Wiring fixings

Slimy38 - 18/3/24 at 03:20 PM

Is there anything in the IVA that says whether a cable fixing is good or bad? I know there's a fair bit about fuel and brake lines being

adequately fixed, but I don't remember anything about wiring.

As an example, I have a pair of wires going from a side repeater, along the body front half up to the hinge (whole front of the car is hinged at the

front), then it'll come back into the car at that point. I reckon there's a metre or so of wire I need to pin inside a GRP body.

Would those adhesive cable tie bases do the job, or should it be something a bit 'more'?

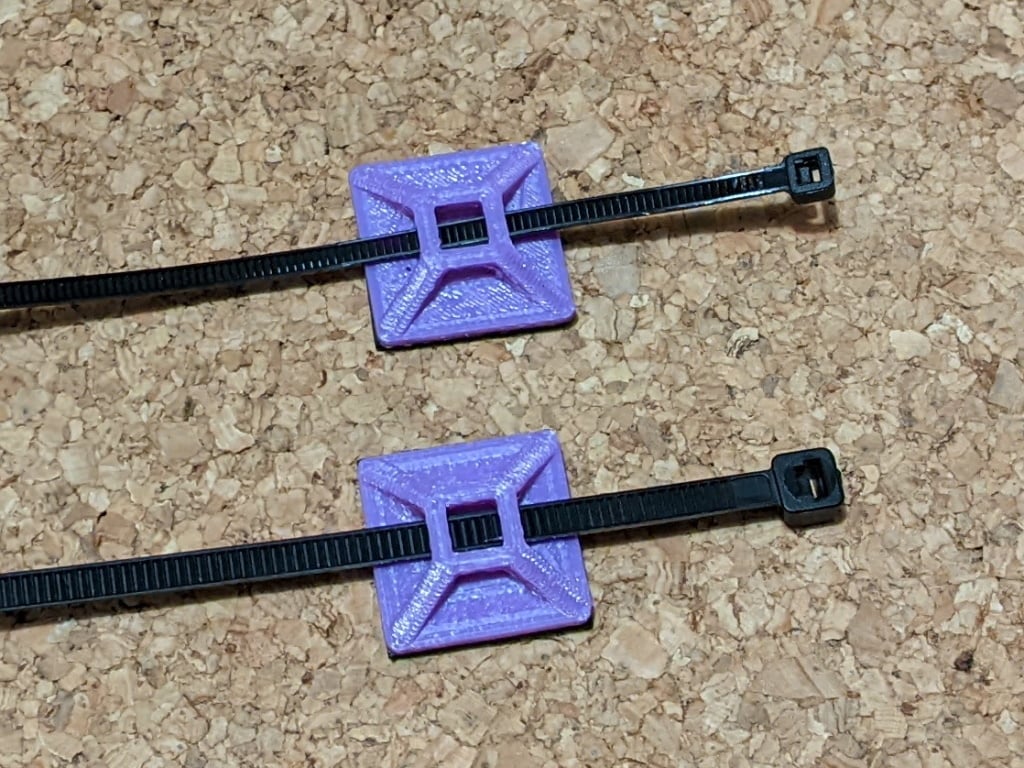

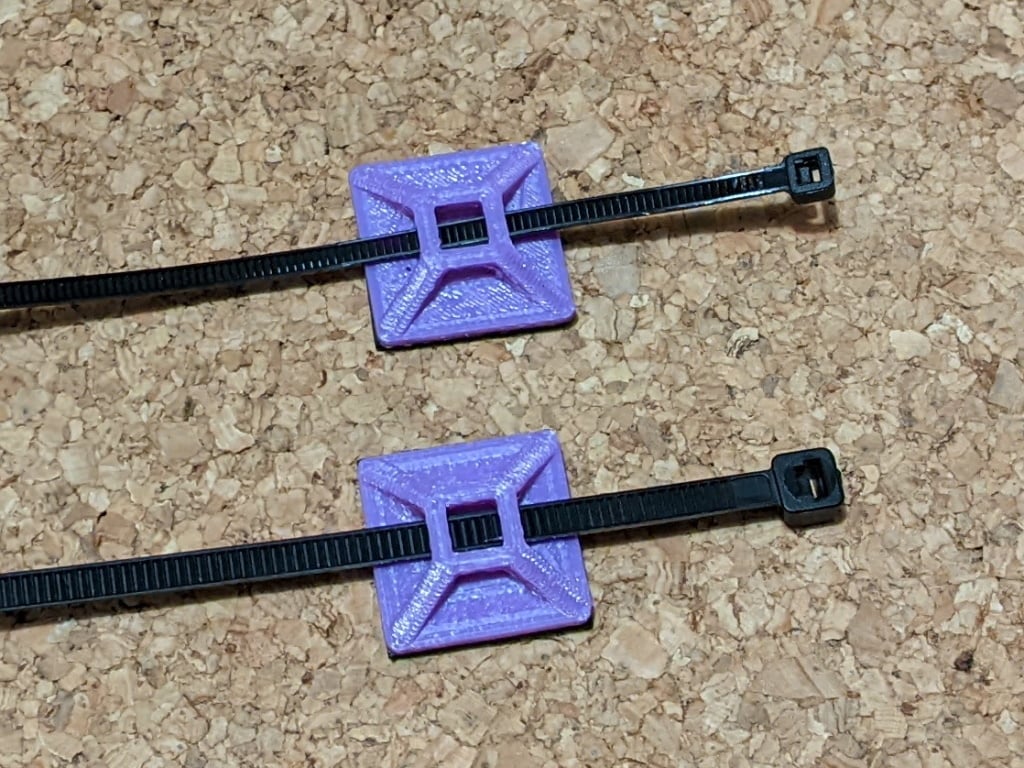

This is what I'm talking about;

gremlin1234 - 18/3/24 at 03:46 PM

the General Construction part covers

"8. All electrical cables/wires must be free from chaffing and secured at intervals

of at least every 300mm unless contained in a secure hollow component (see

Note 4).

