures of sanded filler can you all stand?

Probably more than you'd imagine

mistergrumpy - 17/7/08 at 10:43 PM

Wow! Don't know how I missed this thread previously. Been thinking about it today whilst trudging around at work. Am I right in thinking that

after all those measurements that you took you knocked a few mm off them overall to take into account the depth of the filler etc.?

Great project

Fred W B - 18/7/08 at 05:37 AM

thanks Grumpy

quote:

Am I right in thinking that after all those measurements that you took you knocked a few mm off them overall to take into account the depth of the

filler etc.?

That would have been the right thing to do, but we didn't bother. Who knows how close we actually are to the real thing anyway?

Cheers

Fred W B

Fred W B - 20/7/08 at 04:21 PM

A couple more photos. Have now worked off the second go round with filler on the rear clip top surface and the whole left hand side.

[img][/img]

Fred W B - 20/7/08 at 04:28 PM

Although it doesn't look like it here, due to the camera angle, I made a template so I could match the top curve of the LH and RH side rear

arches.

Cheers

Fred W B

[img][/img]

:{THC}:YosamiteSam - 20/7/08 at 08:04 PM

dont you just love seeing someone building a car like this? to put so much heart and soul into their *baby* and seeing it starting to look like a car

too.

i think there are 2 types of kit car builders - those who make bits for the car and those that buy bits - personally i prefer the making bits type -

because it stimulates the mind the make better things- after all if you can make something like this - you could make just about anything given the

time and patience

Fred W B - 6/8/08 at 11:20 AM

Random Thoughts while shaping

I havenít posted much progress detail lately. The work Iím doing now doesnít show well in photos, but the shape and surface is getting better and

better. I prefer to post details of what Iíve done, not talk too much about what Iím still going to do. I saw on another car building forum a guy

posted nice renderings of a car body he was going to build. He gave himself a month to build the plug. After two weeks he had a lump of hacked about

foam, and he gave up. Sorry mate Ė It doesnít work like that.

All this sanding means you have a lot of time to think while toiling away in the garage. Making a body pattern single handed is a silly amount of

work. To do this I think you do have to be determined, some would say bloody minded. It reminds me of when I was cycling competitively, and later

racing karts. Sometimes while doing the activity (cycling Ė while feeling bad and just just hanging on the back of a bunch, karting Ė being nerfed off

the track, or having other issues during a race day) I would think to myself Ė ďthis is madness, Iím not enjoying myself, Iím going to give upĒ. But

then at the end of the day you see you have finished a bit higher up than last time, and you feel better, and so you give it yet another go. Having

like minded mates to chat/drink beer with after also helps a lot.

I have seen a couple of references that state doing a body pattern the old fashioned way takes maybe 1000 Hours. I reckon I am averaging at most about

10 hours a week on the project, so that would be two years. Currently just starting the 20th month of work on the pattern and I hope to finish this

year still, so that 1000 hours seems about right in my case. I read in USA magazine ďHot RodĒ's paint and body issue that rod or muscle car high

end professional paint jobs may have 200 to 300 hours of block sanding alone in them Ė and thatís on an existing car!

I try to concentrate on just the area I am working on, without thinking about the all the work yet to do. When I get despondent I look back through

this thread and see how far Iíve come, and that improves my resolve to keep going, as does the positive responses from you guys here.

Experienced builders might smile at the notes below, but I put this down for others who may be considering a similar project. Maybe they are just

notes to myself:

There is no ďeasy wayĒ

Donít agonize over how to approach or do something. Just start, and move on from there. You may find that eventually the first thing you did has been

changed/replaced, but at least you started.

Get each stage as good as you can before you move onto the next. Itís easy to shape wood/foam, less easy to shape GRP, a pain to correct stuff at the

body filler stage. Getting it absolutely correct at the drawing stage would be first prize.

Donít expect to get every section 100 percent the first time. Get it good, do another section, work round the car, when you get back to it you can get

it better.

Even when you donít feel like it, or just have a little bit of time, get in the garage. Things donít get built if you arenít in the garage. Even if

you just tidy up a bit, you will do something.

Do everything to the standard you want. If it bothers you every time you look at something, rework it.

If you get tired, or find yourself rushing to finish something at the end of a day, stop. Do it next time. You will make mistakes and have to redo it

if you donít.

