2004 MK Indy Busa Project

yellowcab - 2/3/12 at 07:29 PM

Hi guys,

Not really a 'build' thread as such, as it's already built - but I'll certainly been changing a few bits & bobs on the car as

time goes on, in between being on track, which is 99% of the reason I've bought it.

Throwing money at it isn't something I'm interested in, my mindset is very much - get it on track, like NOW. Avid track day & sprint

goer, I'm interested in nothing that doesn't make me go quicker, smoother etc.

My YouTube channel is (cringes at the username) www.youtube.com/trackdaynova

For now, here is the first photo of her at home, but being a photographer - they'll be plenty more.

Yes the heavy 15s will go along with the Kuhmo Ecstas, but got some reading up to do on whether to drop to 13s or not, as the FD is already at 3.14,

so wouldn't want to limit my top speed much more...

Thanks for reading

Olz

danny keenan - 2/3/12 at 07:38 PM

hi olz

please join our MK Owners page on facebook.i update this all the time with our new products and there are some real nice cars on there.

check out our new rear diffuser on there

any help you need with your car just ask me.

thanks danny mk sportscars

yellowcab - 2/3/12 at 08:01 PM

Hiya Danny,

Thanks for the warm welcome - I'll nip over to Facebook now to click Like have a read...

Got so many questions to ask, but would sooner search and read forums, rather than doing the annoying newbie thing of asking questions that have been

covered over and over again  )

)

Take care

Olz

afj - 2/3/12 at 08:04 PM

dropping to 13s wont decrease your top speed as long as your on 205/60 at the rear

yellowcab - 2/3/12 at 08:10 PM

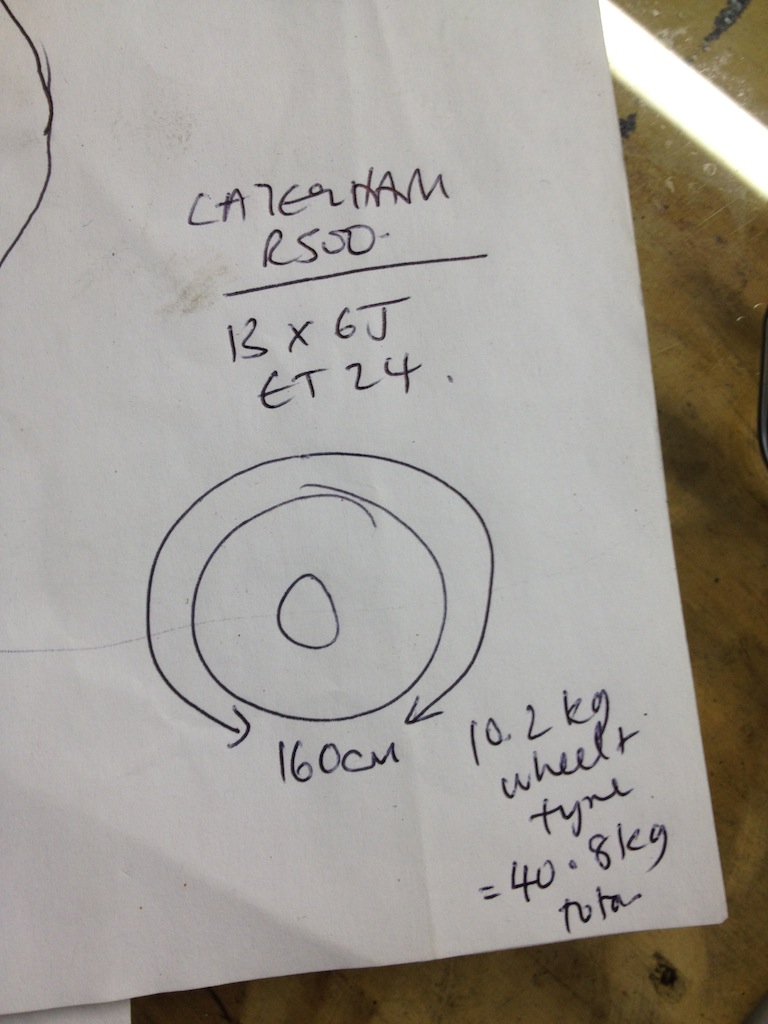

Awesome, Thanks... so the rolling radius on my current 205/50/15's is the exact same as a 205/60/13... in which case... what to buy...

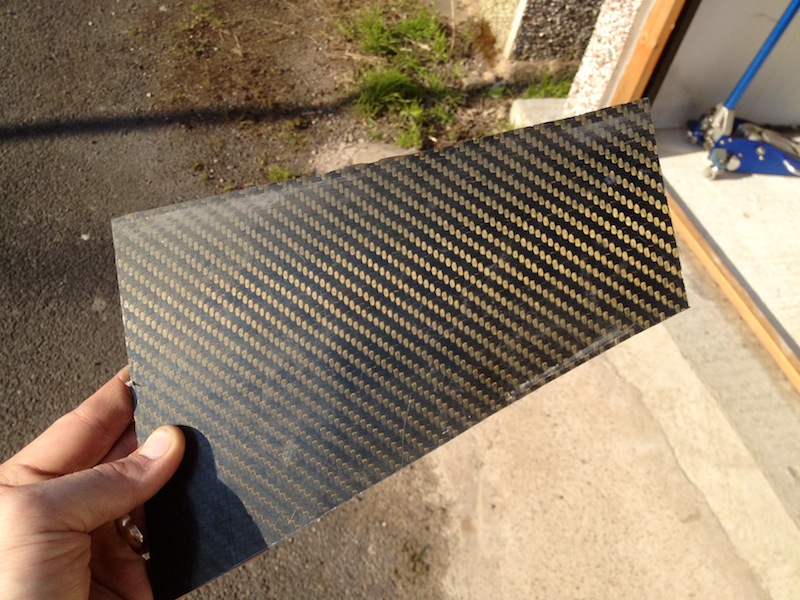

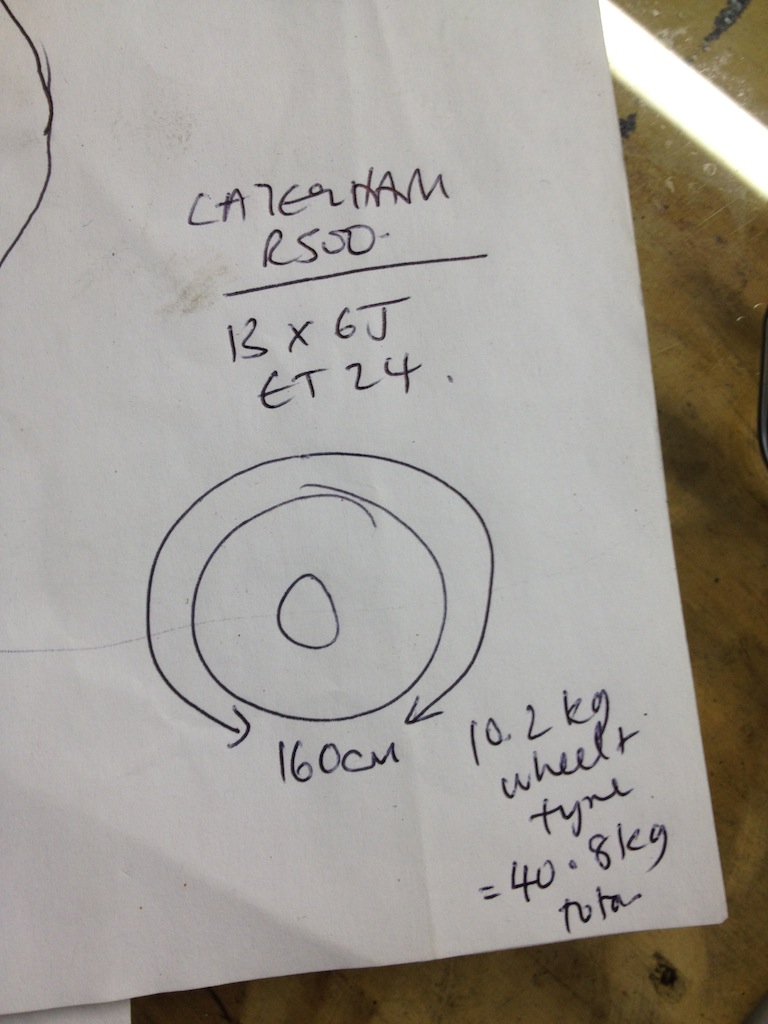

I'm unfamiliar with even the PCD of my current wheels, I can only presume they are Ford fitment which I believe is 4x108... so I guess the R500

wheels won't fit as I believe they're 4x100...

What offset am I after, and also are they 6J fronts, 8J rears?

afj - 2/3/12 at 08:27 PM

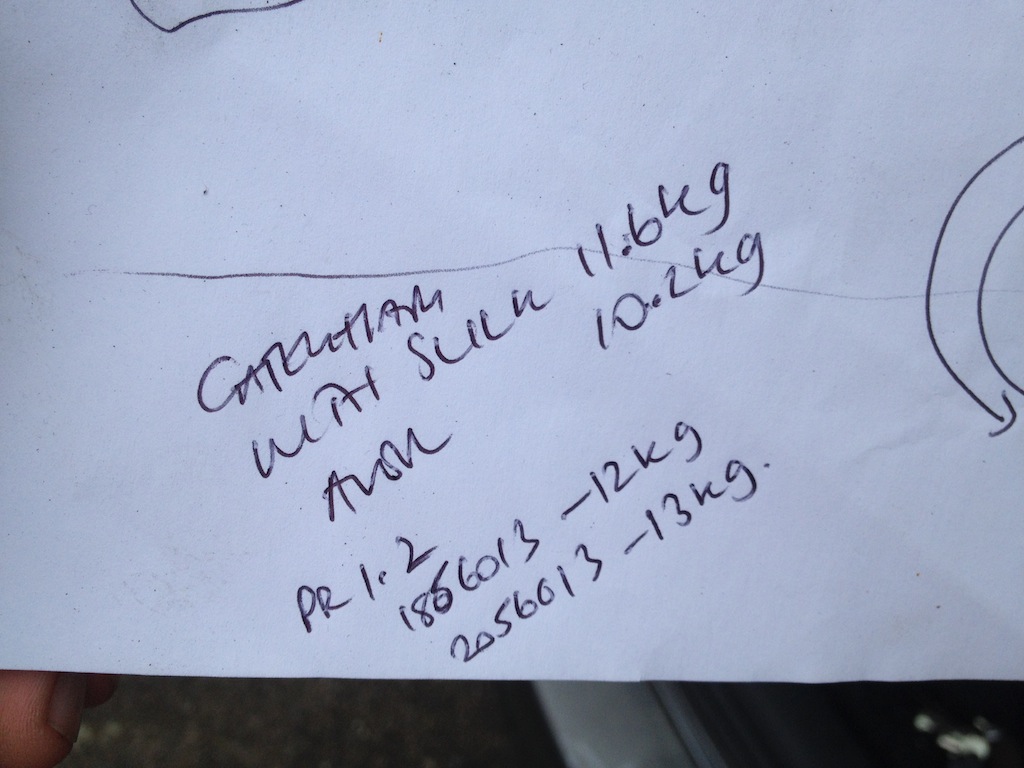

the radius is about the same as 195/50/15 so may drop a couple mph my compomotive cxrs are 6 inch front 185/60 and 7 rear 205/60 and the off sets

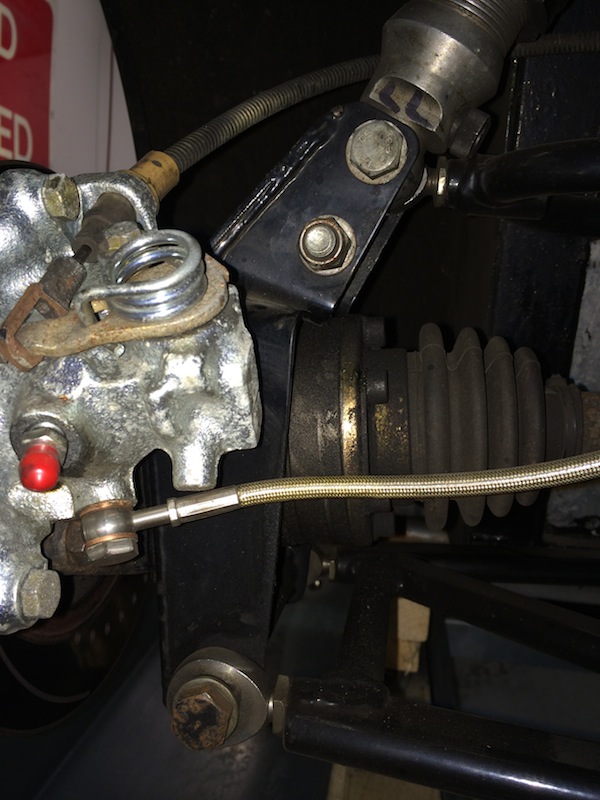

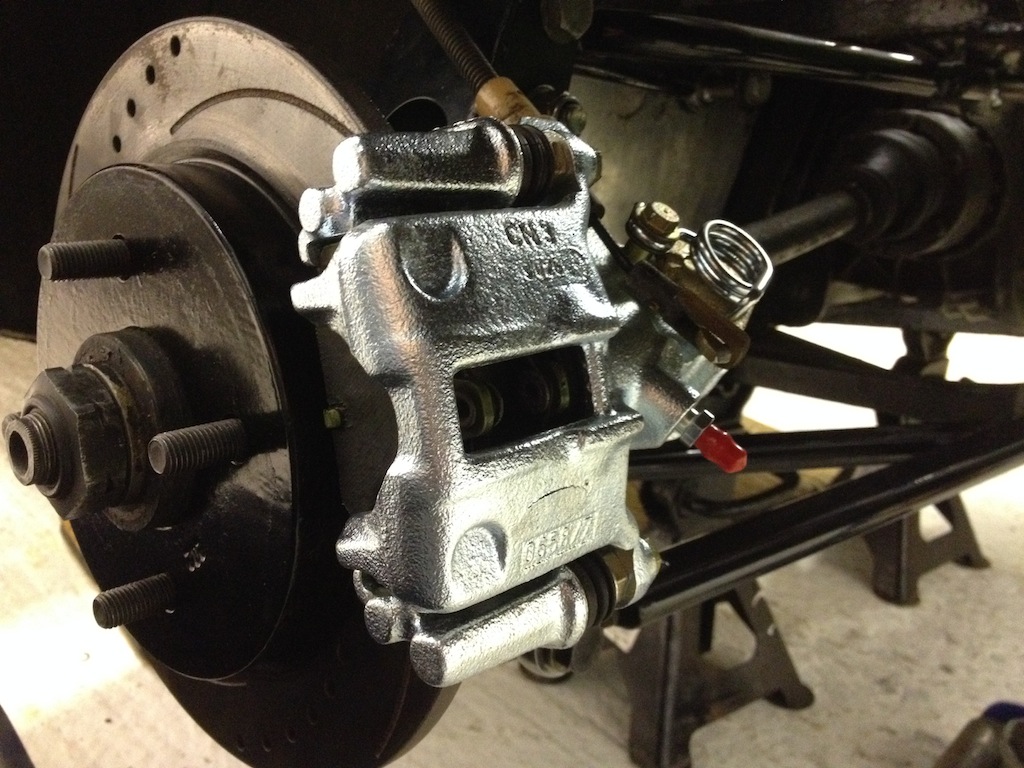

are about et27 rear and 23 front and seem to sit about right on my old 15s had 6.5 wide and et36. the only problem with 13s is the rear brake

caliper clearance if using sierra calipers i and other here had to remove the coil return spring some on here have sourced a custom small spring, i

just fitted a compression spring on the hand brake cable, wheel choise is limted to compomotive cxrs team dynamics pro race 1.2 and some expensive

split rims oh think daniel mason on here has cateringvan wheels look very

daniel mason - 2/3/12 at 08:38 PM

I have r500's on my Mnr. 4x 108

Proby - 2/3/12 at 08:47 PM

Great pic Olz....

Andy B - 2/3/12 at 08:50 PM

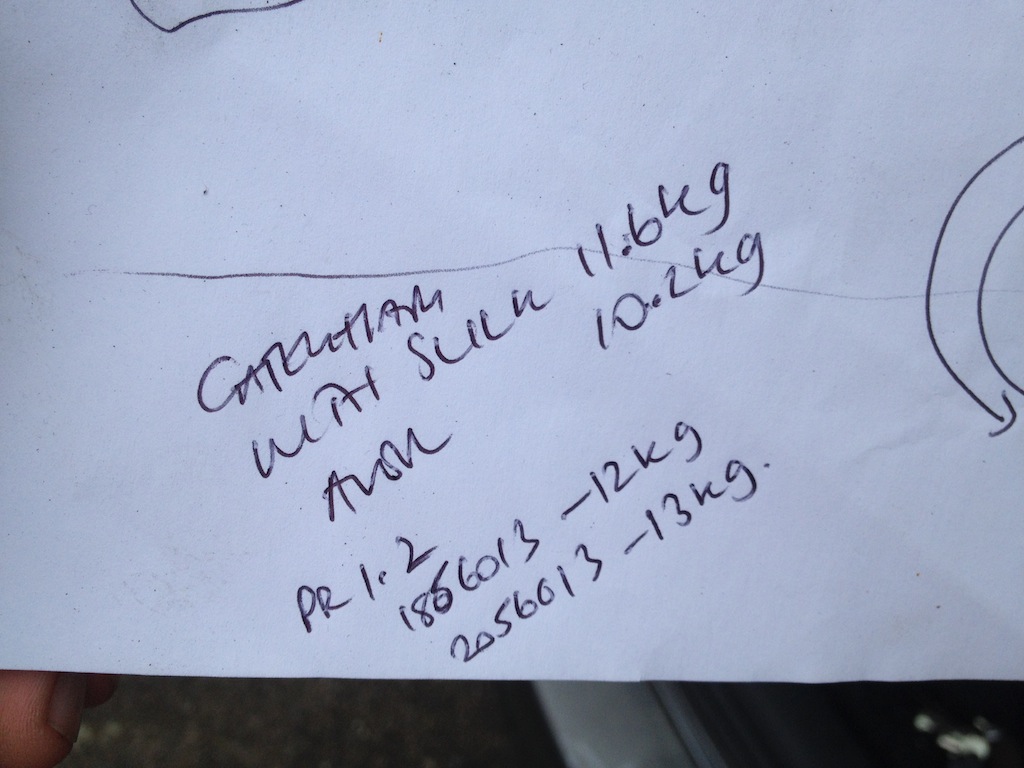

We dropped from 7 x 15's shod with 205 50 15's to 7 x 13's on 205 60 13, the difference in diameter is negligible but we took 12kgs out

overall. We are using pro race 1.2 wheels which are available in all the usual et offsets and ford fitment. Noticeable improvement in handling as

well.

Regards

Andy

yellowcab - 2/3/12 at 10:09 PM

afj - thanks for the gen on the radius' and wheel/tyre options, will certainly be looking into them!

Daniel - nice one, always imagined r500 wheels were 4x100, nice to know they'll go on Ford hubs!

Proby - just a quick snap using the iPhone, not cracked out my proper gear & rig on it yet lol

Andy - looking forward to unsprung weigh advantage and handing too  )

)

big_l - 2/3/12 at 11:39 PM

your car looks nice mate congrats

where you based ???

yellowcab - 3/3/12 at 12:25 AM

Just in between Leicester & Coventry on the M69 :-)

yellowcab - 3/3/12 at 06:19 PM

lol broke it already, a spirited drive down the country roads going through the gears leaves me with a snapped gear linkage rod just where it enters

the engine bay... luckily it snapped whilst in 3rd gear, so pulled over, switched off, had a look, and then drove it home...

Can only presume its a relatively common procedure just due to the nature of the wear & tear such a joint... lol

Hey ho, great excuse to have a tinker

daniel mason - 3/3/12 at 06:32 PM

i assume its a stick shift,so have you thought about a paddle shif setup? think andy bates does a nice one if my memory is correct!

yellowcab - 3/3/12 at 07:09 PM

I kinda liked the idea of a stick shift, up until this afternoon lol

Just felt with paddle shift it'd take some of the 'driving' out of things, but maybe not...

What kinda money are they? any links to any pic setups?

danny keenan - 3/3/12 at 08:25 PM

if its and old linkage its madde from rpush rods.we now make them with a push pull cable.they work alot better and never break.

its the same cable we use on our paddle shift system which works really good.

thanks danny

yellowcab - 3/3/12 at 08:38 PM

Danny, would you recommend that I replace with cables either way then, rather than what I currently have?

