b14wrc

|

posted on 13/7/12 at 09:37 PM posted on 13/7/12 at 09:37 PM |

|

|

Build table.

Right chaps,

Just looking for some advice, started making my build table tonight, and was wondering if you had any tips?

This is progress so far, it's seems pretty strong, going to make adjustable legs so it can be levelled. Any thing I have missed?

Regards, Rob

20vt powered rear engined locost

|

|

|

|

|

loggyboy

|

| posted on 13/7/12 at 09:40 PM |

|

|

Nice long spirit level to check its nice and flat.

Mistral Motorsport

|

|

|

Padstar

|

| posted on 14/7/12 at 08:54 AM |

|

|

Out of interest how are you doing the legs? I plan to build similar at the end of the month. I want to attach casters to the legs so the table is

moveable. Is his a bad idea?

|

|

|

b14wrc

|

| posted on 14/7/12 at 12:29 PM |

|

|

Hi,

Well table is almost done. I'm not 100% happy with the flatness, with my straight edge I have a slight dip in the middle and there is a slight

run off at the front to the edge, I'd say the difference is about 2mm, saying this, my garage floor is fairly uneven where the pit is and

I'd guess there could be as much as 5mm difference in the floor where the legs are sitting.... It isn't level and I reckon once I have

finished the legs and adjusted it all, maybe I will get it perfect. As an engineer 2mm is more than I'd like, but the wood and even MDF was not

true to start and I don't have any flat surface to work on big enough.

Hoping it will be better when levelled. A metal frame might have been better... Not changing it now anyway. What's peoples opinion on starting

with 1-2mm out? Will it even be noticed?

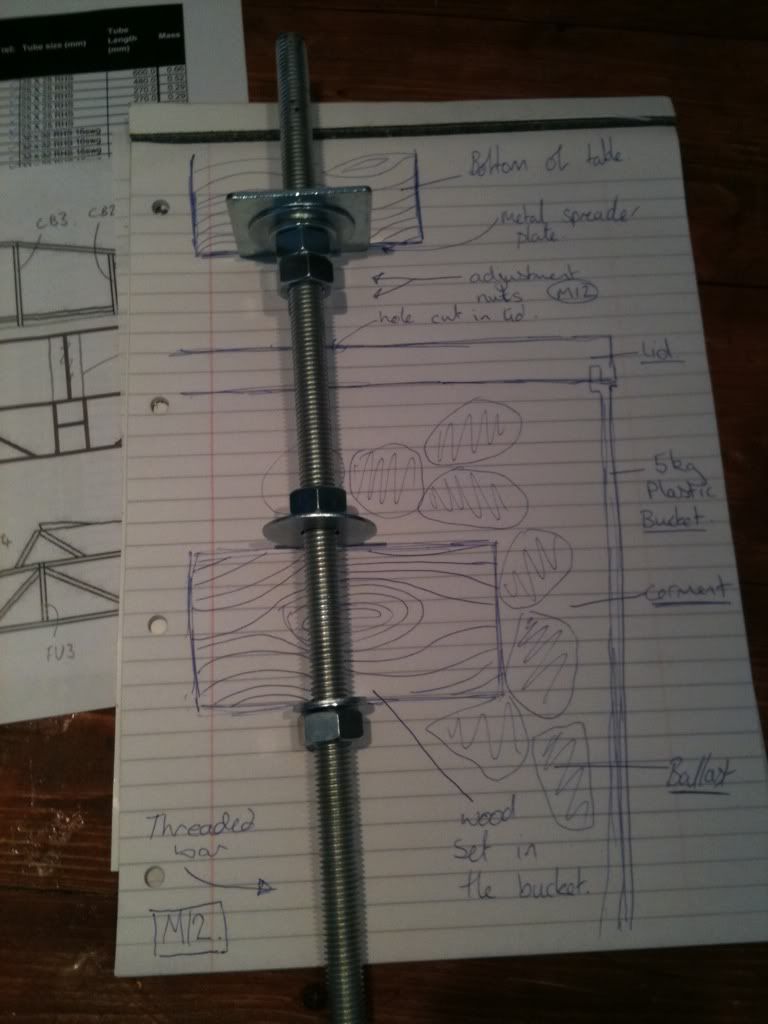

Leg wise, see below:

I am basically going to fill those buckets with cerment and rubble and cast the threaded bar in the mix, so I can the adjust the table over a 10mm

range, so should get it flat and they will be super strong and not move around. By the way, table weighs a tonne! I'm not bothered about moving

it around, more concerned in levelness and sturdy. Rubble is going to be the rubbish I took out the bathroom. So a handy recycling idea too!

Can finally get on and build it for real and not play with wood any more.

Rob

20vt powered rear engined locost

|

|

|

Fred W B

|

| posted on 14/7/12 at 01:13 PM |

|

|

Why bother with the buckets? I would just Rawl Bolt the base of the legs to the floor.

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

b14wrc

|

| posted on 14/7/12 at 01:19 PM |

|

|

The buckets are the legs?? Saves shifting a whole bath full of rubble out the garden too.

There are no wooden legs, it's just a work top. I thought the buckets would give a larger stable base at each corner. I also get them for free.

20vt powered rear engined locost

|

|

|

RichardK

|

| posted on 14/7/12 at 02:02 PM |

|

|

If the chassis is already built why so concerned about the table being totally flat?It's only really important when tacking your chassis

together IMHO

Cheers

Rich

Gallery updated 11/01/2011

|

|

|

iank

|

| posted on 14/7/12 at 02:07 PM |

|

|

Would it be possible to put a small shim between the frame and top to get rid of the dip?

Doubt 1-2mm would make a lot of difference, but if it will bug you then worth sorting if it's easy enough.

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

iank

|

| posted on 14/7/12 at 02:08 PM |

|

|

quote:

Originally posted by RichardK

If the chassis is already built why so concerned about the table being totally flat?It's only really important when tacking your chassis

together IMHO

Cheers

Rich

Think the current chassis needs a bit more metal in it (take a look at the pictures in his archive)

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

b14wrc

|

| posted on 14/7/12 at 02:53 PM |

|

|

Thanks iank, I was going to point out to Rich the chassis is still wood, it's a mock up of the car. I havn't actually started building the

car yet. Lol.

Not sure if the 1-2mm can be fixed, unless table is slightly twisted where it is sitting at the moment, when I jack the corners up to level it may

right itself.

Fingers crossed any way.

Rob

20vt powered rear engined locost

|

|

|