T66

|

| posted on 23/1/12 at 07:17 PM |

|

|

Lathes - What have you made for your car ?

Just recently got myself a lathe, would be interested to see some of the car related jobs you have created.

|

|

|

|

|

big_wasa

|

| posted on 23/1/12 at 07:34 PM |

|

|

very boring, spacers and more spacers. I did turn one very nice dcoe to bike Tb adapter but got bored and never made the other matching three.

|

|

|

coozer

|

| posted on 23/1/12 at 07:38 PM |

|

|

Spacers, adapters, gearknobs..

Next is a steering wheel boss and some indicator stalks...

Thats after the sump, gearbox, front wings and stays, some gauges and roll cage have been sorted...

1972 V8 Jago

1980 Z750

|

|

|

NigeEss

|

| posted on 23/1/12 at 07:52 PM |

|

|

Wishbone bushes, fishmouths on round and square tubes, coolant and oil pipe connectors and lots of spacers.

Should start taking piccies of things !

Time is an illusion. Lunchtime doubly so.................Douglas Adams.

|

|

|

clanger

|

| posted on 23/1/12 at 07:52 PM |

|

|

Fitter & turner by trade, and worked in a place with lots of lovely aluminium when I built my first car, recipe for disaster (from the

company's productivity point of view!!!). If I could get in a chuck I made it

Steering column & shroud

Spacers

Nutcovers

hub covers

trackrod extensions

bushes

core-plugs

bearings

bearing housings

widgets and wass-inames

catch tank (out of a nice piece of 6" billet)

hose joiners

gear knobs, several different designs

plus other stuff I forgotten about............

Go MAD

|

|

|

AdrianH

|

| posted on 23/1/12 at 07:57 PM |

|

|

Steering rack extensions.

Cleaning up flywheel (machining face).

Brake drums, disks changing centre hole. Truing up etc.

Spacers and crush tubes.

Steering shaft adapters.

Boring pulley centres

Injector boses

Various jobs for various cars!

Adrian

Why do I have to make the tools to finish the job? More time then money.

|

|

|

T66

|

| posted on 23/1/12 at 08:01 PM |

|

|

quote:

Originally posted by clanger

Fitter & turner by trade, and worked in a place with lots of lovely aluminium when I built my first car, recipe for disaster (from the

company's productivity point of view!!!). If I could get in a chuck I made it

Steering column & shroud

Spacers

Nutcovers

hub covers

trackrod extensions

bushes

core-plugs

bearings

bearing housings

widgets and wass-inames

catch tank (out of a nice piece of 6" billet)

hose joiners

gear knobs, several different designs

plus other stuff I forgotten about............

Go MAD

" If I could get in a chuck I made it" hahahaha - Bench going in next week, just need to go get some scrap to play with.

The Amateur lathe is in the post, my mind is racing already.

|

|

|

owelly

|

| posted on 23/1/12 at 08:03 PM |

|

|

Steering wheel bits:

Bits for Type 9 hydraulic clutch gubbins:

Skimming manifold flanges:

Spigot centre for flywheel:

PugV6 to Type 9 adapter plate:

Adapter locating spigot:

Wheels for beading tool:

Skimmed Sierra rear hubs to take Escort discs:

Bits for De-dion:

MGF solid subframe mounts:

There's hundreds more things I've had in the lathe (including me) but you get the idea? I like my lathe.

http://www.ppcmag.co.uk

|

|

|

T66

|

| posted on 23/1/12 at 08:12 PM |

|

|

You have a daddy lathe, mines just a small one.

|

|

|

owelly

|

| posted on 23/1/12 at 08:31 PM |

|

|

For a lot of stuff, a smaller lathe is better than a big 'un! A gap-bed is the best of both worlds. Sometimes its hard to explain to folks that

a lathe can be used for making things flat, as well as round!

http://www.ppcmag.co.uk

|

|

|

AdrianH

|

| posted on 23/1/12 at 08:34 PM |

|

|

So where is Clairetoo's input?

Adrian

Why do I have to make the tools to finish the job? More time then money.

|

|

|

clairetoo

|

| posted on 23/1/12 at 08:44 PM |

|

|

quote:

Originally posted by AdrianH

So where is Clairetoo's input?