Regardless of sticking with stick shift or going paddle?

danny keenan - 3/3/12 at 08:42 PM

its alot smoother gear change with a cable instead of rods.i would change it for what it costs.

you have my mobile numer if you need any help or advice.

thanks danny

yellowcab - 3/3/12 at 08:49 PM

I'll give you a tinkle tomorrow is that's OK? Or would you rather me wait until Monday?

danny keenan - 3/3/12 at 09:00 PM

tomorrow is fine mate any time you want.

thanks daany

yellowcab - 5/3/12 at 08:42 PM

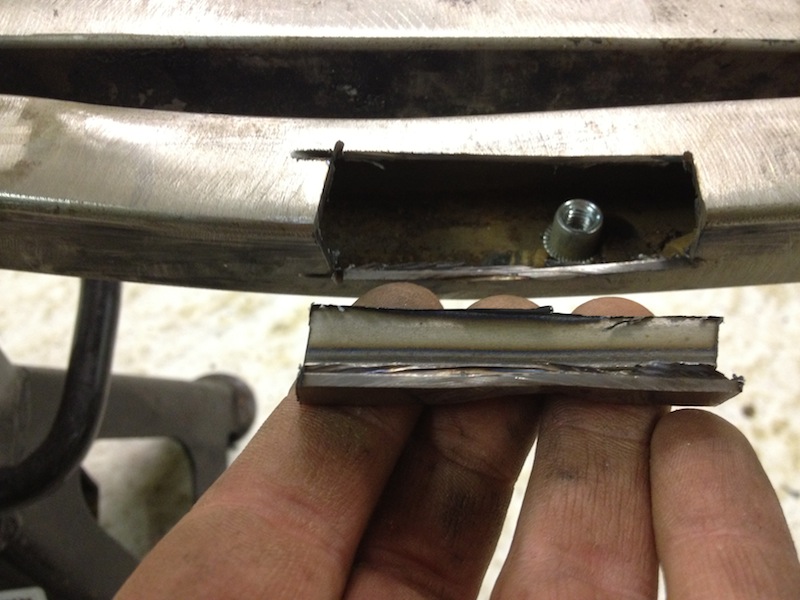

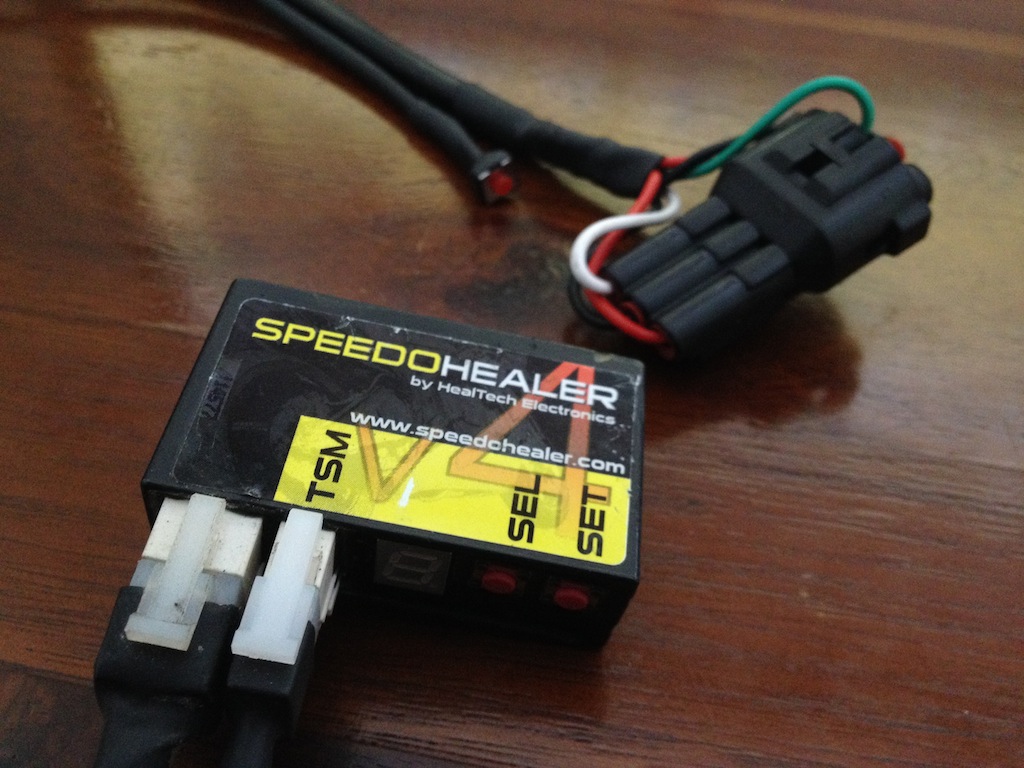

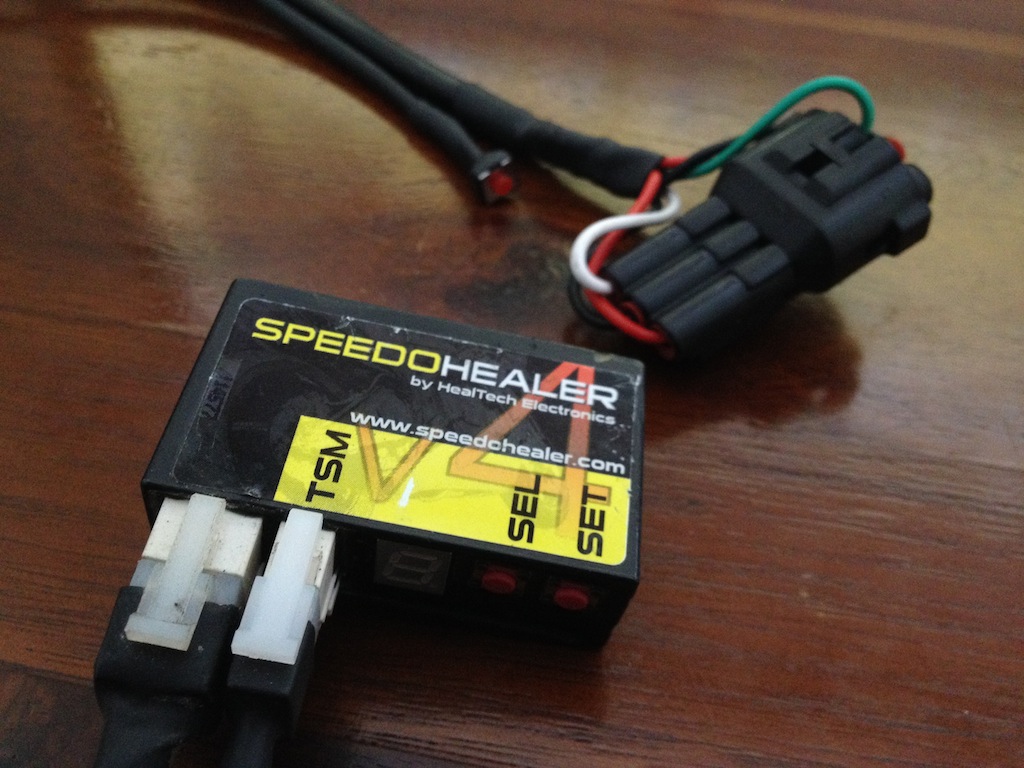

Managed to see what's actually broke on my shifter, and it's the DynoJet Quickshifter itself, it has '07 1 PULL' written on it,

and the threaded bar has sheared off... Surely these should be high tensile no?

yellowcab - 13/3/12 at 09:41 PM

Just a small update, sent the unit back to Dynojet UK who confirmed that the fault was not a manufacturing defect which I kinda knew, they told me to

look out for a slight twist in my gear throw... As a gesture of goodwill, they have offered me 25% discount on a replacement unit which is good of

them, so doing that.

For now, I went down to B&Q, got 30" of steel tubing (£4.18), 1mm wall thickness x 16mm diameter, rounded the shoulders off two m8 nuts,

popped them in the ends and seam welded them, smoothed them off, popped the rose joints back on, and job jobbed... Car fixed... Just means for now I

have to use the clutch to change gear, ad no full throttle up changes!

Here is a small video I made because I was bored from before I broke it last week sometime  )

)

http://m.youtube.com/watch?feature=mhee&v=MZekIs2zkv4

yellowcab - 17/3/12 at 01:01 PM

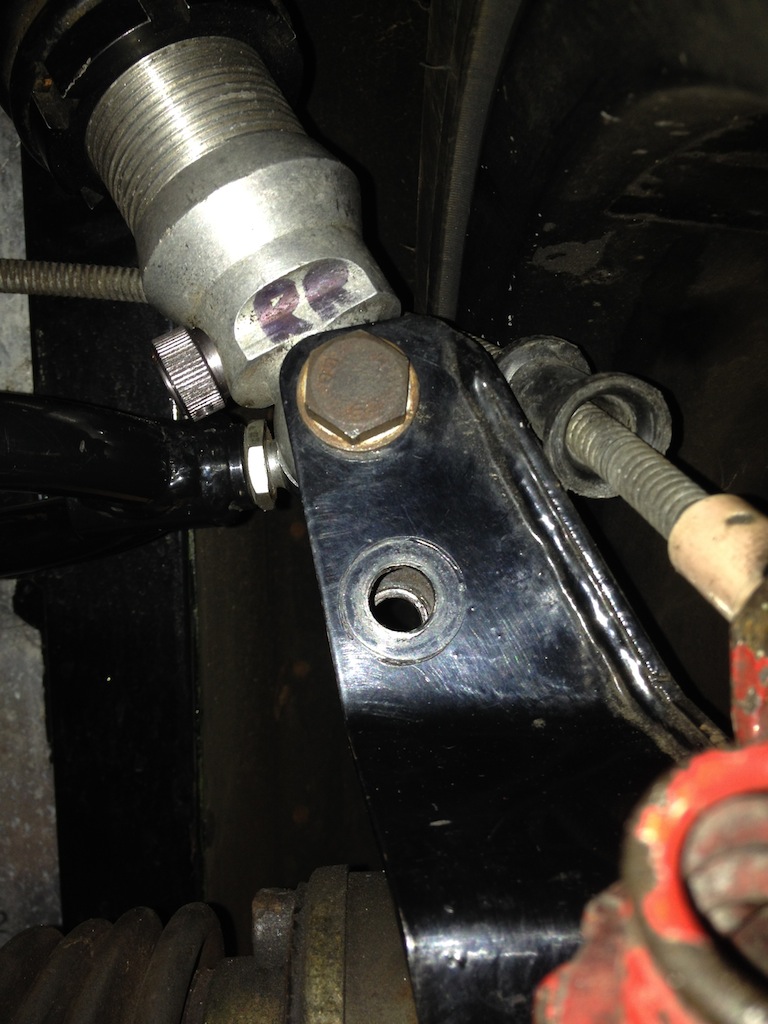

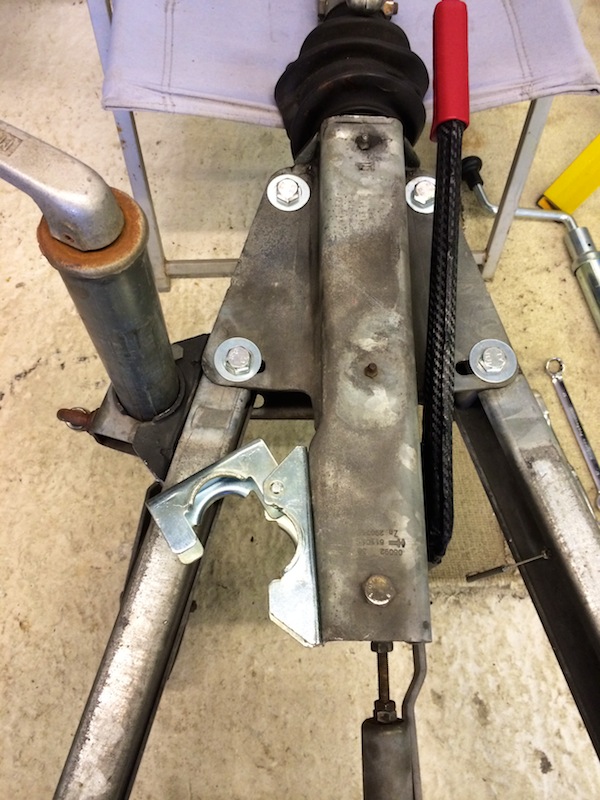

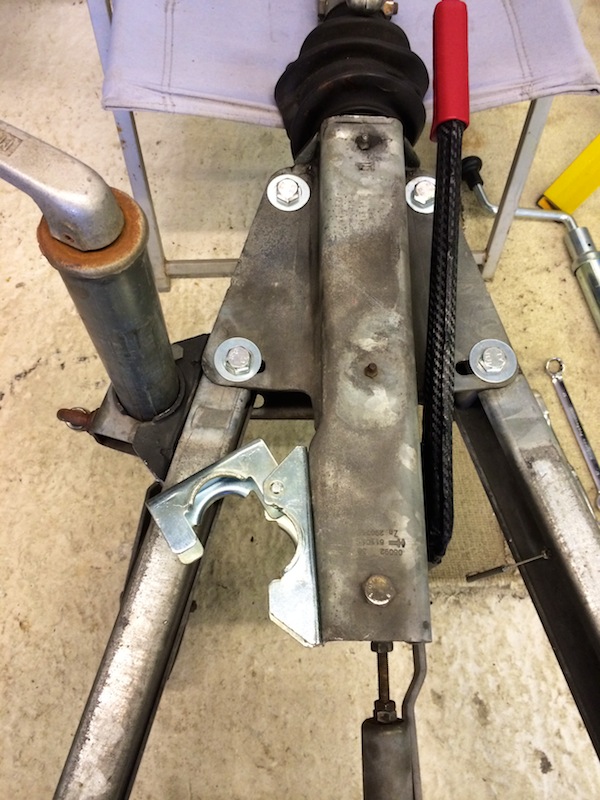

broke it again, luckily I was with a group of mates in a well kitted out garage at the time - so removed said broken part, looked at why it broke, and

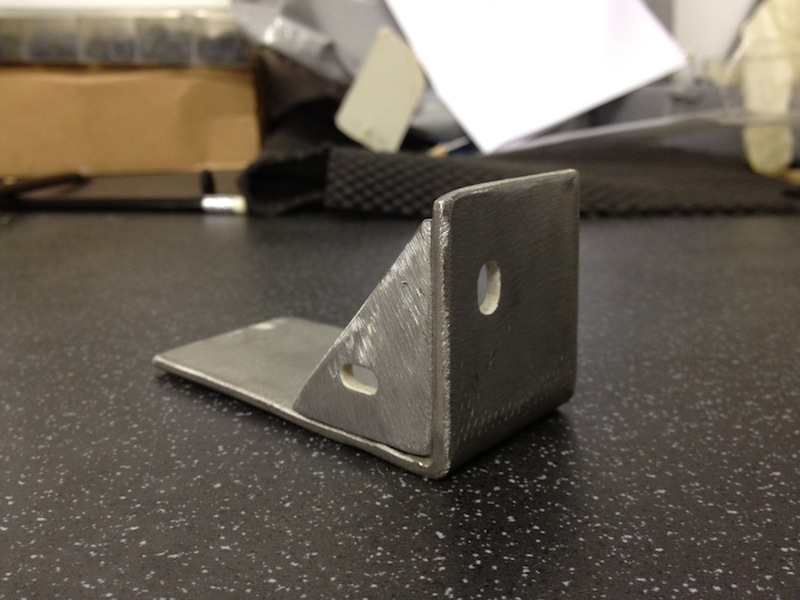

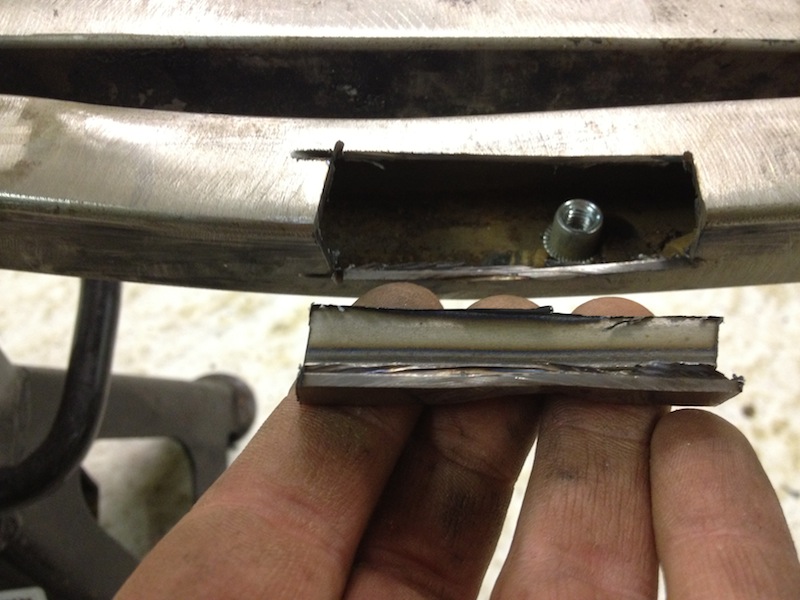

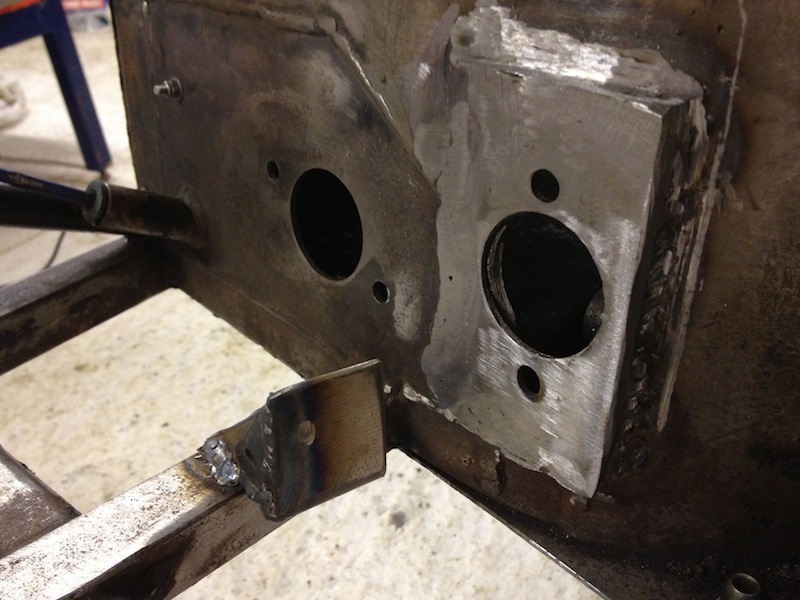

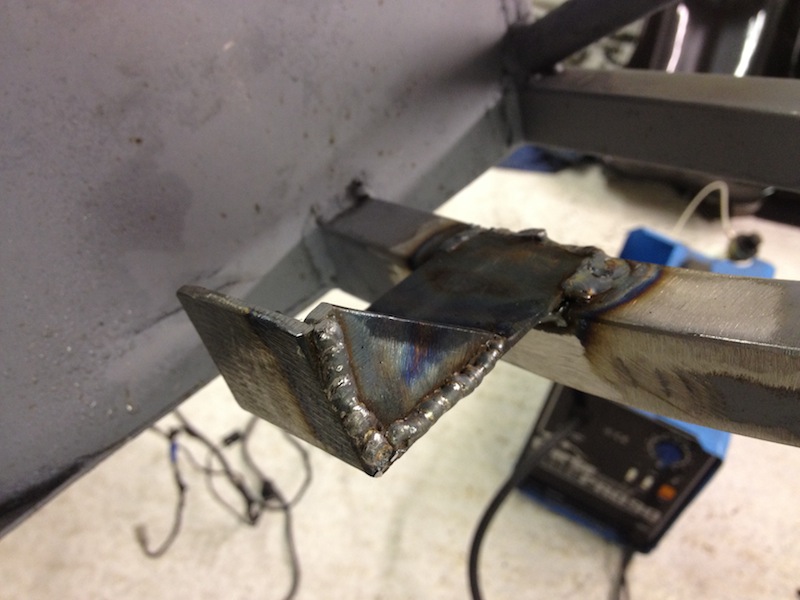

improved it - win win!!!

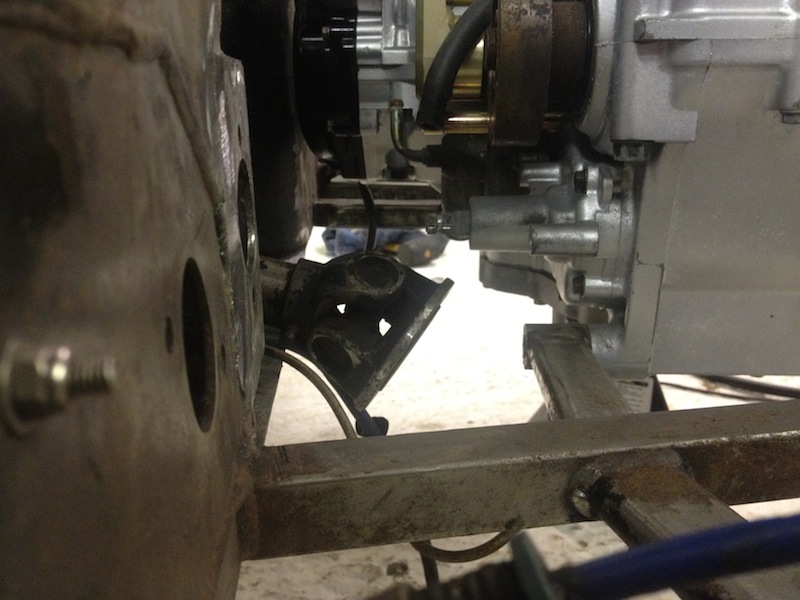

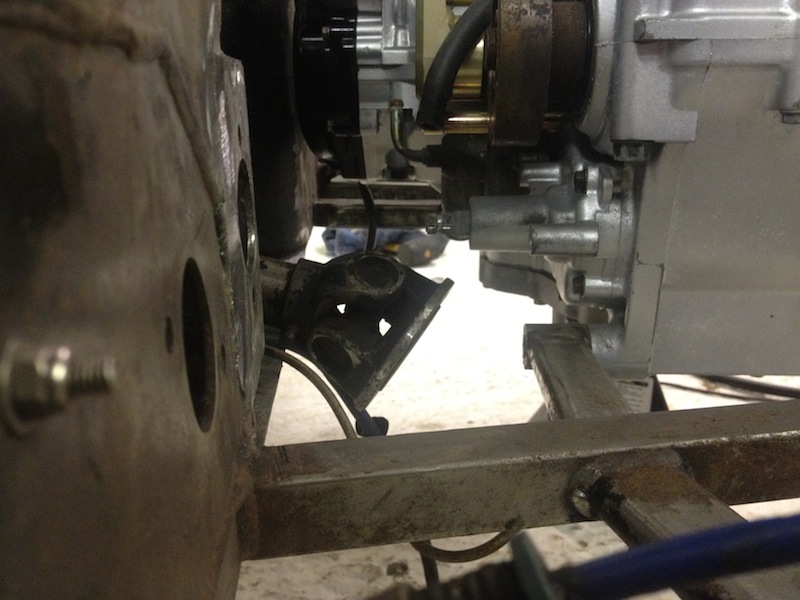

The supporting bracket that was operating/ holding the clutch arm into the gearbox stripped the threads out of the gearbox upon a hard 'rev

up' (it was in gear at the time, but clutch was depressed)

Rolled the car forward thinking it was proper broke to find an M8 nut (not snapped) with the last three threads being full of alloy... offered up the

bracket to put the bolt back in, and it was only held in by those three turns of the bolt...

