Road Runner Racing Diff Failures/Poor customer service

Rocket_Rabbit - 16/3/16 at 01:50 PM

So i have been building a Roadrunner Racing SR2 for the past couple of years. It has an S2000 engine in and is one of two chassis with this engine

configuration.

Before I get onto the main issues, there were a few things that did happen.

The RRR supplied steering wheel setup was hopeless and had more play than a room full of 4 year olds at christmas drinking fruitshoots.

I bought a lifeline quick release which had no play, except fitting it proved an issue because the steering column was too narrow to accept the spline

end. It meant I had to get it runed down and welded. You may or may not be suprised how NO ONE want's to touch steering columns because they

think Ayrton Senna will happen to them. I'm not joking either....

Manged to get it turned down at fitted though and it is MUCH better

So onto the main issues...

The car was ready for a shakedown run at Anglesey a couple of weeks ago. My Dad took it for a test run up the road and this happened:

Yep, that is the diff arm broken.

Upon breaking there was a fair bit of stuff damaged:

So I spoke to Roadrunner Racing who said:

quote:

Hi we have had a few broken casings (only after serious use ie slalom/drifting etc) Mazda deliberately weaken the casting (half round hole on

top and bottom edge) we now plate factory built higher powered cars with 2mm alloy on either side of the alloy differential casing. We also have added

an extra top front mounting on some cars. Also polybushes seem to be more forgiving than the solid bushes allowing small movement of the differential

under extreme loadings.

There is one other S2000 engined SR2 in existence and on it's maiden voyage last week, this happened to it:

Stuart contacted Roadrunner Racing and got told 'This shouldn't happen'. No offer of help other than the same 'plate the

diff' BS.

In my frustrations I posted a comment on the RRR facebook page and got a PM back with this reply (Norman is my Dad's mate who has the car at the

moment):

quote:

Spoken to Norman about this, from speaking to him it looks like someone has not fitted the front mounting bolts 2 x 14mm. If that is the case I

am not surprised the rear casing broke. I recommend on higher power cars the rear casing is plated with 2mm alloy. Mazda weaken the casing for

collision compliance.

The problem is the front mount. On the MX5 it is mounted to the gearbox by means of a PPF (Powerplant Frame) and on the SR2 it is mounted to the

chassis. Its design has to take about 3000ft/lbs of torque in 1st gear which it can't do because it is too close to the centre line of the

prop.

I message RRR about it all and how they have been, well, f ucking useless:

quote:

Hi, Thanks for the reply. I have spoken to Norm, the bolts were installed (They are 12mm cap head bolts, not 14mm and they would have been

installed by you when you put the reconned diff in) and the mount has twisted. What he said to you was that he couldn't see the bolts because

they were obscured by the diff. Regardless, I have been speaking with Stuart and his diff has broken despite Poly bushes and the latest design for

the front mount. Please bear in mind, that I have already replaced a prop you supplied that was completely inappropriate for the car by being a CV/UV

joint combination. Please also note that the diff was supplied and installed by yourselves. I have found other users running turboed MX5 engines that

are also having their differentials snapping. Looking at the MX5, the diff is NOT solid mounted at all. The front mount is fully floating as it is

supported by the PPF connected to the gearbox. This is why your front mount continually fails - it's rigidity is not allowing movement until it

bends and puts full load on the oxbow of the diff. In the OEM car these diffs handle 400bhp after all! Finally, it is all very well quoting the

285bhp supercharged one, however you have now had two failures of exactly the same nature on cars with the same engine - there is a problem. I'm

sure Stuart would say the same in that we'd be willing to work with you - hence why I told you about the mistake you made with the prop that I

paid for to rectify. Please see it from a customer point of view. I am now over £20k into a car that doesn't work.. I have had to replace the

prop, had to have sections of the rollcage welded that had been missed, had to have the seat mounts welded where they had come off, will have to fit

new springs to get some compliance in the suspension, and now I'm having to redesign the rear end to accept a different differential and mounting

solution. How can I recommend you to others? I even sent a request for a quote on a new rear boot panel through your website and got nothing back!!

So that is my current stance on the vehicle and the customer service. I look forward to your reply. Thanks.

Their reply to this:

quote:

:thumbup:

That's it! All that and all they give is a thumb up?!

They can do one.

So where am I now?

