I am trying to get my rover v8 to run correctly. Its got a weber 500 and megajolt. I have uploaded a standard Rover V8 ignition map to the megajolt.

The idle is just rough as anything. I have adjusted the idle screws on the weber but other than preventing it from petering out altogether it's

not made a great deal of difference. Any ideas?

Sounds not great

I should probably add that I am a right newbie when it comes to engine building and tuning. I don't know if I should start with the carb or the ignition.

No idea - but is it firing in the correct order?

quote:

Originally posted by minitici

No idea - but is it firing in the correct order?

Also the carb has been sat for 3 years without use.

have you checked that TDC is where megajolt thinks it is with a timing strobe ?

[Edited on 14/7/2014 by mcerd1]

quote:

Originally posted by mcerd1

have you checked that TDC is where megajolt thinks it is with a timing strobe ?

[Edited on 14/7/2014 by mcerd1]

^^ it could just be a few degrees out one way or the other - easy enough to play around with the map to find out...

Are all 8 headers getting hot? If so the firing orders is most likely correct, if you have a cold one it indicates a misfire.

It does sound very retarded, double check the 36-1 wheel, as you know the vr sensor should be 5 teeth AHEAD of the missing tooth at TDC.

Can we offer to map megajolt and jet carb?

Www.baileyperformance.co.uk

All the headers are getting hot. It was running on just four cylinders until I chased down a wiring issue. I'll double check the cog.

I would dearly love to get you to map the ignition and jet the carb. At some point I will probably be knocking on your door for you to do this. At

this present moment in time however I need to get the car running well enough to be drivable and through the IVA. I have no trailer available to get

the car to you which just pushes the cost far beyond my budget.

quote:

Originally posted by Irony

All the headers are getting hot. It was running on just four cylinders until I chased down a wiring issue. I'll double check the cog.

I would dearly love to get you to map the ignition and jet the carb. At some point I will probably be knocking on your door for you to do this. At this present moment in time however I need to get the car running well enough to be drivable and through the IVA. I have no trailer available to get the car to you which just pushes the cost far beyond my budget.

I would suggest playing with the timing - advance / reduce the timing at idle points and see what the impact is.

quote:

Originally posted by stevebubs

I would suggest playing with the timing - advance / reduce the timing at idle points and see what the impact is.

quote:

Originally posted by stevebubs

I would suggest playing with the timing - advance / reduce the timing at idle points and see what the impact is.

quote:

Originally posted by BaileyPerformance

quote:

Originally posted by stevebubs

I would suggest playing with the timing - advance / reduce the timing at idle points and see what the impact is.

Worth a try, just set the whole map to 20deg and see what happens. The engine will idle fine at anything from 5 to 20deg, if its idles better it points to an error in the trigger wheel.

At no load the timing in the map could be blanket changed to anything that makes it run better - not something i would do with the engine under load but no harm can be done at idle. The worst that can happen is kick-back on the starter if the timing is over advanced or massively retarded.

With megajolt, as it uses an EDIS module, the actual MJ unit can be unplugged leaving just the EDIS in place - this will give a fixed timing of 10deg. Any engine should idle like this, if not there is a trigger wheel problem and / or a fulling problem.

No, you will not damage the engine AS LONG AS YOU DO NOT DRIVE THE CAR :-)

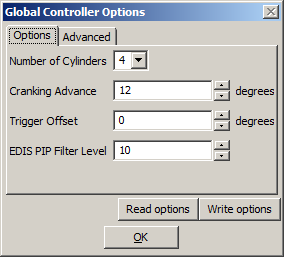

The trigger offset allows you to correct any MINOR error in the trigger wheel position, but its best to correct any error by moving the wheel or

sensor.

I would leave the offset at zero and just change the numbers in the map.

It seems to me (as you have unplugged the MJ) that the wheel is on wrong or you have a fuelling issue and from the video i can see your cranking at

6deg and running around 14 deg which should be fine, EDIS default is 10 which also is fine.

Are you sure the VR sensor wires are the correct way around? sometime it will run with them swapped but will give you a timing error.

quote:

Originally posted by BaileyPerformance

No, you will not damage the engine AS LONG AS YOU DO NOT DRIVE THE CAR :-)

The trigger offset allows you to correct any MINOR error in the trigger wheel position, but its best to correct any error by moving the wheel or sensor.

I would leave the offset at zero and just change the numbers in the map.

