SausageArm

|

| posted on 24/4/12 at 08:08 PM |

|

|

ZX10R turbo engine rebuild and baffled sump fabrication

Here we have one poorly sounding ZX10R turbo engine

Oil drained and engine was turned upside down and the sump removed, some metallic particles were found in the sump

More metallic particles evident on the sump gasket

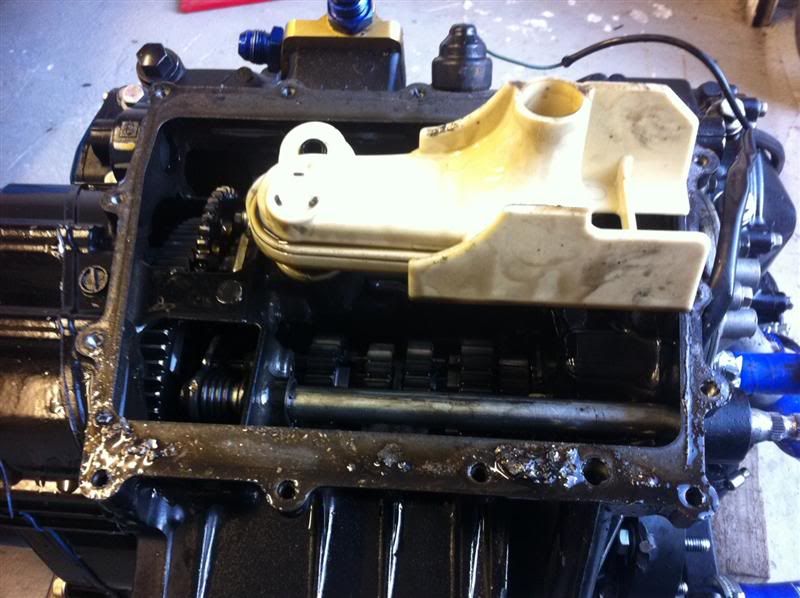

With the oil pickup and clutch cover removed the engine looks like this

Removed the covers and idler gear from the starter motor assembly

Crank position sensor cover and clutch plates removed

Clutch basket taken off

Clutch basket assembly

Remove this circlip from the gear selector shaft, then it can be slid out of the transmission casing

With the selector shaft removed, things look like this inside

Starter motor removed which gives access to the generator cover

Generator assembly removed

Big hole where the generator lives

Sprocket adaptor and water pump removed

Oil pump drive gear removed

Lower gear selector fork shaft being withdrawn

Lower selector and shaft

[Edited on 24/4/12 by SausageArm]