Adrian

Who....me ?

I'm in the `if it fits in the lathe , I'll have a go' camp - I've done everything from small spacers to billet alloy flywheels

- and before I got a small miller , a bit of milling as well . Being a time-served turner/toolmaker has come in kinda handy over the years !

On my Fury at the moment are - alloy front hubs (to fit Rover 820 285mm discs) , alloy flywheel and all engine pullies , modified throttle bodies on

angled adapter plates (which were skimmed to the required angle on my `big' lathe) , and a quick release steering wheel boss .

The lathe(s) are getting a bit of use on the Mx5 project as well........

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

MikeR

|

| posted on 23/1/12 at 08:44 PM |

|

|

She'll still be in the garage on the lathe .....

|

|

|

big_wasa

|

| posted on 23/1/12 at 08:46 PM |

|

|

worst thing I did, swaping my old english lathe for a little chinease one but I couldnt keep it and build the car in the garrage.

|

|

|

clairetoo

|

| posted on 23/1/12 at 09:02 PM |

|

|

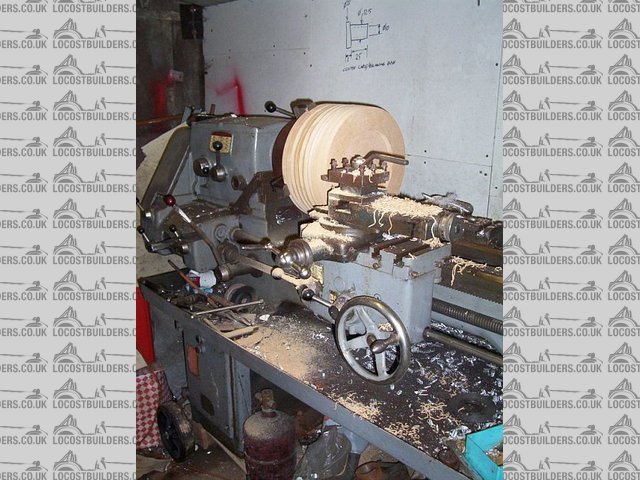

Just to show the range of stuff you can do with a lathe - this was part of a large `tool' for a fibreglass molding I was making at work , this

part needed to be round and tapered - its 14" diameter and some 5" long made from several layers of MDF glued together ,

And a quick release steering wheel adapter for some one on here .

Its cuz I is blond , innit

Claire xx

Will weld for food......

|

|

|

Stott

|

| posted on 23/1/12 at 09:07 PM |

|

|

quote:

Originally posted by clanger

catch tank (out of a nice piece of 6" billet)

Ha ha!

Check this out for material wasteage, Peugeot 205 rear beam bushes from Phos Bronze billet, it was the only bit on the rack!

Waste Of Material?

|

|

|

T66

|

| posted on 23/1/12 at 09:07 PM |

|

|

Appears your lathe is bigger than my lathe too Claire - I like the steering wheel QR

|

|

|

ashg

|

| posted on 23/1/12 at 10:05 PM |

|

|

beginnings of the spacer i made for the omega box to get it to work with the saab clutch, cant seem to find a picture of the finished item

you can almost see it here behind the slave cylinder

made a plug for the heater circuit that i eventually took out and bypassed as the motor kept overheating lol

90 degree elbow for my saab waterpump that i tigged onto the cast housing.

custom trigger wheel for my old pinto engine

holes through m8 bolts to make indicator extensions

wishbone parts

headlight mounts

custom made steering shaft

plus thousand of other parts.

last week i made some spacers for nash's suspension. the month before that i mad some spring platforms for mark's tiger, also made mark

and dick some crush tubes for the control arms on their tigers. the list goes on and on and on. btw my harrison lathe is a gap bed, i have managed

to skim the head of a fiat punto on it with a bit of mucking about

[Edited on 23/1/2012 by ashg]

Anything With Tits or Wheels Will cost you MONEY!!

