bumpy

|

| posted on 16/8/13 at 07:35 PM |

|

|

Adding substance to fibreglass panels

On some kit cars, things like door panels are often fairly flat and a bit 'wobbly'. These can obviously be strengthened up by laying on

more fibreglass matting on the inside, but is there a simpler way to do it?

Whatever goes on the inside of the panel needs to adhere well, needs to be light, and needs to be rigid. I have been pondering the use of polyurethane

spray. This comes in two types

Open cell (like a sponge), but this tends to be quite pliable. Or closed cell which is claimed to be more rigid. The latter could be a way to go if I

can find it in an aerosol spray can.

Any comments or other ideas.

|

|

|

|

|

balidey

|

| posted on 16/8/13 at 07:39 PM |

|

|

Core material is what the parts are refered to.

Can be virtually any material, balsa, foams (watch the styrene content) filler and resin mix, woven glass roving with padding between, hemp ropes.

Dutch bears have terrible skin due to their clogged paws

|

|

|

rdodger

|

| posted on 16/8/13 at 07:43 PM |

|

|

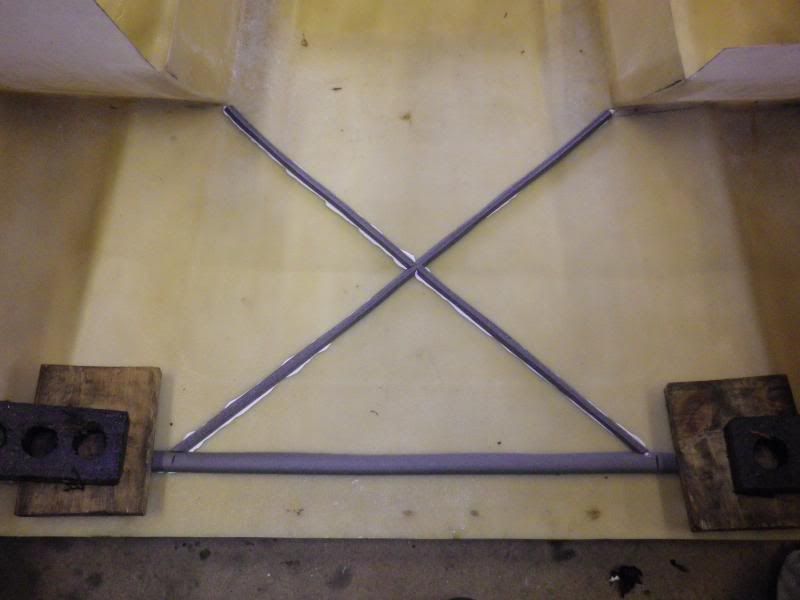

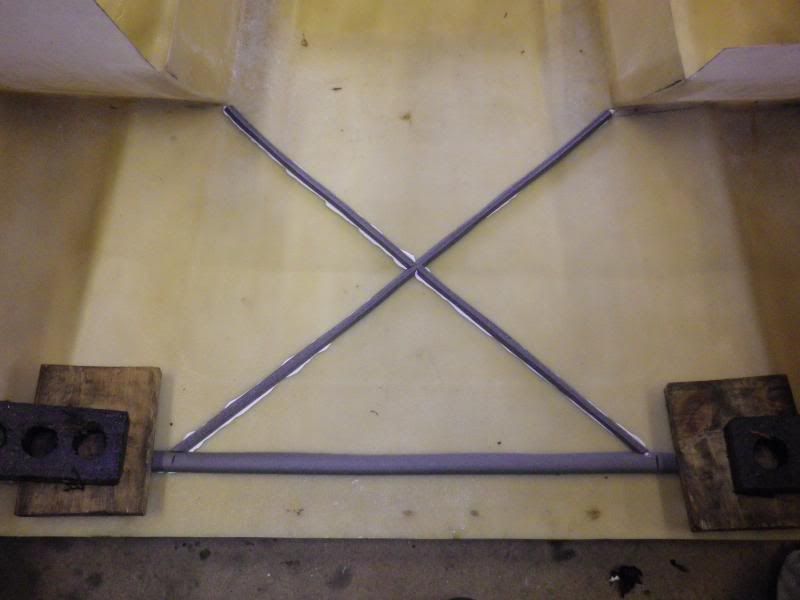

I bonded some supports to my front clam.