The rear of the car is getting a bit of an overhaul now. I will be using an RX8 diff and it will be supported on the front by part of the PPF from the

RX8 and a custom top mount that transmits the loads to the bushes in the same orientation as the RX8 and NC onwards MX5. The entire diff design is

much better and can take a lot more loading than the MX5 diff. The only issue is that the RX8 diff accepts different diameter CV joints so I need to

find some that are compatible with the MX5 shafts.

In addition, the way the rear dampers are mounted - directly to the hubs, is poor and if you tighten the bolt too much you'll crush the wishbone

as there is no tube. So the lower damper mounting point will be moved and a tube welded on to allow a proper compression of the pinch bolt.

So that's where I am with the car - £23k into it and still nowhere near ready. Don't get me wrong, eventually I'll run out of things

to go wrong and it'll be absolutely amazing

luke2152 - 16/3/16 at 02:09 PM

Its interesting because those diff arms are obviously being loaded in the way they are designed to be loaded and still breaking - makes you wonder if

its actually a design flaw in the diff (and a bit more torque going through than originally intended).

For the record on my mx5 based gbs zero (as per its design) I cut those diff arms off and the diff is mounted solidly by the vertical bolts alone and

seems to be standing up to some abuse.

dinosaurjuice - 16/3/16 at 02:16 PM

On the MX5 those rear rubber mounts were only ever designed to resist the torque from the propshaft (hence why they are positioned close to the

centreline of the drivehshafts, and quite far apart, and mounted on an I section casting transverse to the prop). The torque from the drive shafts is

almost entirely transferred to the PPF, this does result in a small downwards load on the rear mounts during hard acceleration, as well as pulling up

on the gearbox slightly. Not surprised it failed so quickly being mounted like that  dissapointed by the response from RR. Hope you can get it

sorted

dissapointed by the response from RR. Hope you can get it

sorted

Rocket_Rabbit - 16/3/16 at 02:21 PM

As my first post quotes, RRR recommend plating the diff to reinforce it.

However the problem is with the lower mount.

The RX8 diff (which has the same casing as the NC MX5) has a much better take on the mounting and is a lot stronger of a unit too.

This thread does show alternative mounting methods:

http://www.locostbuilders.co.uk/forum/2/viewthread.php?tid=197677

daniel mason - 16/3/16 at 02:22 PM

All I can say to this is that's why I always recommend Mnr to anyone who asks.

My old s2000 engined vortx has been thrashed to death in the extreme heat of the south of France as a pure track car. In the last few years the only

thing it's needed is tyres and brake pads and oil changes!

You would never ever get a reply like that from them.theyd have probably hitched a trailer,collected it from your house and fixed it by now!

daniel mason - 16/3/16 at 02:23 PM

I also used the 4.1:1 Honda Torsen diff from the s2000

Rocket_Rabbit - 16/3/16 at 02:25 PM

quote:

Originally posted by dinosaurjuice

On the MX5 those rear rubber mounts were only ever designed to resist the torque from the propshaft (hence why they are positioned close to the

centreline of the drivehshafts, and quite far apart, and mounted on an I section casting transverse to the prop). The torque from the drive shafts is

almost entirely transferred to the PPF, this does result in a small downwards load on the rear mounts during hard acceleration, as well as pulling up

on the gearbox slightly. Not surprised it failed so quickly being mounted like that  dissapointed by the response from RR. Hope you can get it

sorted

dissapointed by the response from RR. Hope you can get it

sorted

Thanks. You're bang on, and that is the way I see it. The new idea we have is going to use part of the RX8 PPF and introduce a bush to support

it.

The car is going to be driven hard, and possibly supercharged in the future, so I feel it is the best solution.

Rocket_Rabbit - 16/3/16 at 02:30 PM

quote:

Originally posted by daniel mason

All I can say to this is that's why I always recommend Mnr to anyone who asks.

My old s2000 engined vortx has been thrashed to death in the extreme heat of the south of France as a pure track car. In the last few years the only

thing it's needed is tyres and brake pads and oil changes!

You would never ever get a reply like that from them.theyd have probably hitched a trailer,collected it from your house and fixed it by now!

Dan, totally agree. My mate was going to build an RRR, but a number of factors moved him to MNR. I only hear good things about them too.

dinosaurjuice - 16/3/16 at 02:33 PM

quote:

Originally posted by Rocket_Rabbit

quote:

Originally posted by dinosaurjuice

On the MX5 those rear rubber mounts were only ever designed to resist the torque from the propshaft (hence why they are positioned close to the

centreline of the drivehshafts, and quite far apart, and mounted on an I section casting transverse to the prop). The torque from the drive shafts is

almost entirely transferred to the PPF, this does result in a small downwards load on the rear mounts during hard acceleration, as well as pulling up

on the gearbox slightly. Not surprised it failed so quickly being mounted like that  dissapointed by the response from RR. Hope you can get it

sorted

dissapointed by the response from RR. Hope you can get it

sorted

Thanks. You're bang on, and that is the way I see it. The new idea we have is going to use part of the RX8 PPF and introduce a bush to

support it.