Haynes Roadster (Finished)

Exocet (Finished & Sold)

New Project (Started)

|

|

|

ashg

|

| posted on 23/1/12 at 10:23 PM |

|

|

couple more aluminium sparkles

Anything With Tits or Wheels Will cost you MONEY!!

Haynes Roadster (Finished)

Exocet (Finished & Sold)

New Project (Started)

|

|

|

rf900rush

|

| posted on 23/1/12 at 10:32 PM |

|

|

Would not be with out a small lathe.

A few spacers

Clutch Slave for GSXR1100 / RF900 ( a bit of milling on this one).

Both machines are cheap chinese thing's.

Slave

O2 Lambda Nut thingy.

Nut

Now with added CNC control. does need some improvements but,

managed to make a Bike Led lamp.

Best bit was doing a 51mm buy 1mm thread for the lense cover.

|

|

|

coyoteboy

|

| posted on 23/1/12 at 10:39 PM |

|

|

Only this of any real interest so far, and not my lathe... I wish I had one!

New sensor by j.buckle, on

Flickr

|

|

|

ashg

|

| posted on 23/1/12 at 10:43 PM |

|

|

quote:

Originally posted by Stott

quote:

Originally posted by clanger

catch tank (out of a nice piece of 6" billet)

Ha ha!

Check this out for material wasteage, Peugeot 205 rear beam bushes from Phos Bronze billet, it was the only bit on the rack!

Waste Of Material?

can really tell who has to pay for materials

the lump of square steel i machined in to a slave cylinder spacer was found in the work carpark, they are used as counter weights on the machines we

make, some twonk had used loads of them to hold a tarp down in the carpark. once the paint finish on them is battered from being used in that manner

they were all considered as scrap as its too much bother to sand them all down and repaint. fortunately i was there to help the facilities guys clear

them up into the scrap bin. the only other material we really have at work is 99.999999% pure copper which is used to make the rf wave guides on the

particle accelerators. they are machined to a tolerance of 6 microns and the material is so expensive the cnc laves are hovered out for swarf and its

melted down and reused for slightly less critical components of the machine. think last time i looked at the price of medical grade pure copper it was

£1000 for a piece that is 100x100mm 1mm thick :S dont think i would get away with wasting any of that

Anything With Tits or Wheels Will cost you MONEY!!

Haynes Roadster (Finished)

Exocet (Finished & Sold)

New Project (Started)

|

|

|

Wadders

|

| posted on 23/1/12 at 11:06 PM |

|

|

This lot was all done on an old 3 1/2 " lathe, eventually upgraded to a bigger harrison machine, but the smaller lathe was great for learning

on. You can lose hours making stuff with lathes, best tool ever invented.....great fun.

Description

Description

Description

Description

Description

[Edited on 23/1/12 by Wadders]

|

|

|

907

|

| posted on 24/1/12 at 08:39 AM |

|

|

I can't think of a single item that I 100% made on my lathe.

Rack extensions and fuel filler cap almost, but still needed a bench drill.

A lathe is however a tool that makes other things a lot easier to fabricate.

Wish bones for instance.

Facing off the bush tubes, nice and square. Tapping the M18f threads.

Even the "fish mouth" tube ends can be done with a milling tool in the chuck.

And those much talked about crush tubes lengths? A doddle to get those right.

It's not just the lathe though. You need all the tooling that goes with it.

Cheers,

Paul G

|

|

|

kipper

|

| posted on 24/1/12 at 08:58 AM |

|

|

myford lathe

sorry to hijack this but I still have my Myford ML7 for sale since I bought my Harrison L5.

I could really do with it out of the workshop and will be putting it on Ebay shortly.

It has had very little use as the Harrison came up just after I had bought the Myford.

The man who had it before me had retired and bought the lathe to make a model steam engine but he fell ill shortly after starting it and never got to

finish it.

It then stood in the house until his widow died ,I bought it from the son when he cleared the house.

It has a brand new 3 jaw chuck ,a 4 jaw,vertical milling slide,catch plate,quick change tool post,Face plate, is on riser blocks, has graduated lead

screw, plus lots more bits and pieces.

Pics of lathe in my archive.

Regards Denis

Where did that go?

<<<<

|

|

|