dangerousbrian

|

posted on 16/3/13 at 01:01 PM posted on 16/3/13 at 01:01 PM |

|

|

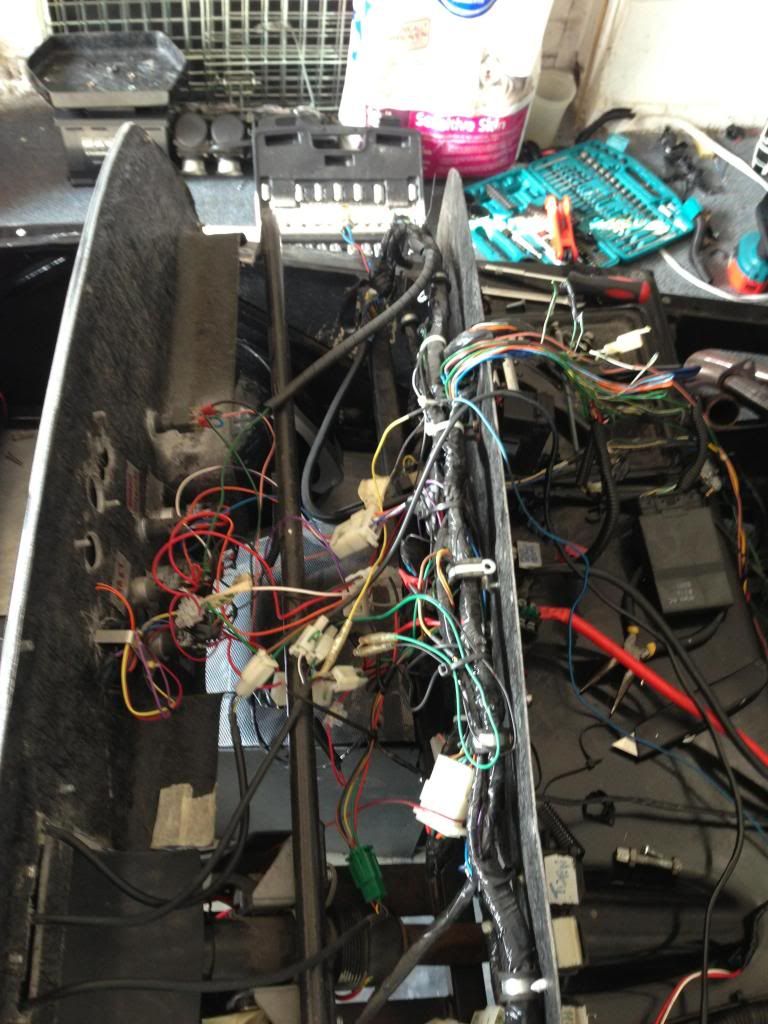

OK.... What goes where?

I'm in the process of stripping out the blade engine in my Indy ready to put an R1 engine in. Only problem is....... removing the bike loom from

all the existing wires that are there. I think i've already removed about 10lbs of electrical tape already!

I didn't build the car to start with so i'm having a hard time knowing what is what with everything being taped together the way it is,

what do you think is the best option? cut it away and start again? or would that give me an even bigger problem?

|

|

|

|

|

loggyboy

|

| posted on 16/3/13 at 01:24 PM |

|

|

I would spend a day trying to understand it, get annoyed and start again, or at least strip it back to basics.

Mistral Motorsport

|

|

|

spiderman

|

| posted on 16/3/13 at 01:43 PM |

|

|

Label everything which is connected as you detach each connector. Even if you end up making a new loom you can never have enough information when

sorting out the wiring. I know the temptation is to just cut it out and start from scratch but you may regret it later on when you are trying to

fathom out how it all goes back together. Patience is the key and be methodical/logical. Break it down into smaller sections i.e.

ignition/lights/instruments etc, oh and don't wrap it up with loom tape until you are 100% certain you have nothing else to add. I have used

convoluted tubing, rather than loom tape, to put my wiring in and kept lighting separate to engine loom. Take your time and when you get frustrated

with it walk away and come back to it when you feel a little more relaxed.

The wiring is usually the last part of a build to get done and a lot of people at that stage just want to get it finished and the wiring suffers from

hastily made connections and ill thought out routing. It is a job that a lot of people hate doing but is one of the most important where reliability

is concerned. Most car fires are started by electrical problems so important to do it right the first time as I am sure you don't want to have

to do it all again when the loom melts.

Spider

|

|

|

gottabedone

|

| posted on 16/3/13 at 02:40 PM |

|

|

Wiring is scary on any car if you have a mess like that to sort out.

