silky16v

|

| posted on 9/10/12 at 12:09 PM |

|

|

ST170 VCT Delete Kit from the States

Just incase anyone is interested in wanting to the delete the VCT on the inlet cam on there ST170 engine & doesn't have the correct ECU to

control the PVM solenoid

I was looking to do this as cheap as possible but still retain the ST170 camshafts

You may or may not be aware of this little bit of kit from the states

http://www.massivespeedsystem.com/_massive_speed_system_/massive_speed_vct_delete_systems/mamc3402/i-545863.aspx

combined with the info from this post on TurboSport (think the users is on here too)

http://www.turbosport.co.uk/showthread.php?220142-ST170-VVT-Delete-Washer-spacer&p=1946957#post1946957

Hopefully get some feedback on the issue with oil at the camseal

Just need to buy a Zetec Vernier for the inlet and i should be good to go

I emailed Massive Speed on Facebook and they sent me a Paypal invoice with the correct UK postage all in it worked out at

£30.13 i probably couldn't get someone in the uk to make it for that

I'm aware that i will loose the low down Torque i get now switching the solenoid on at 2000rpm/20% throttle

I'm using a Omex 600 ECU so don't have PVM control

But the fact the engine in this state doesn't seem willing to rev freely past about 6250rpm, i hope with a fixed cam postion it will more than

make up for the loss of torque low down & the engine will rev far better at top end

once the kit has arrived i will update this post again

|

|

|

|

|

mikey p

|

| posted on 9/10/12 at 02:06 PM |

|

|

yes the PWM signal on the road car is not as simple as full advance through the RPM range as it advances midrange and then retards back to around

110Deg ATDC iirc for peak power. Will defiantly keep it on the boil at high RPM with fix timing around this figure as st170 themselves love to pull

hard all the way to the limiter.

|

|

|

Dusty

|

| posted on 9/10/12 at 07:07 PM |

|

|

I had a mate machine me up a new centre for a vernier. Cam now timed with the vernier zero set at 20 degrees advance over vvt base position using 20

degree cam bar. Can swing +or- 10 deg (10 to 30 degrees of cam advance) using the vernier adjustment and found 24 degrees seemed best power spread on

rolling road. Bit like a rally cam. Power from 3000 to 7500. No miracles.

I still think the ST170 is a dead end engine. The stock cams are a compromise. Very expensive to fit better.

As the head gasket is blown on mine I'm currently thinking flowed blacktop head with rally cams on the ST bottom end.

[img]

vvt delete 1

[/img]

[img]

VVT delete 2

[/img]

[img]

vvt delete 3

[/img]

[img]

vvt delete 4

[/img]

[Edited on 9/10/12 by Dusty]

|

|

|

silky16v

|

| posted on 9/10/12 at 08:44 PM |

|

|

quote:

Originally posted by Dusty

I had a mate machine me up a new centre for a vernier. Cam now timed with the vernier zero set at 20 degrees advance over vvt base position using 20

degree cam bar. Can swing +or- 10 deg (10 to 30 degrees of cam advance) using the vernier adjustment and found 24 degrees seemed best power spread on

rolling road. Bit like a rally cam. Power from 3000 to 7500. No miracles.

I still think the ST170 is a dead end engine. The stock cams are a compromise. Very expensive to fit better.

As the head gasket is blown on mine I'm currently thinking flowed blacktop head with rally cams on the ST bottom end.

[img]

vvt delete 1

[/img]

[img]

VVT delete 2

[/img]

[img]

vvt delete 3

[/img]

[img]

vvt delete 4

[/img]

[Edited on 9/10/12 by Dusty]

thanks for that if i've read the above right you are running 109 deg of advanced on the inlet? which you found the best compromise

Can is ask what you did to block the oil ways?

What cam position did you use the exhaust vernier?

What power did it make?

Thanks

|

|

|

Rob Allison

|

| posted on 10/10/12 at 12:47 AM |

|

|

Cam timing on the ST170 inlet is 85deg to 145 deg. I think the normal position on a zetec is about 110 ? Found that piper have most of there cams at

106deg full lift.

So the above figure of 20deg from base would be 104deg, not far off what is normaly set at and another 4deg added as you said making it 108 deg.