The car is going to be driven hard, and possibly supercharged in the future, so I feel it is the best solution.

Sounds good to me  Plenty of high power MX5's and RX8's around so the OEM mounting method is obviously good enough!

Plenty of high power MX5's and RX8's around so the OEM mounting method is obviously good enough!

daniel mason - 16/3/16 at 02:42 PM

I really feel for you. It's shite when stuff like that happens.

Am sure there are may be other good manufacturers but I only have 1st hand with one.so I can only comment on there service which along with Andy at ab

performance was superb.

sdh2903 - 16/3/16 at 03:10 PM

quote:

Originally posted by luke2152

Its interesting because those diff arms are obviously being loaded in the way they are designed to be loaded and still breaking - makes you wonder if

its actually a design flaw in the diff (and a bit more torque going through than originally intended).

For the record on my mx5 based gbs zero (as per its design) I cut those diff arms off and the diff is mounted solidly by the vertical bolts alone and

seems to be standing up to some abuse.

No its not. On the mx5, mnr, and westfield the diff hangs down from those arms as it's designed. On the sr2 it's clamped down putting load

in the arms that they aren't designed for.

And by the way MNR have issues too. I know they have a loyal following on here but they aren't all that. My chassis went back for a full refund

for several issues that MNR were unable/willing to put right. I think the kit industry in this country needs a boot up the arse before the nimbys stop

the whole thing.

rdodger - 16/3/16 at 03:15 PM

Have you considered the Diff case from Phil at Talon?

http://www.talonmotorfabrication.co.uk/shop/4581381144/fabricated-diff-cover/9582956

Rocket_Rabbit - 16/3/16 at 03:24 PM

quote:

Originally posted by rdodger

Have you considered the Diff case from Phil at Talon?

http://www.talonmotorfabrication.co.uk/shop/4581381144/fabricated-diff-cover/9582956

I have seen that and it looks very good indeed! I don't think it's be compatible with the SR2 chassis without a fair bit of modification.

roadrunnerracing - 16/3/16 at 04:40 PM

I normally don't get involved or follow online discussions, however it has been brought to my attention that Roadrunner is getting a fair amount

of negative comments. In particular from one person who I have never met in person or as far as I know does not even own an SR2.

I won't deal with this person for obvious reasons.

Some cars have broken the rear differential casing. Most of the earlier chassis have been upgraded regarding the mounting points (free of charge) and

we now also use 14mm x 2 bolts on the front mounting not 12mm as in the original chassis design.

Stuart Adam with a late S2000 chassis offered to design an additional support which we have fitted on his car (along with a different roll cage) and

also a few other cars. However I strongly recommended to him that the rear differential housing was also plated. He did not want to pay the additional

cost to have it plated saying to me that he would try it first with the other additional mount he had designed. When it broke he expected me to cancel

my other work and sort him a plated differential casing as a top priority, unfortuately I am not in a position to abandon other work just like that.

We had a massive fire affect our main business last November (it started in the company next door).

http://www.hulldailymail.co.uk/Firefighters-tackle-blaze-Brough-industrial/story-28214481-detail/story.html

We are lucky to still be in business, but my staff and I are working hard to come out the other side. We have had to move premises 3 times in 5

months. However we are doing our best to support genuine customers during and after builds the same as we always have.

I am only a phone call away or a simple email to roadrunnerracing@hotmail,.co.uk will get a response if not from me from one of my staff.

This was my first SR2 demo car loaned to Javelin Trackdays for the weekend a few years ago it did two days of this giving over 200 passenger rides

and going through 18 sets of tyres. Standard earlier chassis with a standard LSD with no issues. Then it had a standard 1.6 engine, it is now in Italy

with a 1.8 rotex supercharged engine with a modified and plated differential, no issues with it to date.

https://www.youtube.com/watch?v=B4opzWiXvtU

Like all products we make improvements and learn from customer feedback and the cars in everday use either on the track or the road. we are always

happy to discuss improvements we have made to later chassis or factory builds with our customers.

