02GF74

|

| posted on 21/3/07 at 01:39 PM |

|

|

DIY cam vernier gear

How difficult/feasible would it to be to make you own adjustabe (aka vernier) cam gear?

In particular for a crossflow (cna't remember how this is fixed - peg or key)?

On a V8, the gear is positioned by means of a woodruff key engaging in a keyway in the camshaft and a slot in the gear.

Now if one were to take a file to enlarge the slot, one could reposition the timing. Now the hard bit (lierally) - if one could make ones own

woodrudd key with an offset by filing, one could set the cam toiming exactly.

Can one make the key and then do a DIY case hardening on it? Presumably mild stell won't be long lasting.

|

|

|

|

|

coozer

|

| posted on 21/3/07 at 02:00 PM |

|

|

Not worth the hassle IMHO. Enlarging the woodruff slot just means it will slip and you will get the valves puting holes in the pistons...

Much cheaper to buy a second hand one off ebay.

BUT, if you have a nice milling machine in your garage thats another matter.

1972 V8 Jago

1980 Z750

|

|

|

02GF74

|

| posted on 21/3/07 at 02:44 PM |

|

|

quote:

Originally posted by coozer

Not worth the hassle IMHO. Enlarging the woodruff slot just means it will slip and you will get the valves puting holes in the pistons...

Much cheaper to buy a second hand one off ebay.

no it wouldn't, the key itself would be made thicker to take up the gap, and on v8 there is a big bolt to hold it in place - the key is just to

locate it (gotta be similar arrangmeent on other cars).

5 minutes with a file is all yo need.

|

|

|

Dusty

|

| posted on 21/3/07 at 02:48 PM |

|

|

Burtons used to make offset woodruff keys for crossflows specificaly to deal with small cam timing variations. Maybe they still do!