When you think you are just about finished, you arenít - The last 10 percent takes 90 percent of the time.

Anything can be fixed / reworked.

Cheers

Fred W B

adithorp - 6/8/08 at 12:41 PM

"...(cycling – while feeling bad and just just hanging on the back of a bunch,..."

I know that feeling! It's looking good.

adrian

Benonymous - 6/8/08 at 01:05 PM

Hi Fred, I'm not only impressed with what you have achieved but also with your work philosophy. The car you are building comes from an era where

design was functional but also aesthetically pleasing. Your ideas about carrying out the work also come from that era of patient craftsmanship.

I know for a fact that one day I'll see a gleaming Lola twinkling in the sunlight on this thread. I don't care how long it takes.

Power to your sanding arm mate!

sgraber - 6/8/08 at 02:53 PM

Thanks for that philosophical musing Fred. You've dredged up a rush of memories on my part! I would like to just stand beside you in agreement on

all of your above mentioned points.

That part about just doing a small thing every day even when you don't feel like it, that is a core value that will see you finish this project

and it's the one trait lacking in so many people. Dedication. You've got it in spades! Congratulations.

G.

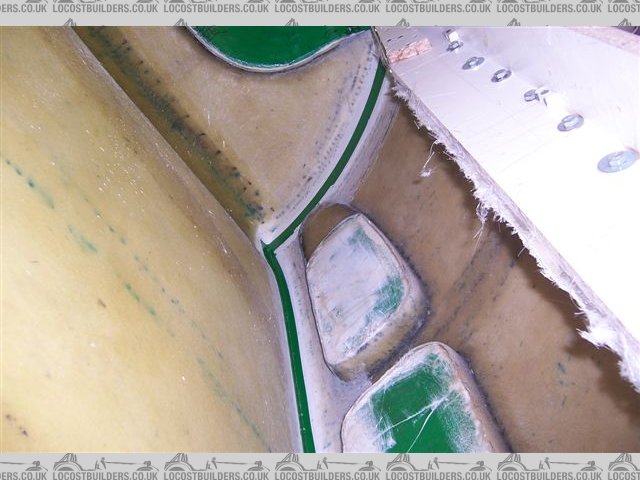

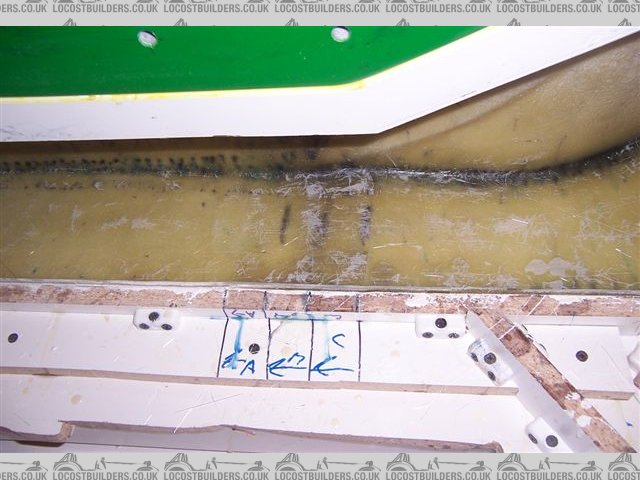

Fred W B - 22/12/08 at 05:42 PM

So, an update!

I have not been making progress as fast as I'd like, getting a consistent uniform shape and radius on the edges around all the openings has been

taking ages. I have got through over 50 kg of body filler so far. I am now working with 120 grit paper and trying to get up to a dark ABF guide coat

that will be the last iteration before the primer surfacer can go on.

Currently I am pretty happy with all the top, side and rear panel surfaces, as well as the cockpit edges. The rear wheel arch edges are pretty much

done, as are the edges of the "hip" ducts. The internal surfaces of these still need some more work, as does the front wheel arches and the

edges of the openings in the front of the nose. After that the only major job left is finishing the inner faces and edges of the radiator exit duct.

