alistairolsen

|

| posted on 18/4/09 at 10:24 AM |

|

|

Anyone with a lathe fancy some beer tokens?

I need a spigot spacer making. I have a bearing which fits the crank tunnel with an internal dimension of 17mm (as best I can measure with a vernier,

Dont have in internal mic)

The input shaft of the box Im usin measures 11.45mm using a micrometer.

The bearing is 10mm thick.

So Im looking for a space to take up the gap. Not sure on the most appropriate material, I guess bronze but steel would also probably be fine.

A slight bevel on the edges would also be handy for pressing it in.

Anyone handy with a lathe and fancy helping me out? Drop me a u2u and let me know!

Cheers

|

|

|

|

|

coozer

|

| posted on 18/4/09 at 11:46 AM |

|

|

I could, but the problem would be getting the internal 11.45 imo. Thats an odd size even converted to " 0.45.

1972 V8 Jago

1980 Z750

|

|

|

hillbillyracer

|

| posted on 18/4/09 at 03:53 PM |

|

|

Are there any numbers on the bearing you're going to use? It'll be a fairly standard bearing & if the number is known then the specs

& size will be available somewhere to confirm your measurement. Chances are it is spot on 17mm, it'll be a metric bearing & they tend to

be made to round figure like 17mm & not 16.85 or 17.1.

I have a lathe but I'm not the most talented of operators & hav'nt anything other than a boring bar to make an accurate internal cut

& non of mine are that small.

[Edited on 18/4/09 by hillbillyracer]

|

|

|

alistairolsen

|

| posted on 18/4/09 at 04:15 PM |

|

|

its a standard 6003 bearing 35x17x10 so it should be exactly 17mm.

The inside diameter I suspect was 12 bang on (input shaft on a getrag gearbox) but after a little corrosion and a cleanup with emery paper is now a

few thou under.

Id prefer a snug fit in the bearing and loose in the shaft tho so 17 and 12 exactly should do fine

|

|

|

NigeEss

|

| posted on 19/4/09 at 08:12 AM |

|

|

Here's a good start

FLEABAY

I could finish one off to your requirements.

Time is an illusion. Lunchtime doubly so.................Douglas Adams.

|

|

|

alistairolsen

|

| posted on 19/4/09 at 09:28 AM |

|

|

good spot, bid on those!

|

|

|

alistairolsen

|

| posted on 20/4/09 at 11:58 AM |

|

|

Right, i won the bushes on ebay so I can arrange postage to someone if they want to do this for me.

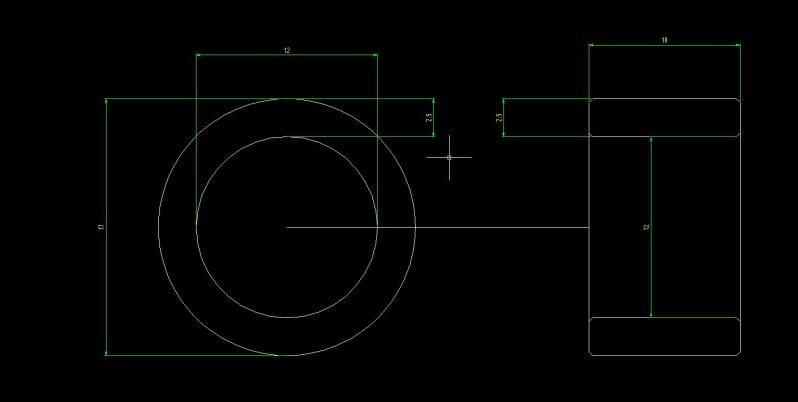

drawing as a jpeg:

dxf available if required.

An interference fit into the bearing would be great, and given its a mass made precision part Id assume its 17 exactly so Im not sure what normal

procedure is? Couple of thou oversize and then freeze it to fit or what?

Cheers

[Edited on 20/4/09 by alistairolsen]

|

|

|