Talon Motorsport

|

| posted on 5/3/16 at 04:57 PM |

|

|

Off topic some what I know and I'm sorry....The MX5 cast ali cover and arms is designed to fail at that point it has two notches cast in to the

arms. The diff when mounted in the MX5 floats within the sub frame on the rubber bushes and the nose is connected to the back of the gearbox by the

ali back bone (the correct name of it escapes me just now). You need to solidly mount the nose of the diff and replace the rubber bushes in the arms

with some thing a lot stiffer.

I how ever did away with the cast cover all together in the TMXR and made the MX5 diff fit in to the standard Roadster suspension cage with this

fabricated item which gives four mounting points.

[Edited on 5/3/16 by Talon Motorsport]

|

|

|

|

|

snapper

|

| posted on 5/3/16 at 07:12 PM |

|

|

I'm just going to add a bit more to the exhaust parts of the thread

Working with exhaust primary lengths and diameters is a very exact science, it takes into account not just the exhaust but also the inlet tract length

from the end of the bell mouth to the valve head, the cam duration and I believe the stroke.

The guy who did the calculations for me on Turbosports forum provided ideal inlet tract length and the length, diameters of the primaries and the

collector with different lengths for the 1st 2nd 3rd and 4th harmonics he also said which worked best for my engine

I was lucky the Pinto 4 branch I had fitted neatly into one of the preferred ranges, the collector was ok and the can near enough, pipe size was to

large

I did not loose any bhp but didn't gain much

In any case the ideal exhaust would be built to deliver the torque at the desired revs and will only be at one small rev band

For me I want to enhance mid range torque as this is where I mostly am, brief excursions to high revs doesn't give me any advantage on the road

especially with high lift long duration cams, you want to fill the off cam gaps to get a better driving experience

IMHO

I eat to survive

I drink to forget

I breath to pi55 my ex wife off (and now my ex partner)

|

|

|

SPYDER

|

| posted on 5/3/16 at 08:41 PM |

|

|

It wouldn't be easy to make the perfect manifold for the F20 engine. To achieve the excellent HP figure they surely must have tuned the system

toward high revs. To match the variation in cam timing given by the VTEC system I would be expecting the sort of variable tuned length systems used on

some superbikes. Think "EXUP" or "HIVEX" to name the Yamaha and Honda versions. But Honda don't deem it necessary for

the F20. In fact, I can't think of one car engine using this concept.

But loads have used a similar system on the inlet side.

Does this indicate that tuned lengths are more beneficial on induction than on exhaust?

|

|

|

Rocket_Rabbit

|

| posted on 6/3/16 at 10:57 AM |

|

|

quote:

Originally posted by SPYDER

It wouldn't be easy to make the perfect manifold for the F20 engine. To achieve the excellent HP figure they surely must have tuned the system

toward high revs. To match the variation in cam timing given by the VTEC system I would be expecting the sort of variable tuned length systems used on

some superbikes. Think "EXUP" or "HIVEX" to name the Yamaha and Honda versions. But Honda don't deem it necessary for

the F20. In fact, I can't think of one car engine using this concept.

But loads have used a similar system on the inlet side.

Does this indicate that tuned lengths are more beneficial on induction than on exhaust?

No superbike has 'variable length' per se, but a restrictor/throttle valve in the exhaust to increase back pressure at low rpm.

On my GSXR600 it is called the SET valve. One of the first things I did to it was bin it!