Regards Mike

INDY BIRD - 16/3/16 at 05:08 PM

Sorry to here you have had a failure that's very frustrating,

If you are redesigning The rear end, can you not look to go the honda diff route,I know that's a big task and lots of other issues crop up like

drive shafts etc, new prop, but if you are going to boost it at some point this diff should take the power aswell,

Either way I wish you the best of luck getting it back on the road, where I'm sure you want it after spending your very hard earned cash

Rocket_Rabbit - 16/3/16 at 05:54 PM

quote:

Originally posted by roadrunnerracing

I normally don't get involved or follow online discussions, however it has been brought to my attention that Roadrunner is getting a fair amount

of negative comments. In particular from one person who I have never met in person or as far as I know does not even own an SR2.

I won't deal with this person for obvious reasons.

Some cars have broken the rear differential casing. Most of the earlier chassis have been upgraded regarding the mounting points (free of charge) and

we now also use 14mm x 2 bolts on the front mounting not 12mm as in the original chassis design.

Stuart Adam with a late S2000 chassis offered to design an additional support which we have fitted on his car (along with a different roll cage) and

also a few other cars. However I strongly recommended to him that the rear differential housing was also plated. He did not want to pay the additional

cost to have it plated saying to me that he would try it first with the other additional mount he had designed. When it broke he expected me to cancel

my other work and sort him a plated differential casing as a top priority, unfortuately I am not in a position to abandon other work just like that.

We had a massive fire affect our main business last November (it started in the company next door).

http://www.hulldailymail.co.uk/Firefighters-tackle-blaze-Brough-industrial/story-28214481-detail/story.html

We are lucky to still be in business, but my staff and I are working hard to come out the other side. We have had to move premises 3 times in 5

months. However we are doing our best to support genuine customers during and after builds the same as we always have.

I am only a phone call away or a simple email to roadrunnerracing@hotmail,.co.uk will get a response if not from me from one of my staff.

This was my first SR2 demo car loaned to Javelin Trackdays for the weekend a few years ago it did two days of this giving over 200 passenger rides

and going through 18 sets of tyres. Standard earlier chassis with a standard LSD with no issues. Then it had a standard 1.6 engine, it is now in Italy

with a 1.8 rotex supercharged engine with a modified and plated differential, no issues with it to date.

https://www.youtube.com/watch?v=B4opzWiXvtU

Like all products we make improvements and learn from customer feedback and the cars in everday use either on the track or the road. we are always

happy to discuss improvements we have made to later chassis or factory builds with our customers.

Regards Mike

You really aren't getting it are you. You knew about these issues, yet you let them happen. I have had no warning that the diff breaks so in

retort you had my email and you didn't get in touch with me.

So instead, you know 'High power cars' have issues and let's not forget this was a chassis (my chassis) you have a V8 in, so should

have been more than able to take care of a 2 litre 4 pot.

Imagine if that diff would have let go mid corner and caused me to have a serious accident?!

I have used a number of media forms to establish a dialogue with you and they have failed.

I am left with little choice but to place this up here for others to see whilst I foot the bill for your failings.

chillis - 16/3/16 at 06:32 PM

Unless a portion of the power plant frame is incorporated into whatever car an MX-5 diff is used then the failure you have is inevitable. As

dinosaurjuice points out the mx-5 powertrain works as a single unit mounted to the vehicle with two engine mounts on the front subframe and the two

diff mounts on the rear subframe and no doubt explains why those who use the entire powertrain such as mev have no such problems.

They way the diff is mounted in the RRR product (and others) appears to be the issue, not the way Mazda used it, after all they used it the way their

design team intended and unless you suffer accident damage there are no issues with it.

perksy - 16/3/16 at 07:47 PM

Sorry if ive got the wrong end of the stick here, but is the chap from RRR saying a 'customer' had/has offered to re-design part of their

chassis for them ?

I could possibly understand if this car had been on slick's on a circuit but if this happened just going up the road I'd be seriously

concerned ?

Presumably the calc's have been done to check what power/forces the chassis can take ?

I remember when a chap wanted to fit a small block chevy in a SEIW Westfield the factory said Nope until extra bracing was added to the rear section

of the chassis...

Matt21 - 17/3/16 at 11:32 AM

quote:

Originally posted by roadrunnerracing

I normally don't get involved or follow online discussions, however it has been brought to my attention that Roadrunner is getting a fair amount

of negative comments. In particular from one person who I have never met in person or as far as I know does not even own an SR2.

