rob.d

|

| posted on 2/2/14 at 05:30 PM |

|

|

fireblade engine with inline type 9???

Hi all I'm currently building a locost and am considering powering it with a fire blade engine and possibly fitting a

ford rocket box inline in the transmission tunnel with the bell housing removed.Has anyone tried this?my thoughts are if it works I will have reverse

gears and 4 sets of ratios to run the bike gearbox through e.g. tall ratio for driving to track days( on motorway) then shorter ratios at the track

my thought is to fit a short prop from the output of the blade engine to the input shaft of the rocket box which will be rigidly mounted in the tunnel

like you would with a reverse box and then another short prop/donut to the rear diff.

anyone tried it ? or whats your thoughts.

cheers rob

|

|

|

|

|

rdodger

|

| posted on 2/2/14 at 05:42 PM |

|

|

I know it's been done in a mid engine car. A GTM Libra with the bike engine mated to a PG1 gearbox. I'm not sure what happened to it in

the end or if it worked well. He was having problems last I heard.

Didn't the Light Car Company Rocket use both bike and car gearboxes?

Any way I don't think the extra weight and trouble making it work would be worth it.

You could always use bigger wheels on road than track? :-)

|

|

|

Sam_68

|

| posted on 2/2/14 at 06:30 PM |

|

|

quote:

Originally posted by rdodgerDidn't the Light Car Company Rocket use both bike and car gearboxes?

The LCC Rocket used a custom designed and manufactured transaxle, by Weismann transmissions, driven from the bike engine's gearbox sprocket,

which integrated a differential with high- and low- range final drive gearing and a reverse gear. It was more akin to the diff/reversing boxes produce

by Quaife for Radical.

Some mid-engined 750 Formula cars (eg. the Darvi 977) used a Reliant car engine, directly coupled to the Reliant inline gearbox (using a normal

bellhousing arrangement), then coupled by a short propshaft to the mandatory live rear axle, but it gives a very long package. It only made sense in a

F750 car because the rules effectively banned most alternative solutions; although the very neat Cowley MK. IV used a U-shaped arrangement that

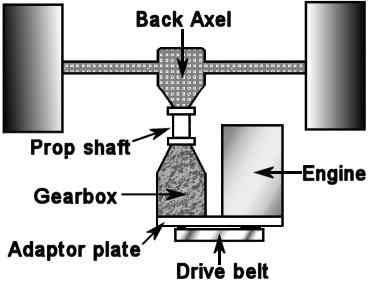

packaged things rather better:

Diagram (not mine - I can spell 'axle' properly!) of the Cowley installation

...and a picture of the Cowley Mk. IV, probably the prettiest F750 Formula car ever built.

Len Terry designed a road car that used a very similar arrangement to the Cowley, too, with a Ford V6 engine (back in the days before suitable

transaxles were readily available for road-going mid engined cars).

It's a pretty clumsy, heavy solution unless you're faced with the straight-jacket of the Formula 750 Rule Book, though.

Edited to add: using a donut, as you suggest, would make things a little shorter, admittedly.

Part of the problem with F750 cars was that you needed a long enough propshaft (with twin UJ's) to allow articulation of the rear axle.

...Unless you did what the Omag Reliant did (which was to bolt the output flange of the gearbox directly to the input flange of the axle and reduce

the suspension compliance to next to nothing).

[Edited on 2/2/14 by Sam_68]

|

|

|

Doctor Derek Doctors

|

| posted on 2/2/14 at 06:43 PM |

|

|

If you were going to do that wouldn't it be better to use an Audi FWD transaxle at the back which would eliminate the need for a separate diff

and so not add as much weight as just adding a whole extra gearbox. It's something I have thought of doing anyway.

Designer and Supplier of the T89 Designs - Single Seater Locost. Build you own Single Seater Racecar for ~£5k.

Plans and Drawings available, U2U or e-mail for details.

Available Now: The Sports Racer Add-On pack, Build a full bodied Sports Racer for Trackdays, Sprints and Racing.

www.t89.co.uk

www.racecarwings.co.uk

callan@t89.co.uk

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Sam_68

|

| posted on 2/2/14 at 06:50 PM |

|

|

The Audi transaxle's a big heavy bast*rd, though - kind of defeats the object of using a bike engine?