|

|

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:10 PM |

|

|

Upper selector fork shaft being withdrawn

Gear selector drum being withdrawn

Gear selector drum assembly

Selector fork shafts and drum removed but upper selector forks still in position

Upper selector forks

Oil pump

Oil pump housing

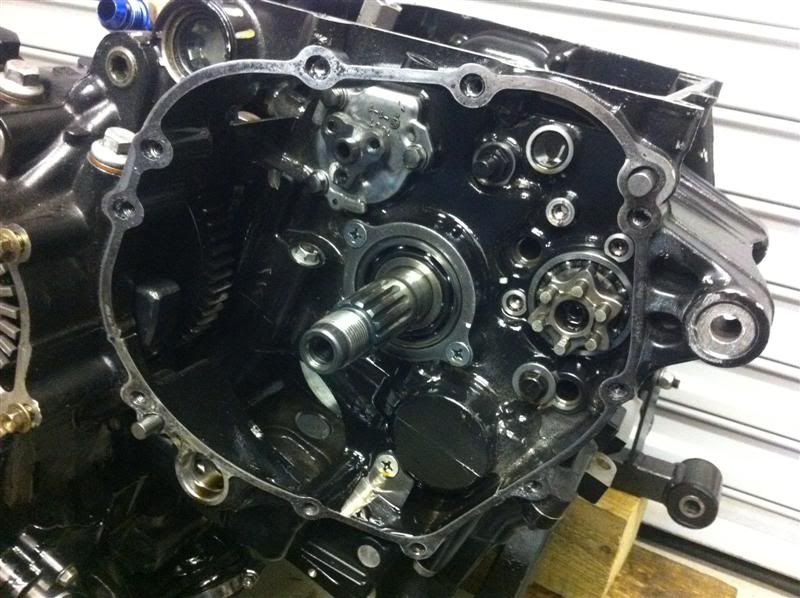

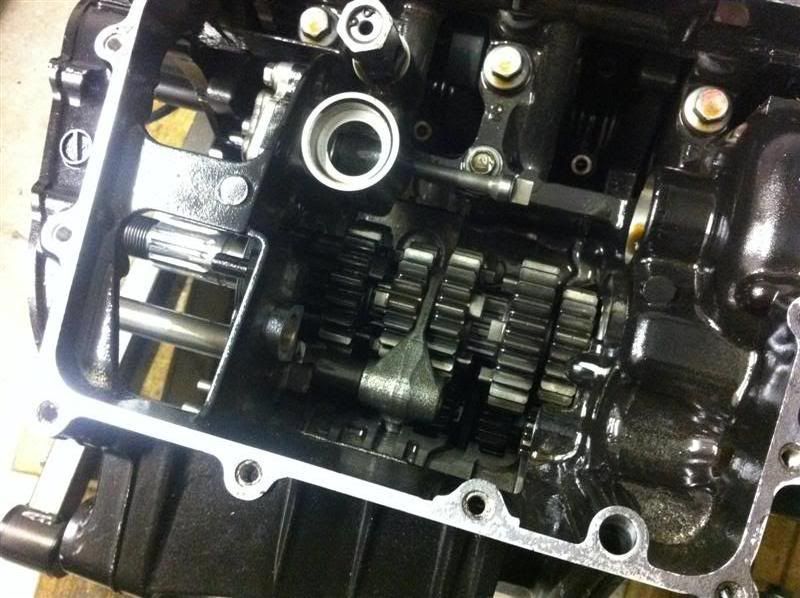

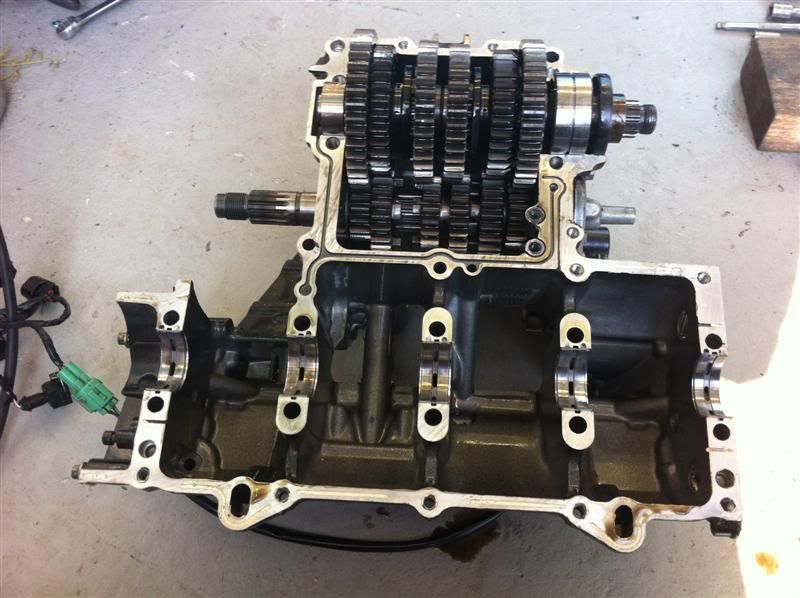

Engine casing split and the transmission removed

Transmission

Transmission output shaft removed

Transmission shafts

Having got to this stage of the stripdown and not found anything obvious wrong I was getting a bit concerned, due the large pieces of debris in the

sump it had to be something fairly sizeable and obvious which had gone wrong, the issue turned out to be a damaged big end shell.

As you can see here, the big end shell isn't in great shape and the rod cap appears to be scored

Hopefully the rod will be able to be salvaged, but that can't be ascertained until it it cleaned up and measured.

I'm very suprised that with the big end fault I have found that there was no excess noise/vibration while the engine was idling.