Cut pipe insulation into suitable width strips and sikaflexed them to the panels. When the sikaflex had gone off I went over them with a layer of CSM

about 4x the width of the support.

It looks like the underside of a car bonnet now.

[img] [/img] [/img]

|

|

|

bumpy

|

| posted on 16/8/13 at 07:43 PM |

|

|

quote:

Originally posted by balidey

Core material is what the parts are refered to.

Can be virtually any material, balsa, foams (watch the styrene content) filler and resin mix, woven glass roving with padding between, hemp ropes.

So do you add these materials to fibreglass gel and paint it on?

|

|

|

bumpy

|

| posted on 16/8/13 at 07:47 PM |

|

|

quote:

Originally posted by rdodger

I bonded some supports to my front clam.

Cut pipe insulation into suitable width strips and sikaflexed them to the panels. When the sikaflex had gone off I went over them with a layer of CSM

about 4x the width of the support.

It looks like the underside of a car bonnet now.

[img] [/img] [/img]

Sorry for my ignorance but what is CSM?

|

|

|

Slimy38

|

| posted on 16/8/13 at 07:47 PM |

|

|

I was thinking of attaching some polystyrene or foam strips to the inside of the panels, fixed by a layer of fibreglass. It won't be the

polystyrene that supports the panels, more the box section of fibreglass. I'm hoping the panel itself can stay thin and light.

Edit: rdodger can type faster than I can, but I will be doing exactly what he's done!

CSM=Chopped Strand Mat, or fibreglass...

[Edited on 16/8/13 by Slimy38]

|

|

|

rdodger

|

| posted on 16/8/13 at 07:50 PM |

|

|

CSM. Chopped strand mat. Basically fibreglass you then put the resin on.

The pipe insulation is just there to form the fibreglass over. The strength is in the fibreglass section.

Edit: It looks like a type off Slimey!

[Edited on 16/8/13 by rdodger]

|

|

|

gremlin1234

|

| posted on 16/8/13 at 08:19 PM |

|

|

quote:

If I can find it in an aerosol spray can.

wouldn't

http://www.wickes.co.uk/invt/156665

do what you want, maybe with, card or plastic on the inside to limit its spread.

|

|

|

Carbonman

|

| posted on 16/8/13 at 08:21 PM |

|

|

Along the same idea lengths of garden hose pipe, air line hose, PVC electrical conduit hot glued into position and then glassed over all work well. As

said you are just using the hose etc as a former the strength comes from the glass once cured.

Just make sure you "key" the surface well. Polyester resin doesn't like bonding to itself.

If its a panel with an inner skin like a door then filling the gap with expanding foam will add lots of stiffness to a flat panel. Just don't

put too much in as you could distort the panels.

[Edited on 16/8/13 by Carbonman]

Carbon Copies Ltd

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

bumpy

|

| posted on 16/8/13 at 09:20 PM |

|

|

quote:

Originally posted by Carbonman

Along the same idea lengths of garden hose pipe, air line hose, PVC electrical conduit hot glued into position and then glassed over all work well. As

said you are just using the hose etc as a former the strength comes from the glass once cured.

Just make sure you "key" the surface well. Polyester resin doesn't like bonding to itself.

If its a panel with an inner skin like a door then filling the gap with expanding foam will add lots of stiffness to a flat panel. Just don't

put too much in as you could distort the panels.

[Edited on 16/8/13 by Carbonman]

Thanks for that. Certainly glassing over pipe etc looks like plan A.

Just to pursue you comments on expanding foam, can you recommend a spray can of the right stuff? Screwfix seem to do a few. Do you think if the door

is single skinned that the foam would be as effective if built up to a thickness of say 20mm on just the inside of the outer skin.

|

|

|

chrism

|

| posted on 16/8/13 at 09:48 PM |

|

|

I remember seeing a while ago on a guide to making moulds and panels that an Australian guy used rolled up newspaper as a former to make ribs of

fibreglass on the back of the panel, similar to the above shown with pipes. Its the ____n____ shape on the back of the panel that adds strength, its

the same principal as folding a piece of sheet steel it a U shape for strength.

