iscmatt

|

| posted on 22/9/08 at 05:08 PM |

|

|

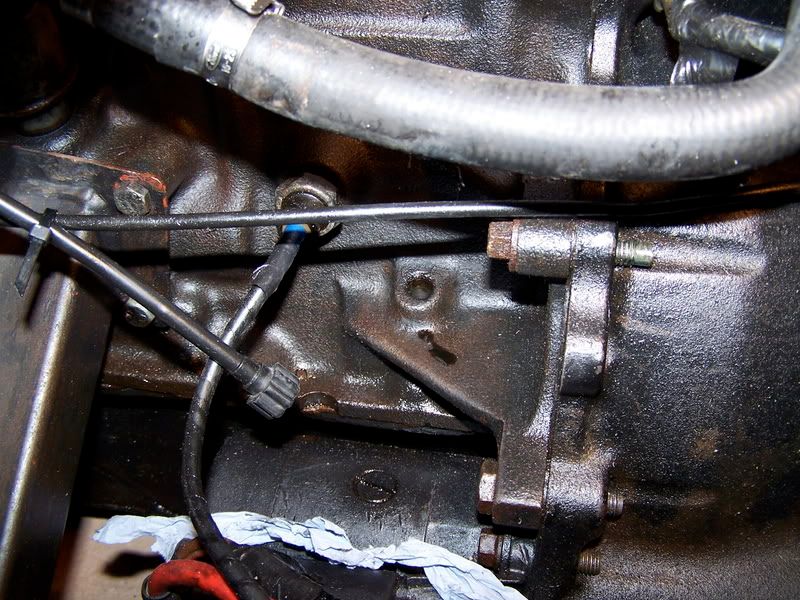

dipstick tubes come out :S

Well, the area around the bottom of the dipstick 'tube' had been leaking a little oil for a while now, it became a bigger issue on a

trackday. So i decided to have a look at it - went to pull out the dipstick and and the whole lot came away from the engine block!!

So, my question is what is best to get it back in place. Do i just use some araldite or is there someting in particular i need to use or do i actually

need to fix something??

All help appreciated as usual

Some pics to make it clear whats going on

|

|

|

|

|

delboy

|

| posted on 22/9/08 at 05:18 PM |

|

|

yes, araldite will do the job fine.

|

|

|

RichardK

|

| posted on 22/9/08 at 05:23 PM |

|

|

Usually a friction fit, I would see if I could flare it out a bit and thouroughly clean both sides but uderstand the sump end maybe difficult to

degrease, cotton buds?? then chemical metal it in, I also made a bracket that goes onto one of the bell housing bolts and stop any flex in the

dipstick tube.

Like this

Cheers Rich

Gallery updated 11/01/2011

|

|

|

iscmatt

|

| posted on 22/9/08 at 05:28 PM |

|

|

yes, was thinking of making a bracket to restrict movement, so thanks for that.

I'll degrease it best i can and flare it for a tight fit and use some araldite to fill the gaps.

Thanks for the help and quick replies, means i can go and sort now rather than later

Cheers again matt

|

|

|

Richard Quinn

|

| posted on 22/9/08 at 06:00 PM |

|

|

quote:

Originally posted by RichardK

Usually a friction fit, I would see if I could flare it out a bit and thouroughly clean both sides but uderstand the sump end maybe difficult to

degrease, cotton buds?? then chemical metal it in, I also made a bracket that goes onto one of the bell housing bolts and stop any flex in the

dipstick tube.

Like this

Cheers Rich

Sorry for the hijack - What fittings have you used on your ally catch can (I have a very similar set up for my expansion bottle)

|

|

|

RichardK

|

| posted on 22/9/08 at 08:41 PM |

|

|

Them euro type air compressor fittings, be warned though getting a half nut on the back was a right sod, bent thick welding wire twisted round the

edge to hold in position, then a home made spanner!

Wanted to use big bore tubing to help breathing on the recommendation of people on here, think the id was 12mm but don't hold me to that. Loads

of pictures in the link below.

Cheers

Rich

Gallery updated 11/01/2011

|

|

|