bikecarbfred

|

| posted on 18/1/16 at 10:56 PM |

|

|

valve grinding

how would you grind valves?

I want to slim the bottom end of the valve stem down to 4mm.

dremel tool?

|

|

|

|

|

Nickp

|

| posted on 18/1/16 at 11:34 PM |

|

|

Do you mean the end of the valve stem near the head of the valve? Thinning it to 4mm? If so then that's really really not advisable!!

|

|

|

mark chandler

|

| posted on 18/1/16 at 11:59 PM |

|

|

You need to put them in a lathe, then use a grinding attachment.

I would not even consider freehand with a dremmel, if you must and do not have the correct tools and want to risk your engine then stick your drill in

a vice with the valve as a drill bit then carefully use an angle grinder..... I shudder to think of the mess.

For the gains I would not bother, port shape will yield more power without risk, get a good book like this by Graham Bell

https://haynes.co.uk/catalog/general-interest-manuals/car-driving-modifying-restoration/four-stroke-performance-tuning

|

|

|

Adamirish

|

| posted on 19/1/16 at 12:40 AM |

|

|

Any particular reason why? They are made as they are for a reason.

MK Indy 1700 Xflow

|

|

|

bikecarbfred

|

| posted on 19/1/16 at 10:40 AM |

|

|

I have found someone to do a trial one on a lathe.

The stem original size is 6mm which goes down to 5mm at the bottom.

I am making the 5mm down to 4mm and having it blended. Then they are grinding more off the valve head so it is very flat and again blending it into

the 4mm stem.

They are doing it on a scrap one I gave them. The plan is to then get it tested.

How do you strength test a valve. Is there machinery out there?

P.S the valve stem size will always be 6mm through out the guide!

[Edited on 19/1/16 by bikecarbfred]

|

|

|

Paul Turner

|

| posted on 19/1/16 at 11:33 AM |

|

|

If one of your DIY modified valves breaks it will almost certainly wreck the engine.

If you want slimmer valves buy them from a genuine supplier and fit them as manufactured.

Why are you doing this?

|

|

|

DW100

|

| posted on 19/1/16 at 12:09 PM |

|

|

I have seen a few engines where the valve head has come off. They are always a mess and usually a total loss.

Saw a cross flow that dropped a valve at 10,000 RPM, We saved nothing from that engine. Rod through the side of the block took out the exhaust

manifold, steel crank was mashed, cam knackered, dry sump pump mashed, rocker gear smashed through the alloy cam cover. Even lost one of the carbs

after the valve head had shot up the port smashing its way through the venturi and ending up in the air filter.

|

|

|

grist_e

|

| posted on 19/1/16 at 12:26 PM |

|

|

Now thats a bad day in the office.

quote:

Originally posted by DW100

I have seen a few engines where the valve head has come off. They are always a mess and usually a total loss.

Saw a cross flow that dropped a valve at 10,000 RPM, We saved nothing from that engine. Rod through the side of the block took out the exhaust

manifold, steel crank was mashed, cam knackered, dry sump pump mashed, rocker gear smashed through the alloy cam cover. Even lost one of the carbs

after the valve head had shot up the port smashing its way through the venturi and ending up in the air filter.

Craig

One man on his mission to spend as long as he can in that garage till completion or divorce whichever comes soonest

|

|

|

r1_pete

|

| posted on 19/1/16 at 12:43 PM |

|

|

Not a great idea, the manufacturer left it at 5mm for a reason, most likely reliability.

By further machining the valve you will create fatigue points where the step down and back up occur.

It used to be a common racing mod to chrome plate valve stems so they would run better in iron guides, but, where the chrome plating stopped was

enough to cause a fatigue point and the head break off.

You don't say what you are trying to achieve, but for all out power ports, port matching, a decent cam, and careful setup yield more than valve

re-shaping, trimming valves may add a little more but lights the fuse IMO.

|

|

|

britishtrident

|

| posted on 19/1/16 at 12:55 PM |

|

|

Back in the 1980's I remember i blow on a single seater Renault powered 2litre F2 car a Knockhill, the engine started to self destruct at the

Hairpin a valve and seat insert was deposited via the exhaust on the start finish line and the whole ground to halt on the entry to Clark Curve.

Nothing left salvageable of the engine total right off ................