----------------------------

A little hard work never killed anyone, but why take the risk!

-----------------------------

|

|

|

Carbonman

|

| posted on 17/8/13 at 02:44 AM |

|

|

quote:

Originally posted by bumpy

quote:

Originally posted by Carbonman

Along the same idea lengths of garden hose pipe, air line hose, PVC electrical conduit hot glued into position and then glassed over all work well. As

said you are just using the hose etc as a former the strength comes from the glass once cured.

Just make sure you "key" the surface well. Polyester resin doesn't like bonding to itself.

If its a panel with an inner skin like a door then filling the gap with expanding foam will add lots of stiffness to a flat panel. Just don't

put too much in as you could distort the panels.

[Edited on 16/8/13 by Carbonman]

Thanks for that. Certainly glassing over pipe etc looks like plan A.

Just to pursue you comments on expanding foam, can you recommend a spray can of the right stuff? Screwfix seem to do a few. Do you think if the door

is single skinned that the foam would be as effective if built up to a thickness of say 20mm on just the inside of the outer skin.

The Expanding Foam idea only really works when the panel is double skinned. You are effectively bonding the inner and outer skin together, making a

composite sandwich panel. The greater the distance between the panels the stiffer it will be. Having said that just a 20mm layer on the back would

have some effect. It may be easier to cut pieces of 25mm Kingspan Insulation Board to size, peel of the foil backing and bond that to the back of the

panel.

As for the type of expanding foam I use the "Everbuild" stuff only because its available from the builders merchants round the corner.

They do two types, the standard stuff that expands up to 150% or what they call "precision" which only expands 5-10%.

Carbon Copies Ltd

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

bumpy

|

| posted on 17/8/13 at 08:24 AM |

|

|

quote:

Originally posted by Carbonman

quote:

Originally posted by bumpy

quote:

Originally posted by Carbonman

Along the same idea lengths of garden hose pipe, air line hose, PVC electrical conduit hot glued into position and then glassed over all work well. As

said you are just using the hose etc as a former the strength comes from the glass once cured.

Just make sure you "key" the surface well. Polyester resin doesn't like bonding to itself.

If its a panel with an inner skin like a door then filling the gap with expanding foam will add lots of stiffness to a flat panel. Just don't

put too much in as you could distort the panels.

[Edited on 16/8/13 by Carbonman]

Thanks for that. Certainly glassing over pipe etc looks like plan A.

Just to pursue you comments on expanding foam, can you recommend a spray can of the right stuff? Screwfix seem to do a few. Do you think if the door

is single skinned that the foam would be as effective if built up to a thickness of say 20mm on just the inside of the outer skin.

The Expanding Foam idea only really works when the panel is double skinned. You are effectively bonding the inner and outer skin together, making a

composite sandwich panel. The greater the distance between the panels the stiffer it will be. Having said that just a 20mm layer on the back would

have some effect. It may be easier to cut pieces of 25mm Kingspan Insulation Board to size, peel of the foil backing and bond that to the back of the

panel.

As for the type of expanding foam I use the "Everbuild" stuff only because its available from the builders merchants round the corner.

They do two types, the standard stuff that expands up to 150% or what they call "precision" which only expands 5-10%.

Excellent info thanks.

I would bet that the standard stuff is open cell and the precision stuff is closed cell as referred to in my opening post. For most uses people will

ignore the precision stuff as it expands much less, but for this purpose it is much more rigid and therefore better.

The idea of creating a sandwich is a good one, and could be as simple as pushing a piece of thin ply wood onto the exposed surface of the foam. This

you would then leave in place.

[Edited on 17/8/13 by bumpy]

|

|

|

Carbonman

|

| posted on 17/8/13 at 09:14 AM |

|

|

For something like a door or boot lid you could bond the "kingspan" onto the back of the panel and then glass over it. That way you would

create an inner skin that would be bonded to the outer skin on all edges. Two layers of 300grm CSM pus the resin would give you a skin about 1mm

thick.