I attach some photos

Cheers

Fred W B

buck dec 018

[Edited on 22/12/08 by Fred W B]

Fred W B - 22/12/08 at 05:43 PM

[img][/img]

Fred W B - 22/12/08 at 05:44 PM

[img][/img]

Fred W B - 22/12/08 at 05:45 PM

[img][/img]

Fred W B - 22/12/08 at 05:46 PM

[img][/img]

Fred W B - 22/12/08 at 05:47 PM

[img][/img]

Fred W B - 22/12/08 at 05:48 PM

[img][/img]

Fred W B - 22/12/08 at 05:49 PM

[img][/img]

Ivan - 22/12/08 at 07:39 PM

I remain in awe of what you are achieving  - it's something I would love to do but know I don't have the perseverance to ever reach

your standard of workmanship

- it's something I would love to do but know I don't have the perseverance to ever reach

your standard of workmanship  I know I would eventually take a short cut and spoil the job

I know I would eventually take a short cut and spoil the job

I'm much better at mechanical things that don't need the endless fettling and repetition to get them right.

smart51 - 22/12/08 at 07:54 PM

I am in awe. Seriously, if mine gets to look as good as yours does now, I'll have finished, not be thinking of finishing.

quote:

Originally posted by Fred W B

Making a body pattern single handed is a silly amount of work. To do this I think you do have to be determined, some would say bloody minded.

You don't say

quinnj3 - 24/12/08 at 12:18 PM

I've been on this site for a couple of years now and have only just stumbled across this post. I've just spent about an hour reading it and

taking in all the work you have done. And all on top of having a job and normal life to go with it. You must be a very stuborn person! I only wish I

had the patience and the drive to build something to half the quality that you are doing. Keep up the good work. No doubt when you are finished

I'll still be reading and wishing!

Fred W B - 24/12/08 at 05:48 PM

Thanks for the kind comments guys, helps to keep the motivation up

Cheers

Fred W B

Echidna - 28/12/08 at 10:28 AM

You've done a magnificent job! Keep on with the updates!

chrsgrain - 29/12/08 at 09:22 AM

Wow - that is going to be awesome when its done....

Chris

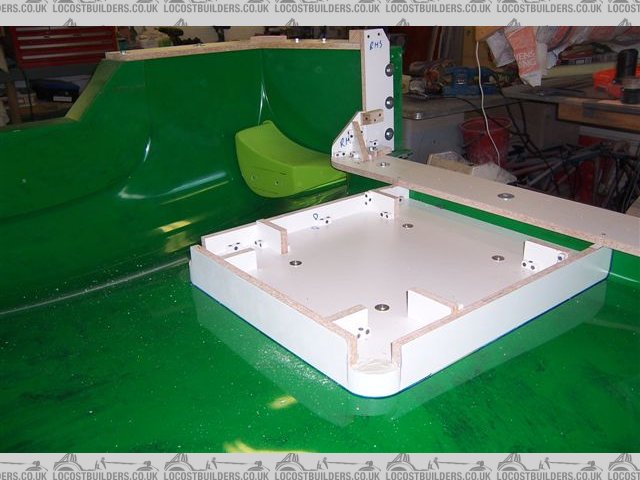

Fred W B - 4/1/09 at 06:44 PM

Being on leave at the moment, I have been able to make quite a bit more progress.

The front wheel arch edges are almost finished. Here you see the arch opening shape template (the spirit level is screwed to it) and the lip profile

checking plate.

In this first shot you can see that the blend of the lip to the fender still needs a bit more work, although the flash does seem to exaggerate the

effect.

jan 09 arch temp

jan 09 arch edge

[Edited on 4/1/09 by Fred W B]

Fred W B - 4/1/09 at 06:46 PM

Nose now looks much better, shown here with a guide coat on.

[img][/img]

Fred W B - 4/1/09 at 06:47 PM

Although the pattern is solid enough that I can sit on it, it is difficult to reach down far enough to work in the bottom of the rad exit duct. I had

to make this platform to kneel on. Its hard work sanding at the full stretch of your arms!

Cheers

Fred W B

[img][/img]

Hugh Paterson - 4/1/09 at 07:40 PM

Hey Fred, what paint are u using for the guide coat? something off the shelf, or a brew up from all your old tins!!

Shug

Fred W B - 4/1/09 at 07:53 PM

Hi Hugh

It's just rattle cans, I hate to think how many I have got through

When I finally finish this, all the local to me hardware stores are going to wonder why their stocks of rattle cans has just stopped turning over.

Cheers

Fred W B

chrsgrain - 5/1/09 at 12:45 PM

OMG - that's awesome....

How far do you reckon to go until you can mould it? Have you got to scratch build the chassis to go with it as well?