I like the machined centre

[Edited on 10/10/12 by Rob Allison]

|

|

|

Dusty

|

| posted on 10/10/12 at 11:28 AM |

|

|

109 sounds like a conventional figure. I get confused when some of the degrees are cam degrees and some are crank degrees.

It runs. Can be slow to start from cold. Exhaust runs 6 degrees retard. I get a couple more horses with 8 degrees but over a narrower range which

makes it less fun to drive. Using less inlet advance does reduce the intake roar considerably!!!

I did nothing with the oil supply to the vvt. Still get 3.5 bar. When I take the head off I will find a suitable ball bearing and tap it in the oil

feed with some loctite.

Power output depends on the mapping and the optimism of the gauges on the rolling road. Real world it's about 170 at the wheels. All delivered

with very little excitement but perhaps I'm used to it. Passengers usually go very quiet but that could be my driving.

As I said before I don't like the ST engine. With the vvt just switched by omex 600, not PWM, it's all over at 6000 when you only seem to

have come 'on cam' at 3500. As it is now it's gutless below 3000 but pulls all the way to 7500. If I had the cash then keeping the

vvt by fitting an ecu that will properly control them like the DTA S60 and fitting better cams would be the way to go. Modifying the head is good as

the exhaust ports are tiny, same size as the standard zetec. I have read that the head is a bit fragile when skimmed.

I currently have a blown headgasket due to a sudden water pipe failure. Cut by a jubilee clip. I was going some when it happened. Only realised when I

got steam through the bonnet vents when slowing for the next roundabout, by which time the engine was cooked. So I don't know if the head is

genuinely fragile. It was severely abused running hard with no coolant!

I'm still in two minds about fitting a modified blacktop head or sorting the blown head gasket. Blacktop heads and cams are much cheaper.

|

|

|

silky16v

|

| posted on 10/10/12 at 12:22 PM |

|

|

quote:

Originally posted by Dusty

109 sounds like a conventional figure. I get confused when some of the degrees are cam degrees and some are crank degrees.

It runs. Can be slow to start from cold. Exhaust runs 6 degrees retard. I get a couple more horses with 8 degrees but over a narrower range which

makes it less fun to drive. Using less inlet advance does reduce the intake roar considerably!!!

I did nothing with the oil supply to the vvt. Still get 3.5 bar. When I take the head off I will find a suitable ball bearing and tap it in the oil

feed with some loctite.

Power output depends on the mapping and the optimism of the gauges on the rolling road. Real world it's about 170 at the wheels. All delivered

with very little excitement but perhaps I'm used to it. Passengers usually go very quiet but that could be my driving.

As I said before I don't like the ST engine. With the vvt just switched by omex 600, not PWM, it's all over at 6000 when you only seem to

have come 'on cam' at 3500. As it is now it's gutless below 3000 but pulls all the way to 7500. If I had the cash then keeping the

vvt by fitting an ecu that will properly control them like the DTA S60 and fitting better cams would be the way to go. Modifying the head is good as

the exhaust ports are tiny, same size as the standard zetec. I have read that the head is a bit fragile when skimmed.

I currently have a blown headgasket due to a sudden water pipe failure. Cut by a jubilee clip. I was going some when it happened. Only realised when I

got steam through the bonnet vents when slowing for the next roundabout, by which time the engine was cooked. So I don't know if the head is

genuinely fragile. It was severely abused running hard with no coolant!

I'm still in two minds about fitting a modified blacktop head or sorting the blown head gasket. Blacktop heads and cams are much cheaper.

Thanks very much for this info it all helps, am i right in thinking the degrees that are quoted are camshaft degree and NOT crank?

I must admit the sudden power kick i had when the vvt kicked in was great but the fact it wouldn't rev freely past 6250rpm really started to

annoy me, especially as i had an R1 powered MK indy before this so i was use to having to rev the engine to get it to go anywhere.

If i can obtain the same BHP figure as before (178bhp) i'll be more than happy i just want an engine that rev's freely lol!

|

|

|

Rob Allison

|

| posted on 10/10/12 at 09:29 PM |

|

|

It's crank shaft degs.