Carbon Copies Ltd

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Fred W B

|

| posted on 17/8/13 at 09:51 AM |

|

|

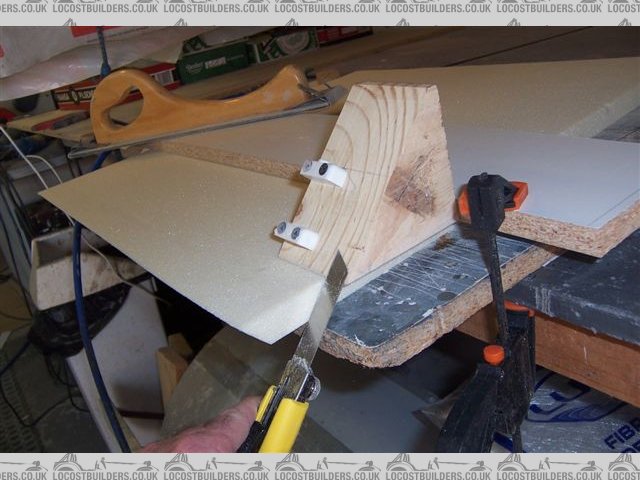

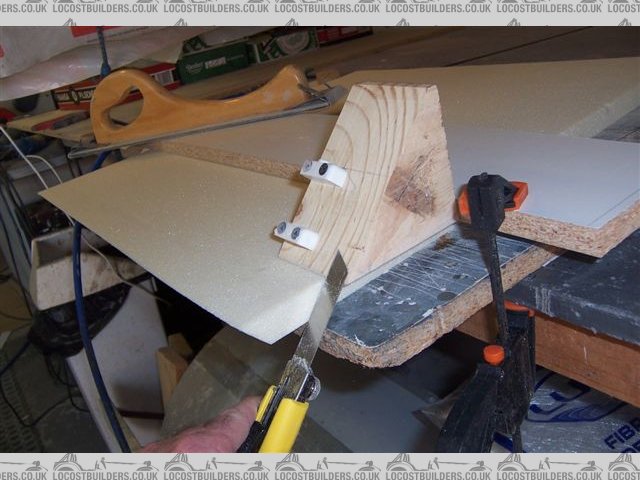

Coincidently I am on a tea break from this job right now. I am cutting reinforcing sections 60 wide by 20 mm tall as shown from polyurethane foam

sheet to glass over.

Cheers

Fred W B

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

bumpy

|

posted on 17/8/13 at 10:22 AM posted on 17/8/13 at 10:22 AM |

|

|

quote:

Originally posted by Fred W B

Coincidently I am on a tea break from this job right now. I am cutting reinforcing sections 60 wide by 20 mm tall as shown from polyurethane foam

sheet to glass over.

Cheers

Fred W B

Now that spreads the reinforcing over a bigger surface area which is good. Is that polyurethane or polystyrene?

|

|

|

Fred W B

|

| posted on 17/8/13 at 11:37 AM |

|

|

quote:

I am cutting reinforcing sections 60 wide by 20 mm tall as shown from polyurethane foam sheet

I made a rough jig to aid cutting the chamfer.

[Edited on 17/8/13 by Fred W B]

You can do it quickly. You can do it cheap. You can do it right. – Pick any two.

|

|

|

bumpy

|

| posted on 17/8/13 at 11:46 AM |

|

|

quote:

Originally posted by Fred W B

quote:

I am cutting reinforcing sections 60 wide by 20 mm tall as shown from polyurethane foam sheet

I made a rough jig to aid cutting the chamfer.

[Edited on 17/8/13 by Fred W B]

OK, I was just checking as it looked like polystyrene and I cant recall seeing sheets like this of polyurethane in the UK . .

I like your little jig, clever.

|

|

|

40inches

|

| posted on 17/8/13 at 01:40 PM |

|

|

In the past I have used fibre tubes, the kind that prints and long thin parts are posted in, cut in half, stuck down and glassed over.

A bonus is that they are hollow, wiring and pipework etc can be fed through them.

|

|

|

Volvorsport

|

| posted on 17/8/13 at 03:55 PM |

|

|

paper rope is another one ....

clan crusaders use this as the basis of their roll cage.........

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|