Chris

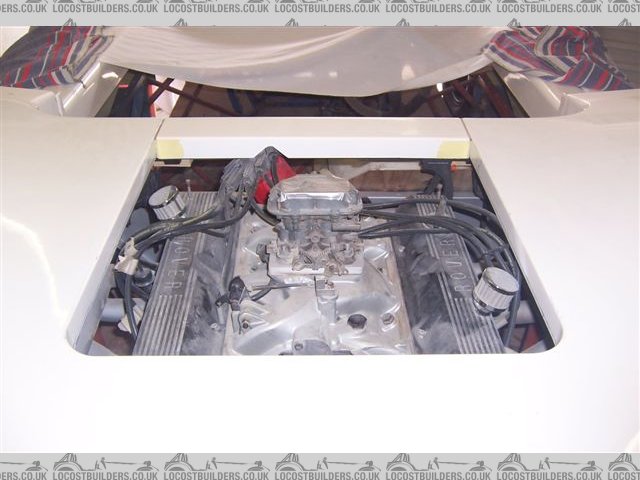

Fred W B - 5/1/09 at 05:33 PM

Thanks for the interest Chris

quote:

How far do you reckon to go until you can mould it?

Will be a good few months yet, the better the surface gets the worse it looks.

quote:

Have you got to scratch build the chassis to go with it as well?

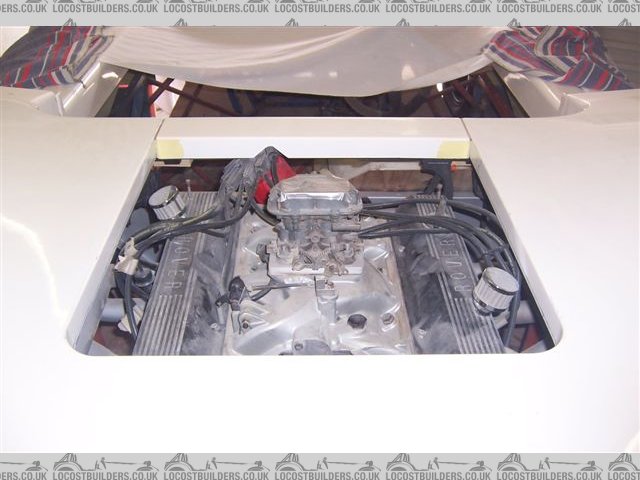

So far I have built a prototype chassis, You can see some detail re the chassis in THIS

THREAD

If you want to see some more about the project, search on this site for "CANAMSA". I put that name in the title of posts I make about

various aspects of the car.

Cheers

Fred W B

[Edited on 5/1/09 by Fred W B]

seansverige - 9/2/09 at 05:53 PM

Hi Fred

stumbled across this whilst doing some online research. First off I would like to congratulate you on what you've achieved - truly, truly

amazing: you seem to have taken the hardest road possible from your 3 axis measuring jig onwards, and look close to completion - many others would

have fallen by the wayside.

I'd like to offer a couple of observations that are too late for you but might prove useful to anyone reading this thread and is inspired to copy

your example - I think these approaches could be applied to any subject.

When I read that you were working from a model my heart sank - models can vary significantly from the reality. This can be unintentional, such as the

case with the rear overhang that caught you out - but I have to say that other than that you've really pulled it off. I don't know whether

the different rear wheelarch on the other model is based on an actual variant or simply a liberty taken. It also use to be the case that a fair bit of

plagiarism went on in the mainstream industry so the first guy to model it makes the tail a little too long, and this get copied in subsequent

variations.

Variances can also be deliberate: smaller features can look out of scale when modelled accurately and in fact need to be exaggerated slightly to look

right - and this effect increases as scale decreases. This is less of an issue with the more organic shapes like the Lola, but a problem with more

complex forms such as the Audi TT's wheelarches (in this case complex means surface breaks and detail.)

The modelmaking scene has really taken off so if possible it's worth investing in a slightly more expensive but hopefully more accurate model. At

the extreme end, I don't know how amenable they might be to sharing information but, on the assumption that actually purchasing one of their

models is out of the question, contacting a high-end modelmaker such as John Shinton (www.johnshintonmodels.co.uk - who in fact makes a 1:8 T70 Mk3B

coupe) might yield some useful info or tips.