Maybe the Imp gearbox (very light, and should be adequate for the limited torque of a bike engine), or perhaps a 2CV gearbox, would be a better

bet?

|

|

|

r1_pete

|

| posted on 2/2/14 at 06:59 PM |

|

|

how about the Porsche 924/944 transaxle??

|

|

|

Sam_68

|

| posted on 2/2/14 at 07:40 PM |

|

|

quote:

Originally posted by r1_petehow about the Porsche 924/944 transaxle??

Same issue as the Audi transaxle - any 'modern' transaxle for a medium capacity car engine is gong to weigh a ton. Ditto the Alfasud or

Renault transaxles. Not that it'd be any heavier than a Type 9, plus a Sierra diff., plus the gubbins to connect the lot together, to be

fair!

The Imp and 2CV are the only really light ones I can think of - the Imp transaxle weighs about half as much as an Alfasud transaxle, and the Alfasud

is still a fair bit lighter than the Porsche and Audi units.

If you're going to accept that sort of weight penalty, you might as well just cut your losses and use the car engine that the gearbox was

designed for in the first place - much simpler, better torque, suitable ratios and a lot less faff!

|

|

|

Doctor Derek Doctors

|

| posted on 2/2/14 at 07:50 PM |

|

|

quote:

Originally posted by Sam_68

The Audi transaxle's a big heavy bast*rd, though

That's pretty sweeping statement considering they have been making them in different versions for 30 years. Also they are bound to heavier than

a normal gearbox because they contain the diff as well whereas a Type 9 will need a standalone diff.

Any facts or figures of weight comparisons to support the statement?

Designer and Supplier of the T89 Designs - Single Seater Locost. Build you own Single Seater Racecar for ~£5k.

Plans and Drawings available, U2U or e-mail for details.

Available Now: The Sports Racer Add-On pack, Build a full bodied Sports Racer for Trackdays, Sprints and Racing.

www.t89.co.uk

www.racecarwings.co.uk

callan@t89.co.uk

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Sam_68

|

| posted on 2/2/14 at 08:37 PM |

|

|

quote:

Originally posted by Doctor Derek DoctorsAny facts or figures of weight comparisons to support the statement?

No, only experience of handling them. I'd guess the different variants of Audi transaxle to weigh between maybe 55 and 80 kilos. In any event,

they're a lot heavier than the old 4-speed Beetle transaxle that the Hewland Mark 9 was based on, which was itself noted for its light

weight and which weighs about 35 kilos (Hewland claim 40 kilos for their 'current' Mk. 9, which must be down to beefed up castings?):

http://www.hewland.com/svga/mk9.html

The Beetle transaxle, in turn, is heavier than the Imp transaxle by a substantial and immediately noticeable amount.

The Imp gearbox weighs 65lbs (about 29 kilos?) with its integral bellhousing - it's lighter than any other transaxle I've handled by a

noticeable margin. You can pick an Imp gearbox up with one hand by simply gripping it by the bellhousing, without being particularly strong. I defy

you to do that with an Audi transaxle!!

I don't dispute that the Ford Type 9 plus a separate diff would be at least as heavy (or heavier still) - see my post above - but either

option would be a serious amount of weight to drag around with a BEC for the sake of a reverse gear?

As an aside, the only inline gearbox (not transaxle) I've encountered that makes even the Imp transaxle look a bit hefty is the Reliant

'box used in the F750 racers, so if you stripped one out to give high- and -low forward ratios and reverse, and found a light enough diff to go

with it, the Cowley Mk. IV arrangement might just about be viable as an option.

You need to read your own 'three questions to make your car lighter'!

|

|

|

Paul Turner

|

| posted on 4/2/14 at 09:07 AM |

|

|

I will admit at this point not being a bike engined cars biggest fan, just too focussed for road use in my very brief experience of one but they do

look brilliant fun on track days.

Having said that I always thought that one of the great advantages of the BEC was the free (6 speed?) dog box you got with every bike engine.

To make a BEC car heavier by fitting a car gear box and then saddling it with only 4 gears would surely make it far less fun than it should be (and at

great expense and trouble). The power band of a bike engine dictates it needs more gears to keep it in the rev range, in a car the engine is pulling

more weight and needs those gears even more.

