Most bike engined race cars rigidly mount the engine, so it's not a huge deal, but...

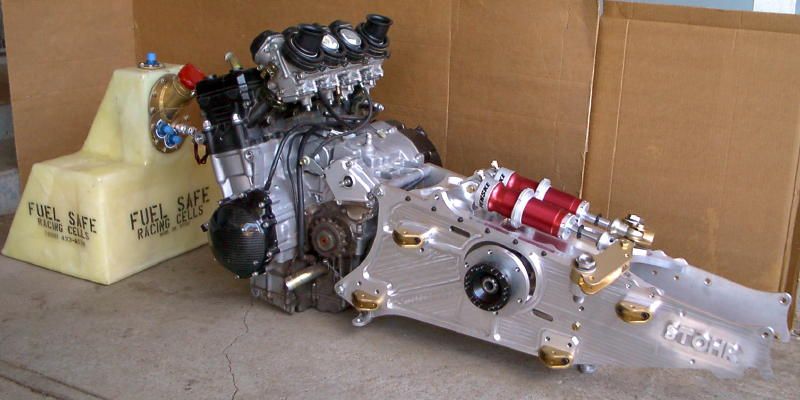

DJ Racecars stressed sump installation:

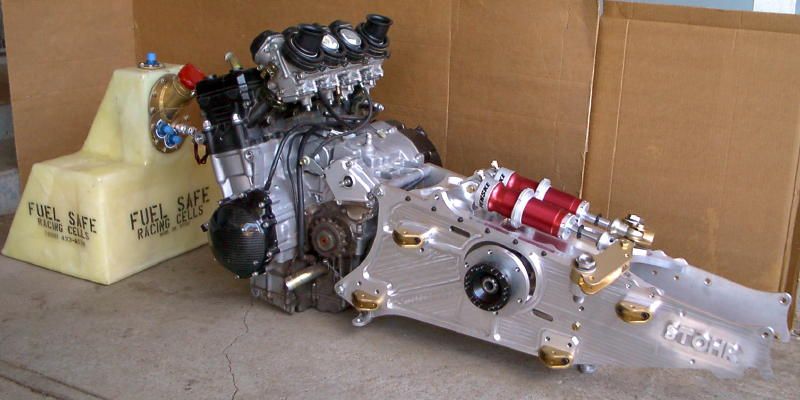

And even closer to what you're describing, the 'transaxle' arrangement on an American Stohr sports racer:

Hi all,

I have a long term single seater project that is in the planning/ideas stage at the moment. I am currently envisioning a terrapin like front end with

a widened haynes like inner rear end (the box that the wishbones mount to).

At the moment I am looking at ideas to mount the chain diff - most of the ones I have see entail bolting the assembly to the rear of the chassis but

from seeing a few failures and doing some research I can see some possible problems (if indeed they exist at all!)

A. Any movement between the engine and the diff will cause a"kangaroo" effect by pulling the chain when on/off the power

B. The chassis would have to be beefed up where the diff mounts as the engine would be trying to pull the assembly towards it when pulling off.

As I see it, if the diff and the engine were mounted together, the above forces would the above forces be contained within the unit and there would be

no need to beef up any mounting points, saving weight.

Is this an idea I should give some thought to?, if so, does anyone have any photos or thoughts on it?

Thanks,

Shaun

Your idea is fundamentally sound, for sure.

Most bike engined race cars rigidly mount the engine, so it's not a huge deal, but...

DJ Racecars stressed sump installation:

And even closer to what you're describing, the 'transaxle' arrangement on an American Stohr sports racer:

The Stohr setup is pure porn...

quote:

Originally posted by prawnabie

Hi all,

I have a long term single seater project that is in the planning/ideas stage at the moment. I am currently envisioning a terrapin like front end with a widened haynes like inner rear end (the box that the wishbones mount to).

At the moment I am looking at ideas to mount the chain diff - most of the ones I have see entail bolting the assembly to the rear of the chassis but from seeing a few failures and doing some research I can see some possible problems (if indeed they exist at all!)

A. Any movement between the engine and the diff will cause a"kangaroo" effect by pulling the chain when on/off the power

B. The chassis would have to be beefed up where the diff mounts as the engine would be trying to pull the assembly towards it when pulling off.

As I see it, if the diff and the engine were mounted together, the above forces would the above forces be contained within the unit and there would be no need to beef up any mounting points, saving weight.

Is this an idea I should give some thought to?, if so, does anyone have any photos or thoughts on it?

Thanks,

Shaun

We make loads of full-bore starts on the stickiest Avons made! If anything chains and driveshafts will fail first, (although up to now I've never

had either fail in over 2 years)

The setup on my Jedi seems spot on although not as complex of the stohr or dj.

What chains are you using? What driveshafts? I'm thinking Fiesta shafts and hubs?

Cheers,

Nev.

In the radical I had the standard radical shafts and a spare set of the (unbreakable) radical shafts which I never used!

The force had dayson shafts which are as good as you can get

And my Jedi has rally spec mini shafts

Not sure what part number of chain is but it's a 530 did drag bike chain i think. I have a spare in the garage so can check, but again Ian dayson

can supply them

[Edited on 7/11/15 by daniel mason]

quote:

Originally posted by daniel mason

In the radical I had the standard radical shafts and a spare set of the (unbreakable) radical shafts which I never used!

The force had dayson shafts which are as good as you can get

And my Jedi has rally spec mini shafts

Not sure what part number of chain is but it's a 530 did drag bike chain i think. I have a spare in the garage so can check, but again Ian dayson can supply them

[Edited on 7/11/15 by daniel mason]

If your sprinting and hillclimbing you'll never get enough heat into an f3 tyre!

You'll pick up a used set of crossplies from a jedi or similar in a15 or a92 Avon compound for a reasonable price