rodgling

|

| posted on 12/3/17 at 12:09 PM |

|

|

quote:

Originally posted by Nickp

Also, when it's ticking over and i disconnect the MAF it improves the idle. When I plug it back in it stalls.

[Edited on 12/3/17 by Nickp]

It's probably your MAF then. Typically it will stutter but then carry on when you plug it back in. Also if it idles significantly better without

the MAF that's another hint.

|

|

|

|

|

Nickp

|

| posted on 12/3/17 at 12:18 PM |

|

|

quote:

Originally posted by rodgling

quote:

Originally posted by Nickp

Also, when it's ticking over and i disconnect the MAF it improves the idle. When I plug it back in it stalls.

[Edited on 12/3/17 by Nickp]

It's probably your MAF then. Typically it will stutter but then carry on when you plug it back in. Also if it idles significantly better without

the MAF that's another hint.

Let's hope so, cheapo one coming Tuesday. If it does the job I'll probably get a proper one later, or not

|

|

|

Nickp

|

| posted on 15/3/17 at 10:57 AM |

|

|

MAF fitted and initially I thought it was sorted as both Lambdas were reading around 0.5v. But just tested again today with it fully warmed up and

they now seem to be alternating between 0.5v and 5v, each taking it in turns to be 5v (full rich). Then started it again and they're both sat

around 2-2.5v!! All very random. I got an adapter lead for an OBD2 reader but it won't connect. A mate's sending his working one over for

me to try, so fingers crossed that'll give me a clue. I suppose there's a chance my cheapo MAF could be dodgy

|

|

|

obfripper

|

| posted on 15/3/17 at 01:59 PM |

|

|

Nick,

Here's a few things that may help you in tracing doen your fault.

What was the lambda value during the fast idle test?

If this value is 0.980-1.030 the mixture is correct and your catalyst may not be capable of oxidising the CO being produced during closed loop running

(this could be due to carbon fouling from extended idling or aftermarket cats that are incapable of oxidising enough CO under test conditions). If it

is in the 0.900-0.970 range the engine is running too rich for the catalyst to operate correctly and further investigation is needed.

If the engine is rich, it is worth checking is the oil separator valve and pipework. If you remove the oil cap with the engine idling and the idle

speed drops significantly/stalls or there is noticable pressure buildup , the pressure regulating part of the valve has failed. There should be 10-15

mbar vacuum at idle in the crankcase with no osv faults present, with a failed osv anything from manifold vacuum to 0.5+ bar pressure may be present

depending on how the valve has failed.

The osv failing will mess up all the long term fuel trims and may be the root cause of your problem, as well as causing excessive oil usage.

It is likely that the pipework may require replacement if there is a problem, as the pipes get very brittle and tend to break upon removal, the

dipstick tube can also block up at the oil separator connector but is cleanable.

If this is part of the problem, you'll have codes 227 & 228 , but they can also occur from faulty maf readings.

I don't think you'll be able to read obd codes unless you have a us market ecu fitted (or possibly us firmware flashed), for eu ecu

you'll need an inpa clone to work with the 20pin adaptor to get codes, or someone friendly to read the codes/live data for you.

With your engine code you definately have titania sensors and your ecu should be a motronic ms41.

Your described behavior for the lambda sensor feedback sounds as expected for titania sensors (as it is a narrowband sensor the only accurate value is

lambda=1 at 2.5v, either side is rich or lean with no accurate indication of actual ratios hence the system cycles rich/lean to maintain lambda=1 at

the exhaust).

Disconnecting the maf is putting the engine into "limp mode", if there is a fuel trim issue it will run better but is not a guarantee of a

fault with the maf.

Going by tech data, at ecu pin 8/maf pin 2 yellow wire you should have 0v with ignition on engine off, 0.6v at idle and 1.5v at 3000rpm, this will be

correct with the engine at normal operating temp. maf pin 1 is engine earth, pin 3 is 12v supply and pin 4 is ecu supplied earth.

You need to discount any codes that have been caused by disconnecting maf etc, clear codes and run up to temp before rechecking codes.

Have a look here for further info:

https://www.picoauto.com/library/automotive-guided-tests/titania-lambda-sensor

Some further reading on interpreting gas analyser lambda values:

http://www.austincc.edu/wkibbe/lambda.htm

Dave

|

|

|

Nickp

|

| posted on 15/3/17 at 02:24 PM |

|

|

Blimey, good answer!!

Yeah it was rich at anything over tickover, around 2.5% which then affected the lambda reading.

So I should be looking for 2.5v then? Seems to be a lot of conflicting info, most says 0.5v is the optimum.

BTW I have an M50 manifold fitted and the associated plumbing under it to the OSV, if this makes any difference?