Why do you need a reverse gear, a Seven is not that heavy to push on the odd occasion you need to go backwards, neither of my acquaintances with BECs

bother with a reverse.

Why reinvent the wheel, simply do what every builder of a BEC car I have met in the past has done in the past, use the free bike gearbox.

As an aside when I was hillclimbing bike engined single seaters became ever more popular. Of all the cars I encountered only one varied from the norm

of transverse engine with bike gearbox with a chain drive to a diff. This chap, at great expense, mounted the bide engine longitudinally onto a type 9

Hewland. Did it give him an advantage, well it looked nice.

|

|

|

Sam_68

|

| posted on 4/2/14 at 09:43 AM |

|

|

quote:

Originally posted by Paul Turner...then saddling it with only 4 gears

You can't detach the bike gearbox from the engine; it's integral. So you would effectively end up with 24 or 30 (4 or 5 x 6) forward gears

and 6 reverse ratios!

The 'advantage' (at a substantial weight penalty), is that you can overcome the normal BEC problem of stupidly short gearing by providing

high- and low- range gears via the car gearbox - possibly omitting the other gears to turn it into a 2-speed + reverse, which is what the

custom-manufactured Weismann secondary box in the LCC Rocket did. You use the low range for track work or B-roads, and the high range for A-road and

motorway cruising.

quote:

Originally posted by Paul Turner...Why do you need a reverse gear, a Seven is not that heavy to push on the odd occasion you need to go

backwards...

Unfortunately, a means of powered reversing is now a requirement of the IVA regulations.

Of course, if you happen to fit an electric reverse, driving a ring gear on the diff, and it happens to fall off after the IVA test...

|

|

|

Paul Turner

|

| posted on 4/2/14 at 09:44 AM |

|

|

2 gearboxes, looks like a complicated solution to a problem that 1000's of BEC's have not needed to solve (other than fit one of the

troublesome reverse gearboxes).

Not only will it be heavier but with an extra gearbox in the car there will be a much greater power loss at the wheels and subsequent loss of

performance.

Don't forget that standard Ford gearboxes do not like revs over 7500. It kills 1st and 2nd gears where they run directly on the mainshaft with

no bearings. The HD kits from Quaiffe etc overcome this by fitting needle rollers on the mainshaft gears. Suppose you could do it with a standard box

but it would mean modifying the mainshaft and boring out the gears slightly and finding suitable bearings.

Most builders try and keep weight to a minimum and power loss to a minimum, the proposed solution ensures both will be maximised.

Crazy.

[Edited on 4/2/14 by Paul Turner]

|

|

|

Sam_68

|

| posted on 4/2/14 at 10:27 AM |

|

|

Yes, I agree - with the caveat that thousands of BECs haven't needed to solve the problem because it didn't used to be a legal

requirement (with SVA), but it is now.

And like you, I'm not a big BEC fan, anyway.

Though to be fair there are only two 'legal' solutions to the question of a reverse gear: an electric drive, or a secondary reversing

box.

The Ford 'rocket' box is quite heavy, but the alternative of a custom-manufactured inline reversing box is quite expensive and I suppose

therefore not really in keeping with the 'Locost' ethos.

A lighter gearbox than the Rocket - possibly a Reliant gearbox with the bellhousing machined off and the redundant gears removed, fitted in the

transmission tunnel, or an Imp or similar transaxle fitted at the back, as has been done with Hewland transaxles on some car-engined Westfields -

might be a cheap alternative?

I've seen the Reliant gearbox quoted as weighing 15kg, on these forums (and I can probably believe that - it's certainly very

light) so with the bellhousing machined off and the redundant gears/selector forks stripped out, it might not be too bad.

There's an interesting web page here, showing the modification of a Reliant box to remove the bellhousing:

http://www.stotfoldengineers.co.uk/stotfold_engineering_blog/2011/02/01/1920s-clyno-gearbox-made-from-a-reliant-gearbox/

Whether it would stand the torque and revs of a Fireblade engine for more than a few minutes is another matter...

[Edited on 4/2/14 by Sam_68]

|

|

|