I won't deal with this person for obvious reasons.

Mike, after having a read through this whole thread, I can't see the obvious reason as to why you won't deal with this customer. Please

could you point these out to me?

As to the 'one person who is dishing out the negative comments', is that Rocket_Rabbit you are referring too? If so, why would he be saying

he has an SR2 if he doesn't actually own one?

Just because you have never met him in person does not mean that he doesn't own one of your cars and instead posts up random photos to a forum of

one of your cars with a broken diff just to get a kick from it.

As you have said, you have had some difficult times recently with the fire etc, in my eyes, things will only get more difficult if bad reputation

starts to spread. As far as I am concerned, customer service is number one priority. If I had had a bad dealing with a company I would do just as the

OP has done and let people know what they can expect from that company.

Sometimes you may need to take a hit in order to come out on top (even for massive car companies that is the case, never mind small ones).

britishtrident - 17/3/16 at 12:23 PM

I recall years back Lotus Elan chassis which had a similar upper mounting for the final drive sufferering elongated holes where the final drive

lower tie bars were bolted to the chassis.

Picture on this Lotuselan.net page

http://www.lotuselan.net/forums/lotus-gearbox-f37/lotus-elan-rear-axle-diff-t26587.html

[Edited on 17/3/16 by britishtrident]

Neville Jones - 17/3/16 at 12:33 PM

RE MX5 diff breakages.

If a person did the calculations, you'd find that the front diff mount that everyone uses, on the housing direct to the chassis, will cause the

upper arms to break every time you do a hard launch. Using a compliant mount doesn't change things a lot.

Plating the top arms front and back with 4mm ali will help, but the main cause is the front mount. Beefing it up won't achieve diddly squat. Just

makes the arms carry an even higher load.

The solution is to make up bracketry to attach to the diff, then go as far forward up the tunnel as you can before landing on the chassis.(

There's good reason Mazda did what they did. )This isn't a simple job, and needs some engineering numbers to be run with your own particular

design. The torque reactions to the input and and outputs can be fairly high.

I've just taken six broken housings, 1.6's and 1.8's to the scrappers, which all happened before we took a proper look at the

situation. Previously we had put the failures down to granulation in the castings, and that little notch at the back of the top arm.

Not a single breakage now for 18 months, with 220hp Zetec and some brutal driver inputs.

Cheers,

Nev.

[Edited on 17/3/16 by Neville Jones]

rdodger - 17/3/16 at 03:08 PM

How are MNR, Westfield etc doing it?

I thought they were all pretty much the same apart fro GBS who cut the arms off and bolt through the housing.

Rocket_Rabbit - 19/3/16 at 07:49 PM

quote:

Originally posted by Matt21

quote:

Originally posted by roadrunnerracing

I normally don't get involved or follow online discussions, however it has been brought to my attention that Roadrunner is getting a fair amount

of negative comments. In particular from one person who I have never met in person or as far as I know does not even own an SR2.

I won't deal with this person for obvious reasons.

Mike, after having a read through this whole thread, I can't see the obvious reason as to why you won't deal with this customer. Please

could you point these out to me?

As to the 'one person who is dishing out the negative comments', is that Rocket_Rabbit you are referring too? If so, why would he be saying

he has an SR2 if he doesn't actually own one?

Just because you have never met him in person does not mean that he doesn't own one of your cars and instead posts up random photos to a forum of

one of your cars with a broken diff just to get a kick from it.

As you have said, you have had some difficult times recently with the fire etc, in my eyes, things will only get more difficult if bad reputation

starts to spread. As far as I am concerned, customer service is number one priority. If I had had a bad dealing with a company I would do just as the

OP has done and let people know what they can expect from that company.

Sometimes you may need to take a hit in order to come out on top (even for massive car companies that is the case, never mind small ones).

Thanks Matt.

I do indeed own an SR2 and I have met Mike, Paul, and Grant. The car was their V8 demonstrator:

https://www.youtube.com/watch?v=A4F0otYFj10

I bought this from them because the chassis had a bellhousing wide enough for the S2000 gearbox.

So I went to them with the engine and gearbox and asked them to mount it in the chassis which they did.

I have owned the car for nearly 2 years and been in talks with RRR for a lot longer.

quote:

Originally posted by Neville Jones

RE MX5 diff breakages.

If a person did the calculations, you'd find that the front diff mount that everyone uses, on the housing direct to the chassis, will cause the

upper arms to break every time you do a hard launch. Using a compliant mount doesn't change things a lot.