9. All electrical components must be secure, be of adequate capacity, and be

insulated as required as to prevent short circuiting during operation."

I am sure bases like this should not be used. I cant find it explicitly in the manual, but would that kind of mount be used in a production car?

just mount them in a similar way to your fuel/brake lines

nick205 - 18/3/24 at 03:51 PM

I did SVA (pre IVA).

I can't promise it, but IIRC they didn't like adhesive fixings.

Heat and age could make the adhesive fail and the wires fall lose.

loggyboy - 18/3/24 at 05:48 PM

Depending on the quality/material of those, I would rather used moulded versions of those.

Not sure how up on 3d printed materials the inspectors are but might be worth making savings else where.

Slimy38 - 18/3/24 at 07:11 PM

quote:

Originally posted by nick205

I did SVA (pre IVA).

I can't promise it, but IIRC they didn't like adhesive fixings.

Heat and age could make the adhesive fail and the wires fall lose.

I was thinking of blobs of tiger seal to make extra sure, if that failed then I'd be in major trouble!

Slimy38 - 18/3/24 at 07:13 PM

quote:

Originally posted by loggyboy

Depending on the quality/material of those, I would rather used moulded versions of those.

Not sure how up on 3d printed materials the inspectors are but might be worth making savings else where.

Aye, it was only because I was on Thingiverse while I was thinking about them, and the image popped up.

Slimy38 - 18/3/24 at 07:33 PM

quote:

Originally posted by gremlin1234

just mount them in a similar way to your fuel/brake lines

Unfortunately while the fuel and brake lines are running along metal, the wiring I'm sorting first (the side repeaters) have no metal routing.

They have about a metre of GRP to be attached to before they can get to metal.

adithorp - 18/3/24 at 09:35 PM

Self adhesive fixings won't pass without a secondary fixing (screw).

Slimy38 - 18/3/24 at 11:09 PM

quote:

Originally posted by adithorp

Self adhesive fixings won't pass without a secondary fixing (screw).

I can't put a screw in, it would be sticking straight out the bonnet. I think these have been suggested before;

https://www.ecfibreglasssupplies.co.uk/m8-x-25mm-male-stainless-steel-thread

I'd most likely do a less fancy/costly version, but fibreglassing those on to the bonnet underside should be ok?

Slimy38 - 19/3/24 at 08:28 AM

Thinking more about this last night, I was wondering whether I'm focusing on the wrong thing. It's not necessarily the mount that is bad

(although I agree a 3D printed version is pushing it). It's the fixing. I've just gone back to Skov's build diary (the source of so

much of my information lately!), and he uses those cable tie mounts but fibreglassed in.

I was particularly impressed how tidy the patches were done, but more importantly that it went through IVA like that. So rather than overthinking the

mount itself, I'm going to get a fibreglass repair kit (I only need a small amount to patch them in) and go for regular mounts with a substantial

fixing.

adithorp - 19/3/24 at 04:17 PM

It's the self adhesive pad/patch they don't like. Bond them on with PU and you'll be ok. I formed some ally strips that the loom could

be threaded under and bonded them on for my test.

SteveWalker - 19/3/24 at 05:01 PM

A completely different idea, but would they need to be fastened to the body/chassis every 300mm if they were supported on a cable chain, designed to

support and protect, while also allowing movement, such as:

Cable Chain

gremlin1234 - 19/3/24 at 08:42 PM

quote:

Originally posted by SteveWalker

A completely different idea, but would they need to be fastened to the body/chassis every 300mm if they were supported on a cable chain, designed to

support and protect, while also allowing movement, such as:

Cable Chain

I guess that might qualify as

"contained in a secure hollow component"

mazie - 23/3/24 at 07:47 AM

On the Fury bonnet I glass and bonded in some of the large sticky cable mounts. They were solid.

gremlin1234 - 23/3/24 at 10:39 AM

if you are ever likely to remove the bonnet for maintenance I suggest fitting a plug and socket.

Slimy38 - 23/3/24 at 10:52 AM

quote:

Originally posted by gremlin1234

if you are ever likely to remove the bonnet for maintenance I suggest fitting a plug and socket.

Yep, I've got one for the front that will live near to the hinge, and another for the rear although hopefully the rear won't come off that

frequently.

gremlin1234 - 23/3/24 at 05:24 PM

while you are in this area, have you thought about where the 'audible warning of approach' (horn/horns) might be?

now would be the time to add any fixings for that, too.

Slimy38 - 23/3/24 at 09:20 PM

quote:

Originally posted by gremlin1234

while you are in this area, have you thought about where the 'audible warning of approach' (horn/horns) might be?

now would be the time to add any fixings for that, too.

Yep that's all ready to be fixed to the chassis. Wiring on the chassis is pretty straightforward, I welded some tabs in appropriate places so I

have lots of options.