So we got a longer bolt, and screwed it in the correct amount, whilst cutting a new thread into said gearbox hole.

Clutch pedal feels more solid than before now, not as much 'loose play' as it were... however it could be tighter with some of the sloppy

joints being replaced, in the near future  )

)

yellowcab - 20/3/12 at 04:40 PM

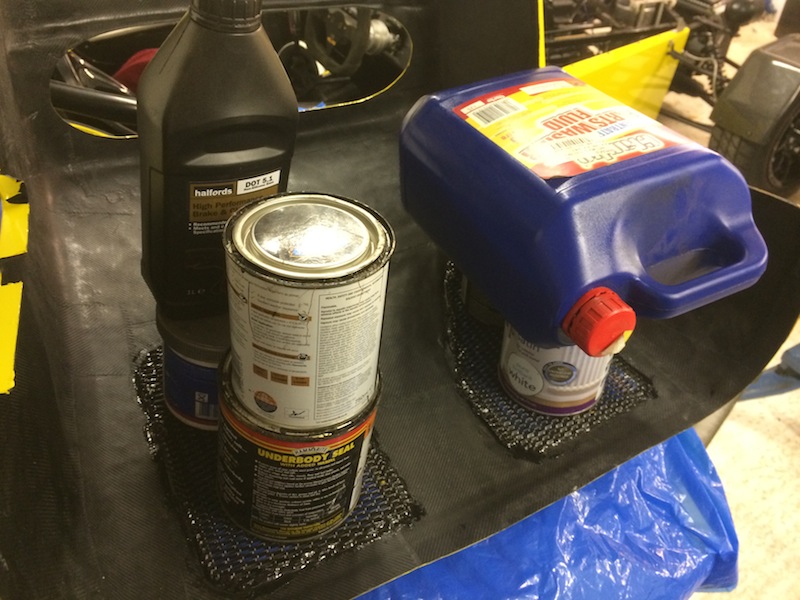

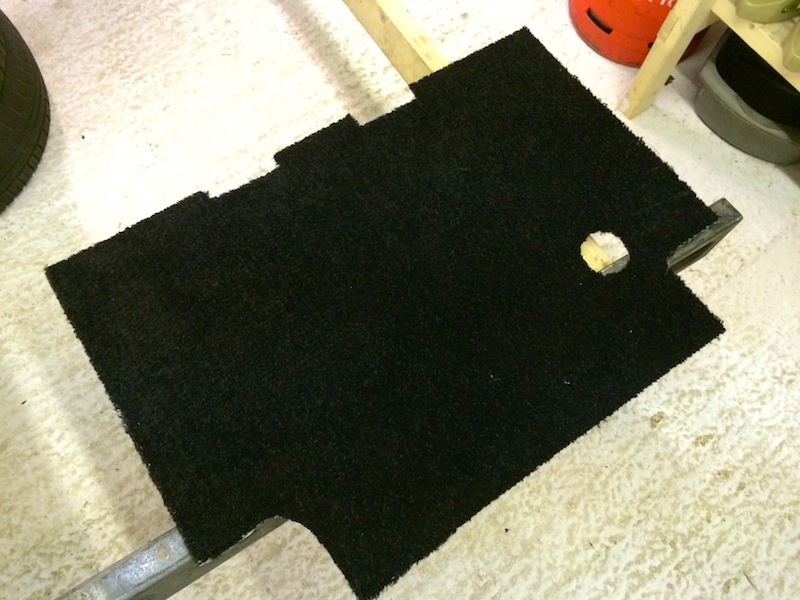

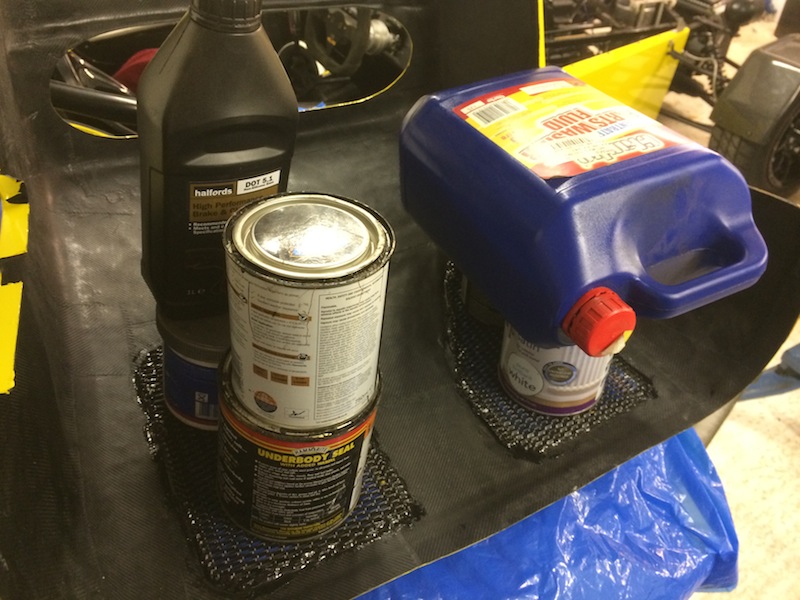

Some old pics that I took that I forgot to upload...

Description

Description

Description

Description

Bought a mini-mic so I could record on my iPhone with zero wind noise, so the mic is placed behind the dash