The main path for heat transfer from a valve is via the valve to the valve guide, a valve stem has to cope with shock loads, fatigue and heat -----

not a thing to take chances with.

[I] “ What use our work, Bennet, if we cannot care for those we love? .”

― From BBC TV/Amazon's Ripper Street.

[/I]

|

|

|

02GF74

|

| posted on 19/1/16 at 02:18 PM |

|

|

A puny honda cg 125 has 5.5 mn stem.

Remember strength and heat transfer is proportional to area, any linear decrease in diameter reduces those by same factor squared.

E.g Cross flow is 8 mm, area 16pi

4 mm is half diameter but 1/4 area.

Diy - valve in drill press and careful application of angle grinder.

Let us know how you get on but i expect an unhappy ending.

|

|

|

bikecarbfred

|

| posted on 19/1/16 at 04:06 PM |

|

|

some horror stories there. even at 6500 rpm this could happen?

Plus were these on a turbo setup where there ismore heat in combustion chamber so more heat transfer.

I am doing a small 1.4 16v NA block rev limit at 6.5k rpm.

Plus I did say I am getting just one done and strength tested. But I'd like to know if there is any where that can test a modified valve to an

OEM one.

[Edited on 19/1/16 by bikecarbfred]

|

|

|

mcerd1

|

| posted on 19/1/16 at 04:12 PM |

|

|

quote:

Originally posted by bikecarbfred

How do you strength test a valve. Is there machinery out there?

P.S the valve stem size will always be 6mm through out the guide!]

As above there is alot more to valve stems than just the pure strength in a tensile test - I'm sure you can get them tested if your willing to

pay enough...(OE suppliers must spend lots of £k's testing)

But as far as practical / diy test goes you've got your engine !

Only problem is the first valve failure will kill the whole thing - so how many test engines can you afford ?

In practical terms if you do this mod your talking a huge and probably unnecessary risk for very little gain (if any)

Your far more likely to make good gains by getting the right valve seat angles and by spending the time to get the transition from this to the

port.

In your other threads you say your fitting H beam rods - do you really need them for a NA engine with a 6.5k limit ?

[Edited on 19/1/2016 by mcerd1]

-

|

|

|

Paul Turner

|

| posted on 19/1/16 at 04:56 PM |

|

|

If you want the lightest, thinnest valves available for your engine I suggest you visit race engine builders who specialise in your engine type. They

will hopefully have the experience to sell products that give power and reliability. If they don't sell home made valves with 4mm waisted stems

there is probably a very good reason.

But if you only plan to rev to 6500 esoteric components are totally unnecessary. My bog standard 2 litre Blacktop revs quite happily to 7000 (would go

higher no doubt but why, power is dropping off and there is loads of torque low down).

|

|

|

bikecarbfred

|

| posted on 19/1/16 at 07:19 PM |

|

|

quote:

Originally posted by mcerd1

In your other threads you say your fitting H beam rods - do you really need them for a NA engine with a 6.5k limit ?

[Edited on 19/1/2016 by mcerd1]

Yes because it's known for the skinny rods in my block to bend.

So I have the h-beams and have the smaller end bush pressed in. all that part is done n dusted.

I appreciate everyones concern. Going to take this slowly.

[Edited on 19/1/16 by bikecarbfred]

|

|

|

rusty nuts

|

| posted on 19/1/16 at 09:02 PM |

|

|

Standard VW air cooled Beetles have much larger valve stems and don't rev anywhere near 6500 RPM , I rebuilt dozens of them due to dropped

valves.

|

|

|

bikecarbfred

|

| posted on 19/1/16 at 09:18 PM |

|

|

When your talking about dropping a valve are you talking about the head breaking from the stem? or dropping right out due to spring or cotter break

I tell you what cheesed me off. The OEM intake valves are 5mm at the lower end and i bought a new pack and they are 5.5mm at the lower end. 0.5

bigger than what they should be.

Now the standard valves are 17 years old! they now make them 5.5mm. It's just the way they roll out of the factory now.

So if you guys are saying they were made 5mm for a reason so is it okay to have the new ones I bought ground to the same 5mm diameter? This

can't be stupid can it?? well

|

|

|

paulf

|

| posted on 19/1/16 at 09:40 PM |

|

|

If you are turboing it then why worry about the valve stems, it is surely easier to just turn up the boost if you want more power.