Also, the engine revs up too high on start up but I thought that could be the ICV, I've got one of those coming too.

Update- if anything the idle rises slightly when I pull the oil filler cap.

MAF voltage appears OK too, 0.6v at tickover and rises as expected with revs.

Does the ECU reset and clear fault codes when you disconnect the battery?

[Edited on 15/3/17 by Nickp]

|

|

|

obfripper

|

| posted on 15/3/17 at 08:23 PM |

|

|

quote:

Originally posted by Nickp

Blimey, good answer!!

Yeah it was rich at anything over tickover, around 2.5% which then affected the lambda reading.

If you have the analyser printout from the test the lambda value will be on there. That value will help to work out what is happening.

I take it when the test was carried out and it failed 1st fast idle that there was then 3 mins of pre conditioning before the second attempt at fast

idle test and this also had a set of results on the printout?

The lambda value is not recorded at normal idle on the mot, i assume it is the same with iva.

quote:

So I should be looking for 2.5v then? Seems to be a lot of conflicting info, most says 0.5v is the optimum.

With your ecu and titania sensors 2.5v is the switchover point from lean-rich and rich-lean, the engine management does not aim to stay at 2.5v, just

to cycle from slightly rich to slightly lean.

A multimeter will not have a fast enough sample rate to see this perfectly but should give a good indication that it is happening.

This is what you would see with an oscilloscope and a correctly operating titania sensor, you can see the general cycling of lambda voltage, and that

it slightly varies in timebase and voltage.

quote:

BTW I have an M50 manifold fitted and the associated plumbing under it to the OSV, if this makes any difference?

Also, the engine revs up too high on start up but I thought that could be the ICV, I've got one of those coming too.

I take it you have the m52 throttle body and icv attached to the m50 manifold?

quote:

Update- if anything the idle rises slightly when I pull the oil filler cap.

That sounds ok, a quick way of establishing vac/pressure in the crankcase is to pull a latex glove over the dipstick so the tube is in one finger and

then cable tie around it. Once the engine is started and settled idling it should lightly suck in the end of the finger, if there is excessive vacuum

it will suck the finger right in, and pressure will inflate the finger.

If you have a manometer you can check it to specs, or macgyver one with some clear tube, water and a piece of batten. 4-6 inches difference in level

is the equivalent of 10-15mbar. Put a bottle or similar in the line to stop water getting sucked into the engine if there is excessive vacuum.

http://www.obairlann.net/reaper/motorcycle/manometer.html

This one's for balancing carbs, but the principle is the same.

Dave

|

|

|

Nickp

|

| posted on 15/3/17 at 09:23 PM |

|

|

1st test was CO 2.34 % 0.931 lambda

2nd was 3.22% 0.905 lambda

It also says that it failed the normal idle test too at 1.33% but I'm sure this was OK before the fast idle was done and was 0.2%

I'll do some more testing in the morning and hopefully my new ICV will arrive tomorrow to fit. A friend is fetching me another OBD reader

tomorrow night to try too.

With the ICV connected the engine revs too high on cold start and also the revs are very slow to fall when blipped. Disconnect the ICV and it's

much crisper, if that gives you any clues?

Yes M52 TB and ICV.

[Edited on 15/3/17 by Nickp]

|

|

|

CTLeeds

|

| posted on 15/3/17 at 09:40 PM |

|

|

Hi Nick,

You're welcome to borrow my unmapped DME if it helps you at all? It's had the ABS and EWS deleted. I'm a little way from needing

it...

Cheers,

Chris

|

|

|

Nickp

|

| posted on 15/3/17 at 09:51 PM |

|

|

quote:

Originally posted by CTLeeds

Hi Nick,

You're welcome to borrow my unmapped DME if it helps you at all? It's had the ABS and EWS deleted. I'm a little way from needing

it...

Cheers,

Chris

Cheers Chris, I may well take you up in that especially with the EWS deleted

|

|

|

obfripper

|

| posted on 16/3/17 at 12:33 AM |

|

|

Those lambda values are a good clue.

That is rich enough to stop the catalysts from working fairly quickly, hence when you returned to idle the CO was a lot higher.

The catalyst should start to work properly once the fueling is corrected.

It looks like the fuel trims were getting richer while the test was being carried out which leaves a few options.

-The engine management is interpreting the lambda feedback as lean and so was richening the mixture to compensate - this could be caused by air

getting into the exhaust system somewhere between head and lambda sensor positions. It would take something like a pinhole or leaking gasket to cause

this kind of problem, but should be noticeable as a blow.

-There is a fault with 1 or both lambda sensors, causing the same richening as above, comparison between sensor voltages and gas analyser measured

lambda may help here. I don't think this is likely but would not totally discount it.