Description

Gear shift indicator cheap eBay bobbie came today

Description

The fix on the broken gear linkage

Description

Description

yellowcab - 20/3/12 at 04:43 PM

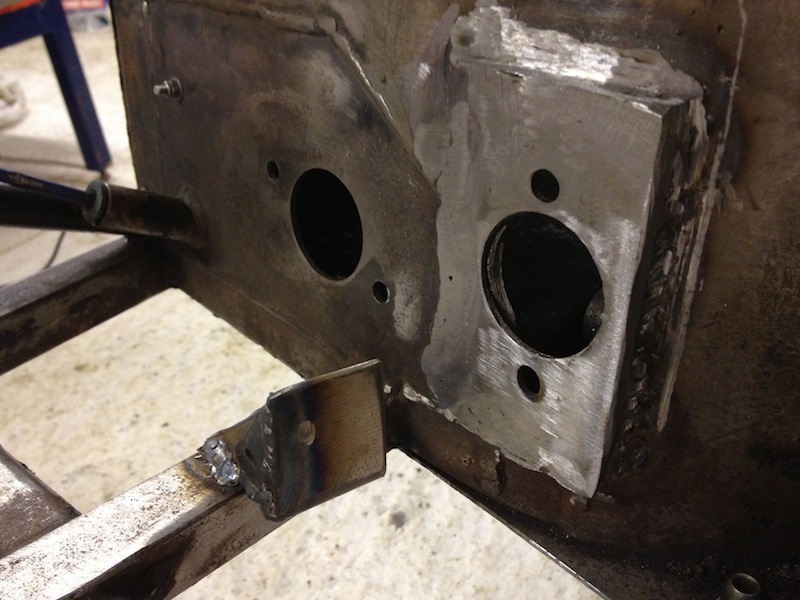

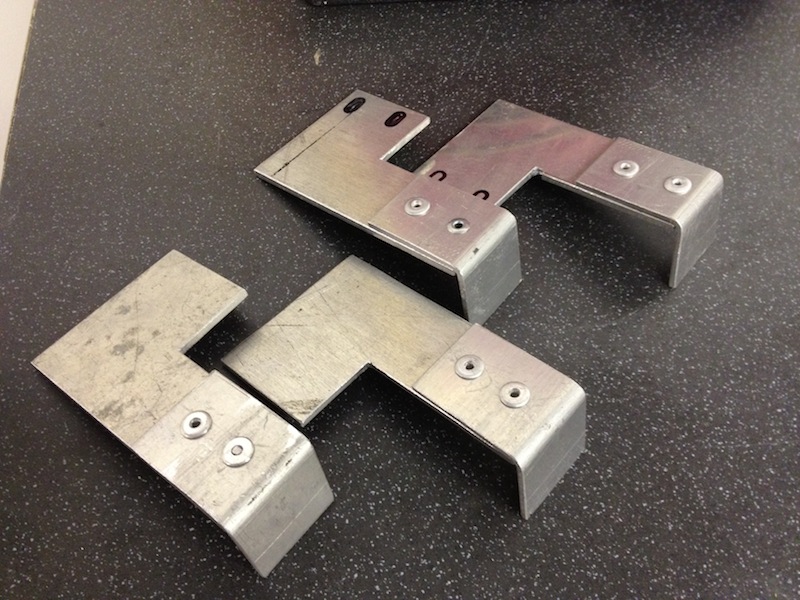

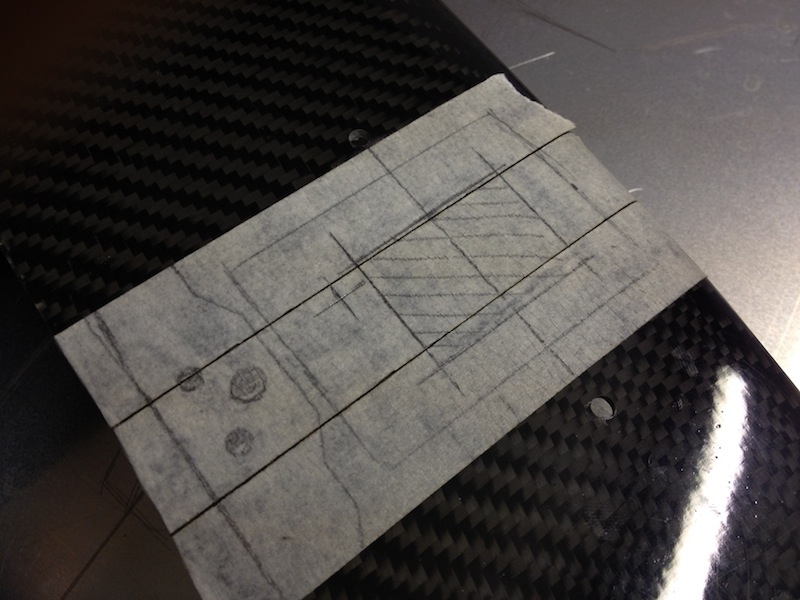

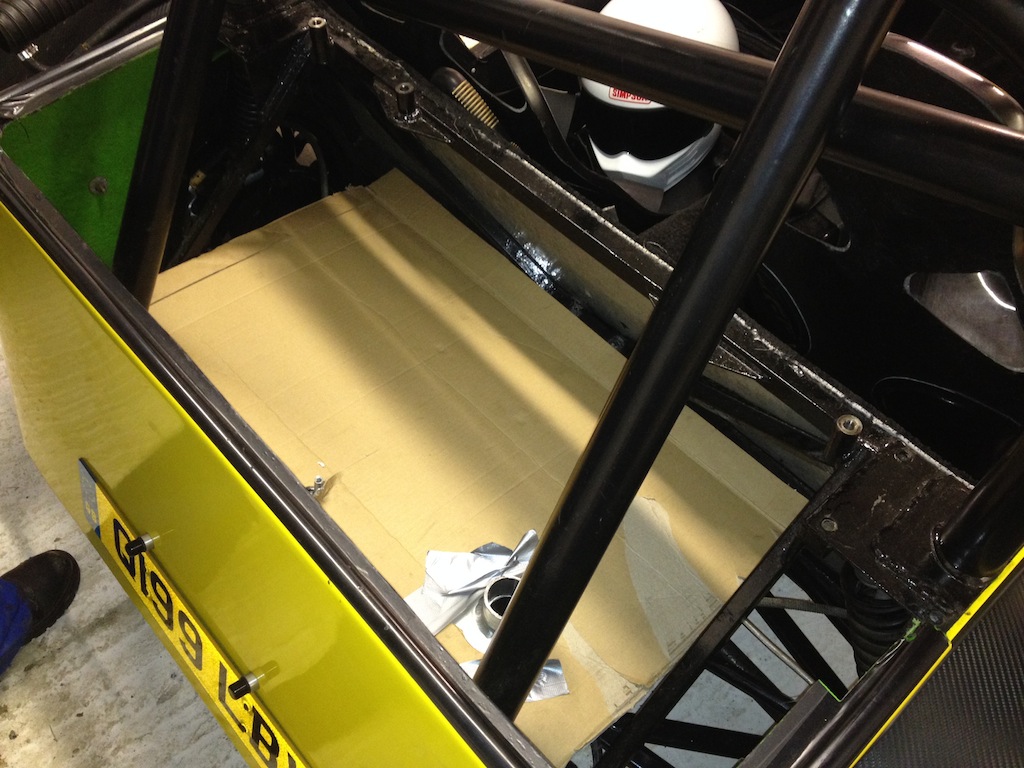

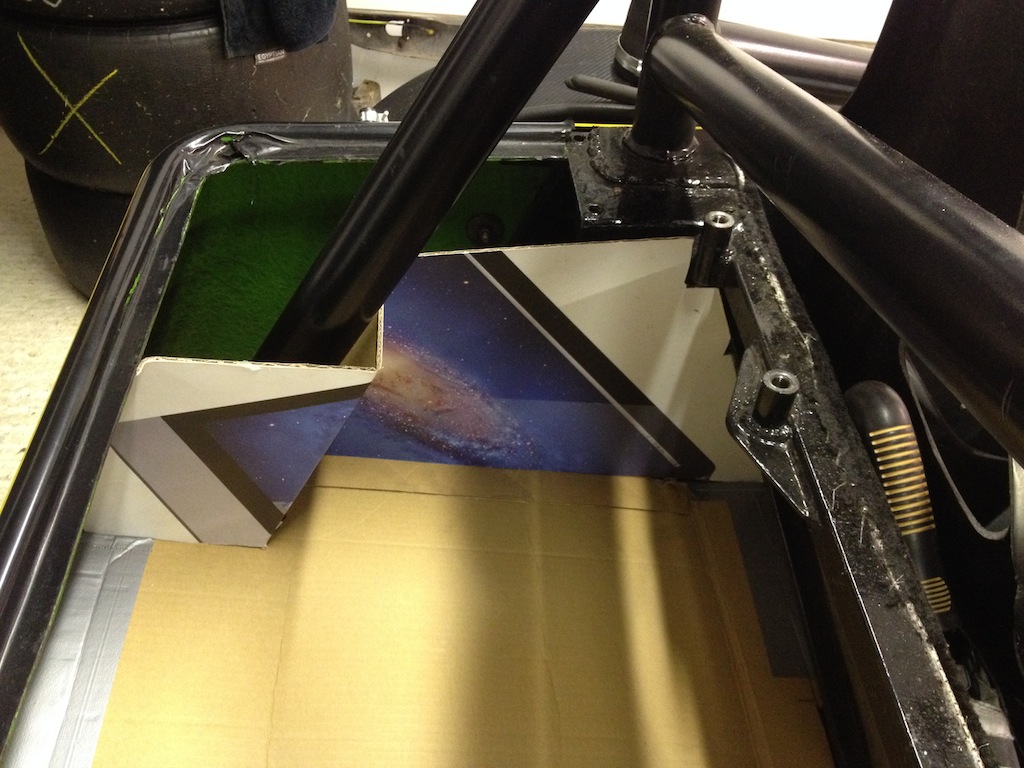

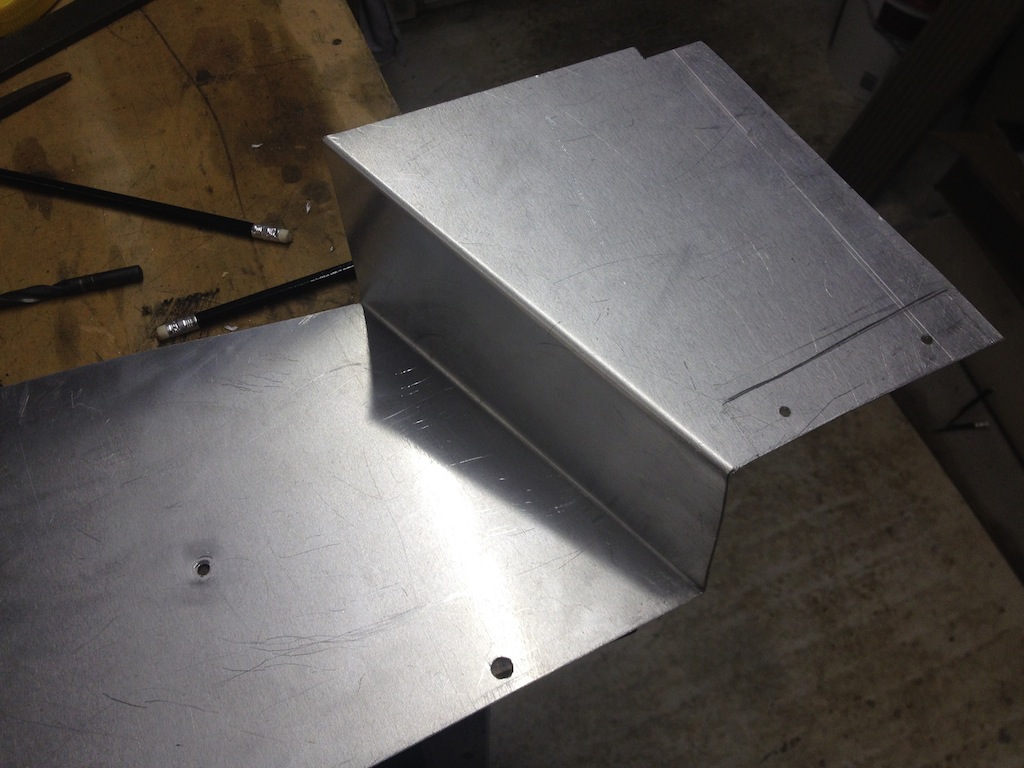

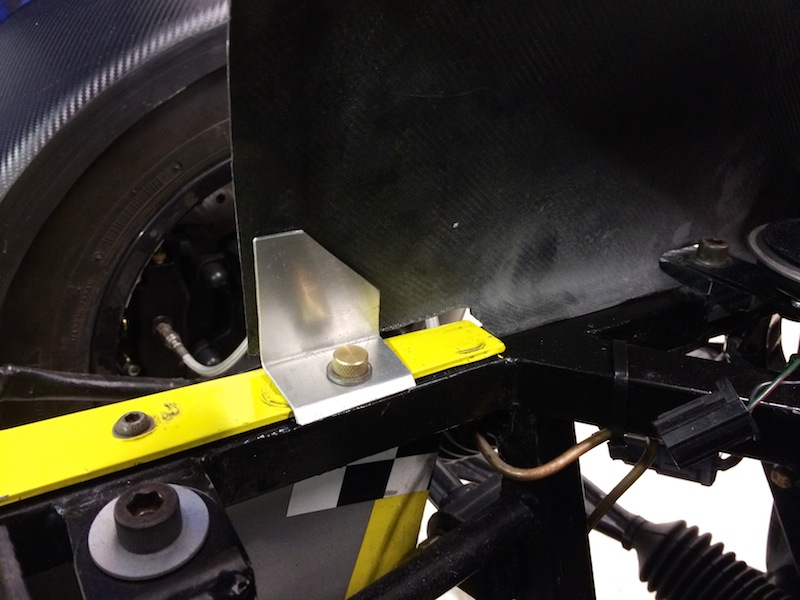

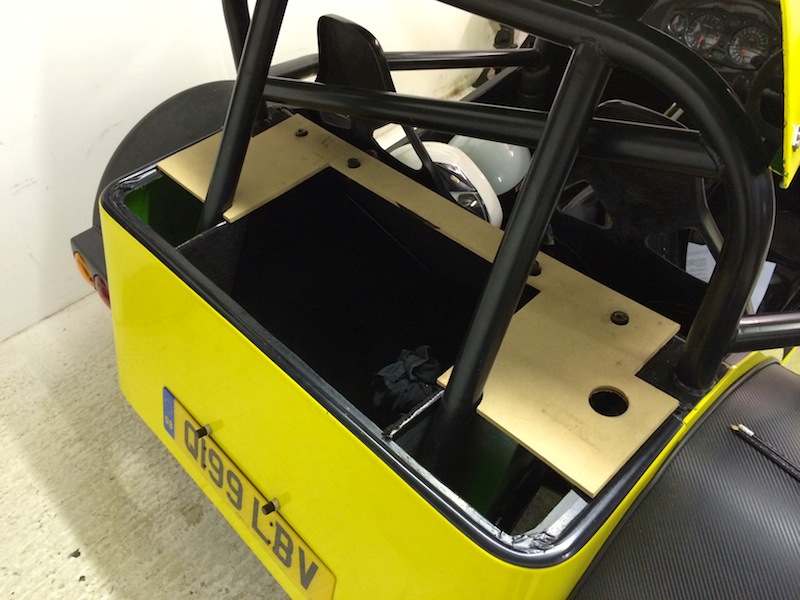

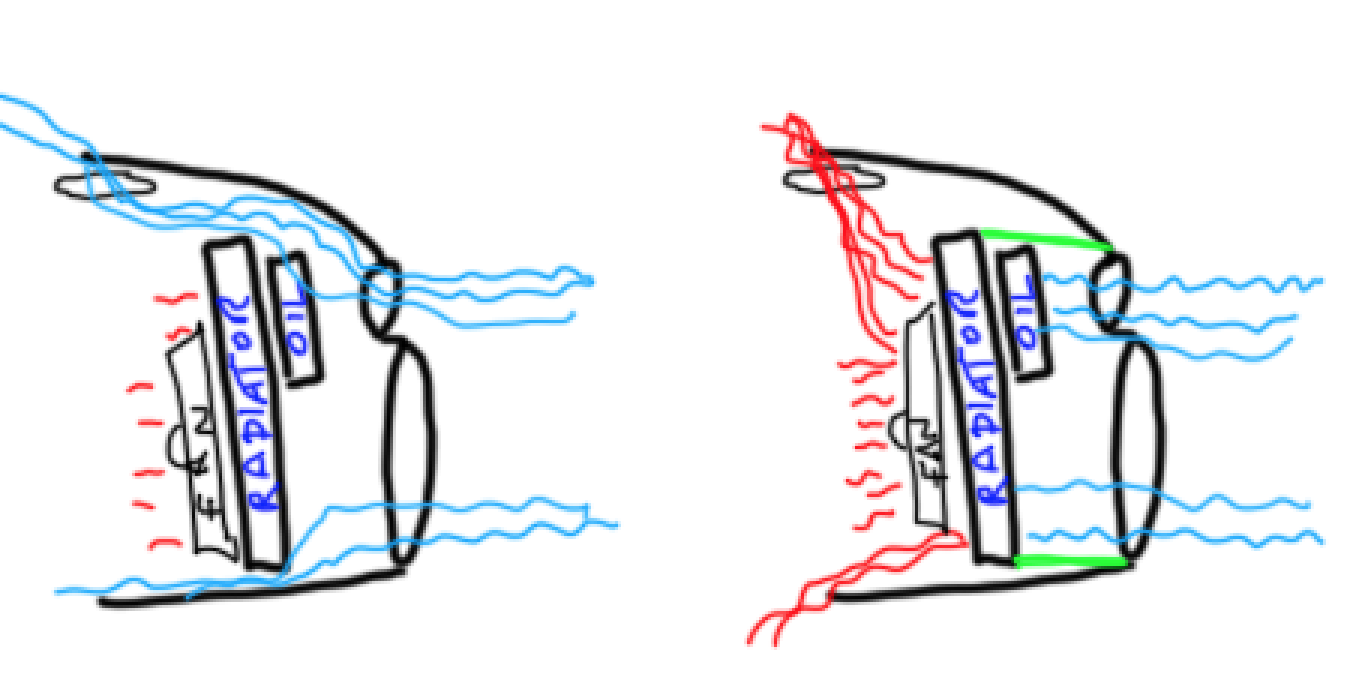

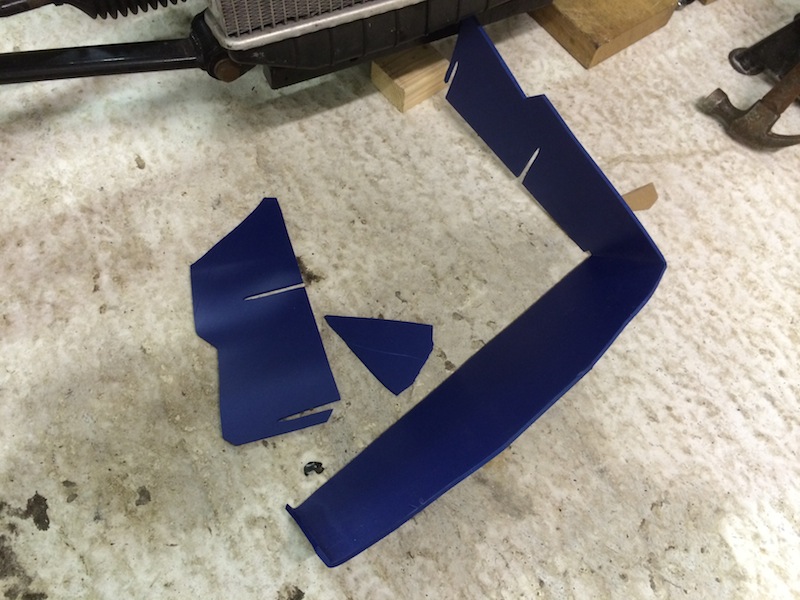

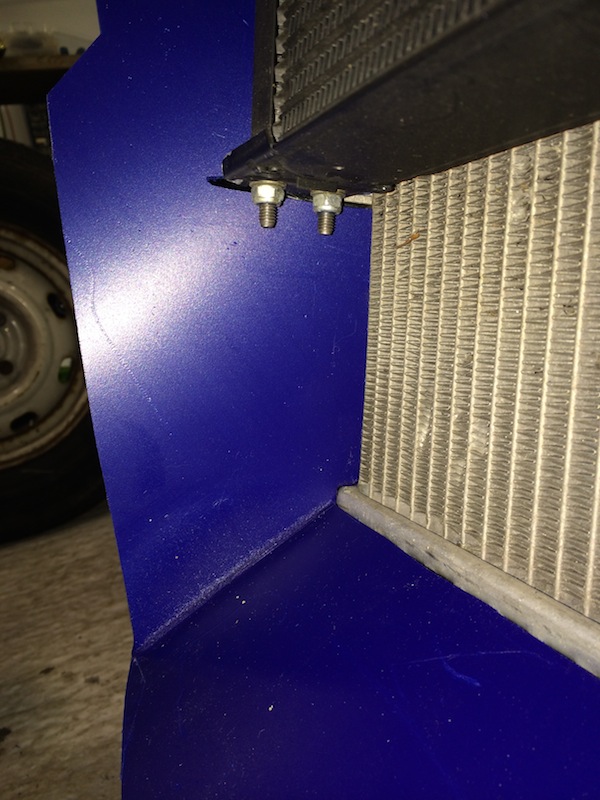

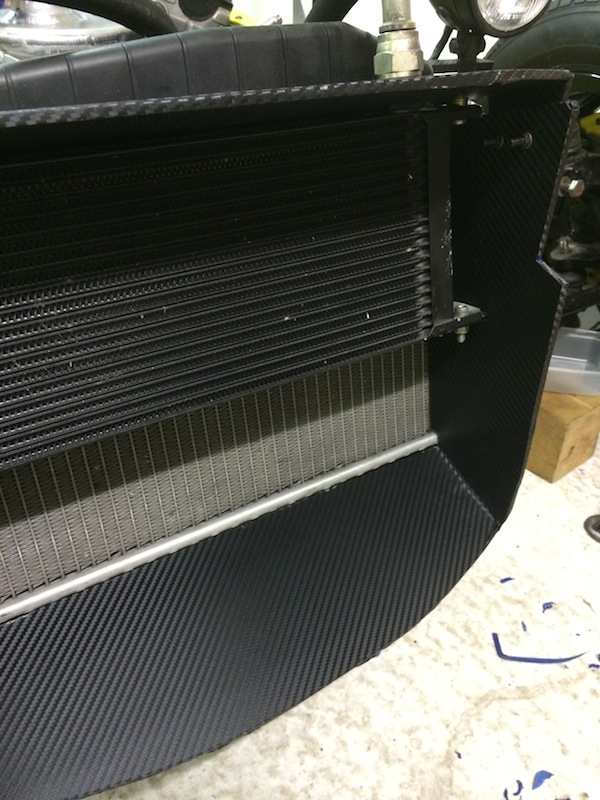

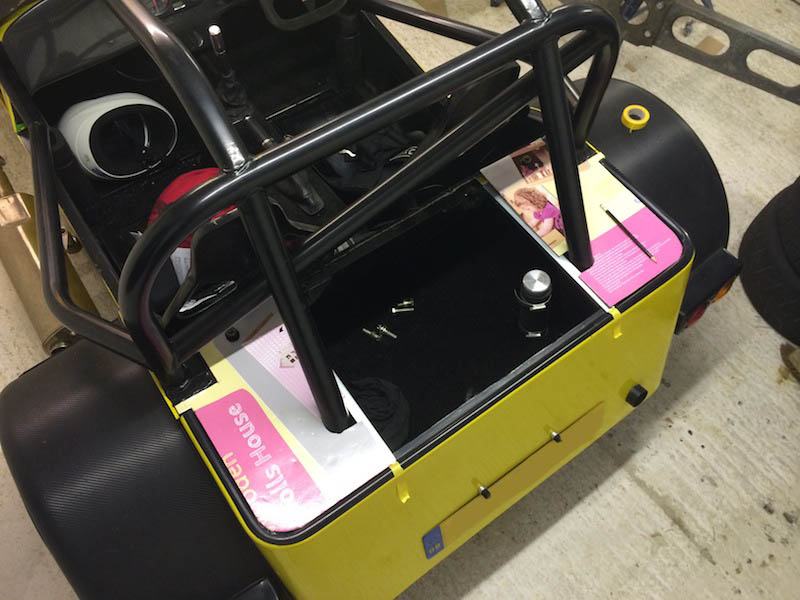

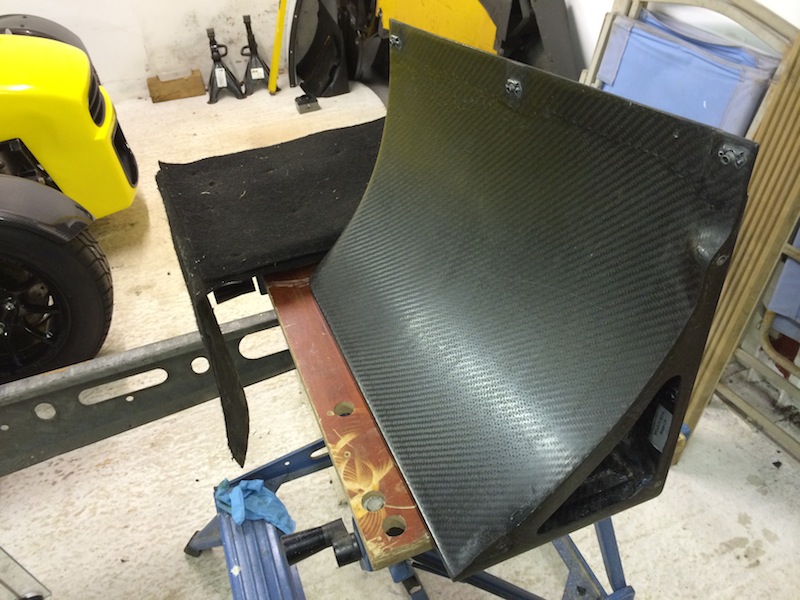

