andylancaster3000

|

| posted on 26/6/07 at 01:53 PM |

|

|

How to bend an engine...

Was helping my dad out last weekend by beginning a head re-build for him after a 'minor' failure. Thought I'd share some

pictures!

It all begins with water pumps deciding they dont like their vanes and ditching them:

By doing so one of the little blighters decides it's going to jam the pump solid and bending the pulley shaft:

Mr. cam belt obviously wasn't too keen on this idea and sheds some teeth:

You can probably see where this is going....:

A slight tweak i'd say:

Luckily, i say luckly as it could have been more, two valve guides are broken to add to the hassle.

Edit: Engine is a 210k VX ecotec engine. Apparently they are prone to the vains falling off from the pump

[Edited on 26/6/07 by andylancaster3000]

|

|

|

|

|

andylancaster3000

|

| posted on 26/6/07 at 01:53 PM |

|

|

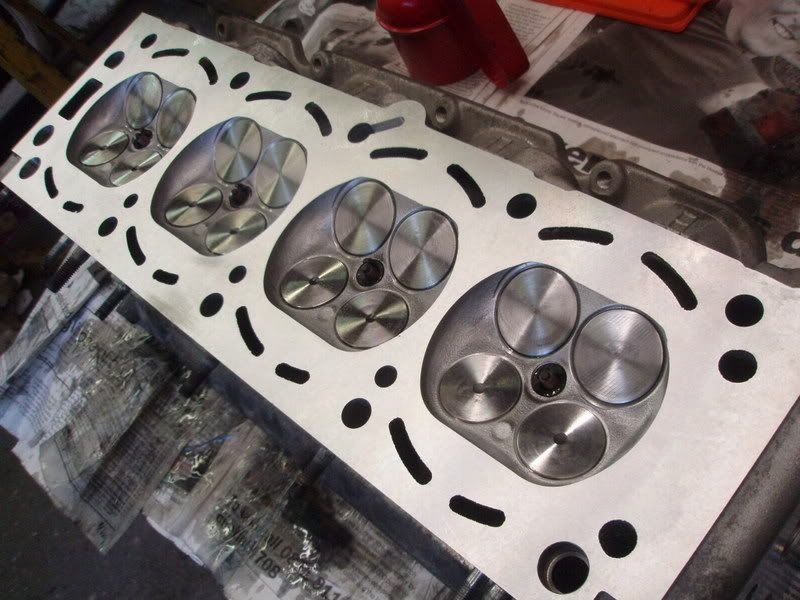

and a couple of days later:

|

|

|

MikeRJ

|

| posted on 26/6/07 at 01:56 PM |

|

|

What caused the metal pump impeller to fail? The vanes don't just fall of them...

|

|

|

Aboardman

|

| posted on 26/6/07 at 02:03 PM |

|

|

is that the same head.?

|

|

|

tks

|

| posted on 26/6/07 at 02:04 PM |

|

|

i would say cafitation as the start of the problem. cafitation starts when airbells are created in the pump. the bells implode and explode and that

can damage every pump!

to create cafitation

- wrong liguiq desnity

- wrong impeller speed

and some more..

Tks

The above comments are always meant to be from the above persons perspective.

|

|

|

MikeRJ

|

| posted on 26/6/07 at 02:08 PM |

|

|

Cavitation can certainly erode impeller vanes, but I suspect it's more likely that something solid passed through the pump, or the bearings in

the pump failed and the vanes hit a part of the block.

|

|

|

Phil.J

|

| posted on 26/6/07 at 02:23 PM |

|

|

I'd bet it was started by bearing failure or seizure. Be surprised if an engine of this spec. revs fast enough to cause significant cavitation.

|

|

|

andylancaster3000

|

| posted on 26/6/07 at 02:24 PM |

|

|

Yup, same head. Managed to get a quick turn around at the local machine shop for guide replacement and a head skim.

I too though it was odd how they just 'fail' but apparently it is fairly common. I suspect something caused one to come away and strip

the rest of the teeth off, as it runs very close to the block on one side (as you would expect)

We managed to fish out all but one of the vanes  from the water jacket. Lets just hope the other one doesn't find its way back.. from the water jacket. Lets just hope the other one doesn't find its way back..

|

|

|

02GF74

|

| posted on 26/6/07 at 04:50 PM |

|

|

stick the vlace in a vice to strighten it

could be nice made into a trophy;

or sell it on ebay as custom valves for improved gas flow.

|

|

|