Back to cams. I was looking at how it would be possible to fi black top cams into the st head. It looks like I would only need an adapted front cam

bearing, st is bigger.

|

|

|

silky16v

|

| posted on 10/10/12 at 10:21 PM |

|

|

quote:

Originally posted by Rob Allison

It's crank shaft degs.

Back to cams. I was looking at how it would be possible to fi black top cams into the st head. It looks like I would only need an adapted front cam

bearing, st is bigger.

Thanks though it would be crank degrees

To me if you can cheaply make the standard cam fixed and obtain 180bhp+ from a standard engine (abet fitted with some sort of throttle bodies &

after market ECU)

Then I would think the ST170 would be a good choice as its a much stronger bottom end to start with & has a better around head

I'm personally hoping that I can get nearer 190bhp+ without having to think about changing cams or any internal engine items to get a black top

to that level would to me be considerably more money

Back to your head I'd suggest getting the head checked for flatness I'm led to believe that's the heads don't take kindly to

skimming

[Edited on 10/10/12 by silky16v]

|

|

|

Rob Allison

|

| posted on 11/10/12 at 09:55 AM |

|

|

Thought i would put up a pic of the st and zetec cams.

Aa you can see the st inlet cam has a larger and different drive end bearing for the vvt system. My thought was that a spacer bearing could be

machined to fill the gap from the zetec cam to the st head. As the vvt is not to be used the phase sensor pickups on the other end will not matter.

There is a difference in the base circle from the zetec to st cam lobes but the cam buckets need to be reset even with modified st cams.

Anyone good with a lathe

[img]

ST170 and Zetec cams

[/img]

[Edited on 11/10/12 by Rob Allison]

|

|

|

silky16v

|

| posted on 11/10/12 at 10:17 AM |

|

|

quote:

Originally posted by Rob Allison

Thought i would put up a pic of the st and zetec cams.

Aa you can see the st inlet cam has a larger and different drive end bearing for the vvt system. My thought was that a spacer bearing could be

machined to fill the gap from the zetec cam to the st head. As the vvt is not to be used the phase sensor pickups on the other end will not matter.

There is a difference in the base circle from the zetec to st cam lobes but the cam buckets need to be reset even with modified st cams.

Anyone good with a lathe

[img]

ST170 and Zetec cams

[/img]

[Edited on 11/10/12 by Rob Allison]

true but what sort of power would a standard black top engine make with just a set of cams and throttle bodies fitted? 175bhp???

where as if the above can be performed on a standard ST170 motor and obtain 180bhp+ i think it will make the ST motor a more viable option for the

locost builder on a budget maybe?

I can what your saying fitted after market cams to the ST head, but what ever option you use (ST specific cams or Zetec) it is quite an expense due to

having re-shim the buckets, but it all depends on how knowledgable the end user is?

My aim is use a standard ST170 motor fit the VCT delete kit and a Vernier and after market management and throttle bodies (mine are GSXR1000) and

obtain 180bhp & free reving engine that is usable on road and occasional track use.

Considering my engine made 178bhp with the VCT switching on at 3000rpm/20% throttle i'm hoping 190bhp is obtainable.

My main aim is a free reving usable engine not gonna chase BHP figures

let me know which ever way you decide to go with replacing the cylinder head or cams

|

|

|

scutter

|

| posted on 11/10/12 at 12:14 PM |

|

|

VVc

I'm gonna stick my oar in here, I run the St lump on an old Omex 500 ecu, GXR 750 throttle bodies and a 2.5" exhaust.

The VVc is run of the shift light output at 2600 rpm, with out the solenoid connected it made 190 in a very linier fashion, now its much more lively

to drive with a massive increase of tourque to pull the car through the rev range.

They do seem very sensitive to exhausts as I found 10 hp byu going from a 2.25 to 2.5 diameter with a proper merge collector.

Apart from the exernal parts my engine is standard, so no worries if it pops.

Just my 2Ps worth. ATB Dan.

The less I worked, the more i liked it.

|

|

|

silky16v

|

| posted on 11/10/12 at 03:31 PM |

|

|

quote:

Originally posted by scutter

VVc

I'm gonna stick my oar in here, I run the St lump on an old Omex 500 ecu, GXR 750 throttle bodies and a 2.5" exhaust.