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:11 PM |

|

|

I gave the garage a tidy up to make some decent workspace to progress the engine overhaul

Removed the cam chain tensioner

Cam chain tensioner

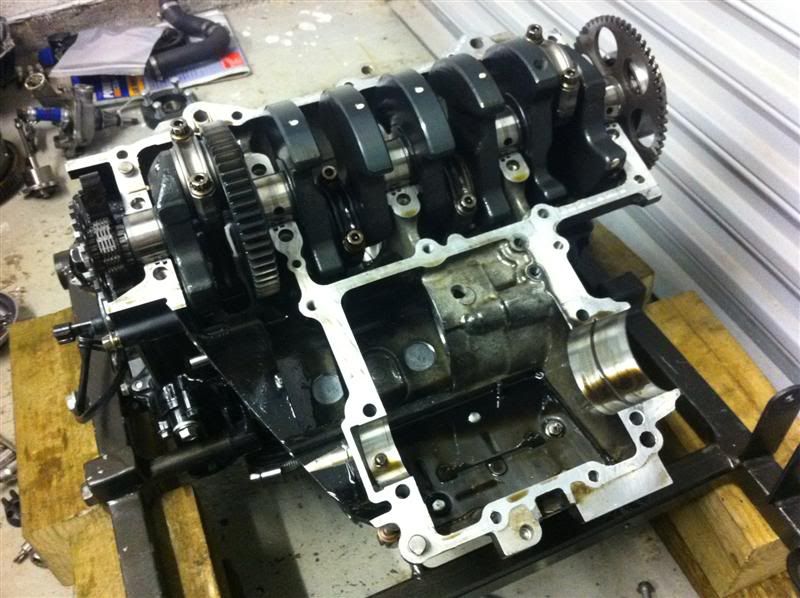

Cam cover removed, exposing the cams

Camshaft retainer caps, camshafts and followers.

Cylinder head without camshafts and followers.

With the camshafts removed the crank was then pulled out the bottom of the engine.

Crankshaft and cam chain.

