Prop aligment - how accurate is yours?

jps - 11/12/13 at 03:16 PM

I tacked up some engine mounts last week (although one weld subsequently snapped - so I am back to square one) but before it broke I did the

following...

1.Mounted the diff.

2. Chopped a piece of wood to act as a dummy prop shaft

3. Used a t square to mark off the angle the prop 'should' have followed if it were perfectly aligned from the diff input flange and the

gearbox output flange

4. Compared to the actual centreline that the 'dummy prop' was following

Without a super sharp pencil - and trying to hold 3 things at once - it looked as though the alignment was out at both ends - and in both the vertical

and horizontal planes.

Horizontally - i.e. left to right in the car - it was roughly 3 degrees at each end - the gearbox effectively pointing more towards the o/s side rear

wheel than it was towards the diff - by my calculation the prop would be about 20mm off centre at one end if it were a rigid tube.

Vertically - i.e. up and down in the car - it was roughly 2 degrees out at each end.

The diff input flange is vertically square - as is the gearbox output shaft - as far as I can tell

How does this compare to anyone elses setup? I know the uj's are there to take out this discrepancy - but I want to be starting from the right

ballpark...

[Edited on 11/12/13 by jps]

daveb666 - 11/12/13 at 03:29 PM

I assume the piece of wood was straight to start with?

David Jenkins - 11/12/13 at 03:35 PM

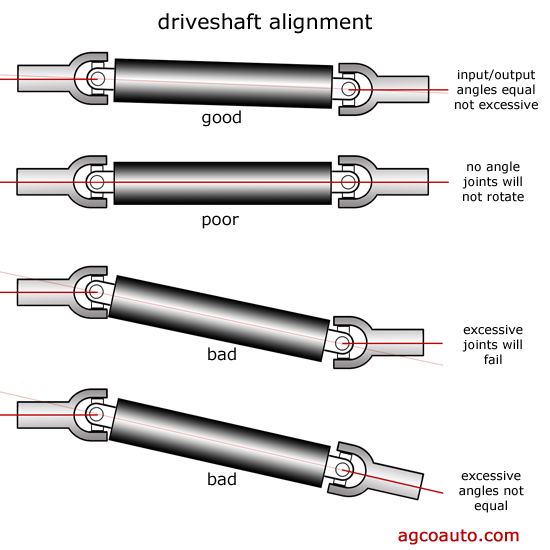

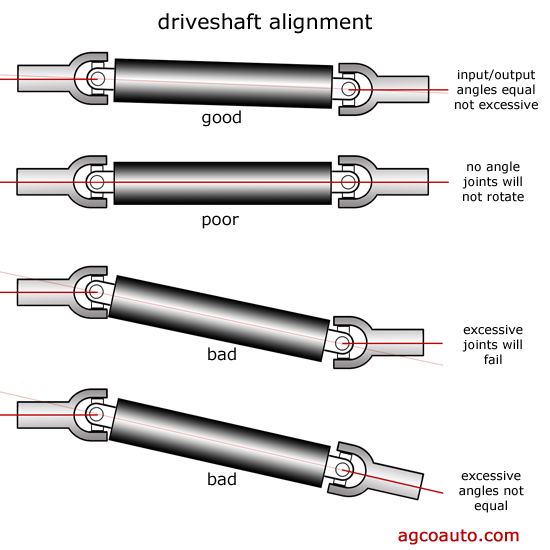

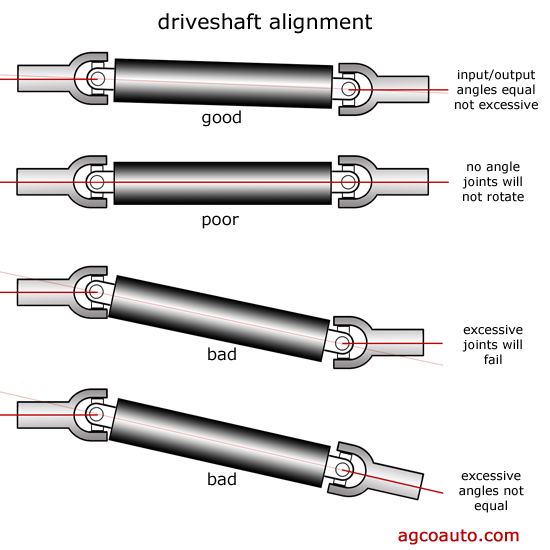

It's hard to picture what you've got from your description, but ideally:

* the engine and gearbox should be parallel to the fore-and-aft centre-line of the car, but not necessarily exactly over it.