Plating the top arms front and back with 4mm ali will help, but the main cause is the front mount. Beefing it up won't achieve diddly squat. Just

makes the arms carry an even higher load.

The solution is to make up bracketry to attach to the diff, then go as far forward up the tunnel as you can before landing on the chassis.(

There's good reason Mazda did what they did. )This isn't a simple job, and needs some engineering numbers to be run with your own particular

design. The torque reactions to the input and and outputs can be fairly high.

I've just taken six broken housings, 1.6's and 1.8's to the scrappers, which all happened before we took a proper look at the

situation. Previously we had put the failures down to granulation in the castings, and that little notch at the back of the top arm.

Not a single breakage now for 18 months, with 220hp Zetec and some brutal driver inputs.

Cheers,

Nev.

That's pretty much what we are doing Nev. The RX8 diff is being used because the PPF mount is on the opposite side to the pinion meaning there

is room down the tunnel to fit part of the actual RX8 PPF.

I reckon the fix will add about 10-15kg to the weight of the car, but it'll be able to take a lot of abuse as such.

prawnabie - 19/3/16 at 09:03 PM

My westie has a bracket bolted to the front mounting holes on the diff and that then bolts to the chassis via a metalastic bush (basically a

westie/triumph suspension bush)

normspanners - 22/3/16 at 12:45 AM

I can confirm that everything rocket rabbit says is factual, the idea that you can mount a diff partially solid and partially flex mounted as far as I

am concerned is fundamentally flawed, in as far as ;' if the rear mount flexes the front mount has to also flex, now if that front mount is a

solid part of the chassis, that is the only section controlling the north south torque reaction of the diff, forget the east west TR at this point,

now as the radius of that front mount is only about 60 mm from the drive shaft centre line, the loading on that part of the chassis becomes

unbearable because the rear flex mounts now offer minimal support but what they do is encourage the front mount and that part of the chassis to

twist north south, now you bring into the equation, the east west location with flex mounts, the diff is allowed to move east west due to prop TR,

BUT now remember the diff is hard mounted to the frame so now you have additional east west torsion on the frame that is only again 60mm from the

pinion centre line .

How can that little piece of chassis be expected to withstand, all those force's without at some point suffering fractures ?

You either have to make the mounts either solid or flex, NOT a combination of both.

With the TR radii in all plains being so small in the case of the mx5 diff, solid is the way to go, but needing massive amount of extra support. IMO

the chassis design does not accommodate enough strength to withstand those forces, so total flex is the way to go and the rx8 diff gives itself to

that possibility.

BTW TR = torque reaction

Neville Jones - 22/3/16 at 12:44 PM

Just putting in a flexi mount at the diff front mount holes, as most do, won't solve the breakage problems alone.

The broken diffs I had were all mounted with compliant front mounts.

The problem wasn't resolved until the front mount was taken a good way up the tunnel to reduce the torsional loads on the diff nose and the

reactions in the 'wings'/arms.

Cheers,

Nev.