Of course the inlet is indeed important and variable volume inlets have been around for ages. DBW throttles take it a stage futher by turning the

accelerator pedal into a torque demand pedal leaving the ECU to decide what position the throttle pate needs to be at in order to offer up the maximum

enigne efficiency at a specific RPM.

|

|

|

Rocket_Rabbit

|

| posted on 8/3/16 at 12:19 PM |

|

|

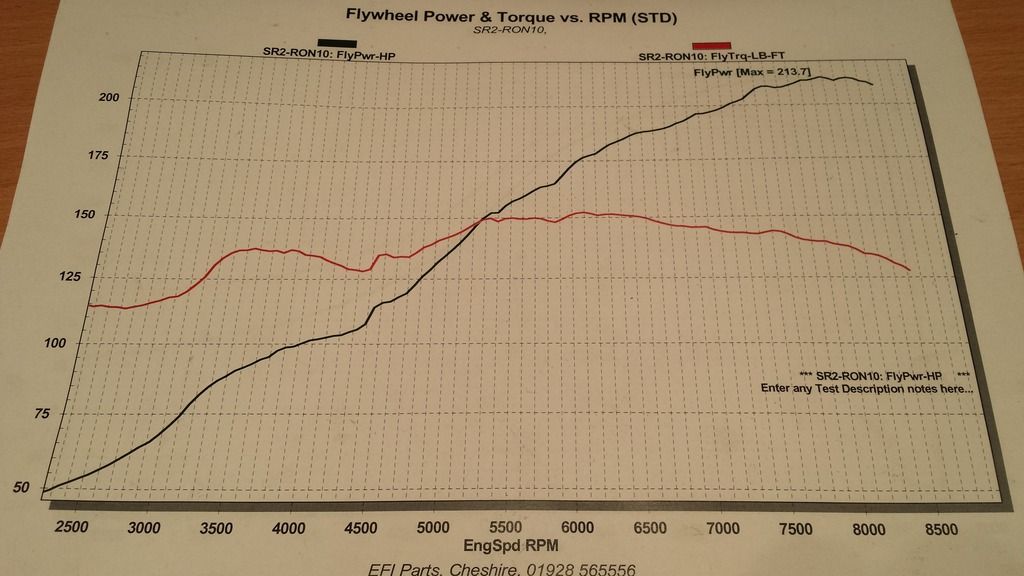

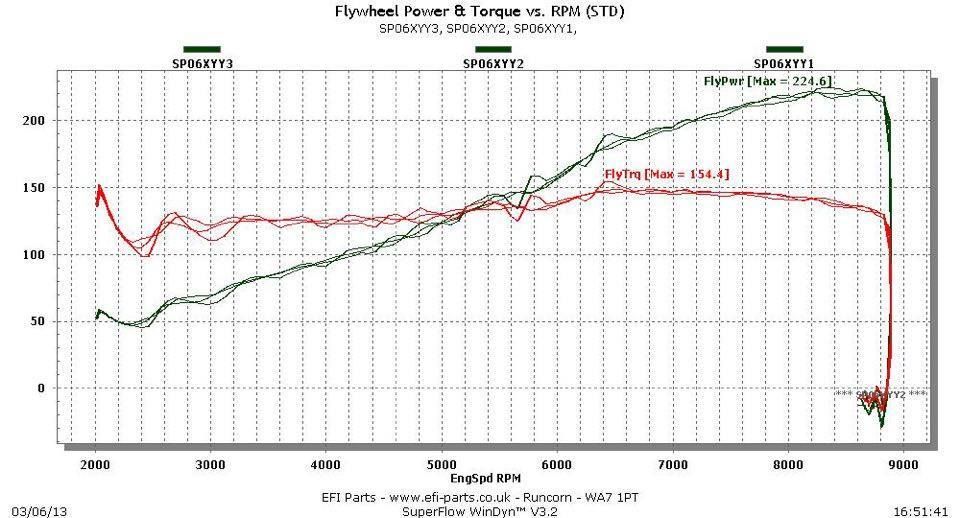

I was fortunate enough to get a RR printout from a standard S2000 on the same RR as mine was tuned on:

Mine:

S2000:

If you look at the torque curve, after 6500rpm on mine, it drops down a fair bit whereas on the OEM car it remains flat.

I am pretty sure this is indicative of a restriction and not a lack of scavenging effect which at high rpm, really shouldn't be as vital.

Opinions welcomed.

|

|

|