I would also look at other modelmaking sites - there are some useful sites and forums out there. There are an increasing number of websites that

collect blueprints (such as www.the-blueprints.com) - these are generally for guys building computer models, but there maybe some useful info there,

especially for the more recent stuff.

I think you mentioned that you've never seen a T70 in the flesh - or at least hadn't when you started the project - making what you've

achieved quite frankly jaw dropping. Historic racing is the fastest growing motorsport segment of late, and a quick search turned up the Zwartkops 9

hour revival race at Kyalami (don't know how much of a trek that is for you) - and the entry list DID feature a T70, although I don't know

what variant. Even at the biggest events such as a Goodwood, paddock access is excellent compared to conventional motorsport meeting.

Having found this thread, I've registered and will be checking back on your progress - keep up the excellent work. Good luck!

/sean

Fred W B - 9/2/09 at 07:02 PM

Hi Sean

Thanks for your comments and kind compliments.

As you say, it seems to have been a long hard road, and I certainly have a much better understanding of the T70 shape now than when I started. As for

working from a model, it was the only reference I had. I don't know where I would have started from without it. As for how accurate the shape is,

I will really only know if my shell ever stands next to a real one. But which real one? The GD/RCR replica is based on the 3 continuation cars that

Lola licensed in the early 80's, and that was quite a bit different to the original 60's cars in some areas. I understand that the GD/RCR

replica shell is 4" narrower than an original.

Also, as I have stated before, I have deliberately done some details differently to the originals. I've got to the stage now when I have to put

the pictures away and just get the damn thing finished and looking good to me. If I was trying to do an absolutely accurate, indistinguishable from

the originals, copy I would have been a gibbering wreck in a nut hose by now.

That said, I'm not sure if I am really looking forward to when I will be able to get it onto wheels and push it out into the sun for the first

real look, in case I am disappointed. I have read that the guy who did the pattern and moulds for the really accurate Kraftwerk 917 replica went

through everything I have done, and then when the first body was out the mould and built up, it did not look right to him, and he went though the

whole thing again, modifying the first set of panels and making new moulds.

But then, looking at various website's where guys discuss the various "high end" expensive replicas of some classic sports racers that

are available, there's always someone who recons this or that is "wrong", and most people are happy to accept.

As you suggest, last year a real T70 spyder did make the trip out here with the David Piper circus to do the Zwartkops (Pretoria, 1100km trip for me)

and Killarny (Cape Town, 800 km trip) races, but I was not able to schedule a trip to see it.

Their are 2 or 3 T70 Coupe replicas/mould sets in SA (I think originally based on a Maurader shell) but no spyders, at least to my knowledge.

Another point, in the now going on 6 years since I started this thing the amount of info and pictures available on T70 spyders on the web seems to

have increased dramatically, unless it has just become more visable to me as I became more aware?

P.S - I dont intend to put "Lola" badges on the car, when people ask what it is, I say its "inspired by" a Lola T70 Spyder.

Cheers

Fred W B

[Edited on 9/2/09 by Fred W B]

seansverige - 10/2/09 at 05:16 PM

Hi Fred - thanks for the swift response.

I was just throwing out ideas that might be of use to others following your example and (just to be clear) not in any way challenging your approach or

wanting to imply that none of the suggestions mentioned hadn't occurred to you - I'm sure you have plenty of hard won knowledge to impart.

Starting with a model was the best way, but I guess the basic principles are to question everything Ė as you did with the rear overhang (it was this

that prompted me to write) Ė and cross-reference data from as many sources as possible to get a levelling effect.

You do yourself a disservice stating you're not being absolutely accurate Ė the attention to detail and quality of workmanship belies that and I

personally applaud your willingness to tweak things to your own satisfaction, which is surely why you're doing it in the first place?

As well as all your other challenges, there are some inherent in your choice of subject matter Ė with low volume race-bred stuff like this I'm

sure very few were completely alike. These guys were concerned with winning, not historical record, and in a pre-digital era only documented as much

as they needed to to get the job done, so reconstructing the picture decades later is open to interpretation - and that's before we consider any

changes made in that period between them being cutting edge and classic, when they were simply old cars; finally, as you say, there's the issue

of 'continuation' models...