-It could also be caused by the maf overreading and fueling to match, but this should be initially rich and lean off as the fast idle was held and the

lambda feedback cut back the fuel trims, which i think is unlikely with given data.

-There is a possibilty that the remapper has turned off the lambda feedback or changed the conditions where open loop is enabled (so the lambda sensor

feedback has no effect on fuelling) or adjusted the number of functioning lambda sensors(usually with turbo conversions), this may be tricky to detect

directly but diagnostic live data may help here. If the lambda feedback has been disabled this may also mean fault codes have also been removed or

disabled entirely. I have encountered before on other ecu's and can make things tricky to diagnose.

I would definately try a standard dme, it's worth getting some time with a friendly garage and their emissions tester, and bring working

diagnostic equipment so if something is not right you can also see why.

Dave

|

|

|

Nickp

|

| posted on 16/3/17 at 06:06 AM |

|

|

There doesn't seem to be any blow on the manifolds. New pair of gaskets and nice and tight.

I've been interchanging my identical lambdas and get similar results with every combination. I've also confirmed that they're

connected the correct way round as they work in 2 banks apparently.

I'm borrowing a std map (ews deleted) ecu but that won't be until next week. So I'll keep trying for now and see what codes if any I

can read off it later today.

Thanks again

Nick

|

|

|

Nickp

|

| posted on 16/3/17 at 11:02 AM |

|

|

Dave,

Just done the rubber glove finger over the dipstick test and I definitely seem to have slight negative pressure as it sucks it in slightly.

Fitted my new ICV and straight away it didn't rev as high from cold and the revs seem to settle quicker now too, so hopefully that's one

issue sorted.

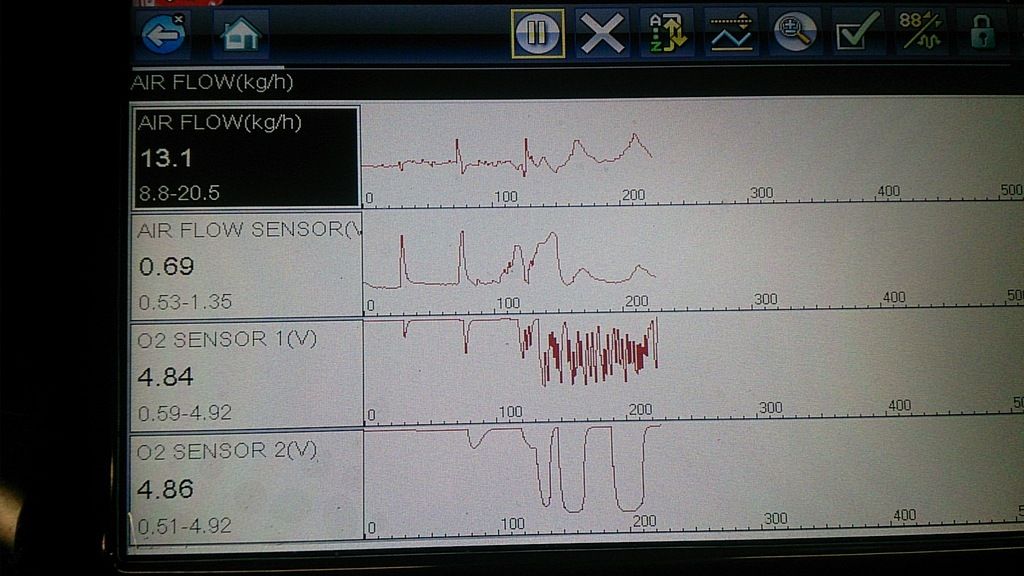

I monitored the voltages as it warmed up and they were sat at a steady 0.5v with very little fluctuation. As soon as it was fully warm the voltages

start to vary from 0.5-4.5v quite randomly. But saying that, one seems to flick straight from high to low while the other seems to climb and drop more

slowly, not sure if this is relevant TBH. The picture above shows it cycling up and down continuosly, does this give an average voltage then? Ideally

2.5v? As my DVM isn't going to show this is it?

I really need to read any fault codes and get it on a CO meter now to see if I've actually still got an issue as it seems to be running much

better now TBH.