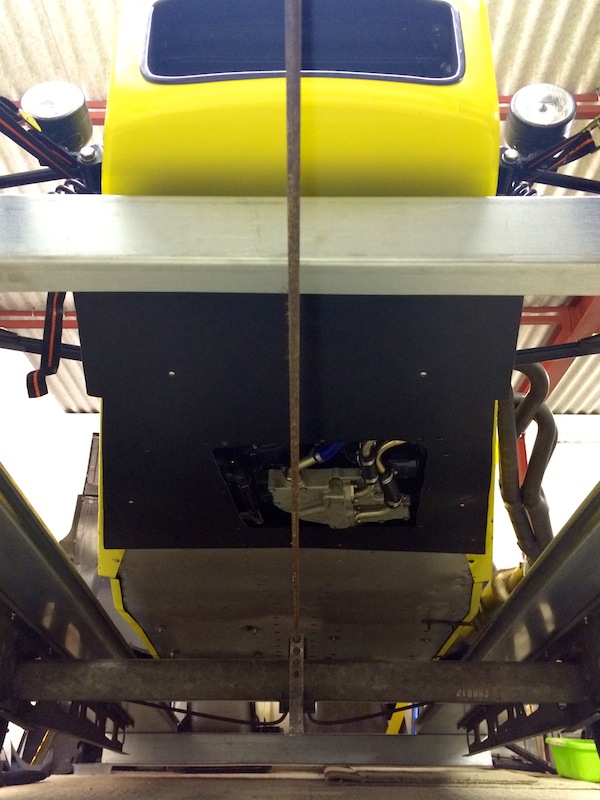

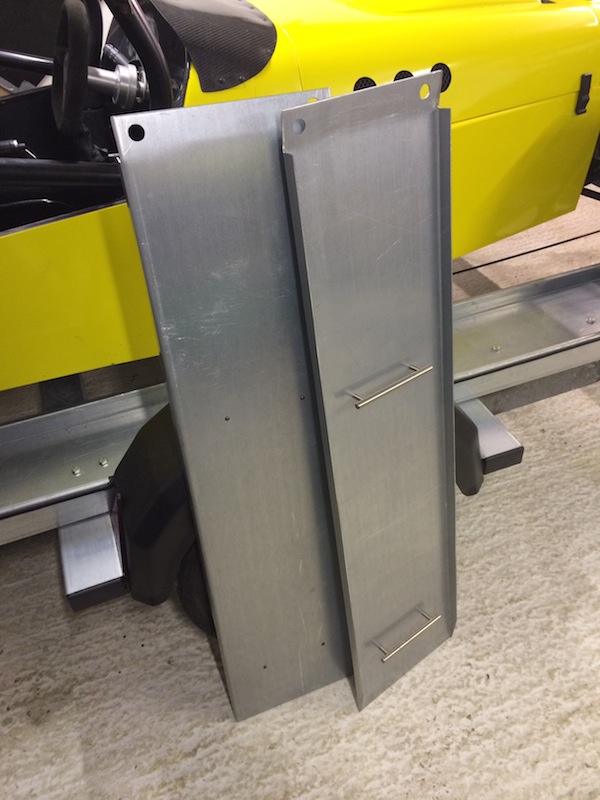

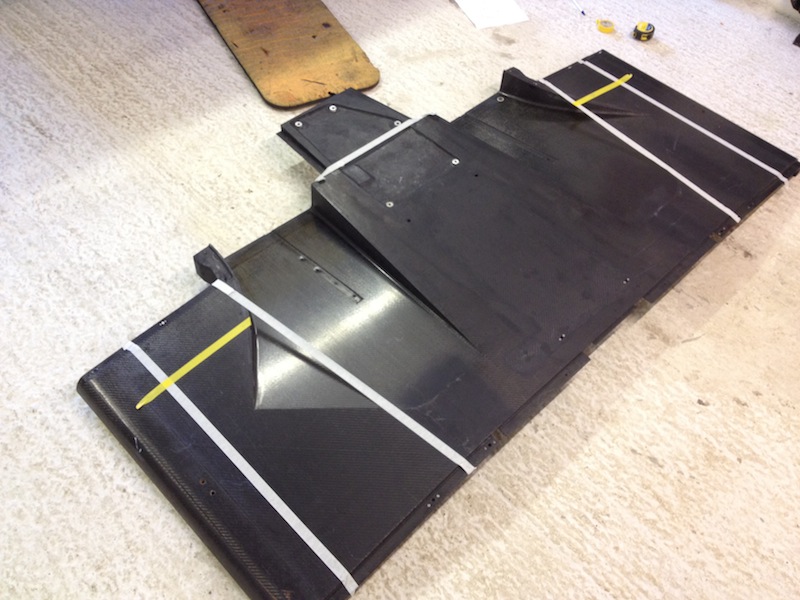

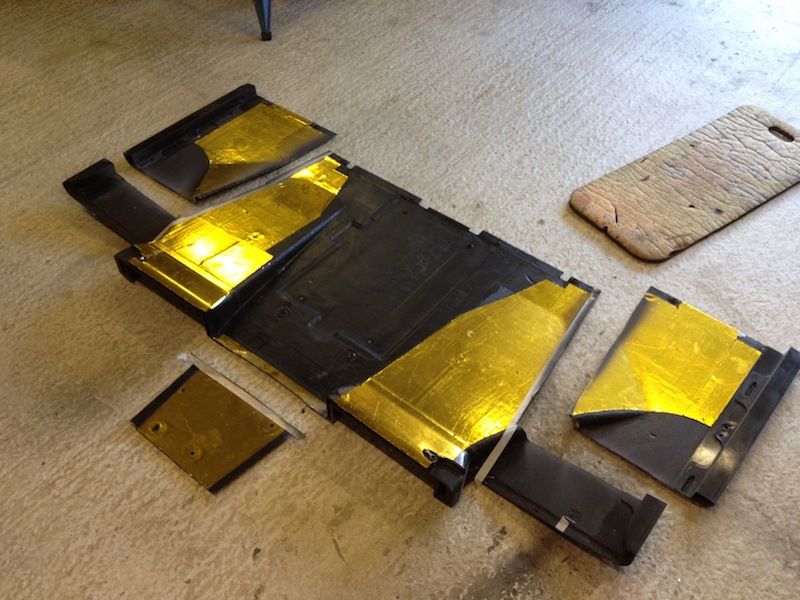

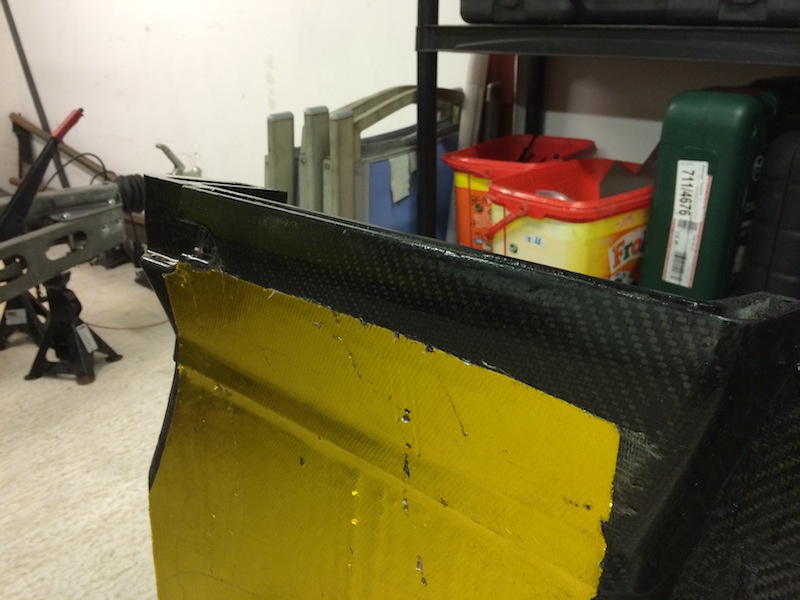

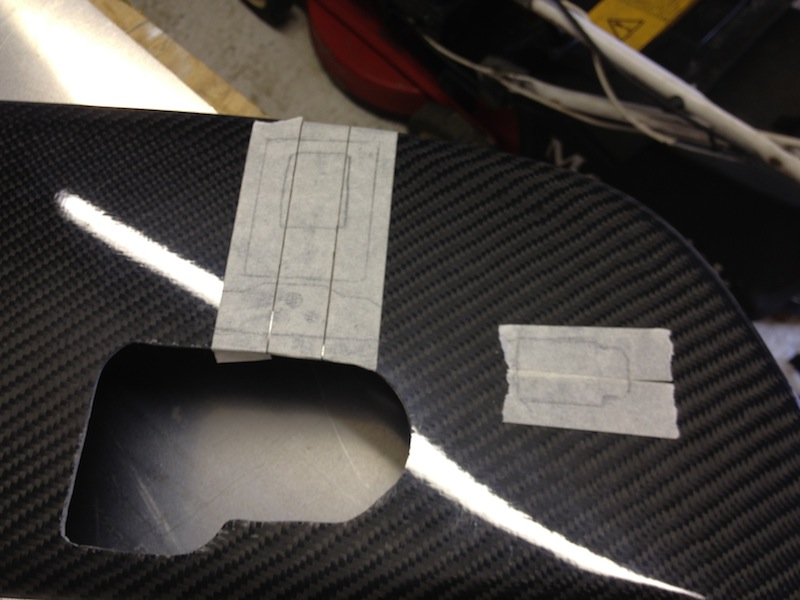

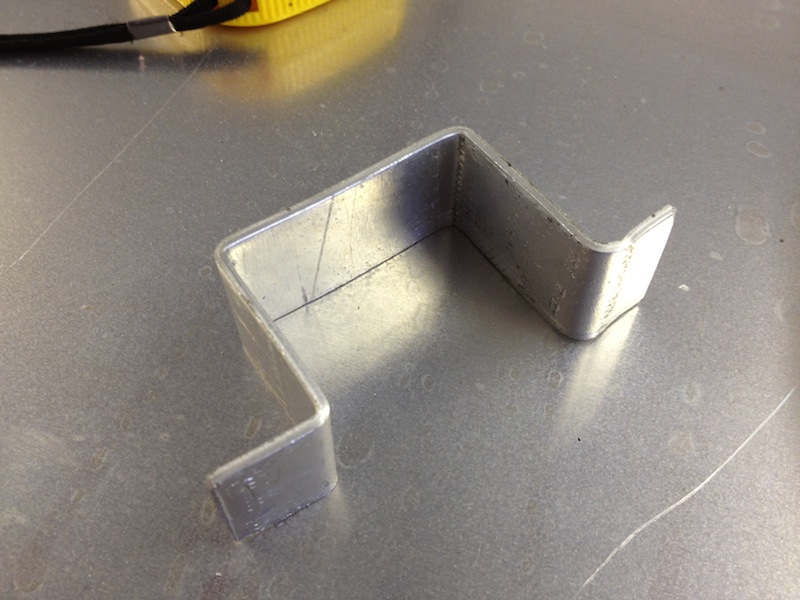

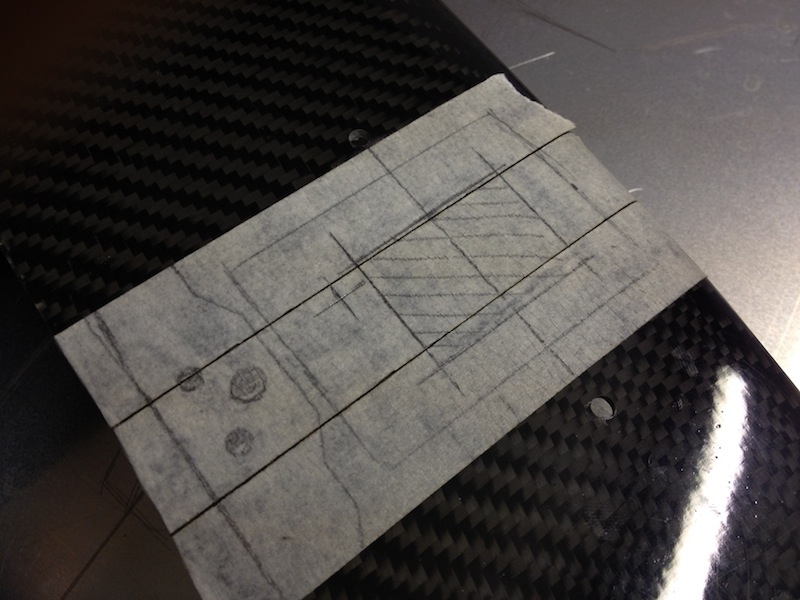

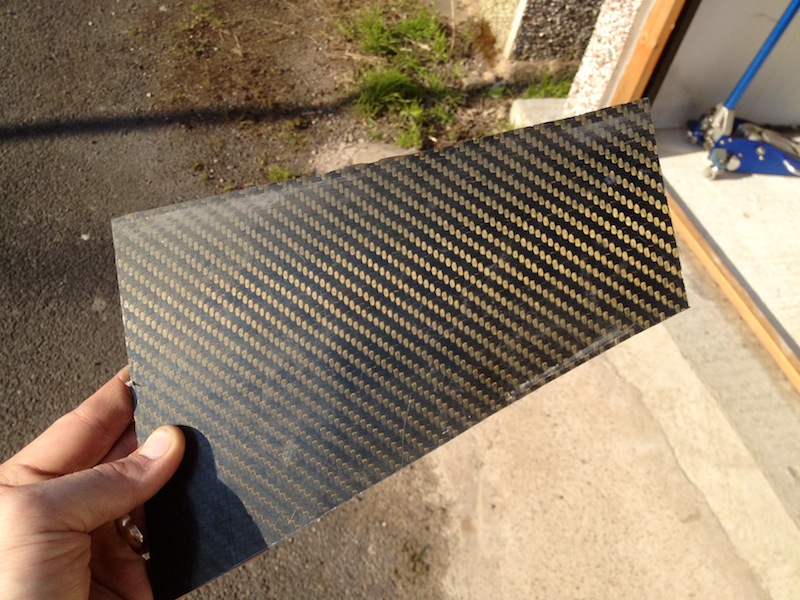

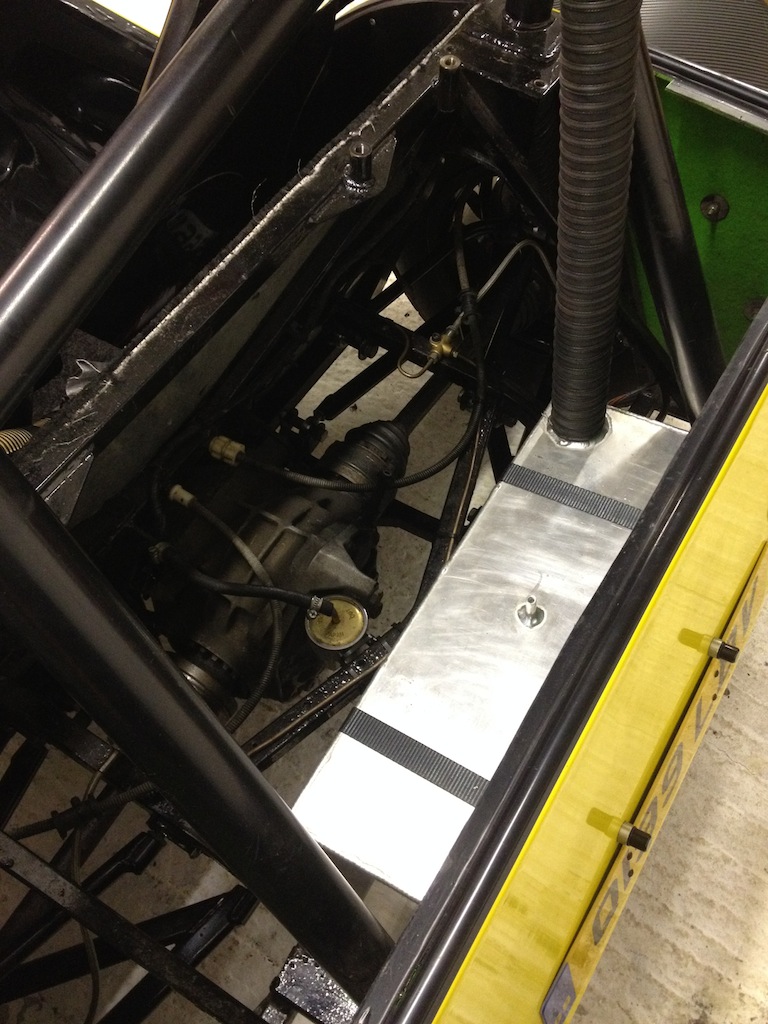

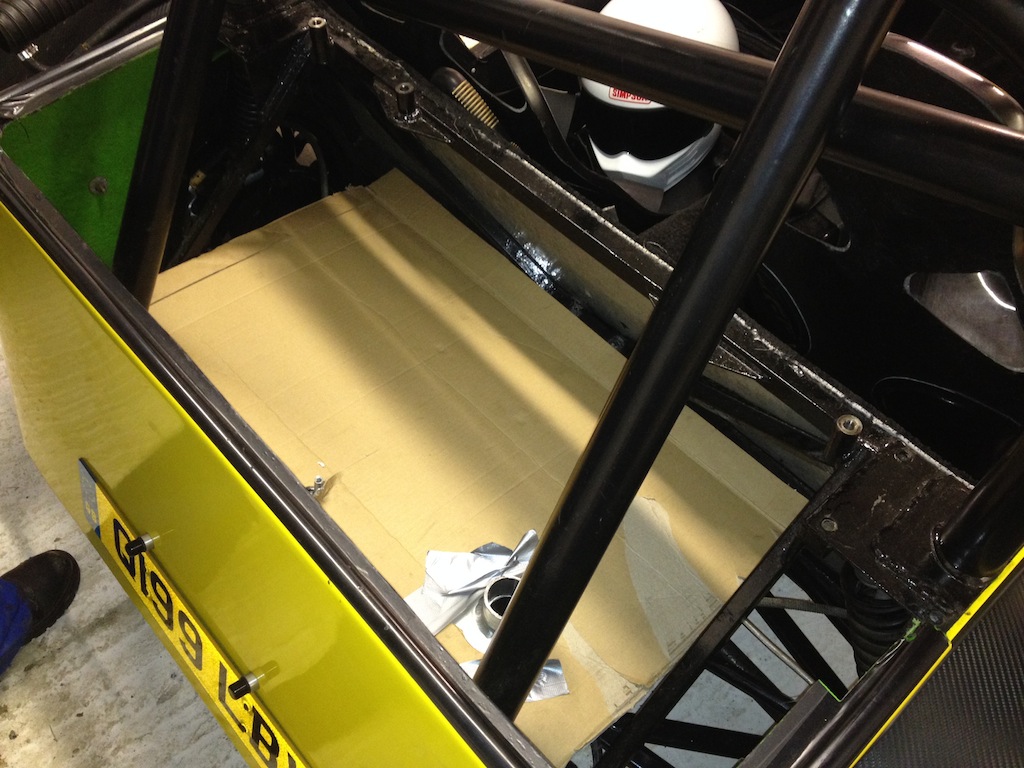

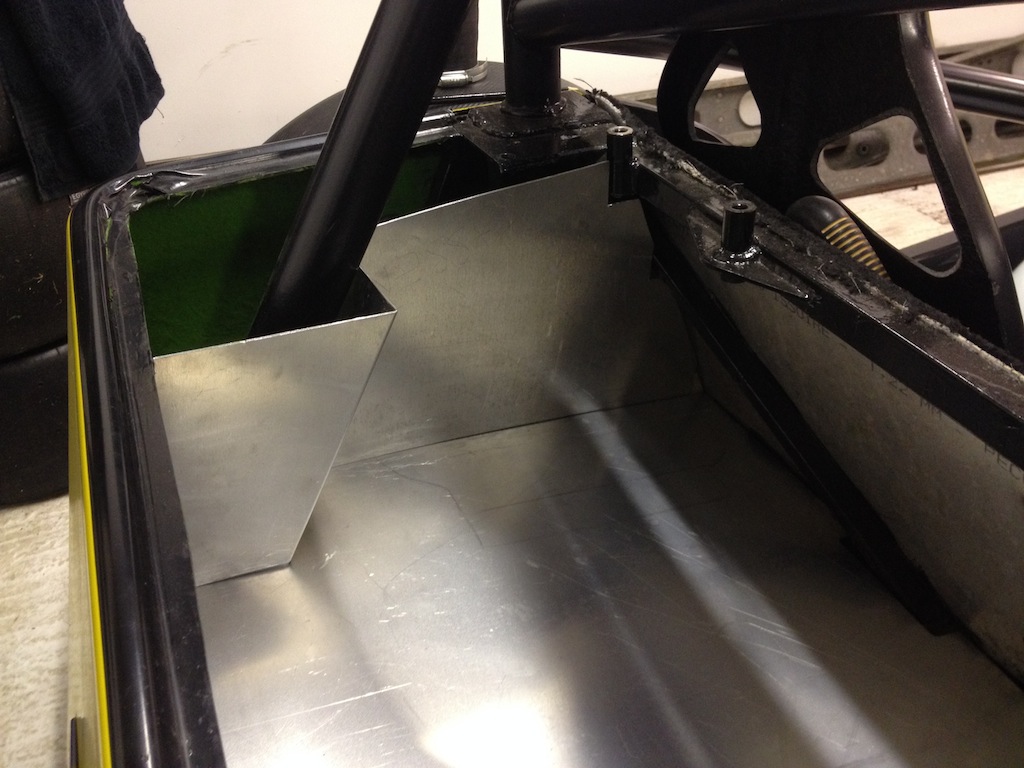

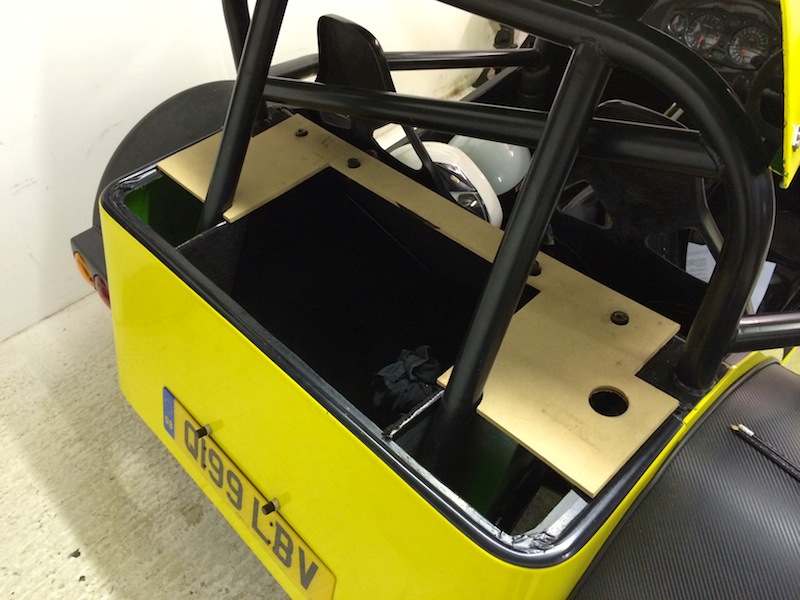

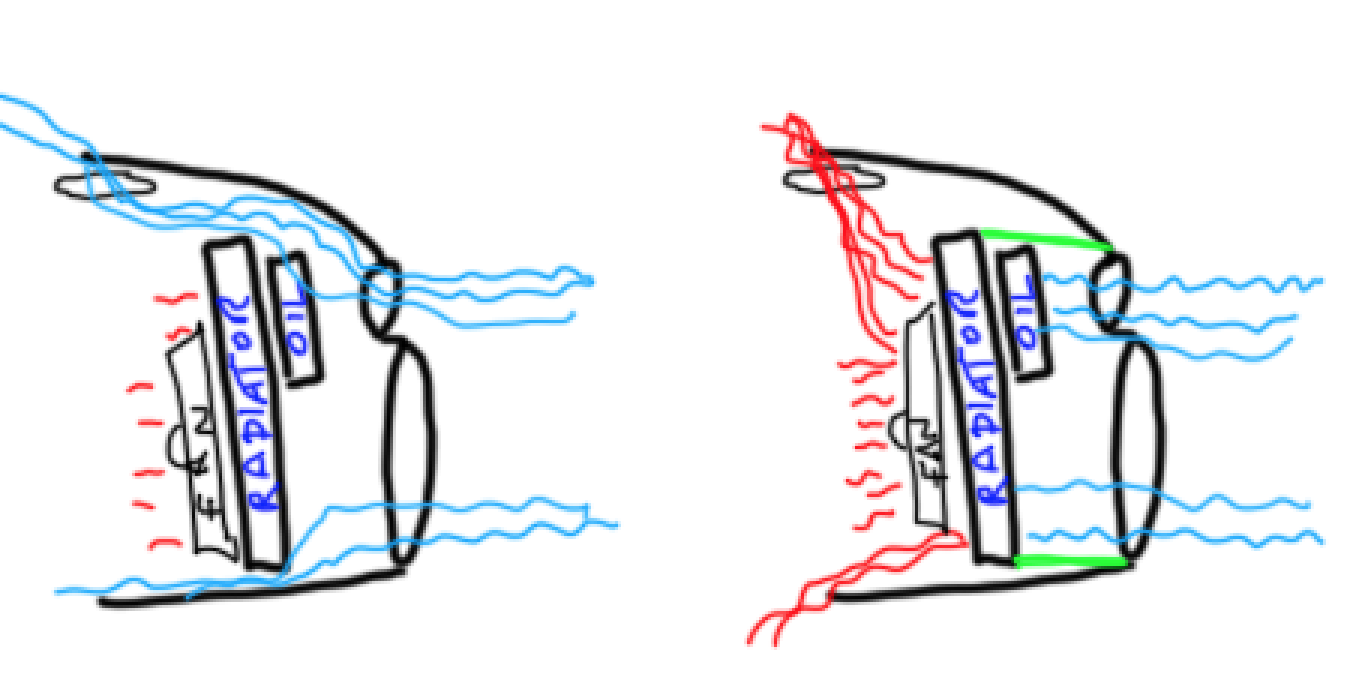

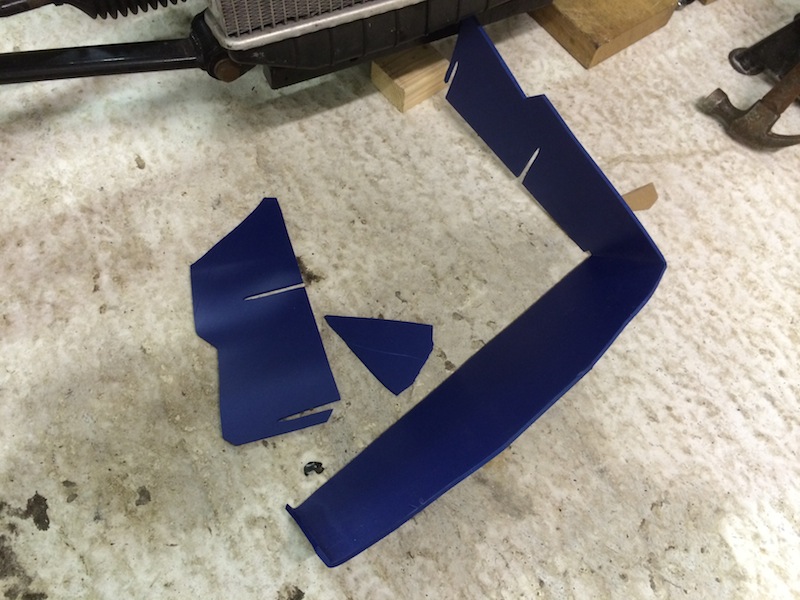

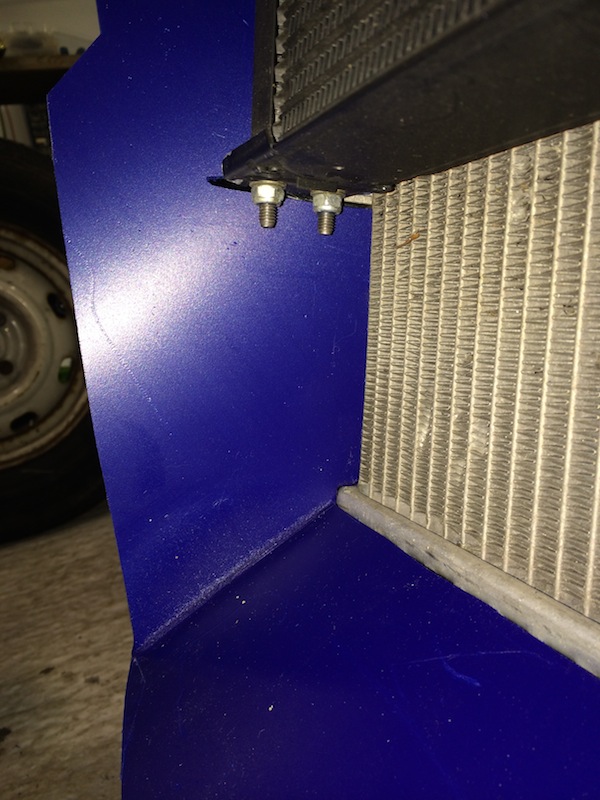

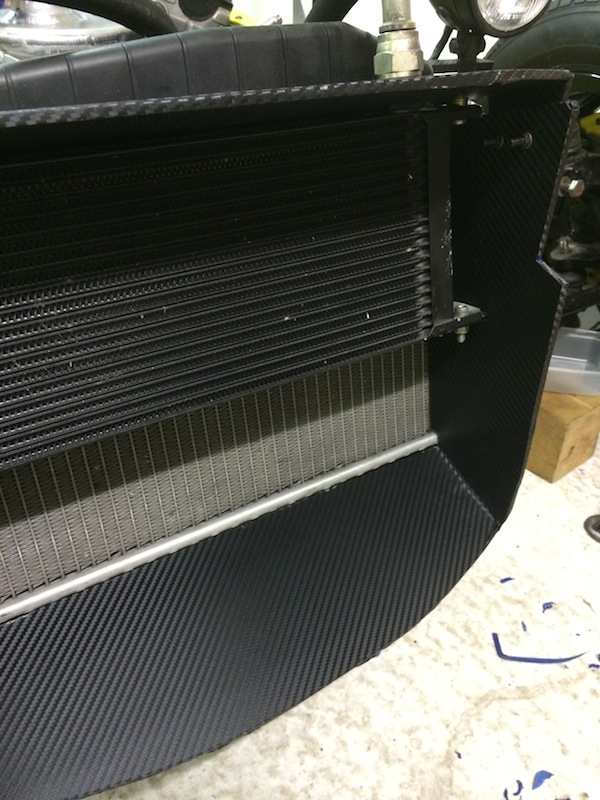

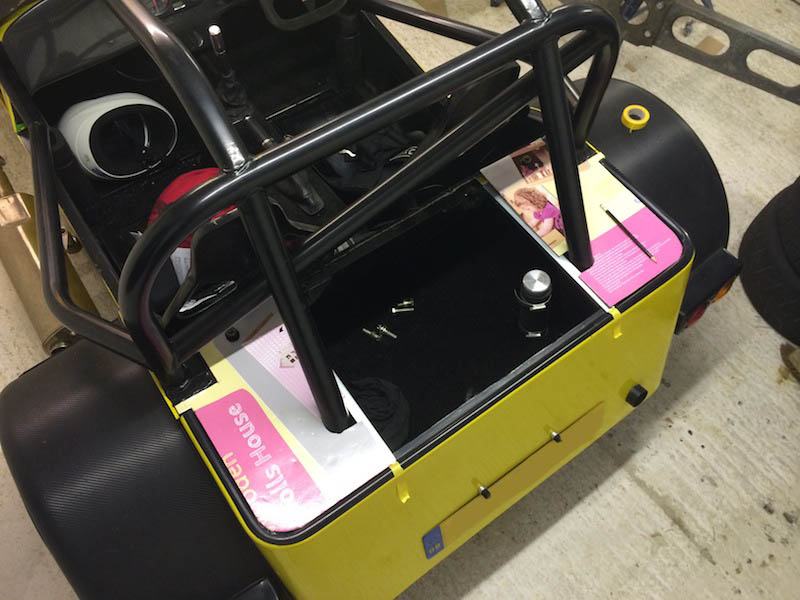