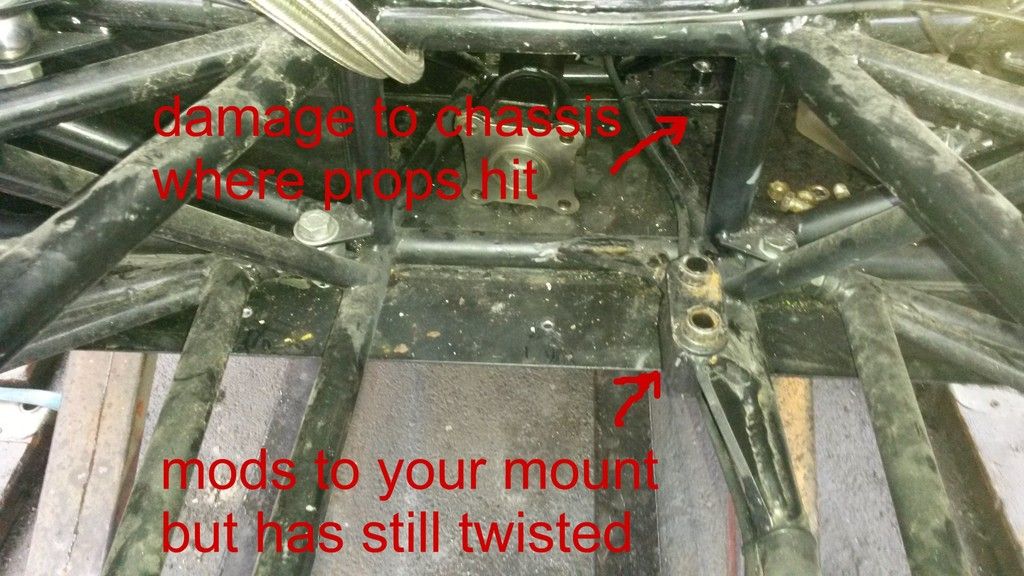

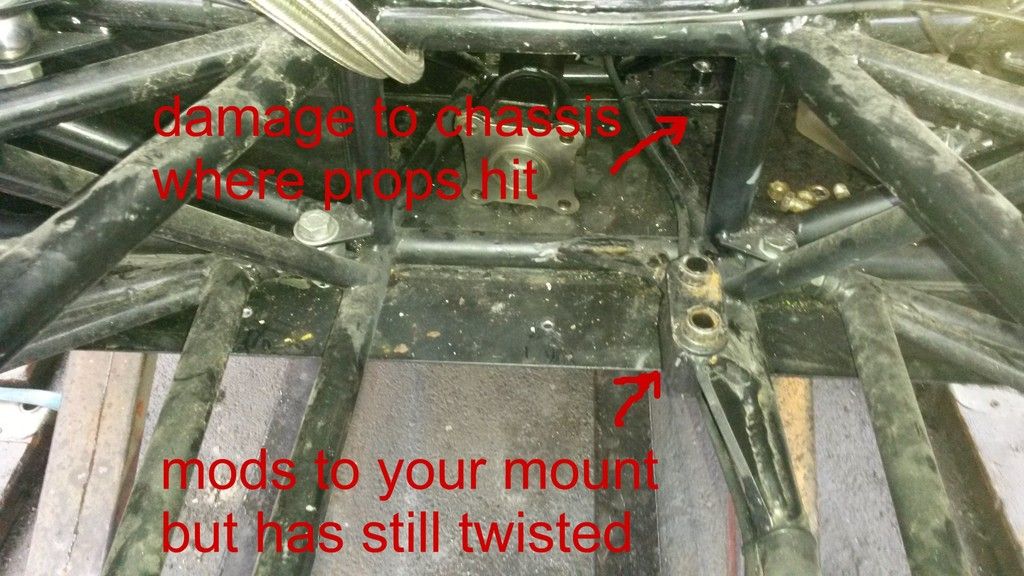

normspanners - 22/3/16 at 11:04 PM

Thanks Nev , as said the mx5 diff doesnt lend its self to the extended nose idea in the sr2 because there is not a lot of space ( read NONE) to the

right of the pinion, because the pinion is itself to the right of the crown wheel, in fact the drive flange has touched the ladder on the right, as

per my photos, when the oxbow snapped.

The rx8 diff on the other hand has its front ppf mount is on the left and that is where there is some space, on this car.

At the moment it is looking like the RX8 unit JUST fits in with mm's to spare.

[Edited on 24/3/16 by normspanners]

[Edited on 24/3/16 by normspanners]

Rocket_Rabbit - 1/6/16 at 02:11 PM

A bit of an update:

