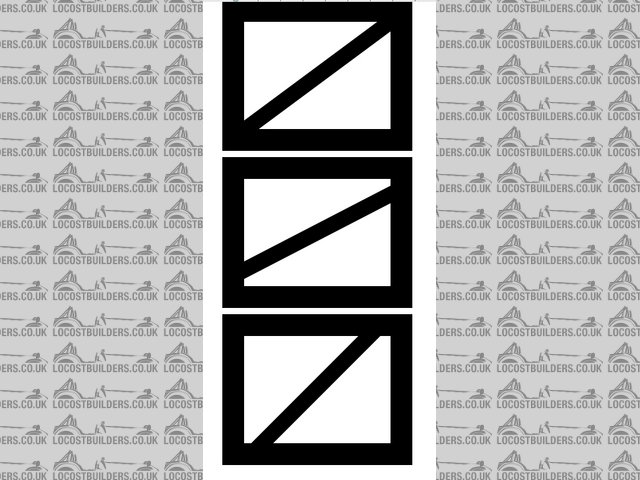

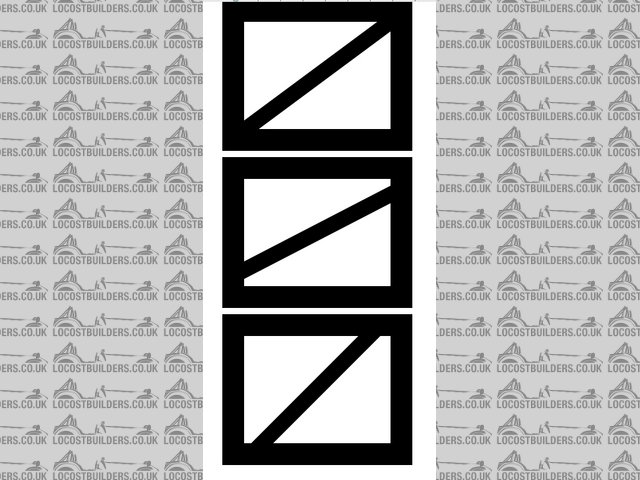

Top... Middle... Bottom???

Is there a 'correct' way to triangulate a square or rectangle?

Top... Middle... Bottom???

Top. The idea is to NOT introduce bending moments in any of the chassis members in a spaceframe. Which the other two options do.

Cheers Sebastiaan!

some basic reading here: http://www.preengineeredbuilding.co.in/space-frame.html

edit: link fixed. I hope...

[Edited on 29/12/11 by sebastiaan]

That links not working Sebastiaan (at least not for me).

no mate it seems to be faulty

Top is best but hardest to weld due to restriction of space to get the welding torch close enough to the weld. Using round tube as the brace helps

with access.

Ask me how I know!

Not a great deal of differance providing the offset from the corner is kept small and best would be subject to the direction and position of the loads

that are to be imposed.

Item 1 would distribute any imposed loads more uniformly.

And there are only two varaitions shown, images 2 and 3 are the same thing veiwed from a different position.(for a square)

[Edited on 29/12/11 by SCAR]

I do 99% of mine by intersecting centrelines, as similar to the top.

Problems with welding torch size??? What size shroud are you using? I use a 12mm and a 10mm, never had one I couldn't get to yet.

Cheers,

Nev.

That's the correct way, tube centrelines should always intersect....well thats what they taught us at school anyhow,

not always possible in practise though.

Al.

Originally posted by Neville Jones

I do 99% of mine by intersecting centrelines, as similar to the top.

Problems with welding torch size??? What size shroud are you using? I use a 12mm and a 10mm, never had one I couldn't get to yet.

Cheers,

Nev.

+1

You actually answered your own question. Only the top method produces triangles.

Top.

All the centre lines of the tubes should meet at the same point.

http://www.shedworks.eu/hints.html

Column 2, 5 down.

quote:

Originally posted by Confused but excited.

+1

You actually answered your own question. Only the top method produces triangles.

Whilst the above comments are of course correct, the location within the chassis may not require 100% triangulation and the lower 2 verions could well

be acceptable if it was practically difficult to achieve perfect triangles.

For example:

the forces applied to the front box would not require perfect triangulation in that position.

imagine you were pinning all the joints ................

Cheers fellas!

Loggyboys pic shows why I was asking... I've seen loads of chassis with diagonal braces like this. In fact, I rarely see perfect triangles.

Maybe I should have used the word diagonal instead of triangulation in the thread title.

Every chassis is a compromise somewhere, a perfect spaceframe is already compromised by the need to put people, engines, fuel tanks etc in

somewhere.

If you can get every tube into a perfect triangle then that's great, but if you need a steering arm to go where the perfect tube would then

it's the chassis that's going to end up compromised. Like most things in life do your best, but don't kill yourself if it's not

perfect.

Having said that some manufactures seem to do rather better than others in this area.