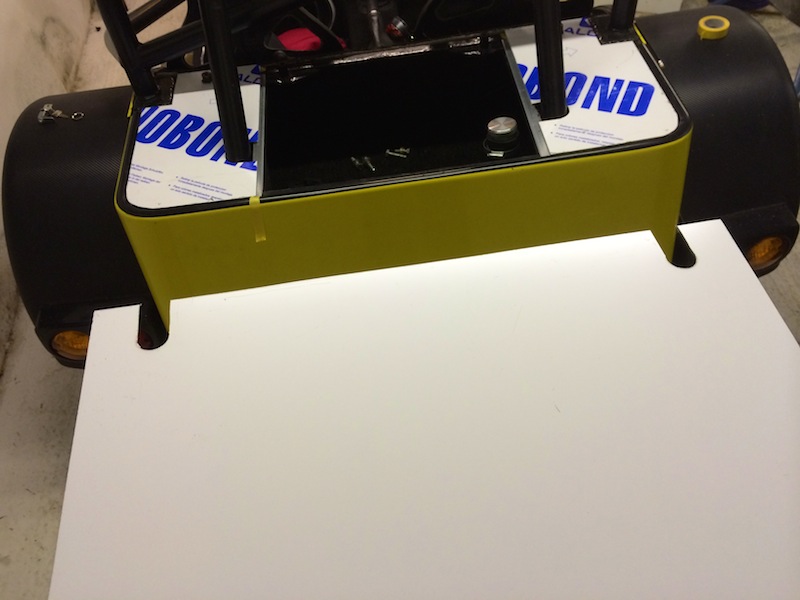

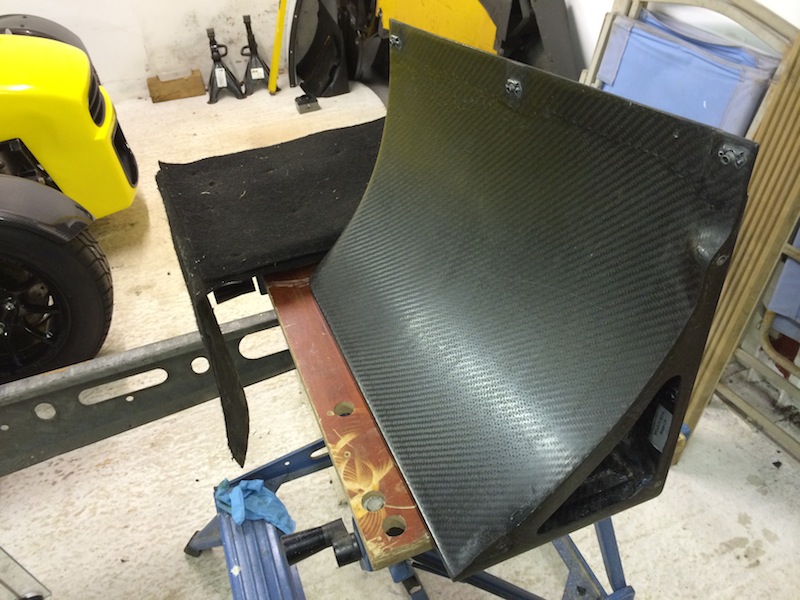

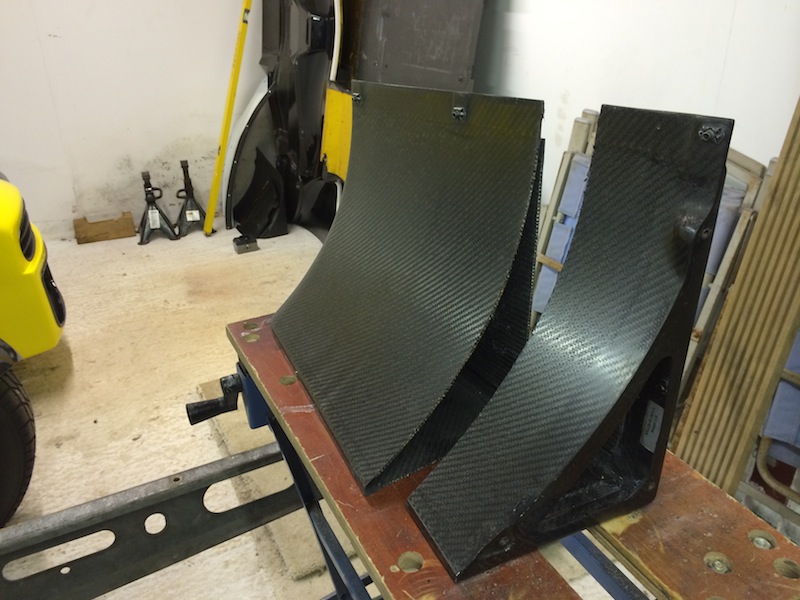

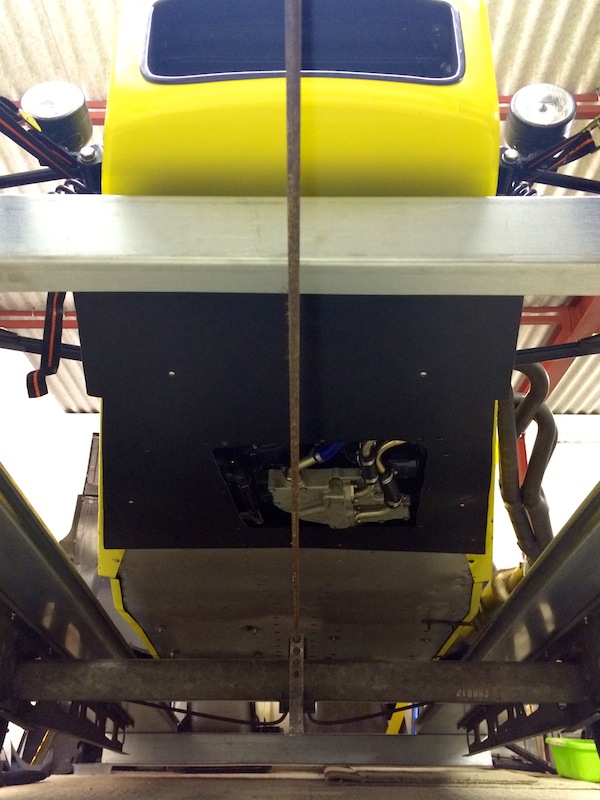

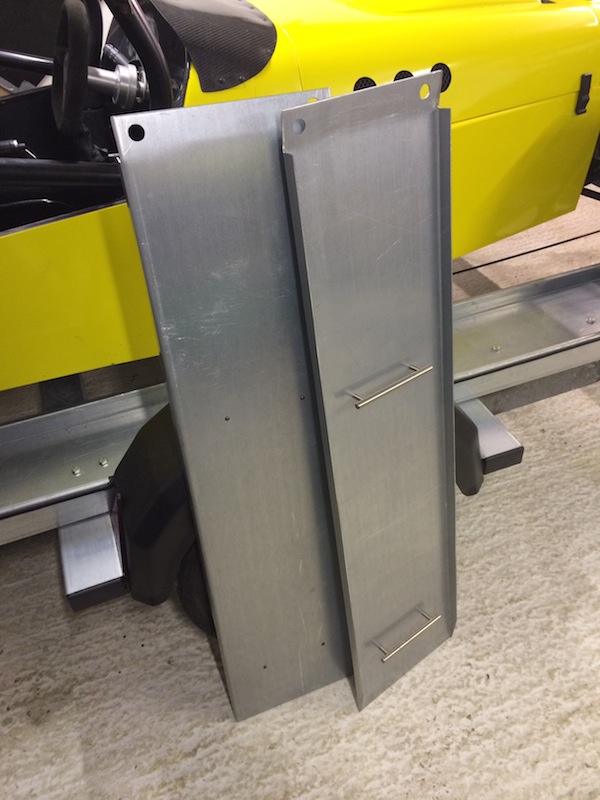

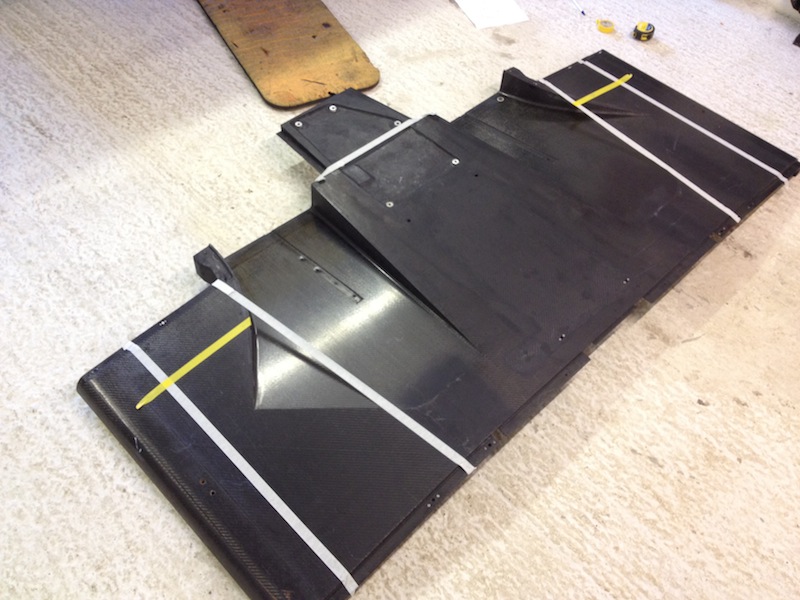

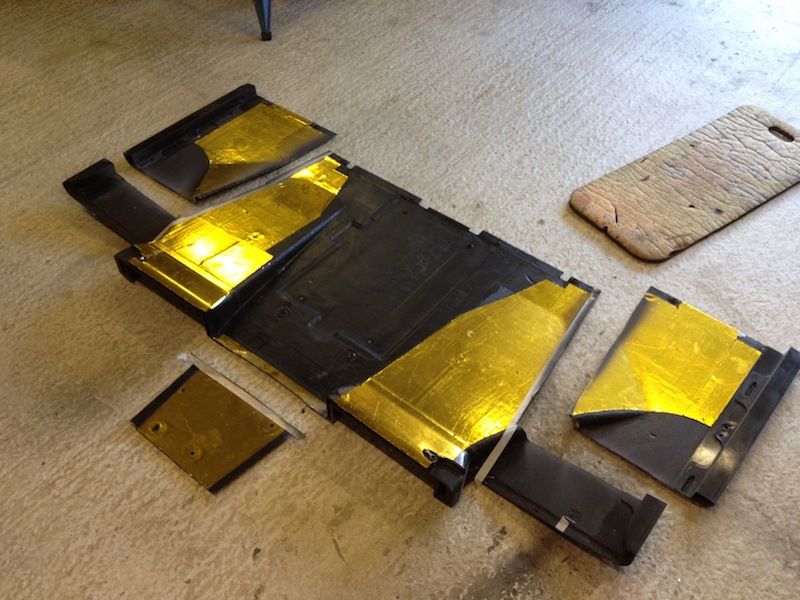

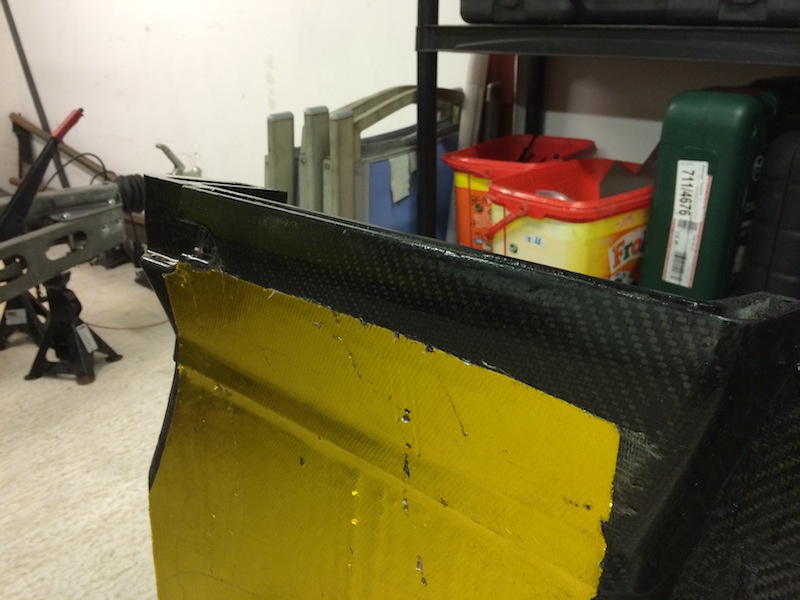

Decided to measure up and design my own MK Indy rear diffuser, so we got making a ply-wood template so its a constant continuation of the flat floor,

which will prevent the rear clam acting as a parachute slowing the car down under hard acceleration

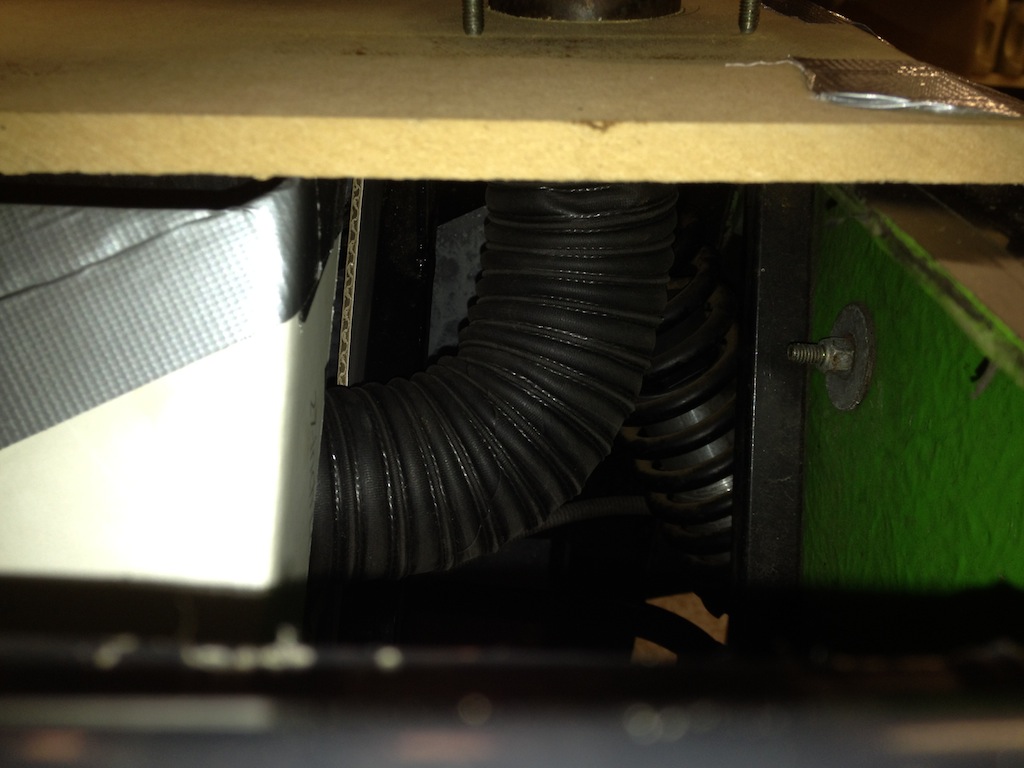

Underside showing the continuation, large fins on the outside, slightly shallower fins on the inners to channel the air correctly