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:13 PM |

|

|

Pulled the head off, here it is sitting on the bench

Bottom end and the shiney JE pistons

Numbered up so they go back in the correct positions

Arrow con rods and JE pistons laid out on the bench

The crankshaft main bearings showing slight signs of wear

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:18 PM |

|

|

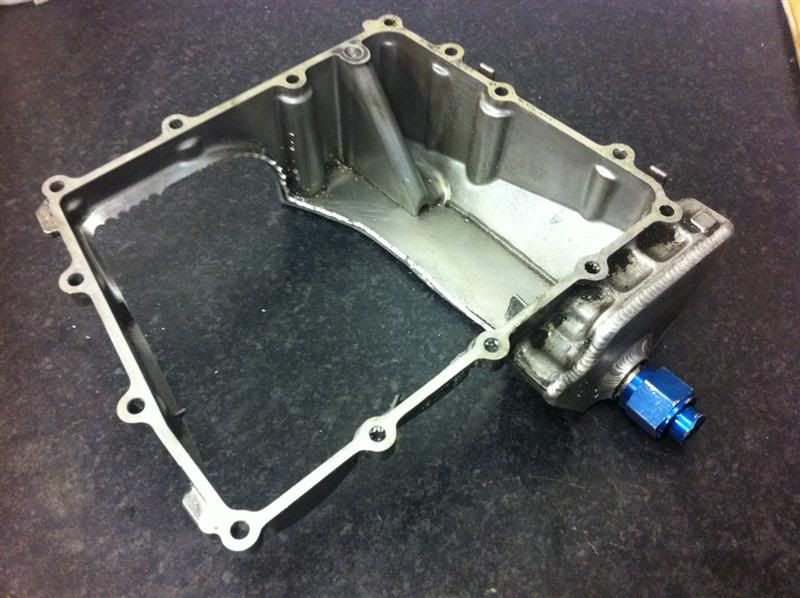

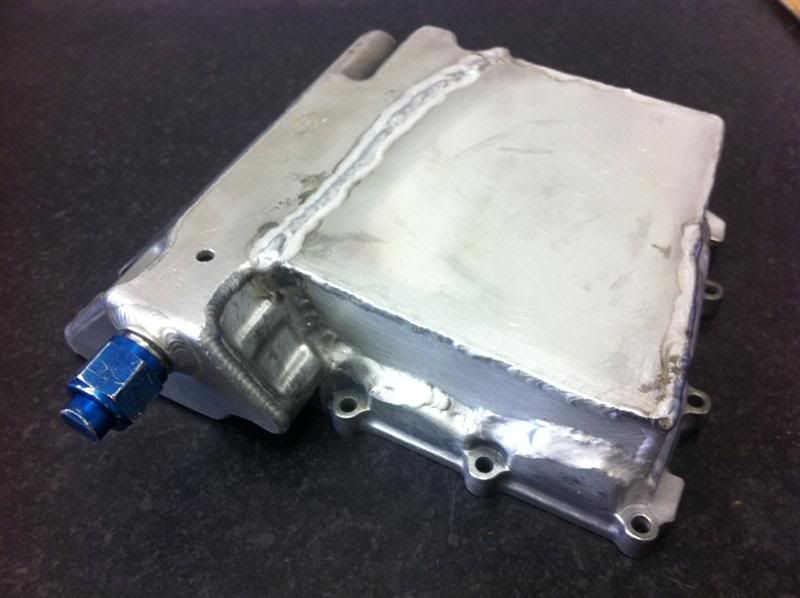

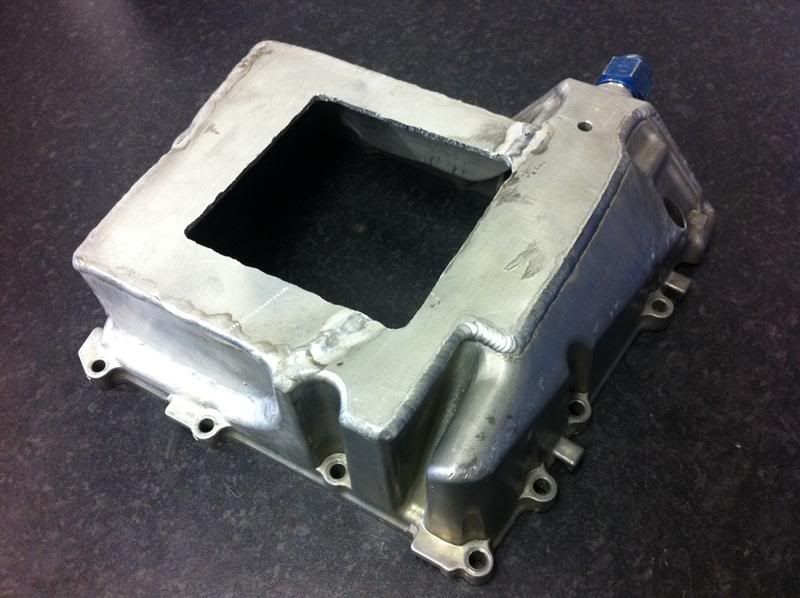

I butchered the standard sump, with the aim of giving it more capacity and also some baffles to stop the oil from moving around during

braking/acceleration/cornering. Will also be a good chance to practice and improve my TIG welding.

Here it is, in the early stages of modification

With aluminium plates welded to the sump to make it square shaped it should hold substantially more oil.

I began making cardboard templates to transfer onto the 3mm aluminium plate I bought yesterday.

The templates for the sump sides look like this

When rested in position the sump looks like it holds a lot more oil than the standard one

one aluminium plate tacked in place

http://img.photobucket.com/albums/0903/Red16/Mac%20Worx%20RR%20Build/SumpModification13Medium.jpg