The VVc is run of the shift light output at 2600 rpm, with out the solenoid connected it made 190 in a very linier fashion, now its much more lively

to drive with a massive increase of tourque to pull the car through the rev range.

They do seem very sensitive to exhausts as I found 10 hp byu going from a 2.25 to 2.5 diameter with a proper merge collector.

Apart from the exernal parts my engine is standard, so no worries if it pops.

Just my 2Ps worth. ATB Dan.

very strange as when i switched my VVT output off my engine would rev freely with no load ie. in netural but on the road it wouldn't rev at all

and once up to 3000rpm just wouldn't go any further, switch it back on and all is fine just no rev's at top end

it does seem strange it made 190bhp with no VVT activated as the cam timing would be all wrong to make top-end power

how have you got your cams timed?

|

|

|

scutter

|

| posted on 12/10/12 at 05:12 AM |

|

|

rolling road 05/08/10

This I hope is the original plot before the vvc activation and exhaust change.( currently in the UAE, on crappy laptop)

Just remembered, I did fit the vernier on the exhaust and set it to a safe 4 deg.

Granted it doesn't produce power past 7K, but if your after that then maybe a bec would be better as i've never had a problem on road or

track.

ATB Dan.

The less I worked, the more i liked it.

|

|

|

Rob Allison

|

| posted on 18/10/12 at 12:56 AM |

|

|

Has the delete kit arrived yet?

|

|

|

silky16v

|

| posted on 18/10/12 at 06:46 AM |

|

|

quote:

Originally posted by Rob Allison

Has the delete kit arrived yet?

Posted out last Friday so hopefully here soon, just need to order another vernier

|

|

|

Jenko

|

| posted on 18/10/12 at 07:53 AM |

|

|

Interesting topic.....Must admit, it makes no sense that the VVT should strangle and limit revs as per Dusty's post. Possibly worth checking the

cam pulley was set correctly when doing the timing. As I understood it, the VVT would gradually advanced the timing based on revs (and pssobly

throttle position), I didn't think it then started backing it off again as the revs climbed.

MY BLOG - http://westfieldv8.blogspot.co.uk/

|

|

|

Rob Allison

|

| posted on 18/10/12 at 06:41 PM |

|

|

Thats not how the ST VVT works. Its a pulsed solenoid which is used to alter the oil supply pressure. This then moves the vvt pulley from it none

pressure filled retarded position. Its not related to revs. The ECU uses a closed loop system with a cam phase sensor to check where the cam timing

is in relation to the crank.

If you just put 12volts onto the solenoid it will go from 85degs full lift to 145 degs full lift. The position which gives the best power is inbetween

them. Thats why only correct control of the VVT will allow good power and the benifit of the inlet VVT.

As said above 108 deg seems to be a good setting, you will not get that by switching the vvt "on and off"

|

|

|

scutter

|

| posted on 18/10/12 at 09:28 PM |

|

|

Rob, that is the technically correct answer so far. To run the VVC correctly you will need a fully controlled PVM.

Every thing else is a compromise.

ATB Dan.

[Edited on 19/10/12 by scutter]

The less I worked, the more i liked it.

