02GF74

|

| posted on 13/8/11 at 10:02 AM |

|

|

OT: Possible to buy brake pad friction material to make own brake pads?

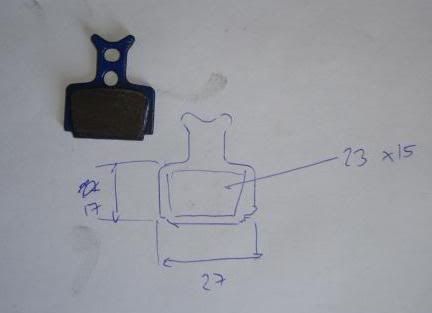

I have fitted KCNC disc to Formula R1 brakes.

Now aftermarket lightweight discs tend to have braking surfaces that are more hole than metal plus tend to be slightly taller. This means that the R1

pads do not sweep the full height, see photo below. The area of disc within the blue outline was marked in blue and what is left as blue is not swept

by the pads. The lower part of the disc is not touched at all (actually the pads I have are slightly worn at the top and bottom so the situation

would not be as bad with new pads).

..... but nethertheless the height of the friction surface on the pads, 15.2 mm, could do with being 1 or 2 mm taller and there is space on the pad

for that.

So if I can get hold of some friction material and then be able to glue it on, I can solve the problem else the alternative is to find another

make/model of pad that has a larger friction are and trim the pad to shape.

Firstly the pad material - can that be purchased?

Secondly the glue - I assume the pads are glued on, what sort of glue is used and can that be pruchased?

|

|

|

|

|

designer

|

| posted on 13/8/11 at 02:20 PM |

|

|

Give Mintex a call, they might do it for you.

|

|

|

Ninehigh

|

| posted on 13/8/11 at 04:46 PM |

|

|

I'd guess that it would be possible to buy a pad minus the fitment, and I figure it would be possible to buy the material that the pads are made

of but I forsee 2 problems.

Do you trust your own gluing method?

Wouldn't the pad material be made by compressing the living hell out of it, or a similar process that can't be done in the shed?

And is that seriously a brake disc?

|

|

|

Macbeast

|

| posted on 14/8/11 at 01:59 PM |

|

|

I think this should be posted in Mad House, not Non-car

I'm addicted to brake fluid, but I can stop anytime.

|

|

|

plentywahalla

|

| posted on 14/8/11 at 02:24 PM |

|

|

Brake pad material is sintered on to the backing plate. That is a process where powdered material is fused under very high temperature and pressure.

The metal backing pads have holes in them which enables the pad material to be mechanically locked into the backing pad in the sintering process.

Forget glue !!!

[Edited on 14/8/11 by plentywahalla]

|

|

|

Peteff

|

| posted on 14/8/11 at 03:32 PM |

|

|

They do look like pushbike brakes to me so probably quite right to put it in non-car chat. Sintering is incorporating metal particles into the pad

material and fusing them to the backing plate, organic brake material is still attached with adhesive.

yours, Pete

I went into the RSPCA office the other day. It was so small you could hardly swing a cat in there.

|

|

|

AndyW

|

| posted on 14/8/11 at 03:37 PM |

|

|

there are some things that should not be "made at home"

|

|

|

SPYDER

|

| posted on 14/8/11 at 03:47 PM |

|

|

Depending on the type of caliper mount you might be able to lower the caliper a couple of mm. There are adjustable adapters out there.

I had a similar issue when I fitted Hope fully floating discs. The pad no longer completely swept the disc area so I went to great lengths to make a

CNC adapter to address the situation. I couldn't tell any difference in the braking power.

|

|

|

thefreak

|

| posted on 15/8/11 at 08:59 AM |

|

|

Give Ian at Carbotech a call, they make custom pads with custom material for any application. I would think they'd be able to make a pair up to

your specs. Wont be cheap though.

|

|

|

02GF74

|

| posted on 15/8/11 at 10:25 AM |

|

|

quote:

Originally posted by plentywahalla

Brake pad material is sintered on to the backing plate. That is a process where powdered material is fused under very high temperature and pressure.

The metal backing pads have holes in them which enables the pad material to be mechanically locked into the backing pad in the sintering process.

I had a feeling that was the case .... pretty sure I read (or rather I misread) that some use glue. Having said that, from the different pad types

(makes and model) that I have, I don't recall seeing glue).

about a foot away from me on my desk are two XTR adapters - if need be, I can trim them down to repositiong the pad over the disc braking surface.

I owuld have preferred to use these:

... but not quite ready to part with £ 22 just yet.

... but not quite ready to part with £ 22 just yet.

As an aside, I have bought off ebay aluminium backed brake pads, I mean, it would have been rude not to  . My understanding is that you do not

want to conduct heat into the pistons and brake fluid so in theory these are a flawed design (stainless steel would be a better metal to use)..... but

on a mtb this should not be an issue, we'll see.... . My understanding is that you do not

want to conduct heat into the pistons and brake fluid so in theory these are a flawed design (stainless steel would be a better metal to use)..... but

on a mtb this should not be an issue, we'll see....

[Edited on 15/8/11 by 02GF74]

|

|

|

kipper

|

| posted on 15/8/11 at 12:14 PM |

|

|

could you not get an over size pad from something else and cut them down to your size and shape? Just an idle lunch time thought

Denis.

Where did that go?

<<<<

|

|

|

02GF74

|

| posted on 15/8/11 at 12:48 PM |

|

|

quote:

Originally posted by kipper

could you not get an over size pad from something else and cut them down to your size and shape? Just an idle lunch time thought

Denis.

... that was my initial idea - there seems to be 1 or two Hope pads that could fit the bill (there is a post on a mtb forum by asking for old pads

...)

|

|

|