a bit of progress on the sump, it's now looking like this

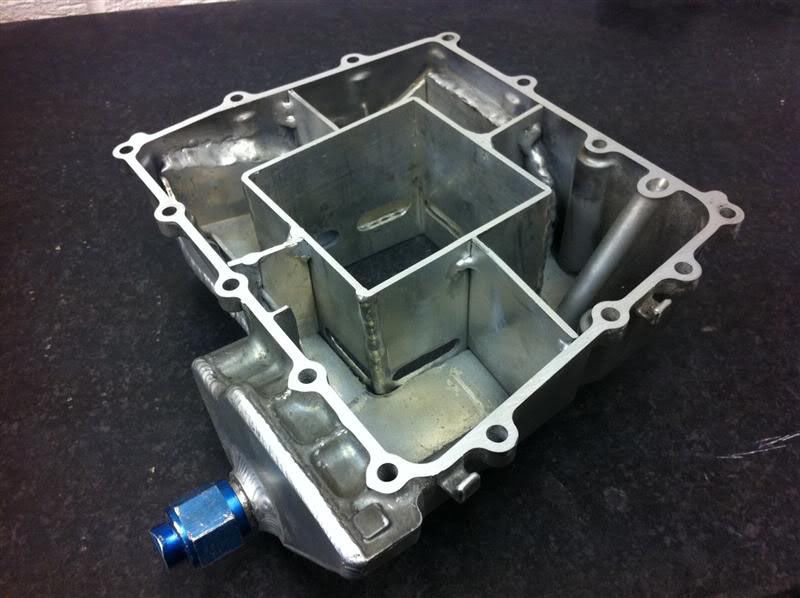

It's all water tight, as i found when i filled it to see what volume of water it held, it now holds 2.8 litres, which is definitely more than

the standard sump, unfortunately i didnt fill the standard sump before cutting it up, would've been nice to know the difference! Doh!

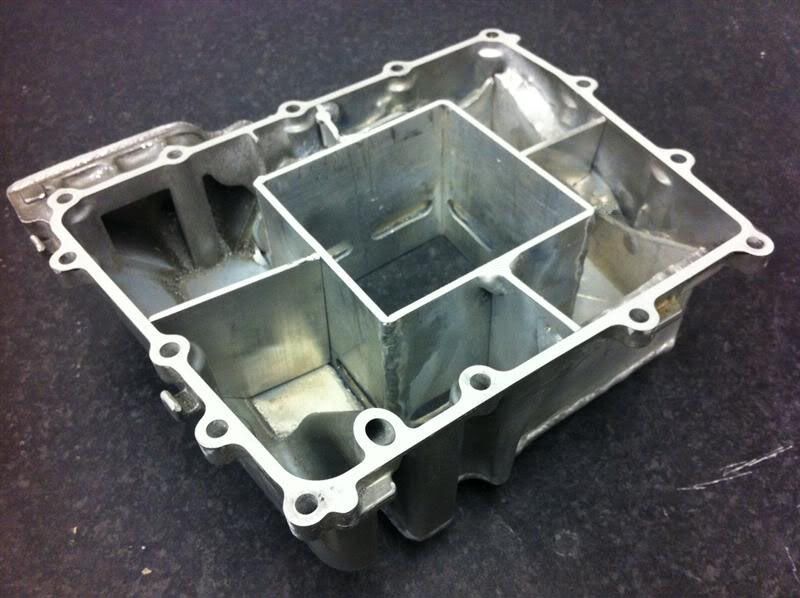

Here's the internal view, it's not baffled yet, as I'm still waiting on an oil pickup being delivered, once I have that in my

possession I can make the baffles accordingly.

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:21 PM |

|

|

Here's the new oil pickup, it's meant for a CBR900RR Fireblade, but it's the perfect size and shape to be modified and used in my

sump.

Here it is

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:23 PM |

|

|

Next task was to sort out a baffle plate to go between the engine and sump, I marked out and drilled the holes for the oil return and sump mounting

bolts.

Here it is trial fitted to the engine to check hole spacings

It was then trimmed down to the shape of the engine/sump

With it resting on the engine it looks like this

Once the sump baffles and oil pickup are finished I will add the necessary holes in the baffle plate to suit.