|

|

|

silky16v

|

| posted on 28/10/12 at 09:11 AM |

|

|

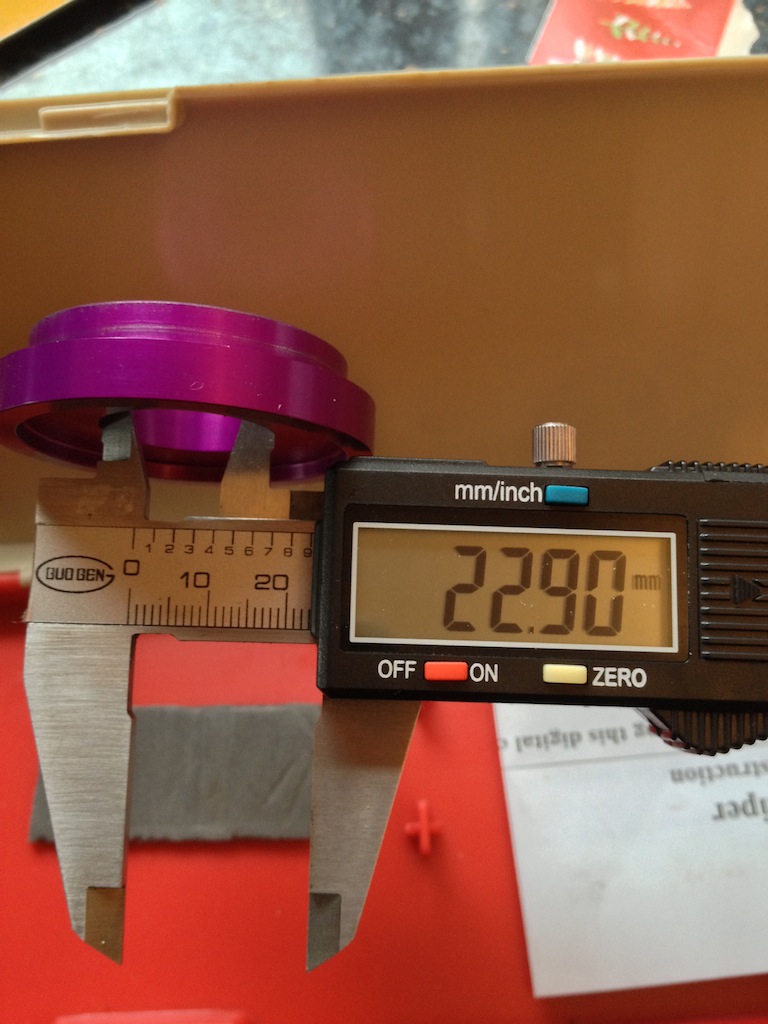

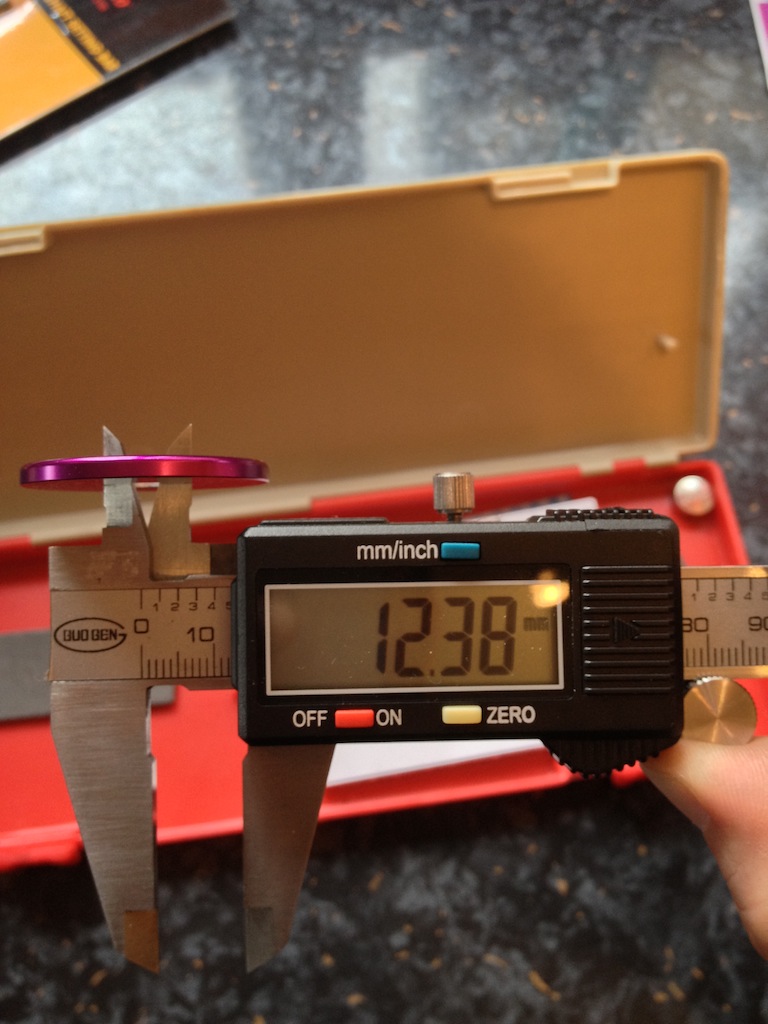

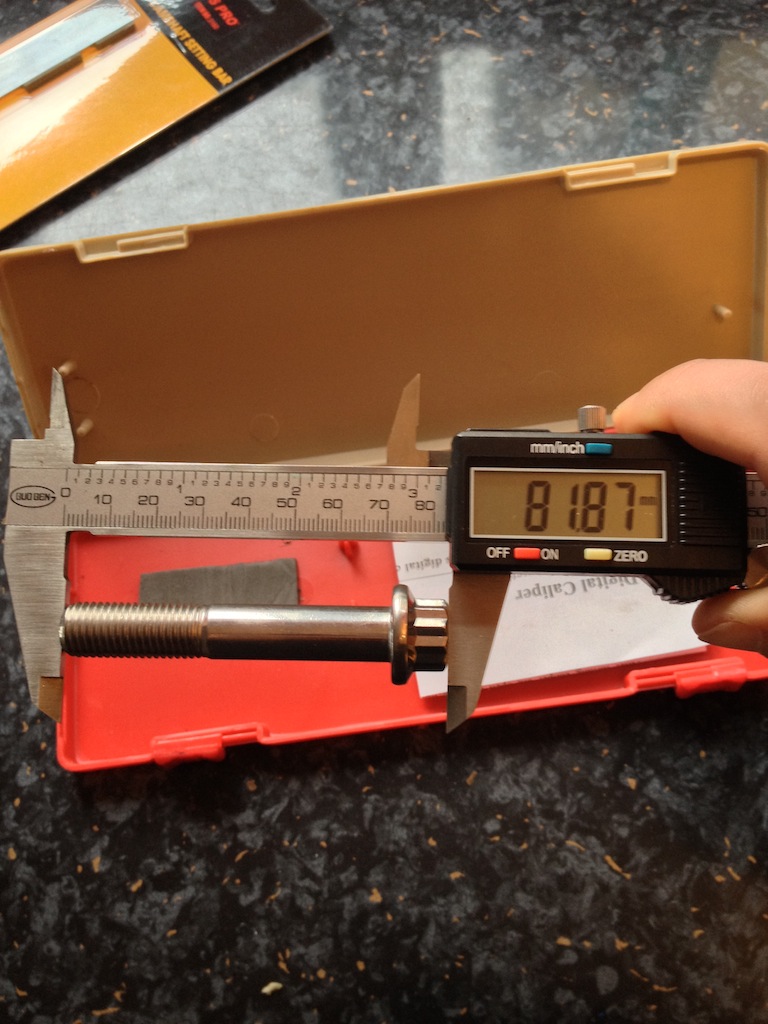

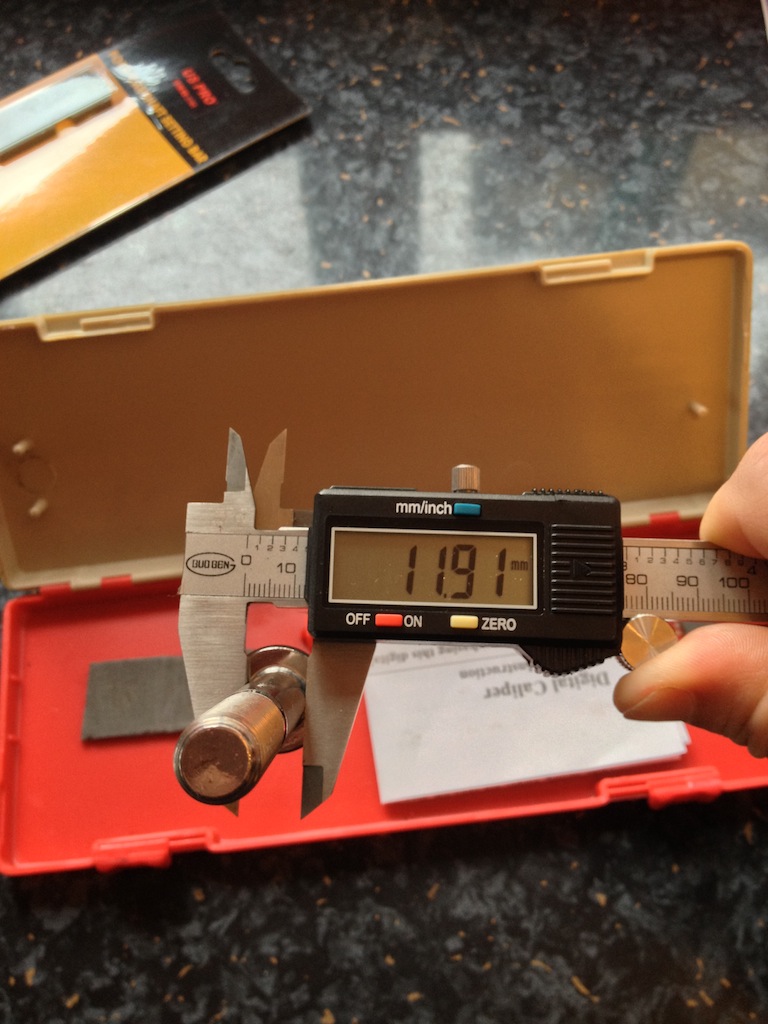

Small update parts have arrived from the USA, just waiting on my zetec vernier to arrive then i can set about setting it up

Here are pictures below is anyone wants diamension of the spacer let me know

|

|

|

Rob Allison

|

| posted on 28/10/12 at 09:27 AM |

|

|

If you wouldn't mind measuring it  please. please.

I may even order one up.

[Edited on 28/10/12 by Rob Allison]

|

|

|

silky16v

|

| posted on 6/1/13 at 10:42 AM |

|

|

Right finally an update sorry for the delay

was too busy of xmas and new year to make a start on things, but i've now had the vernier drilled for the VCT delete kit (12mm hole rather than

the 10mm for a Zetec)

I've also got the pictures with measurement for those who wanted them

I bought a pair of turbosport verniers (will have 1 spare if someone is looking for 1) and will be using this on the inlet

my exhaust already has a Piper vernier fitted

I will do another update as i work away in the garage with how i've setting the static timing