It seems to me (as you have unplugged the MJ) that the wheel is on wrong or you have a fuelling issue and from the video i can see your cranking at 6deg and running around 14 deg which should be fine, EDIS default is 10 which also is fine.

Are you sure the VR sensor wires are the correct way around? sometime it will run with them swapped but will give you a timing error.

I'll be in the workshop till 6.30 tonight if you want to give me a call 07967 222967, mite be able to help over the phone

Irony,

From the vid. Watched on my phone I would look at the following.

If all headers are getting hot that's good.

If it's popping back through carb or popping in the exhaust it's likley to be tinning.

R

Controlling tickover on my v8 is done by putting a v in the timing map and setting that the engine is at tick over when throttle is at <5%

Rover v8s timing marks can be 6 degree out either way and some extreme examples can be 12 deg out.

So bear that in mind when trimming up.

Basic Checks first

are plugs over whet after lumpy idle ?

Are sample plugs from left / right bank same ?

Double check timing not 180 deg out

Double check plug leads

Are you getting good spark ( spare spark plug into a lead and earth onto rocker cover.

Can you check both ign packs by doing the spark plug test above ?

Finally (for now ) can you see fuel mist down both carb barrels ?

Will post back later when watched vid properly.

Just to add my 2p :-

1) Listen to Dale, he is the Oracle

2) I could never see the timing marks whilst the pulley was on the engine, the water pump pulley blocked the view. I mounted my trigger wheel with it

on the bench. Dale then set it all up with whatever it was set as.

3) Assuming you've got two 4 pot coil packs, check that you haven't got two sides on one pack swapped over, if the four pairs are ABCD,

check it isn't ABDC (guess how I know)

4) I didn't mention Dale in the last answer, I'll refer you to point 1) for this one

Regards,

Dave

Thanks for all the replies guys. I really appreciate it.

I went out into the garage last night and I think I have placed the trigger wheel 1 tooth out. I think the sensor was one tooth to close to the

missing tooth. I might even relocate the sensor as it is under the car and I am worried it would get damaged by debris etc. I also checked the Top

Dead Centre of the crank shaft timing marks and I think the mark is within 1-5 degrees correct. It's difficult to get a perfect reading without

a proper gauge. But that means that the cars timing could be a max of 15 degrees out.

Unfortunately I couldn't correct and test last night as I have a toddler and his bedtime is seven and the car wakes him up. To be honest it

wakes the street up.

[Edited on 15/7/14 by Irony]

quote:

Unfortunately I couldn't correct and test last night as I have a toddler and his bedtime is seven and the car wakes him up. To be honest it wakes the street up.

I have now fabricated a new VR Sensor Bracket which is a lot stiffer and a lot better placed for viewing and protected from road debris etc. I think

the original bracket was 10 degrees out so I have done the best I can to make it correct. I have to say finding TDC without a proper gauge is very

difficult. I put a pencil down piston 1 spark plug hole and rotated the crank until I found TDC. I have to say its a bit rough. The Rover timing

marks seems to concur with my own estimate though. On starting the car ran better.

At this point I started to check the ignition lead layouts and I think I had them wrong. I switched the layout around and it ran smoother but there

was a bit of popping. I double checked the layout and switched two round again and now it runs a lot smoother than it did in the original video.

However I am not 100% sure I have the ignition leads correct. I have been over all the documentation on the autosport labs website and I think I

understand it. However I am struggling to implement the Autosport drawings onto my own system. I have Motorcraft Ignition coils off of a Ford KA.

The reason I chose the KA is because the ignition leads are quite long and fit the V8 quite nicely. However the single ignition coils are marked up

1,2,3,4. Each unit is labelled 1 and 2 as per the autosports labs website.

Description

My numbers on the coils differ from those on the autosport labs layout diagram. You can just see the number next to each tower.

Should I ignore the numbers on my coils or should I ignore the numbers on the Autosport labs document?

Hopefully this be some help;

1) The edis-8 plug on the autosport diagram is shown incorrect. See for how the plug actually is.

2) The wiring diagram on the autosport site shows pin 10 and pin 7 connected together.....DO NOT DO THIS....I learnt the hard way

3) This shows exactly how the edis 8 should be wired.

4) This is your photo with what I believe should be how it should be wired up which leads go to which cylinders.