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:45 PM |

|

|

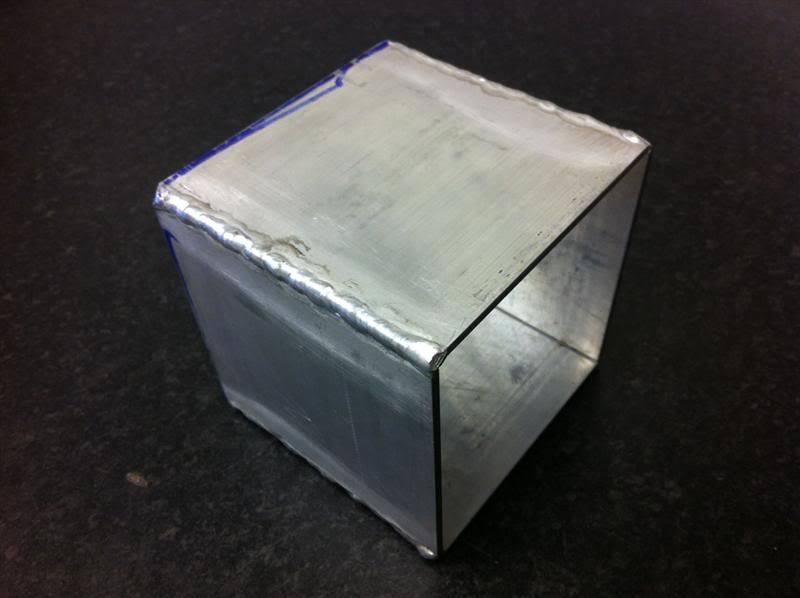

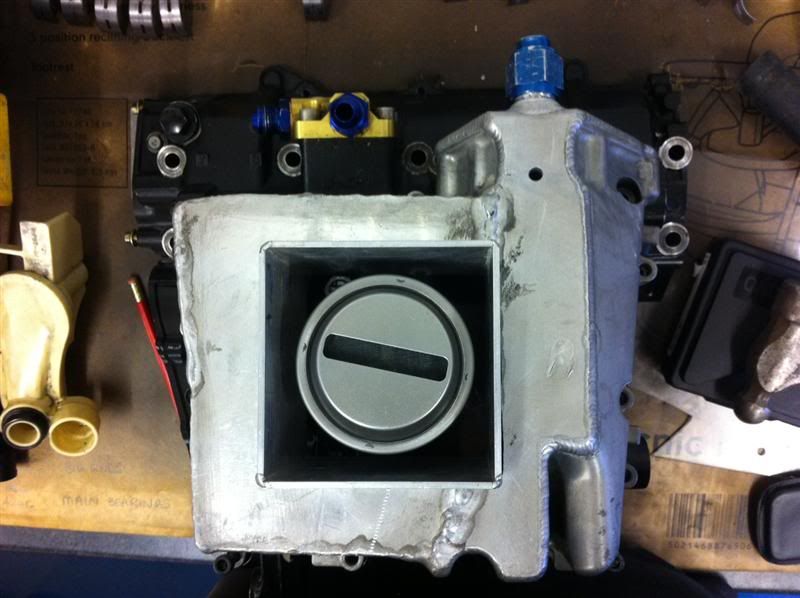

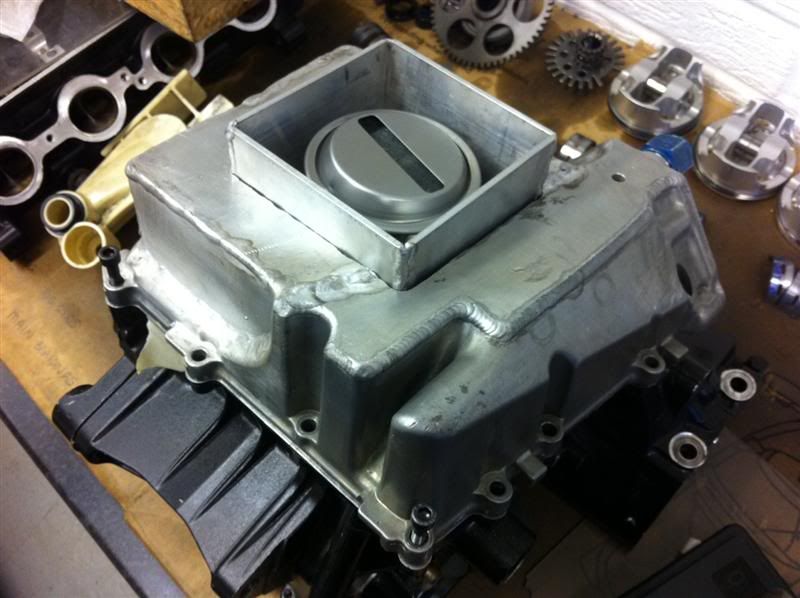

One baffle box for the centre of the sump.