|

|

|

Rob Allison

|

| posted on 6/1/13 at 10:58 AM |

|

|

That's great. I'll try and get a cad drawing done

|

|

|

silky16v

|

| posted on 6/1/13 at 03:29 PM |

|

|

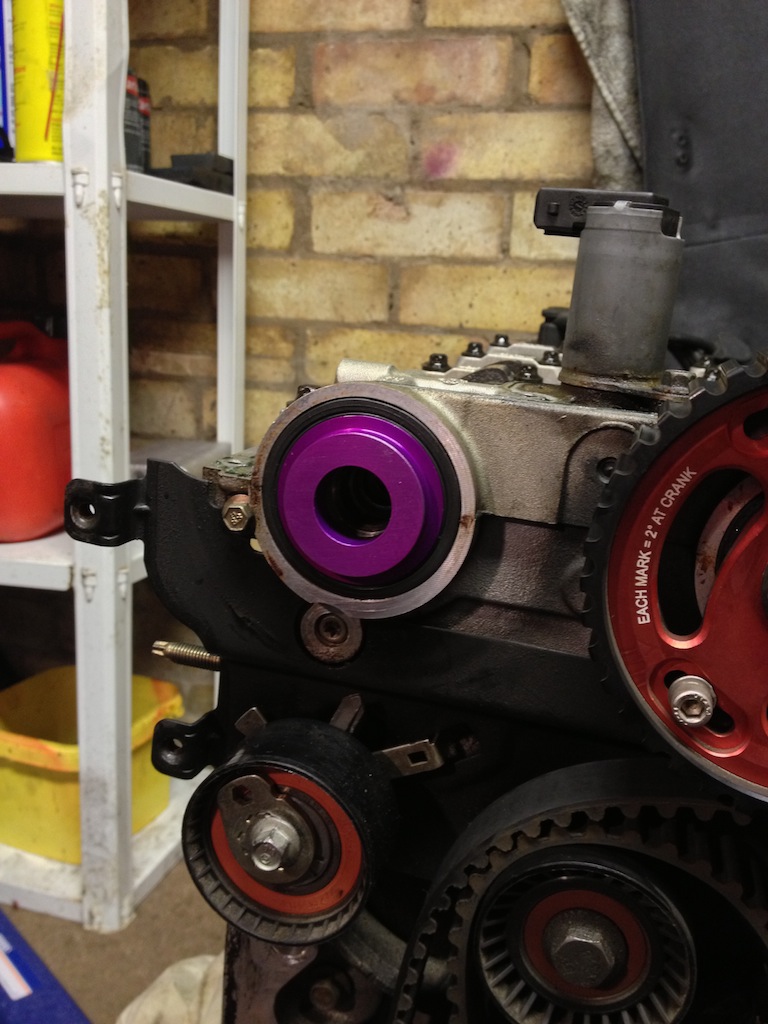

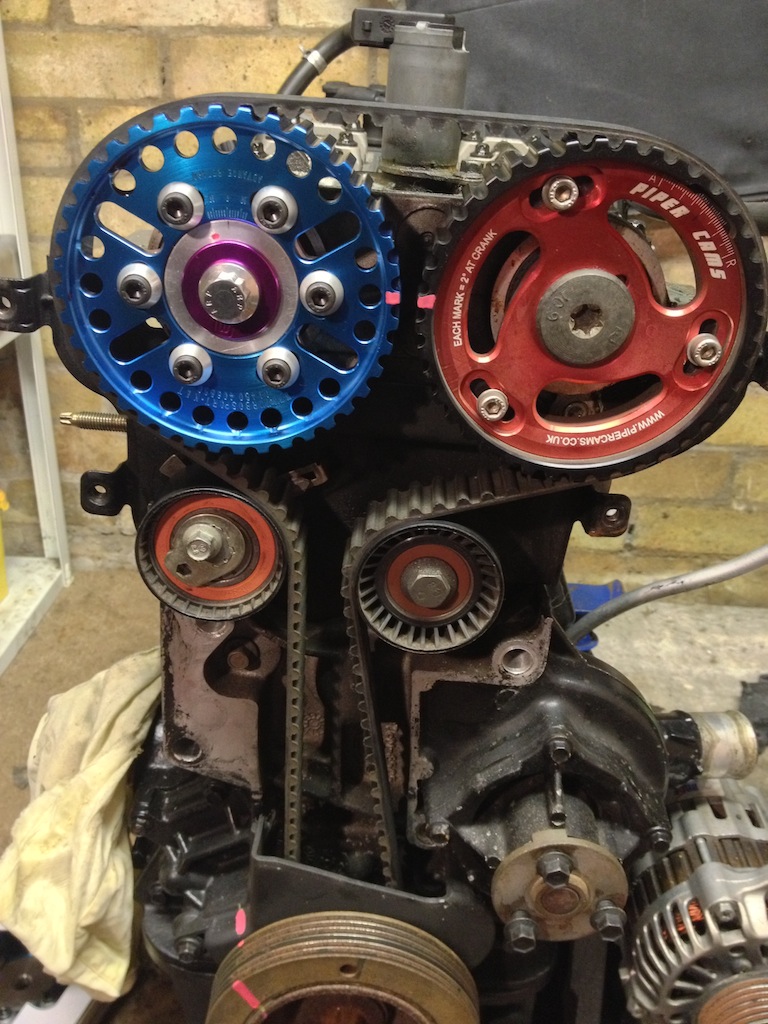

Further progress today all the pulleys and VCT delete are fitted and timed up

VCT all removed

VCT delete spacer in place

Vernier in place with VCT delete kit

Checking clearance with vernier fitted

Cambelt all in place and tensioned, just setting the pulleys in place and then tensioning the cam bolt pulleys

I set the new vernier to -10 as the 0 point so that i have a full 20deg of advance (40deg@crank)

inlet vernier set to 12deg advance (24deg@crank) thus giving static timing of 109deg

view from other end of camshafts showing the inlet camshaft advanced

|

|

|

Rob Allison

|

| posted on 6/1/13 at 03:46 PM |

|

|

Very good that

|

|

|