tegwin

|

| posted on 9/10/08 at 09:26 PM |

|

|

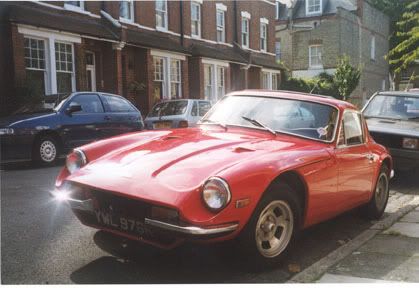

Creating a mold and moldings?

The Steel Chrome bumpers on my classic are passed it..the chrome is all rusty and there are some big holes in two of them...

Plus....why on earth have TVR fitted great lumps of steel on the corners of a lightweight car!!!

How hard would it be to make a mould using the original bumpers and then create fiberglass moldings?

The left and right hand side bumpers are mirror images so I would have to make 2 re-useable molds...

Luckily there are no negative recesses on them, and they are fairly simple..Open at the back as well

But how does one go about making a mold/moulding?

This company in the states do fibreglass numpers for US$138 PER CORNER

Bumpers on car

[Edited on 9/10/08 by tegwin]

[Edited on 9/10/08 by tegwin]

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

|

|

coozer

|

| posted on 9/10/08 at 09:32 PM |

|

|

Dead easy for a fibreglass mould making replica type fella.. an absolute impossible task for a stupid old bugger like me...

1972 V8 Jago

1980 Z750

|

|

|

clairetoo

|

| posted on 9/10/08 at 09:33 PM |

|

|

Dead easy - is the quick answer - a right pain in the ar%*e if that is the only glassing you are planning to do - is the long answer !

The process I would use is - clean them up and spray a coat of `polyester based spray filler` on , flat with 1200 grit wet and dry , then wax with a

silicone free wax .

Apply gel coat , followed by 6 or 7 layers of mat and allow to harden over night .

Clean/file the edges and remove the new molds

A quick t-cutting will bring the molds to a shine , then wax and make your new bumpers

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

Maradona

|

| posted on 9/10/08 at 09:37 PM |

|

|

Is easy and cheap make fiberglass moulds, try to search in the web or in You Tube, how to make a fiber glass moulds, you will find much info.

I search for you in you tube, here are the link

http://www.youtube.com/watch?v=nsvgaWHPMF4

Cheers

Diego,

The locost builder from Argentina

|

|

|

Maradona

|

| posted on 9/10/08 at 09:46 PM |

|

|

quote:

Originally posted by tegwin

The Steel Chrome bumpers on my classic are passed it..the chrome is all rusty and there are some big holes in two of them...

Plus....why on earth have TVR fitted great lumps of steel on the corners of a lightweight car!!!

How hard would it be to make a mould using the original bumpers and then create fiberglass moldings?

The left and right hand side bumpers are mirror images so I would have to make 2 re-useable molds...

Luckily there are no negative recesses on them, and they are fairly simple..Open at the back as well

But how does one go about making a mold/moulding?

This company in the states do fibreglass numpers for US$138 PER CORNER

Bumpers on car

[Edited on 9/10/08 by tegwin]

[Edited on 9/10/08 by tegwin]

This company in the states do fibreglass numpers for US$138 PER CORNER

Call to the company who sell the bumps,and say, If they try to stole people is better if they try with a machine gun in a bank. U$ 138 PER

CORNER!!!!!!!!!!! oh my good!!!!   : :

Diego,

The locost builder from Argentina

|

|

|

clairetoo

|

| posted on 9/10/08 at 09:54 PM |

|

|

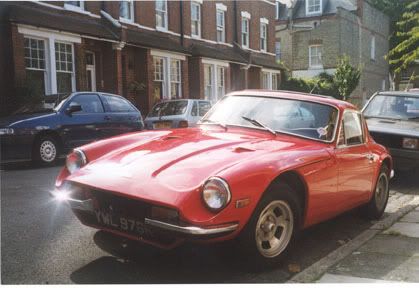

Looking more closely at the photo's I see a small problem - the chrome original's have a rolled edge (against the bodywork) which the

fibreglass copies dont . They appear to have been simplified to make them easier to make , rather than being proper copies .

This would be simple to do , but would need two piece molds (for each one)

Hope that make's sense ?

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

tegwin

|

| posted on 9/10/08 at 10:05 PM |

|

|

What do you mean by rolled?...

My chrome ones look just like those black fibreglass ones....only...chromy..:p

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

clairetoo

|

| posted on 9/10/08 at 10:17 PM |

|

|

Sorry - the last chrome bumper's I saw were Mk1 mini one's , which were'nt `sharp` edged but had a small radius on the back edge - if

yours are just a simple pressing then no prob !

For the sort of money they want ($138 each  ) you could make then in carbon fibre ! ) you could make then in carbon fibre !

I should add that a large part of my `day job` includes fibreglass moldings - from design right through to fitting the finished moldings !

My last `project`

[img][/img]

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

tegwin

|

| posted on 9/10/08 at 10:20 PM |

|

|

Haha...Funy you mention CF.... Was thinking about using that....But somehow I dont think blingy CF would look right on a 1972 car :p

Think I might have to get some more supplies and give it a go...Provided I have some patience.....it could be fun...lol

What sort of weight CSM and how many layers would you suggest for a mold, and then the final moulding?

I have used Polyerster resin before...should I stick with that, or use epoxy instead?

[Edited on 9/10/08 by tegwin]

------------------------------------------------------------------------------------------------------------------------

Would the last person who leaves the country please switch off the lights and close the door!

www.verticalhorizonsmedia.tv

|

|

|

clairetoo

|

| posted on 9/10/08 at 10:27 PM |

|

|

That would depend a lot on how many set's you want to make  If you just want to do a few set's , I would aim for about 4mm thick for the

mold (5 or 6 layer's of 450grm csm) , then , say 3 or 4 for the finished bumper's . If you just want to do a few set's , I would aim for about 4mm thick for the

mold (5 or 6 layer's of 450grm csm) , then , say 3 or 4 for the finished bumper's .

If you go too thick , such a small molding will be dificult to remove from the mold as it wont flex enough to release .

I'd stay with polyester - it's cheap , and since these are purely cosmetic strength wont really be an issue .

[Edited on 9/10/08 by clairetoo]

[Edited on 9/10/08 by clairetoo]

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

Volvorsport

|

| posted on 9/10/08 at 10:39 PM |

|

|

most if not all aftermarket amazon/p1800 bumpers are fibreglass, then chrome plated , its not as good as the genuine stuff , but at least you can

make them cheaply .

www.dbsmotorsport.co.uk

getting dirty under a bus

|

|

|