* the face of the diff should be at 90 degrees to that centre-line.

* the centre-line of the gearbox driveshaft should not be exactly in line with the centre-line of the diff flange - it should be two or three inches

offset (the shape of the diff will usually facilitate this). Having them exactly in line is likely to lead to excessive wear of the UJs (called

'brinelling', if I've spelt that correctly!).

Maybe the following image will help...

[Edited on 11/12/13 by David Jenkins]

jps - 11/12/13 at 03:41 PM

quote:

Originally posted by daveb666

I assume the piece of wood was straight to start with?

The faces were - as was the centre line I drew down it!

jps - 11/12/13 at 03:48 PM

quote:

Originally posted by David Jenkins

It's hard to picture what you've got from your description, but ideally:

* the engine and gearbox should be parallel to the fore-and-aft centre-line of the car, but not necessarily exactly over it.

* the face of the diff should be at 90 degrees to that centre-line.

* the centre-line of the gearbox driveshaft should not be exactly in line with the centre-line of the diff flange - it should be two or three

inches offset (the shape of the diff will usually facilitate this). Having them exactly in line is likely to lead to excessive wear of the UJs

(called 'brinelling', if I've spelt that correctly!).

Maybe the following image will help...

[Edited on 11/12/13 by David Jenkins]

OK - as my gearbox output is effectively pointing off towards one of the rear wheels (to a small extent!) I clearly have the second 'bad'

situation as it stands...

I guess the 2 -3 inches offset depends on the prop length? Unless I lift/drop my gearbox mounts or Mine diff I am going to be closer to 1 inch max I

think?

[Edited on 11/12/13 by jps]

Grimsdale - 11/12/13 at 03:51 PM

why do we all still use UJs instead of CVs for props, given this problem can be tricky to avoid or eliminate completely?

David Jenkins - 11/12/13 at 03:54 PM

quote:

Originally posted by Grimsdale

why do we all still use UJs instead of CVs for props, given this problem can be tricky to avoid or eliminate completely?

Because UJs are far cheaper to make, durable, and work perfectly well when they're set up properly. After all, you've only got to set the

propshaft up once, so why spend a packet on something when a bit of work at the outset will allow you to use something cheaper!

jps - 11/12/13 at 04:02 PM

I think i've had a 'light bulb' moment - thanks to your post David - and because of the limits to how far apart I can actually get the

components.

Just to check - I need to worry less about the actual alignment between the output/input (apart from making sure it isn't 100% aligned!).

If I ensure both diff input and gearbox output are parallel to a centre line in the horizontal and perpendicular in the vertical - the alignment will

be OK?

David Jenkins - 11/12/13 at 06:45 PM

quote:

Originally posted by jps

If I ensure both diff input and gearbox output are parallel to a centre line in the horizontal and perpendicular in the vertical - the alignment will

be OK?

Should be fine!

PhillipM - 11/12/13 at 07:30 PM

quote:

Originally posted by Grimsdale

why do we all still use UJs instead of CVs for props, given this problem can be tricky to avoid or eliminate completely?

Most modern 4wd cars do use CV's just for that reason, plus the NVH is better.

Smoking Frog - 11/12/13 at 08:37 PM

The diff flange and gearbox output shaft should be parallel (hard to measure but a digital angle finder on the bellhousing joint is a good place) with

each other, which you have. But in my understanding either the horizontal or vertical (but not both) should line up. If both are out of alignment

(which you have) the prop shaft will move in and out of the tail shaft on each revolution. Leading to vibration, tail shaft oil seal and UJ failure.

Now I may be wrong and talking a load of BS as it's only what I've picked up on the interweb so hopefully someone else will have a more

expert opinion.

PhillipM - 11/12/13 at 09:00 PM

Doesn't matter, it's only a single angle from the driveshafts POV.

redturner - 16/12/13 at 11:43 AM

Something that is equally as important as lining the flanges up is to ensure that the yokes are in the same plain at either end. Just make sure that

the sliding part hasn't been removed at sometime and put back at 90 degrees....As for the comment about using CV joints U/Js have been used since

day one and as a commercial vehicle engineer I have seen U/J s do hundreds of thousands of miles without failure.....