Description

Larger out fins

Description

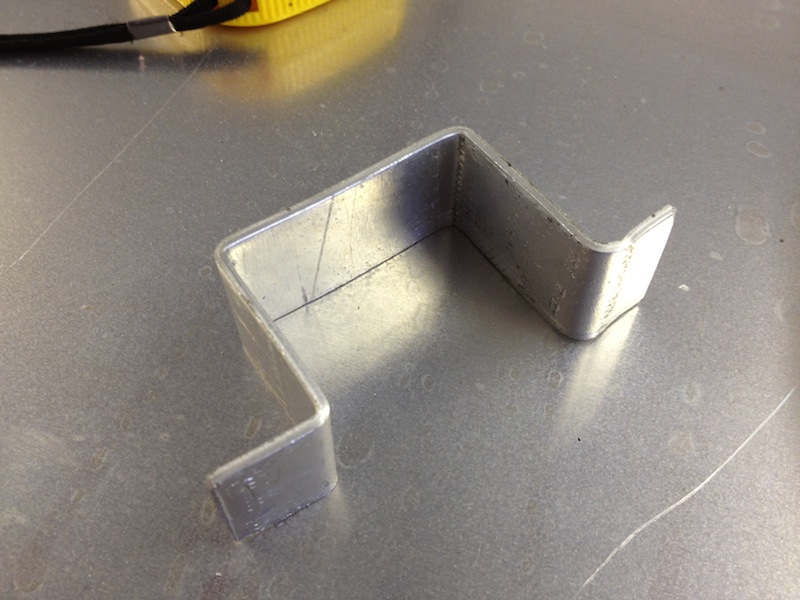

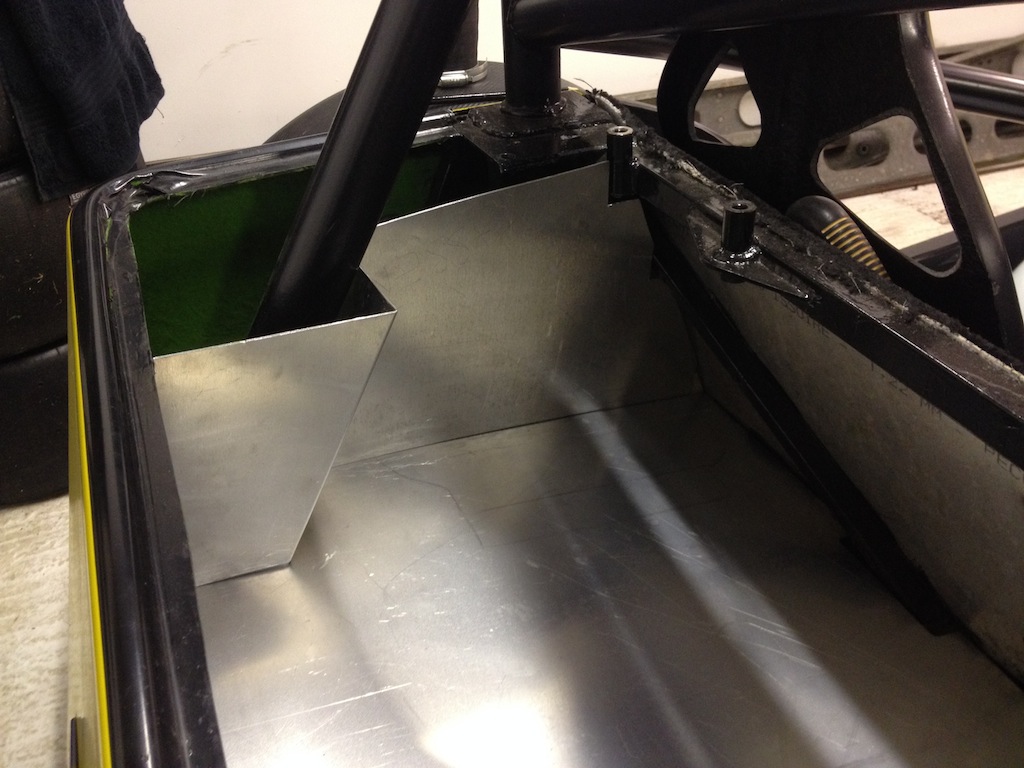

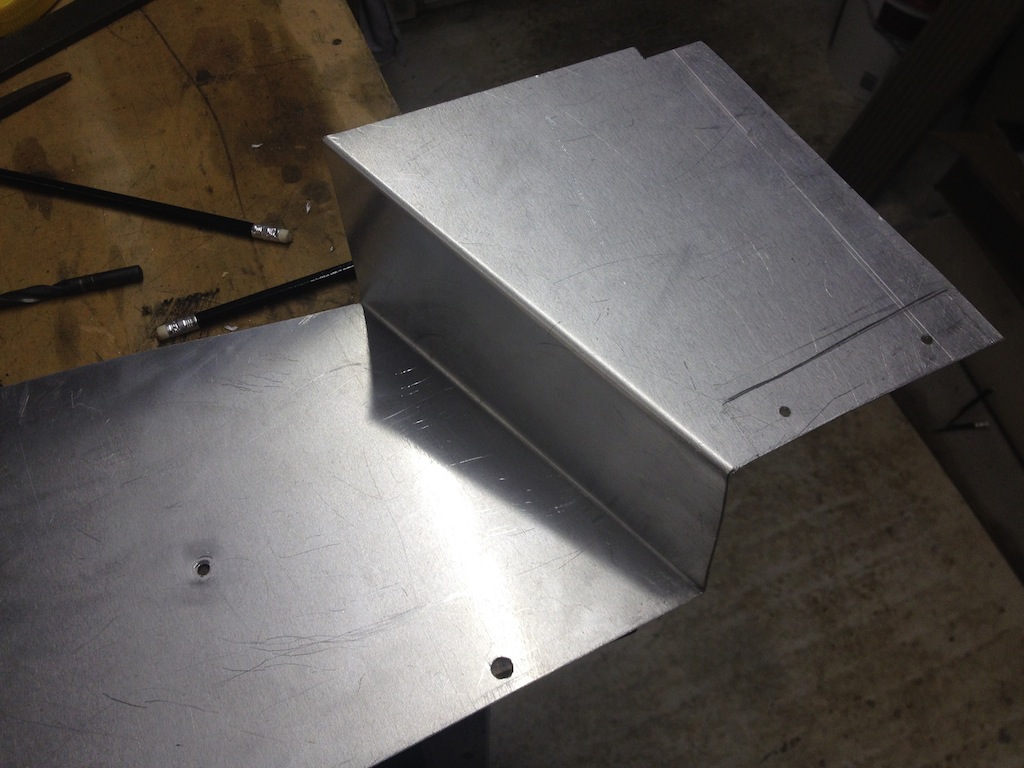

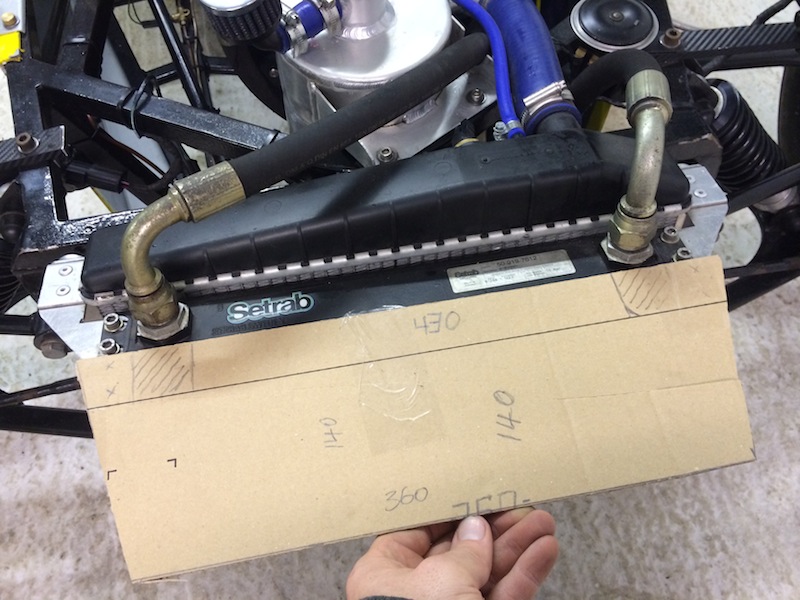

Being made out of 1.2mm alloy sheeting, with folded outer fins, and TIG welded inner fins

Description

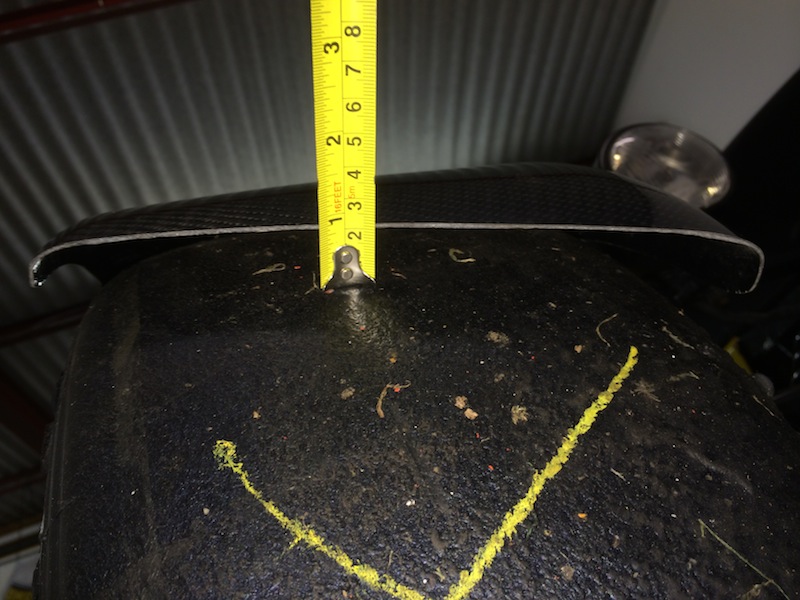

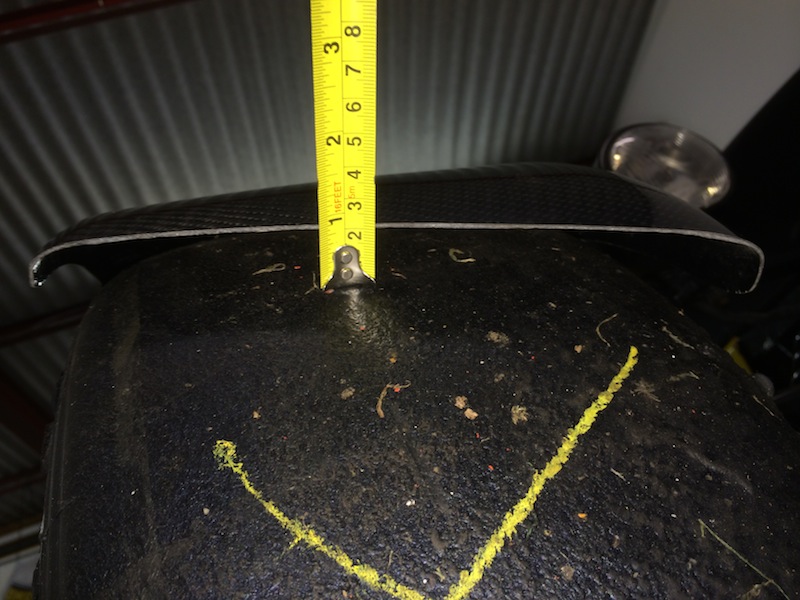

Edge will be rolled and rounded to keep Mr.MOT tester happy, and to keep within guidelines, protrudes the rear of the car by 25mm

Description

Proby - 20/3/12 at 06:30 PM

Lookin good! iPhone mic sounds a good idea!

afj - 20/3/12 at 06:48 PM

Diffuser looking great, just need a splitter at the front next

yellowcab - 20/3/12 at 07:52 PM

iPhone mic behind the dash completely exposed was still too distorted from engine & exhaust tone, so I cut some roll cage padding up, and wrapped

that around it to make a muffler for it, reduced it loads but still distorts under hard-loud-pedal

Next up, is to cut our kitchen sponge up (don't tell the wife) and stick the mini-mic in the centre of that...

One thing I really dislike about trackday/race/car videos is distortion and wind noise lol

yellowcab - 20/3/12 at 07:54 PM

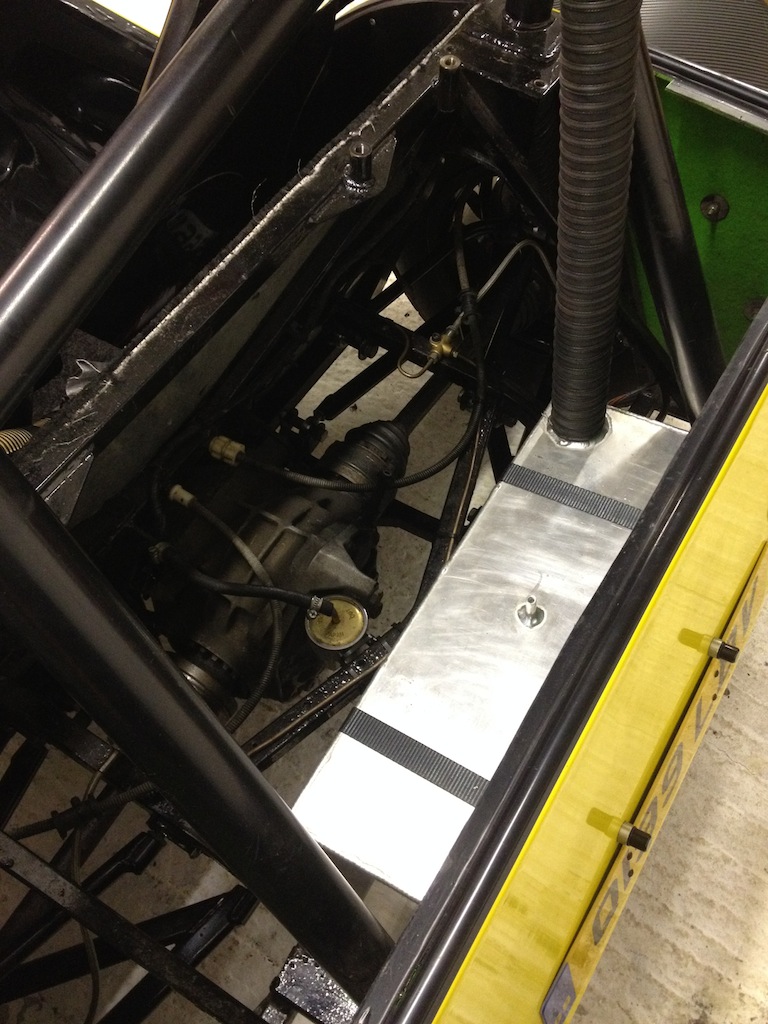

AFJ, good shout, there is already an alloy plate under the engine, but only held on with cable ties, so will be making a front splitter too.

Not fussed about it having louvres in, as I have the wide fin/ wings to aid engine bay cooling to keep engine air temps ambient

yellowcab - 25/3/12 at 08:14 PM

still battling with a horrid distortion from exhaust drone...

http://www.youtube.com/watch?v=d1nArJg2p-I&feature=plcp&context=C49fe7e6VDvjVQa1PpcFMYEPmjO7dsRaWLWeieKQWg2sc7EBZokn4%3D

Proby - 25/3/12 at 08:32 PM

Was that mini mic with or without the wife's washing up sponge?

yellowcab - 25/3/12 at 08:38 PM

I kid you not... the mic has roll cage padding taped round it, then a bathroom sponge taped around it, then stuffed in a jewellery ring box, taped up,

then another bathroom sponge taped around it, and then in a carrier bag to keep it waterproof, and tape around it... I think its just a sh*t mic

lol

Oh and I've moved it from behind the dash as I thought it was too close to the engine, now to behind the passenger seat, to which I now thing its

too exhaust droney... so I'll move it again to behind the under the drivers seat I think...

yellowcab - 28/3/12 at 11:19 AM

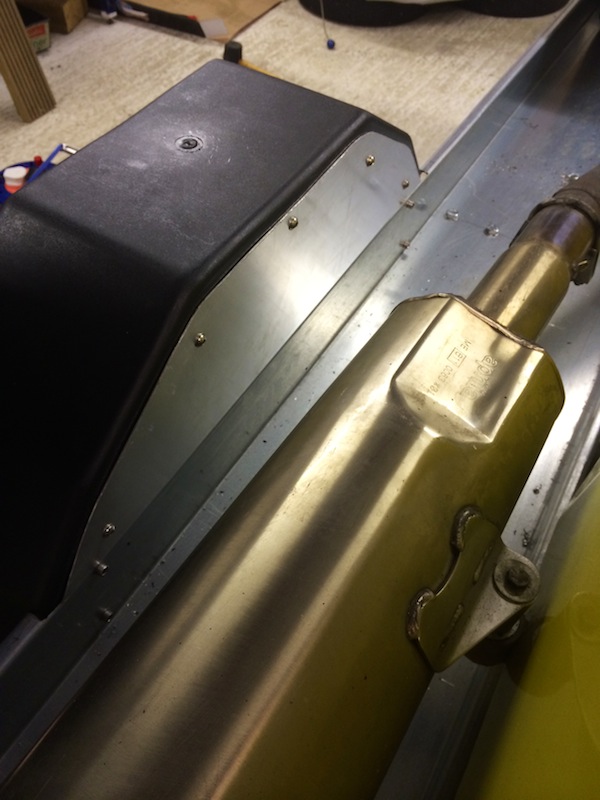

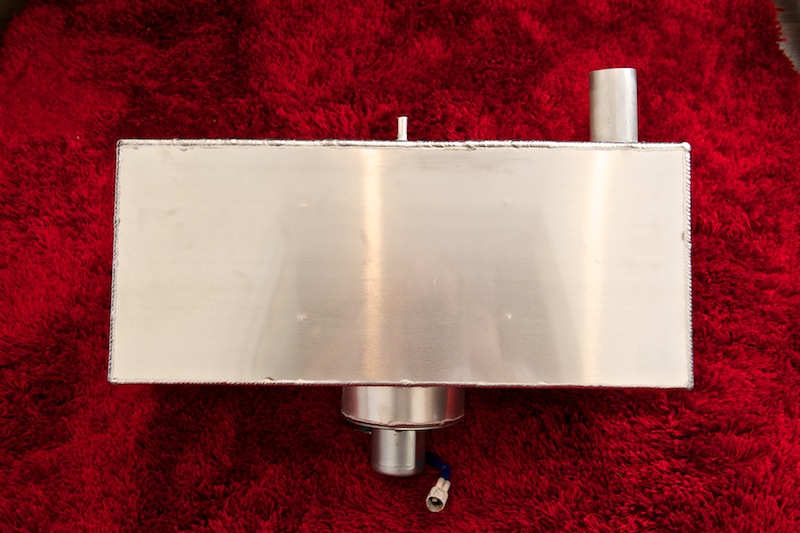

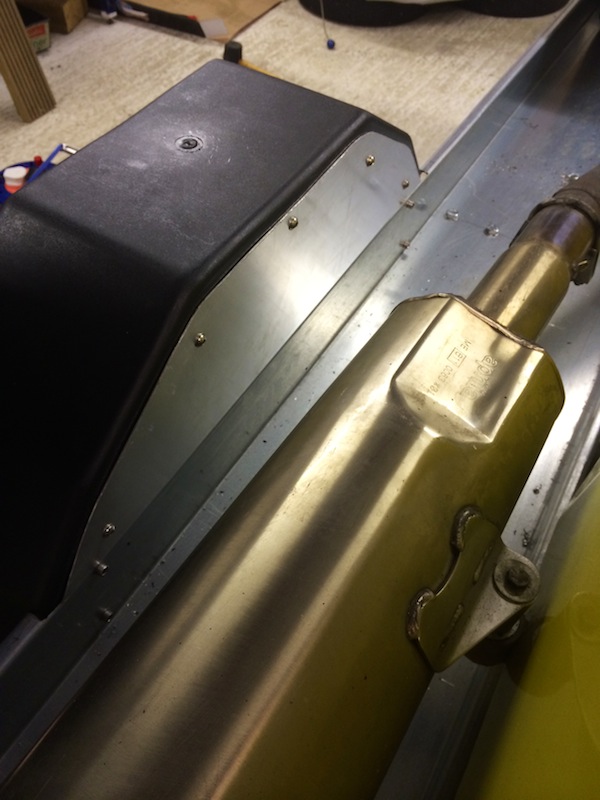

Removed, repacked and refitted exhaust to try and get it a little more quiet - whether its worked or not I don't know, maybe a larger longer can

would have been a better alternative, as this can is only 20inches x 4.5inches, and I think a new 22inch x 6inch would have done a better job

Hey ho...

Description

Description

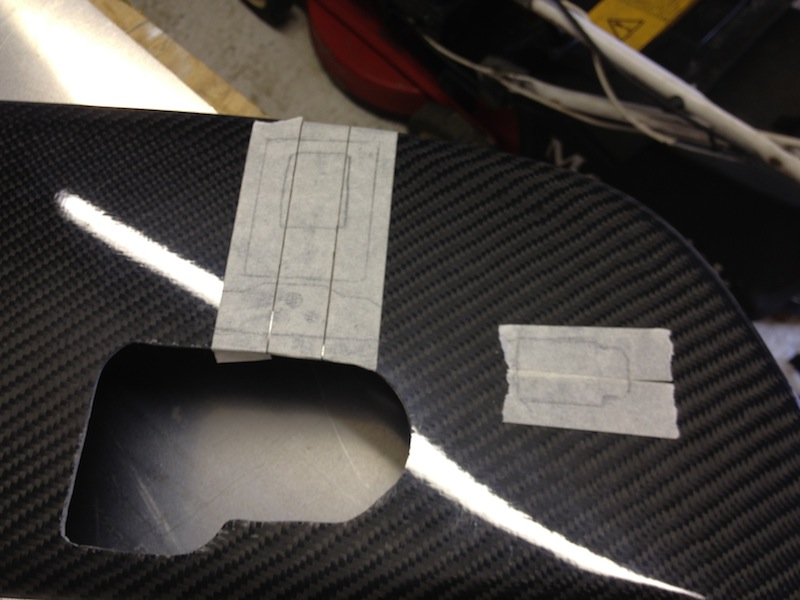

Took delivery of my new carbon aeroscreen today - any tips on how to fit it neatly?

Description

A1 - 28/3/12 at 12:16 PM

measure up from the scuttle/side panel line on each side then tape in place, fix it on one side then do the other.

yellowcab - 28/3/12 at 12:51 PM

Ahhh nice one... didn't really think about it but my scuttle is stepped, but it doesn't matter come to think about it.

I've taped it on and sat in the car to see if any visibility is reduced and it's pretty perfect! My drivers seat is really low down you

see.

Had to remove my mirrors and then I'll plonk them back ontop othe sides of the screen

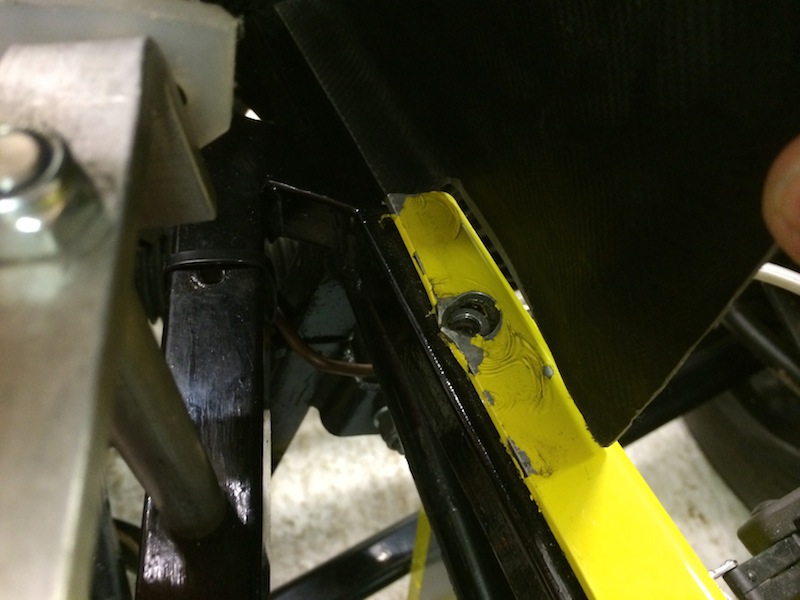

yellowcab - 30/3/12 at 06:16 PM

so on with the carbon aeroscreen that I purchased from Aerodynamix...

Description

Removal of the old home made perspex one which has served its job very well!