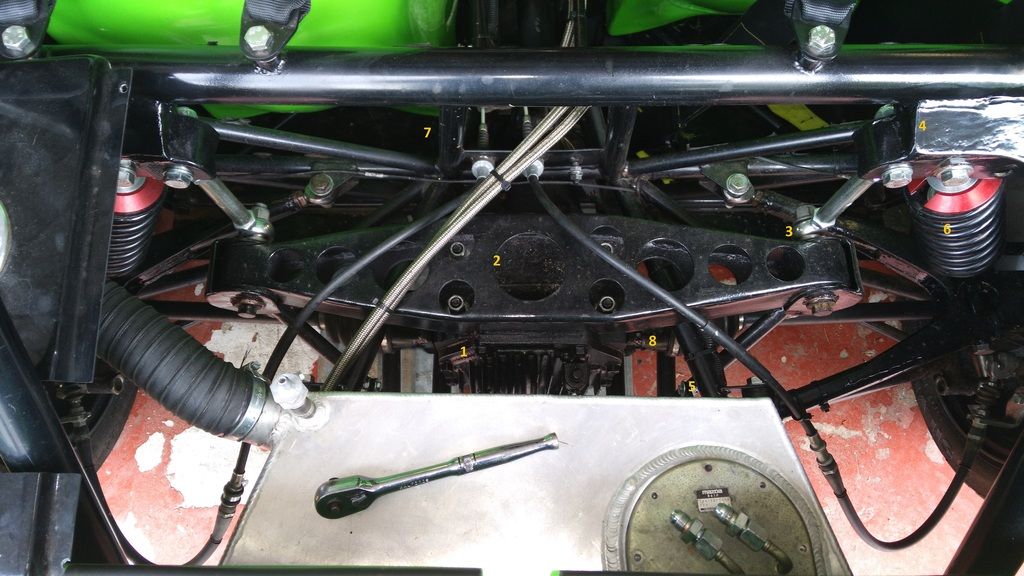

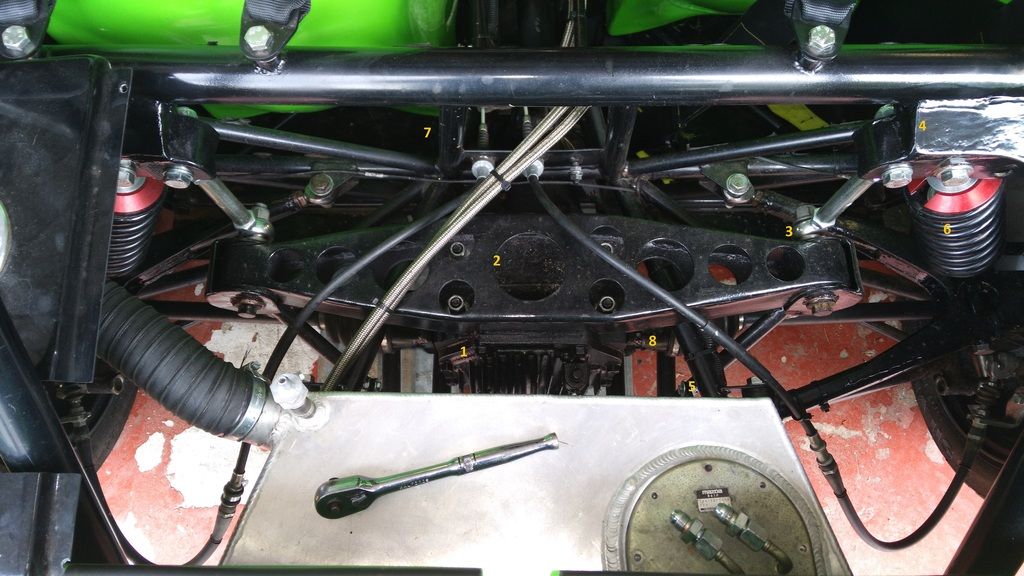

The rear end has now been fixed. See the picture below and I'll explain what each number is:

1) This is a diff from an RX8 as opposed to the MX5 item that was broken.

2) A custom made oxbow mount to replace the RX8 original. It bolts into custom clevis mounts that then bolt into the original SR2 mounts.

Incidentally, the OEM mounts had bent quite a bit upon the diff breaking. They had to be pulled up back into place.

3) A tie bar has been installed to transfer the torque reaction of the propshaft upto the roll cage.

4) An additional lug mount has been attached to allow a more compliant damper movement and to attach the tie bar from the diff mount.

5) Hard to see, but in order to install the diff, the rear bar had to be cut out. This has been 'flanged' and bolted in.

6) The damper has been re positioned in order to achieve better leverage and more travel. It is now running a 400lbs spring.

7) Again, hard to see but this is where the new diff nose mount now attaches. Made from part of the RX8 PowerPlant Frame it provide resistance to the

torque reaction from the driveshafts.

8) The CV cups are a hybrid construction from the RX8 flange and the MX5 cup. A number of shafts were tried, but didn't quite fit. This

solution allows the spider and shaft from an MX5 to slot straight in should it break and mate up to the hub

There is still more work to do on the car as the front is suffering from similar issues to the rear. The front upper wishbones bend under braking and

foul the dampers. This should be a simple fix by bracing the upper spherical bearing joints with a bar.

The lugs for the rear mounts on the lower front wishbones are welded on in completely different locations and orientations!

The steering rack is not in line.

The front ball joints are seemingly of different tapers as they don't locate symmetrically. I have ordered new ones but on a car that has been

built by Roadrunner and done, apparently, 50 miles, you'd have hoped this would have been fixed.

dissapointed by the response from RR. Hope you can get it

sorted

dissapointed by the response from RR. Hope you can get it

sorted