I would say you're correct - in the broadband age more stuff is out there, and Lola's 50th anniversary stimulated that further, but there

were a few good books about. The point about the modelmakers was that with someone like Pierre Scerri (the guy who did the 312 B) Ė his chosen subject

matter is now probably more comprehensively documented than it was when first designed and built; how willing they'd be to share that info is

another matter (if not already done, surely books could be written from the research material generated?)

In terms of actual replicas, I think this term covers a multiude of sins: many of replicas should be called lookalikes, but then categorising your

project with some of these is frankly an insult to you, but that's a whole other discussion. It's not just the internet that's changed

things Ė Goodwood FoS is only 15 years old and the Revival considerably younger; a quick trawl through Flickr the following Monday can yield useful

data.

Look forward to seeing photos of the rolling chassis in the bright SA sun and hopefully the fact that this is your interpretation of a T70 means

you're less likely to be disappointed.

Fred W B - 10/2/09 at 06:32 PM

Thanks Sean, and no, I wasn't taking any offence at all, enjoyed your input.

quote:

in a pre-digital era only documented as much as they needed to to get the job done,

Interestingly enough, one of the most useful references I found was a scan of a scale 3 view line drawing published with a article about the car in a

car magazine when the car was new. The look of the drawings suggests that the author might have had access to the original lola drawings.

It was very kindly sent to me by a guy in Belgium who saw my project on here.

Cheers

Fred W B

[Edited on 10/2/09 by Fred W B]

Fred W B - 21/3/09 at 04:00 PM

Some good news out of the commercial crisis!

I haven't been able to get any time on the car for several weeks now, due to some other things keeping me busy, but this weekend managed to get

back in the garage.

You know how retail establishments only know how to put their prices UP, while those of us in engineering / manufacturing / construction have to

instantly adjust selling prices due to raw material price changes when commodities and petrochemical prices soften?

Today I went to buy some more paint rattle cans, to find the price is now two thirds of what I have been paying in the past. I nearly fell over. As we

know all economic activity has softened but its nice to see a price reduction on the retail shelf when you are taking money out of your own pocket.

Cheers

Fred W B

ceebmoj - 23/4/09 at 07:12 AM

hi,

is there an update / any more pictures?

blake

Badger_McLetcher - 23/4/09 at 11:43 AM

I've just finished reading this thread mate and it's just jaw dropping, absolutely stunning.

Fred W B - 24/4/09 at 03:52 PM

Thanks for posts guys, I'm still making slow progress on finishing off some last details before I go out and buy the surfacer primer.

Haven't had the use of a camera for the last few weeks, but should be able to put up a bit more in a couple of weeks.

Cheers

Fred W B

Fred W B - 2/5/09 at 04:45 PM

I finally have the edges of the openings in the nose and the radiator exit duct pretty much finished.

may 09 top front

may 09 brake duct

may 09 nose duct

[Edited on 2/5/09 by Fred W B]

Fred W B - 2/5/09 at 04:51 PM

I did some housekeeping in the garage and discovered I've made quite a few templates

may 09 templates

[Edited on 2/5/09 by Fred W B]

Fred W B - 2/5/09 at 04:57 PM

As an example, it took some masking tape stripes, a lazer level, 5 templates and quite a bit of work to get the two rear quarters to match.

may 09 rear quarter

[Edited on 2/5/09 by Fred W B]

Fred W B - 2/5/09 at 05:01 PM

I'm now working round the cockpit edges for the final (pre surfacing primer) time

Cheers

Fred W B

[img][/img]

Ivan - 2/5/09 at 05:54 PM

As usual

As usual

seansverige - 3/5/09 at 10:45 AM

Excellent stuff - quality of workmanship shines through in the photos, nose and side intakes look nice and crisp.

Can't wait to see it rolled out into the sun...

ceebmoj - 4/5/09 at 10:56 PM

as many others have said the quality of you're work is truly amassing

MakeEverything - 5/5/09 at 07:20 PM

Holy poo Fred. Youre one clever guy, with a garage load of patience!

Well done my friend. Id love to spend some time in SA to learn some of your knowledge.

Thanks for sharing the experience and good luck.

andygtt - 15/5/09 at 07:49 AM

Hi Fred

Long time no speak, great to see your getting to the final stages of making your Buck.... looking really good, cant wait to see it rolled out into the

sun.

keep up the great work

andygtt - 15/5/09 at 09:21 AM

quote:

Originally posted by Fred W B