The sump was then cut to allow the baffe box to be fitted.

Here is roughly how it will look when assembled, although there will be extra baffle plates between the sump walls and the baffle box.

Once the pipework ha been fabricated, the Fireblade oil pickup will sit in the base of the sump something like this.

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:48 PM |

|

|

I'm waiting on some tube being delivered to allow the sump to be progressed, so I decided to leave that and move onto the cylinder head.

Before stripping the head I wanted to double check the cam journal to cap clearances, so strips of plastigauge were laid across the journals

All the cam caps were fitted, bolts torqued up and then removed, this crushed the plastigauge material, the clearances measured between 0.0015"

and 0.002", whcih were within manufacturers recommendation of 0.0015" and 0.0032"

Next up was the task of removing the valves, a spring compressor was used to compress and hold the valve springs

Here you can see the valve spring has been compressed and the securing collets are accessable

Using a telescopic magnet the collets were removed

With the valve spring compressor removed things look like this

The valve spring retainer was then removed

With the valve spring removed, you can see thevalve stem and valve stem oil seal

The valve them simply pushes out of the head.

The bare cylinder head

I cleaned all the deposits from the valves, here are a couple of before and after comparison photos

The valves stems were then measured, checked for damage/bending and llapped in with fine valve grinding paste

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:50 PM |

|

|

I've had an update from APE Raceparts, my Carrillo rods and gaskets are in stock and have been sent out to me today.

AJ Suttons sent out my new oil pump, filter, and other parts, they arrived today.

I spoke to Chris Applebee the other day regarding my crankshaft being reground, unfortunately when he checked it over, the big end journal number 3

was worn but still within the limits of a regrind and new shells, however the crankshaft was bent around this area, so it is officially scrap!

I have a spot of good news though, I took delivery of this 2005 engine yesterday

I spent this afternoon stripping it down to remove the crankshaft, the crankshaft has been measured up and bearing clearances checked with the old

bearings fitted in my turbo engine, everything looks good.

That means tomorrows jobs list consists of assembling the cylinder head, checking valve clearances and ordering up some new main and big end shells

and possibly some cam follower shims.

|

|

|

SausageArm

|

| posted on 24/4/12 at 08:57 PM |

|

|

The tubing I bought from ebay earlier in the week, arrived today so I was able to make some progress on the oil pickup.

The inside diameter of the standard oil pickup seal is larger than the required pipework for the oil pickup. A larger piece of tube was used as a

sleeve and the tube for the oil pickup now slots inside this.

Here's the modified Fireblade oil pickup tacked together

Here it is with the sump rested in position

Baffle rested roughly in position

The depth of the sump in the centre is still to be finalised, as is the oil pickup height, this is achievable because the sleeve is not welded to the

pipework so the height is still able to be altered easily.

|

|

|

beaver34

|

| posted on 24/4/12 at 09:05 PM |

|

|

Great work as normal!

Follow it on passion ford

|

|

|

T66

|

| posted on 24/4/12 at 09:14 PM |

|

|

Does Chris Applebee do stripped spark plug inserts ? and is he local to you ?

By the way top notch job, the alloy work is spot on.

|

|

|

SausageArm

|

| posted on 24/4/12 at 09:15 PM |

|

|

quote:

Originally posted by beaver34

Great work as normal!

Follow it on passion ford

Thanks

I'm stuck in a hotel room so thought I'd transfer the stuff from pf to here, someone else might be interesting in having a look at the

photos etc.

|

|

|

SausageArm

|

| posted on 24/4/12 at 09:19 PM |

|

|

quote:

Originally posted by T66

Does Chris Applebee do stripped spark plug inserts ? and is he local to you ?

Nah Chris is down in Essex, I'm in South Shields, but I just posted the parts down and he sent them back up via courier.

There must be someone local who'd rework the plug insert for you.

Are you from the Morpeth area?

quote:

Originally posted by T66

By the way top notch job, the alloy work is spot on.

Thanks a lot  it's not perfect but i think it's slowly improving. it's not perfect but i think it's slowly improving.

|

|

|

mark chandler

|

| posted on 24/4/12 at 10:31 PM |

|

|

What's the point in dropping the pickup within that extend square box, you have just reduced the big sump to a tiny one.