[Edited on 4/8/14 by richardm6994]

So

Coil a - 1 & 6

B - 8 & 5

C - 7&4

D - 2&3

This might help as well

http://forums.lr4x4.com/index.php?showtopic=15317&page=26

[Edited on 4/8/14 by richardm6994]

quote:

Originally posted by Irony

I have now fabricated a new VR Sensor Bracket which is a lot stiffer and a lot better placed for viewing and protected from road debris etc. I think the original bracket was 10 degrees out so I have done the best I can to make it correct. I have to say finding TDC without a proper gauge is very difficult. I put a pencil down piston 1 spark plug hole and rotated the crank until I found TDC. I have to say its a bit rough. The Rover timing marks seems to concur with my own estimate though. On starting the car ran better.

My first port of call would be to remove and clean the idle/slow running jets.

I've just put this together which is exactly how my v8 megajolt system is wired up.....hope it is of some help;

Thanks for all the replies guys! I am sure in the future this info will help not just me but others with similar issues!

Yes indeed, been watching this as I am going megajolt, well megasquirt ignition only with a Holley carb as well.

Need to get the exhausts sorted before I start trying it though

I reckon I have the RV8 running a lot better now. Sounds much better. Thanks to all the people that helped me out in the above thread. I started it

up on Saturday and ran it up to temperature for the first time. It was a hot day and it got up to temperature in 10-15 minutes and the fan kicked in

at 86 degrees and shut off again 4-5 minutes later at 82.

Turns out my problems all stemmed from incorrect ignition cables and a megajolt VR sensor installation problem. The wiring diagrams in this thread

cleared any problems up for me.

The only issue I have now is that the idle speed gently increases with engine temperature. On starting from cold the idle speed was about 800rpm but

that crept slowly upwards to about 1200-1300 when warm and stayed there. I think it's probably incorrectly tuned idle screws on the weber 500

carb. I tried setting them up before but I with the wrong ignition cable setup it made no difference. I'll get onto it as soon as I get some

time.

I am also thinking of buying a new water pump, my current water pump is of unknown history and as they are a critical part I think I am going to play

it safe. I have been reading my copy of Des Hammils 'How to power tune the Rover V8' and it recommends changing the water pump every 25K.

Interesting in the book John Eales of J E Developments fame is quoted as saying he believes that Rover miscalculated the temperatures at which Rover

V8s should run. He says that they should be run at less than 80 degrees. He goes on to say that after building literally hundreds of Rover V8 racing

engines he has only had 2-3 cracked blocks/slipped liners. While I have the water system apart I might fit the Rover Hot Climate Thermostat that cuts

in at 74 instead of the standard one.

You right about the engine temp, unless thay have been top hat linered it's too easy to cook a rover v8 and cause the liners to move. From the

factory thay are just pressed in (with loctite)

We recommend 74deg stat.

We noticed the water temp on TVRs will be stable around 85 under load on the dyno, but if you don't keep your eye on it and it goes towards 95

then you have no option but to switch off the engine (bad idea normally) as the temp just keeps rising even with no load. It seems to run away for

some reason - I had wondered if the pump starts to cavitate.

Glad to hear the wiring diagrams were of some help.

With my RV8 installation, I went down the electric water pump route and digital controller.

There is no thermostat in my cooling system as temperature is controlled via the digital controller adjusting the pump speed to keep the engine at

85C.

Although the main reason for going electric water pump was space issues....there have been so many more advantages come from this route......no

overheating in traffic jams (pump can be running at 100% volume irrespective of engine rpm), very quick engine warm up on cold days, and the the pump

runs for a few minutes after you turn ignition off to eliminate heat soak issues....

I've got the EWP115 and it's kept up with all driving and weather conditions and also my recent rolling road session.....the only downside

is that when the pump is at 100% and the kenlowe fan kicks in there is a lot of draw on the battery.

quote:

Originally posted by BaileyPerformance

You right about the engine temp, unless thay have been top hat linered it's too easy to cook a rover v8 and cause the liners to move. From the factory thay are just pressed in (with loctite)

We recommend 74deg stat.

We noticed the water temp on TVRs will be stable around 85 under load on the dyno, but if you don't keep your eye on it and it goes towards 95 then you have no option but to switch off the engine (bad idea normally) as the temp just keeps rising even with no load. It seems to run away for some reason - I had wondered if the pump starts to cavitate.

quote:

Originally posted by Irony

The Des Hammil Book talks about cavitation. Some thing about the blade tips moving quickly enough to create bubbles as there going around which decreases water pressure. It seems there are a lot of different water pump pulleys which will give you different blade speeds. Faster is not always better. Apparently race engines are better suited smaller pulleys because of their constant high revs.