|

|

|

andylancaster3000

|

| posted on 21/3/07 at 02:58 PM |

|

|

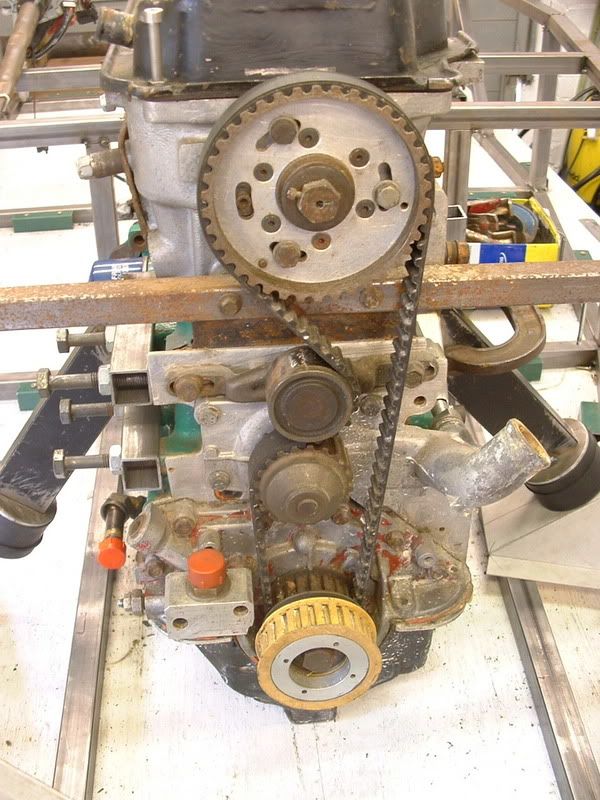

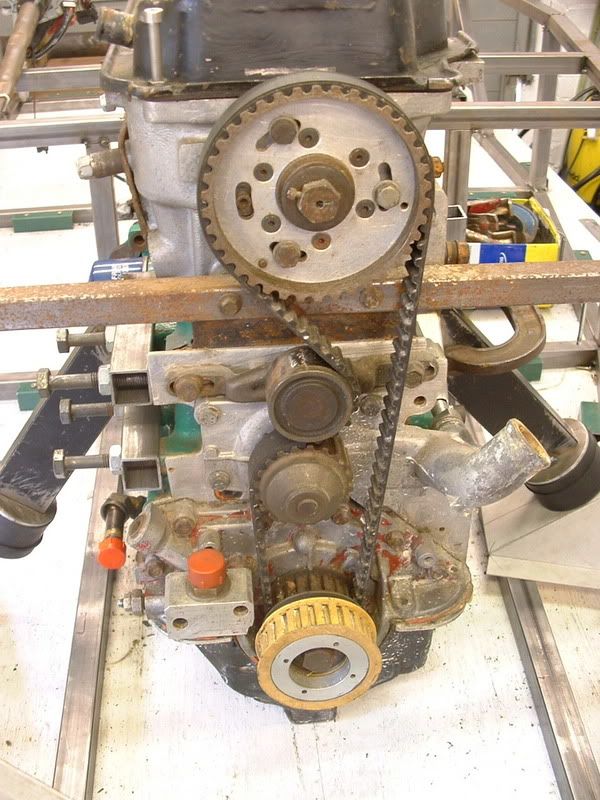

well I don't know about a crossflow but heres a CVH home made adjustable pulley. Used two standard ones (centre of one, outer of the other) with

a disc of billet ally, a lathe, a mill and bob's your auntie.

|

|

|

02GF74

|

| posted on 21/3/07 at 04:31 PM |

|

|

quote:

Originally posted by Dusty

Burtons used to make offset woodruff keys for crossflows specificaly to deal with small cam timing variations. Maybe they still do!

yes, they still do. a full set is about £ 40 whoich contains several keys.

Ofcourse you only need one!

Really looking for DIY solution like he pone above - been thinking along same lines for crossflow i.e. clamping two modified gear together but suing

simple tools i.e. no lathe/mill 'coz I ain't got one

|

|

|

BenB

|

| posted on 21/3/07 at 04:58 PM |

|

|

quote:

Originally posted by andylancaster3000

well I don't know about a crossflow but heres a CVH home made adjustable pulley. Used two standard ones (centre of one, outer of the other) with

a disc of billet ally, a lathe, a mill and bob's your auntie.

Yup- that's what I'm doing on the ST after the supercharger installation to re-time the cams (the decompression gasket will shag the

standard cam timing)....

|

|

|

Dingz

|

| posted on 21/3/07 at 09:14 PM |

|

|

quote:

Now if one were to take a file to enlarge the slot, one could reposition the timing.

It has been done on a pinto, of course you need a tight fitting piece of shim to fill the gap you make behind the key!

|

|

|

NS Dev

|

| posted on 22/3/07 at 10:51 AM |

|

|

quote:

Originally posted by 02GF74

How difficult/feasible would it to be to make you own adjustabe (aka vernier) cam gear?

In particular for a crossflow (cna't remember how this is fixed - peg or key)?

On a V8, the gear is positioned by means of a woodruff key engaging in a keyway in the camshaft and a slot in the gear.

Now if one were to take a file to enlarge the slot, one could reposition the timing. Now the hard bit (lierally) - if one could make ones own

woodrudd key with an offset by filing, one could set the cam toiming exactly.

Can one make the key and then do a DIY case hardening on it? Presumably mild stell won't be long lasting.

Obsolutely no problem at all, and you dont' need to worry about hardening etc, though you will be better to use key steel as its easier to grind

it to shape acurately. Angry grinder can be surprisingly accurate if you are careful for roughing it out.

The key doesn't take the drive, the clamp from the bolt on the sprocket/pulley does that, the key just aligns it.

You have to realise that with most rotating bits on an internal combustion engine, they are subject to horrendous torsional vibration, and keyways

fret out/shear off in no time at all given that abuse.

A clamp fit is what is required.

A couple of revs of a vauxhall XE 16v engine with a loose crank pulley bolt is enough to shear off the key on the bottom cambelt pulley........shows

how much good at driving that key is!

Retro RWD is the way forward...........automotive fabrication, car restoration, sheetmetal work, engine conversion

retro car restoration and tuning

|

|

|