I wouldn't rip any of it out yet but i would remove all of the tape. You have a lot of bunched up wires like the orange/blue etc in top right

in your pic - this is a lazy way of wiring which looks nice when covered in tape but is no help to you at all when you're looking at a birds

nest of different length wires. I would map out the wires that you know (and the components that they're connected to) and label them (take

fotys of your multi connections still connected - useful on a laptop while you're trying to get them all together again) and then map out the

components that are left.

I've re-wired 2 80's/90's Alfa and had many wires one colour one end and a different colour the other ;-( Not to mention not

matching the wiring diagram at all!

I found the green garden wire was useful - i'd start a bunch of wires, hook it to a bit of the car with a bit of green tie and just keep adding

and removing. You can finally tape or use the spiral wrap when you are done.

Con checking both ends of the cables that aren't obvious is a time saver as you can sometimes work back from the item that you know (starter

etc)

As said above, hacking it out will cause you a massive headache and hurt your pocket so when you get to the point of punching something - go sit in

front of the Xbox for half an hour

Steve

|

|

|

steve m

|

| posted on 16/3/13 at 04:24 PM |

|

|

How we all differ !!

I would rip the whole messy loom out, and go straight back to a base level, of nothing,

A blank canvas is so much easier to start with than a load of random wires going in a random direction

Wiring a car like ours, is not a hard job, and im no electrician, but did mine, and a friends cobra 10 years ago,

Both of which have never suffered an electrical problem, just mechanical !!

Steve

|

|

|

bigfoot4616

|

| posted on 16/3/13 at 04:39 PM |

|

|

as above.

rip it out and start from scratch.

spend a bit of time drawing up some diagrams before you start.

|

|

|

dangerousbrian

|

| posted on 16/3/13 at 04:41 PM |

|

|

I followed Spidermans advice earlier and left it alone for a while. I've been back and stripped all of the tape off now but its a huuuuge mess!

i think its all got to go.

There are a lot of wires that connect to various switches and block connectors for the lights etc but then they are all bundled in with part of the

bike loom looped round tangled, everything. i just can't understand why someone would do something like this.

|

|

|

bigfoot4616

|

| posted on 16/3/13 at 04:53 PM |

|

|

mine was like that before i rewired it. must of been twice as much wiring in there as was needed as well, loads of multi plugs not connected to

anything.

i designed my loom in separate sections and connected them with multi plugs. front loom, rear loom, engine loom and dash loom. also the dash switches

where on another multi plug to make dash removal easier.

having a separate engine loom certainly made things easier last year when i changed from a blade to R1

|

|

|

perksy

|

| posted on 16/3/13 at 04:55 PM |

|

|

Some folks do it that way because they think nobody will ever get to see it

Poor wiring is dangerous especially in a GRP bodied 7

Take your time and get it right and if it all needs ripping out and starting again then so be it, it'll be safer and more reliable.

I had a look at a 7 for somebody once and it had all been wired in one colour and that was just bloody wonderful to fault find on

|

|

|

dangerousbrian

|

| posted on 16/3/13 at 05:16 PM |

|

|

quote:

Originally posted by bigfoot4616

mine was like that before i rewired it. must of been twice as much wiring in there as was needed as well, loads of multi plugs not connected to

anything.

i designed my loom in separate sections and connected them with multi plugs. front loom, rear loom, engine loom and dash loom. also the dash switches

where on another multi plug to make dash removal easier.

having a separate engine loom certainly made things easier last year when i changed from a blade to R1

That's how mine is, more wires than there should be, there are some wires in there that connect to nothing and have the ends covered with tape.

|

|

|

renetom

|

| posted on 16/3/13 at 06:39 PM |

|

|

Hi

My suggestion would be to leave all the wiring to lights

back & front to switches stalks fuse board incl brake pressure

switch & fan wiring

Throw the rest away & start again with an R1 loom + additional

keep & use the exup motor saves a lot of fault codes.(just wired in, not connected)

Good luck

René

Where are you ?. always nice to know in case local people can help.

[Edited on 16/3/13 by renetom]

[Edited on 16/3/13 by renetom]

|

|

|

dangerousbrian

|

| posted on 16/3/13 at 09:02 PM |

|

|

I don't really have that option anymore, i've cut it apart from all the switches etc

I have a problem with untidy wires when i'm in work, so there is no way i could deal with all that mess under there not knowing how everything

wired up. So looks like i'm starting from scratch! Wish me luck!

[Edited on 16/3/13 by dangerousbrian]

|

|

|

steve m

|

| posted on 16/3/13 at 09:25 PM |

|

|

Well done M8, you have done the right thing!!

|

|

|