Paul

|

|

|

bikecarbfred

|

| posted on 19/1/16 at 09:53 PM |

|

|

I am not going turbo.

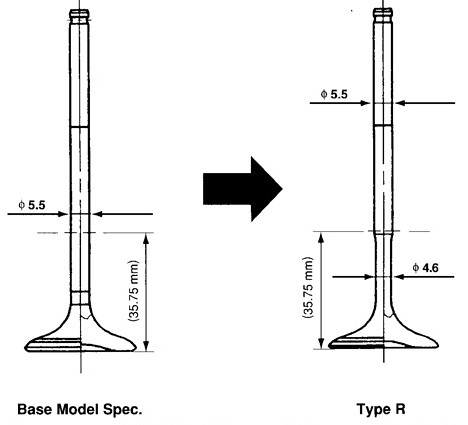

Also see pic.

Type R : 4.6mm

|

|

|

Paul Turner

|

| posted on 20/1/16 at 08:44 AM |

|

|

Problem sorted, buy some tyre R valves.

|

|

|

mcerd1

|

| posted on 20/1/16 at 09:24 AM |

|

|

Your forgetting one major factor - not all valves are made from material of equal strength

Type R valves may appear to be just the standard ones turned down a bit, but it's much more likely that they have been completely reengineered

in much stronger material, probably with fancy heat treatments and coatings too

An example I know of is the cossie YB engine, its crank has all the same key dimensions as the old pinto crank it replaces, but its made from

different metal and machined to better tolerances' too making it significantly stronger.

(the pinto is cast, the cossie one is forged steel with moly coated journals and I believe its induction hardened as well)

Also VW may have changed the spec of the valves for your engine (the often do this because they have had too many failed ones)

Or because they can make them cheaper without affecting the performance...

Again I'd ask are the valve stems actually a restriction ?

Or will you wasting time and money on reducing the valve stems when the real problem / restriction is elsewhere in the engine.....

[Edited on 20/1/2016 by mcerd1]

-

|

|

|

DW100

|

| posted on 20/1/16 at 10:26 AM |

|

|

If you are having one trial made then the obvious answer is to have the head flow tested to see if it actually makes any difference.

Depends on what you are building the engine for. If it is road use and track days then the risk of poor reliability is not worth the trade off for 1-2

BHP. If it is a competition engine that you are looking to get every BHP out of for an advantage over the other competitors then you still have to way

up the risk of not finishing.

|

|

|

bikecarbfred

|

| posted on 21/1/16 at 08:18 PM |

|

|

"Again I'd ask are the valve stems actually a restriction ? "

No because the can runs. But want improvement whilst building from scratch

Is Chrome Silcon steel the common material used to make valve? and your right you can get all sorts of special heat treatment/coatings

[Edited on 21/1/16 by bikecarbfred]

|

|

|

ALLAN 14

|

| posted on 22/1/16 at 11:08 PM |

|

|

Hi before you take a chance on killing your engine look at the Supertec performance site,

Good info on all types of valve's including sodium filled for better cooling.

The usual way to inprove flow is the three angle valve seat with a very narrow land,

good for competion use but do not last long enough for road use unless you want to to do a head rebuild every couple of

months depending on use.

A good rule of thumb is. How much does it cost,How much improvement will I get,How long will it last,and finally how much will it cost

to put it right.

At the end of the day you are paying so its just up to you.

I would look at the experts like Supertec before I started modifiing hi stress componants like valves.

Good luck anyway and keep us posted.

Regards Allan

PS did you get your topend bushes sorted out?

|

|

|

bikecarbfred

|

| posted on 22/1/16 at 11:54 PM |

|

|

yes Alan, I pressed them out my self. And had someone press in the new ones and they put a grove inside of them and the hole on top for the oil feed.

They made it out of Phosphor bronze and it cost £48 for all 4 conrods.

So in total the H-beam with that work cost £250 which I think is cheap as chips. It's the first real spend I've done. I'm thinking

about the rest now.

I will go pick up the single valve I am having cut skinny and will get that tested just for the fun of it. I think I've realised that I will

have to send this valve I have trimmed to professional to copy design it but make it out of some strong material.

The cost is high though. A company in the UK and a company in Israel have quoted me £600 approx. The company in the UK make it out of 1.4882

austinetic stainless steel which has 21% chrome, 4.5% Nickel

|

|

|