If the box was flush inside the sump it creates a well, boxing around the sides like that you are just creating a little oil chamber, or are you then

going to drill holes around the base to let it fill up?

On the plus side, itís easy to see how far behind car engines are when you crack open a bike, the engineering is superb!

|

|

|

SausageArm

|

| posted on 24/4/12 at 10:39 PM |

|

|

Here's your answer Mark, I was just holding back the photos so as not to dump them all on here in one night.

And yes, bike engines are superbly engineered, I love the way everything is so small, light and compact.

I cut the holes in the baffle box and mounted it in the sump

it was then welded into position

Here you can see the last of the sump baffle plates tack welded in position

When i rested the sump on the engine casing for trial fitting it had warped slightly, so a few lengths of emery cloth were stapled to the work bench

and the flange face was lapped back to flat.

[Edited on 24/4/12 by SausageArm]

|

|

|

SausageArm

|

| posted on 24/4/12 at 10:41 PM |

|

|

One set of H beam Carrillo con rods

In the con rod kit comes a bolt torque spec sheet, lubrication for the bolt threads and shoulders and some plastigauge for checking the bearing

clearances.

They were expensive but they look bloody fantastic and super strong!

And just for the hell of it, here's a close up photo of two of the rods

A Cometic multi layer steel head gasket and bottom end gasket set

|

|

|

FASTdan

|

| posted on 25/4/12 at 07:15 AM |

|

|

Nice work :-) I was going to ask if your sump warped much. My Duratec one did - but unlike yours the Duratec has some horizontal fasteners too,

meaning that any skimming/lapping will cause location issues with these.

Did you have it bolted down when welding?

NEW danST WEBSITE NOW LIVE! Bike carbs, throttle bodies and more......

http://www.danstengineering.co.uk/

|

NOTE:This user is registered as a LocostBuilders trader and may offer commercial services to other users

|

Proby

|

| posted on 25/4/12 at 07:27 AM |

|

|

Excellent work Mr Sausage, looks fab, great pictures!

|

|

|

lotusmadandy

|

| posted on 25/4/12 at 08:43 AM |

|

|

Nice work there Ben, i hope to see you back on the road soon

Im fitting the turbo on my zetec this week,so a run out up to steves

is on the cards.

Andy

|

|

|

Toprivetguns

|

| posted on 25/4/12 at 09:19 AM |

|

|

My hat goes off to you sir ! Love the clinical approach to your workshop, especially the cardboard on bench surfaces.

I will follow this thread very closely.

Only drive as fast as your angel can fly... !

|

|

|

coozer

|

| posted on 25/4/12 at 09:32 AM |

|

|

Grrrrrr......

1972 V8 Jago

1980 Z750

|

|

|

imp paul

|

| posted on 25/4/12 at 09:27 PM |

|

|

love this thread top work ben its nice to see it all in picys hope it all works out for you

|

|

|

SausageArm

|

| posted on 26/4/12 at 08:00 PM |

|

|

quote:

Originally posted by FASTdan

Nice work :-) I was going to ask if your sump warped much. My Duratec one did - but unlike yours the Duratec has some horizontal fasteners too,

meaning that any skimming/lapping will cause location issues with these.

Did you have it bolted down when welding?

Bit of a schoolboy error on my part there, I had it fastened down at first, then moved it to weld another section, got carried away and done the rest

without it fastened down, luckily it's ok now.

quote:

Originally posted by Proby

Excellent work Mr Sausage, looks fab, great pictures!

Thanks a lot.

quote:

Originally posted by lotusmadandy

Nice work there Ben, i hope to see you back on the road soon

Im fitting the turbo on my zetec this week,so a run out up to steves

is on the cards.

Great news Andy, don't forget to pop past mine sometime with the MK, be good to have a look/ride again.

quote:

Originally posted by coozer

Grrrrrr......

What you grrrr'ing about Stevey?

quote:

Originally posted by imp paul

love this thread top work ben its nice to see it all in picys hope it all works out for you

Cheers Paul, I hope it does too, it should do really.

|

|

|