[Edited on 16/3/17 by Nickp]

|

|

|

Nickp

|

| posted on 16/3/17 at 06:51 PM |

|

|

Just been looking at the live data. No codes coming up, which is a shame!! Lambda volts still all over the place but each set of 3 very different. One

spiking up and down and the other much smoother. It has a rhythmical misfire to it now. Wonder if something is breaking down on ignition side? All

plugs are black but none look any worse tbh.

|

|

|

Nickp

|

| posted on 16/3/17 at 08:44 PM |

|

|

We may have a breakthrough, and it may have been all my doing

After seeing it had no fault codes, all the plugs were black but the lambdas were responding very differently I thought about the only difference

between the 2 manifolds - a 90deg adapter I'd fitted to one to avoid the bonnet.So I've now taken this out and the lambda voltages seem to

follow a similar pattern now  I'm not out of the woods yet as I still need to check the CO (Oh and trim the bonnet to clear the feckin

Lambda!!) but I think I'm a big step nearer. I'm not out of the woods yet as I still need to check the CO (Oh and trim the bonnet to clear the feckin

Lambda!!) but I think I'm a big step nearer.

[Edited on 16/3/17 by Nickp]

|

|

|

gremlin1234

|

| posted on 16/3/17 at 09:23 PM |

|

|

quote:

Originally posted by Nickp

We may have a breakthrough, and it may have been all my doing

After seeing it had no fault codes, all the plugs were black but the lambdas were responding very differently I thought about the only difference

between the 2 manifolds - a 90deg adapter I'd fitted to one to avoid the bonnet.So I've now taken this out and the lambda voltages seem to

follow a similar pattern now  I'm not out of the woods yet as I still need to check the CO (Oh and trim the bonnet to clear the feckin

Lambda!!) but I think I'm a big step nearer. I'm not out of the woods yet as I still need to check the CO (Oh and trim the bonnet to clear the feckin

Lambda!!) but I think I'm a big step nearer.

[Edited on 16/3/17 by Nickp]

so a sensor was not 'in the flow'?.. that wouldn't help,

but really well done, good problem solving & feedback, I hope it does work.

and also hopefully helps others with similar problems.

|

|

|

Nickp

|

| posted on 16/3/17 at 09:45 PM |

|

|

[Edited on 16/3/17 by Nickp]

so a sensor was not 'in the flow'?.. that wouldn't help,

but really well done, good problem solving & feedback, I hope it does work.

and also hopefully helps others with similar problems.

Thanks. Mixed feelings really, glad it looks like I've got to the bottom of it (with lots of help from others) but a bit miffed it was something

so daft that could've been avoided. These adapters are sold for lambda sensors but generally used after the cat I think. I had no idea it would

be so critical using it how I did and completely screw the fueling. Oh well you live and learn eh??

I'll be popping some new plugs into it too as these poor ones have had to withstand some pretty serious sooting up.

[Edited on 16/3/17 by Nickp]

|

|

|

gremlin1234

|

| posted on 16/3/17 at 10:13 PM |

|

|

quote:

but a bit miffed it was something so daft that could've been avoided.

yea and ALL other things you got RIGHT first time,

building a road legal car ain't easy!

[Edited on 16/3/17 by gremlin1234]

|

|

|

obfripper

|

| posted on 16/3/17 at 11:38 PM |

|

|

That looks like it'll yield an improvement on the gas tester.

If the ethos/solus you've borrowed can display the long term fuel trim data, with the engine run up to temperature they should be in the +/- 5%

is spot on , up to 20% should still give a pass on CO and lambda with no further work.

It is odd that no codes were logged, but the ms41 is an oldish ecu and may only record current persistent fault codes, so anything that is now fixed

will not show up as a stored fault.

Dave

|

|

|

Nickp

|

| posted on 17/3/17 at 03:48 AM |

|

|

quote:

Originally posted by gremlin1234

quote:

but a bit miffed it was something so daft that could've been avoided.

yea and ALL other things you got RIGHT first time,

building a road legal car ain't easy!

[Edited on 16/3/17 by gremlin1234]

Cheers, I suppose I didn't do bad overall really

|

|

|

Nickp

|

| posted on 17/3/17 at 03:50 AM |

|

|

quote:

Originally posted by obfripper

That looks like it'll yield an improvement on the gas tester.

If the ethos/solus you've borrowed can display the long term fuel trim data, with the engine run up to temperature they should be in the +/- 5%

is spot on , up to 20% should still give a pass on CO and lambda with no further work.

It is odd that no codes were logged, but the ms41 is an oldish ecu and may only record current persistent fault codes, so anything that is now fixed

will not show up as a stored fault.

Dave

Thanks again for your technical input Dave, there's a lot of conflicting information out there about these relatively old BMW engines and their

management.

|

|

|

Nickp

|

| posted on 31/3/17 at 08:14 AM |

|

|

Just popped up to a local MOT place and it's now scrapeing through the fast idle test with <0.2%CO and <200ppm HC.

Hopefully by the time it gets to Nottingham on Tuesday it'll be better still and pass OK. Fingers crossed!!

|

|

|