Description

It was a stepped scuttle type one

Description

As per above advice, I taped it down to begin with to get angles and measurements

Description

Rivetted on, following the curvature of the car

Description

Didn't like the silver, didn't fit in with the colour scheme, so coloured the rivets black

Description

All done

Description

Very happy with my purchase - outstanding service from Julian @ Aerodynamix too

yellowcab - 30/3/12 at 06:18 PM

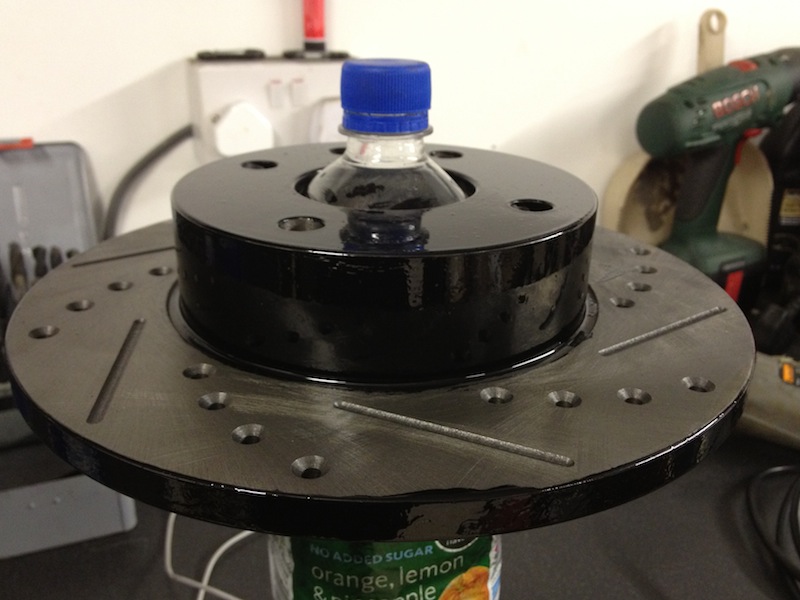

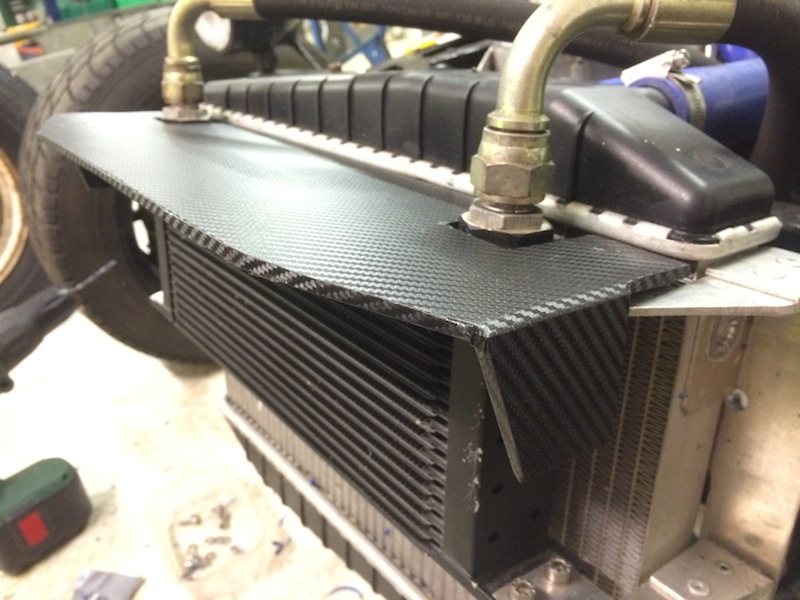

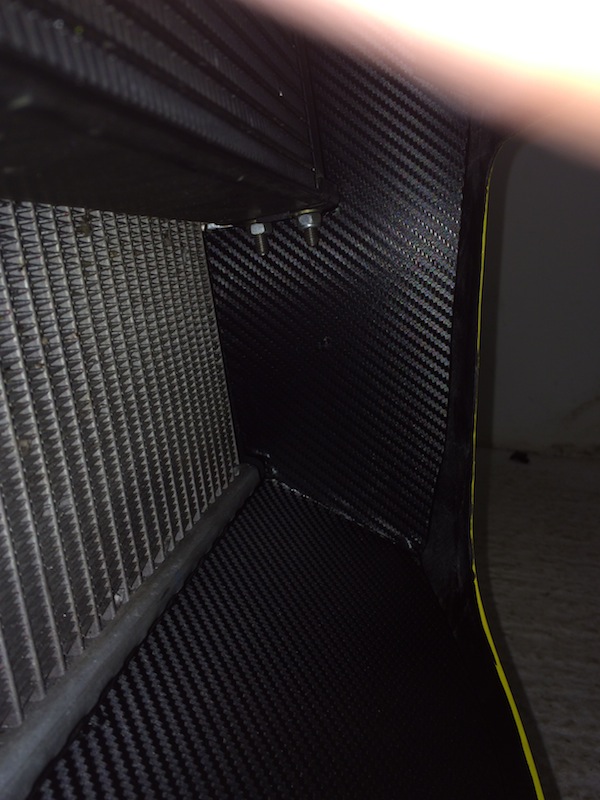

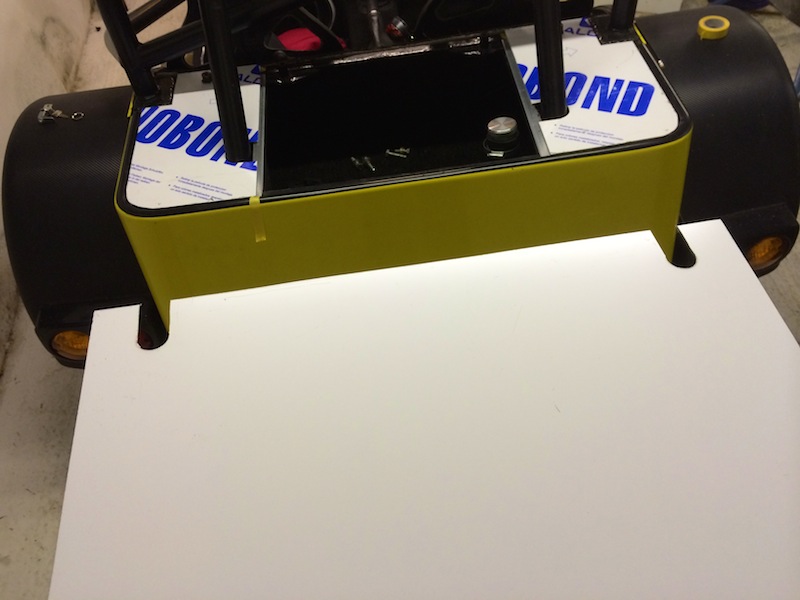

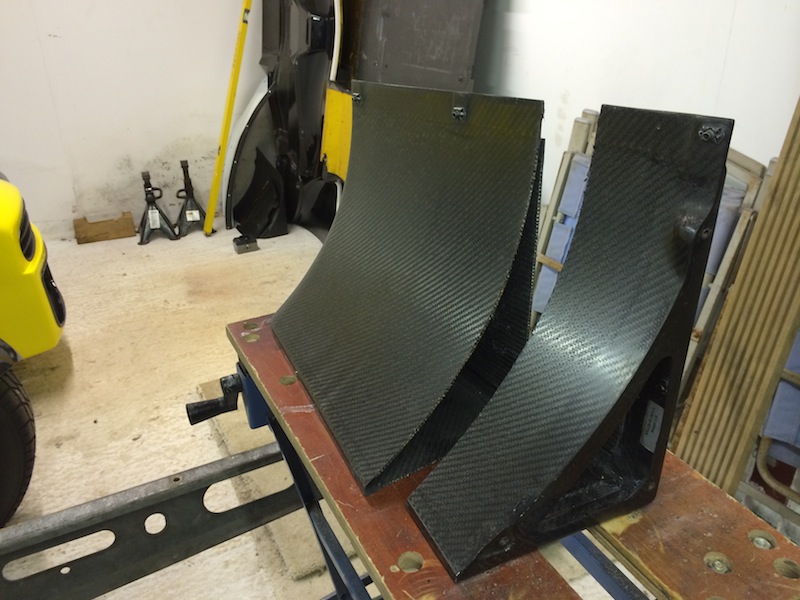

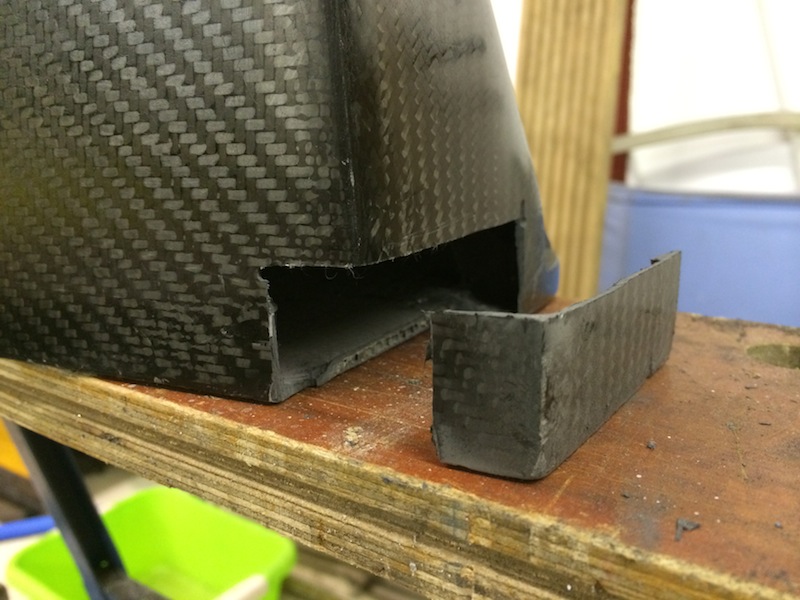

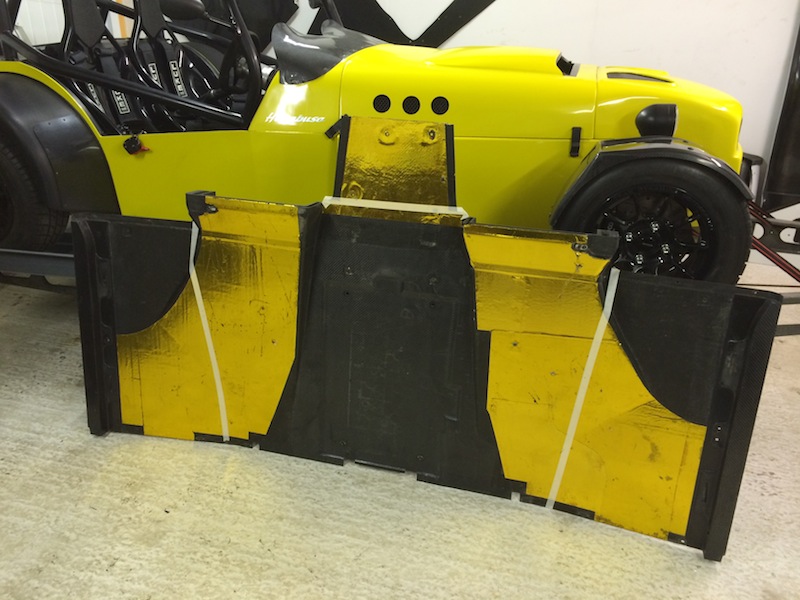

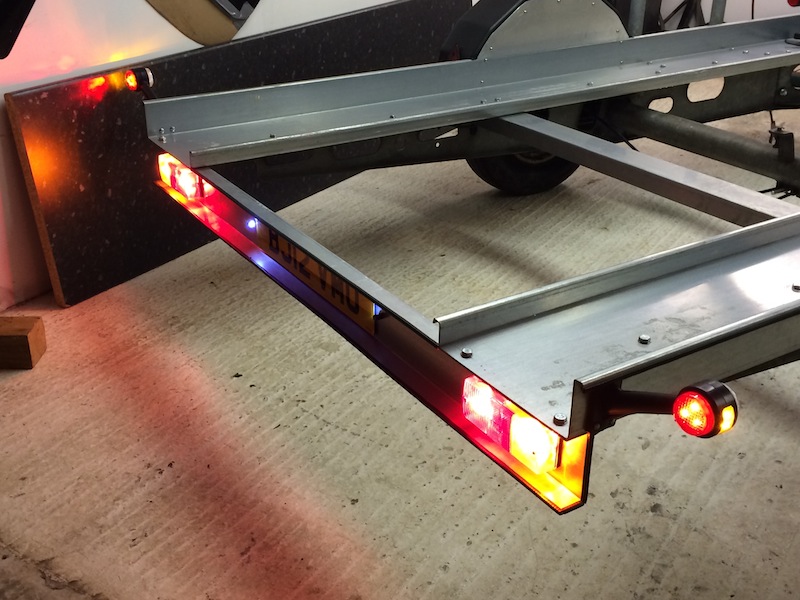

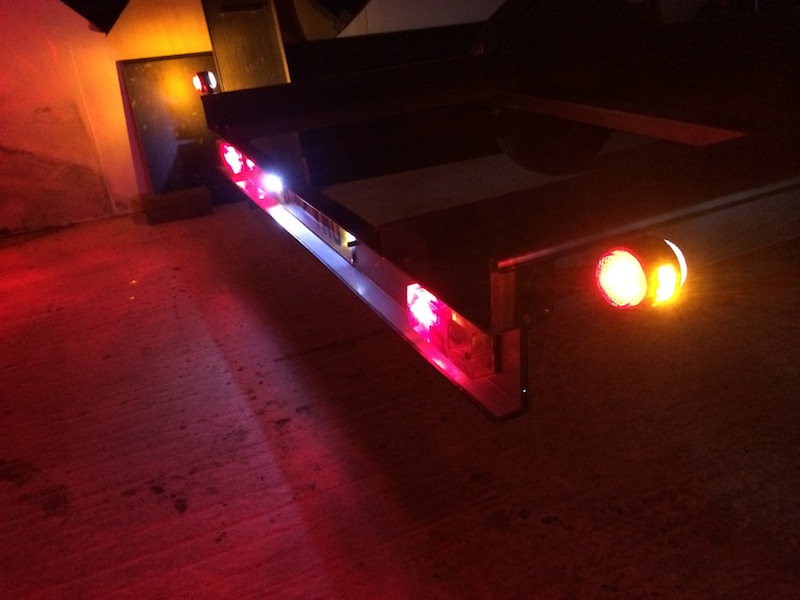

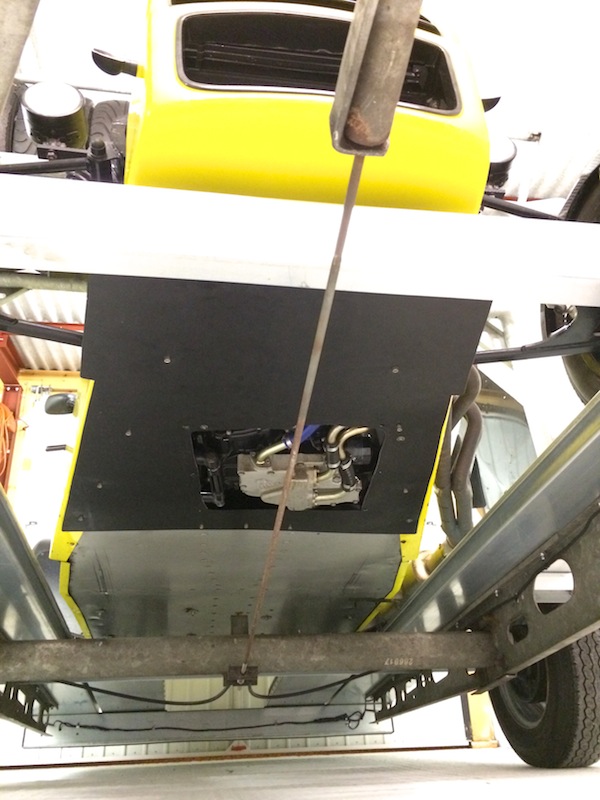

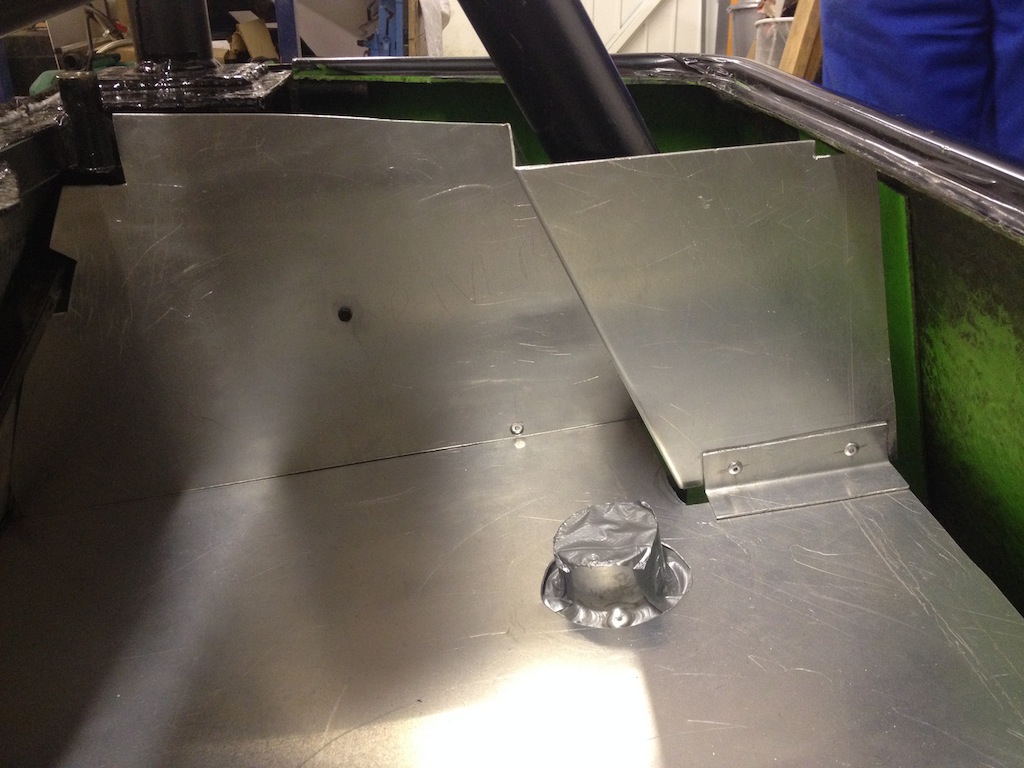

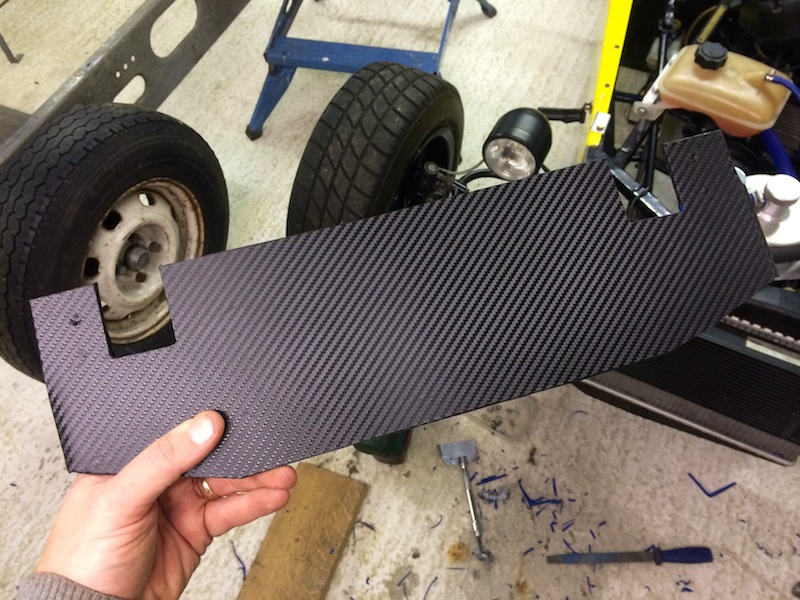

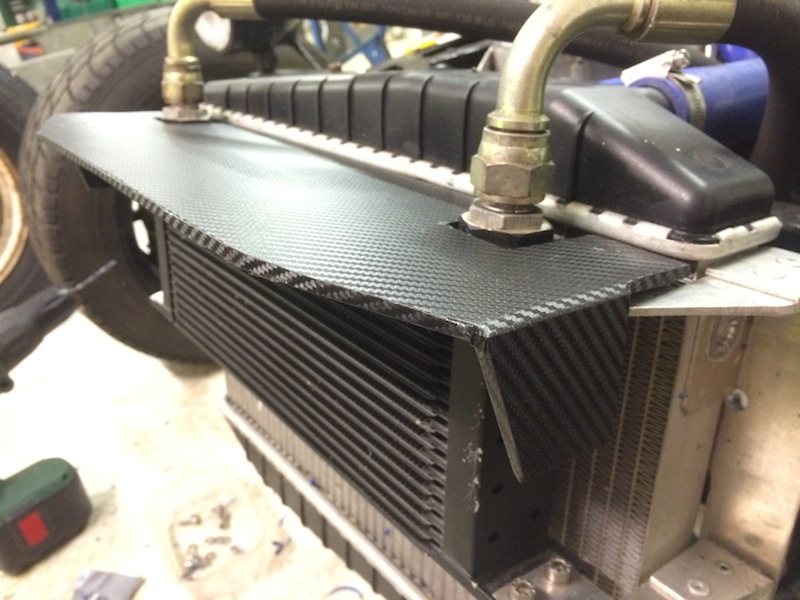

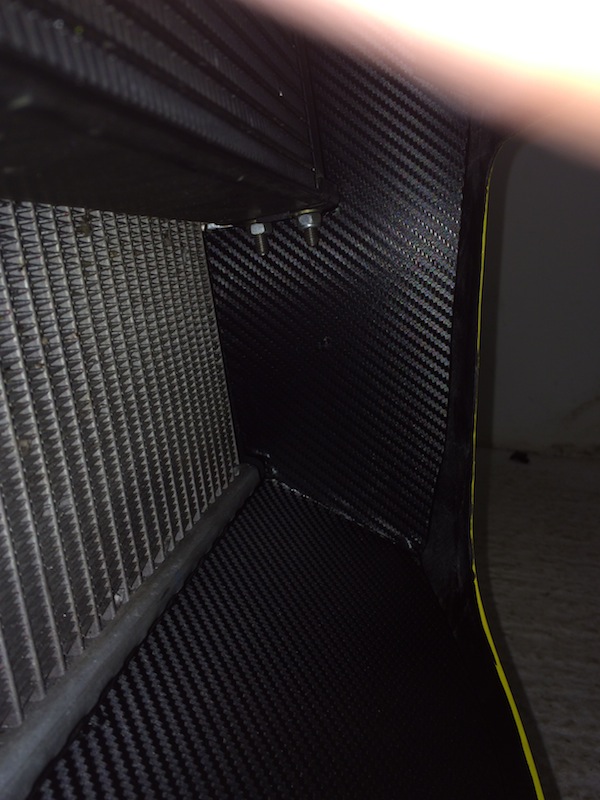

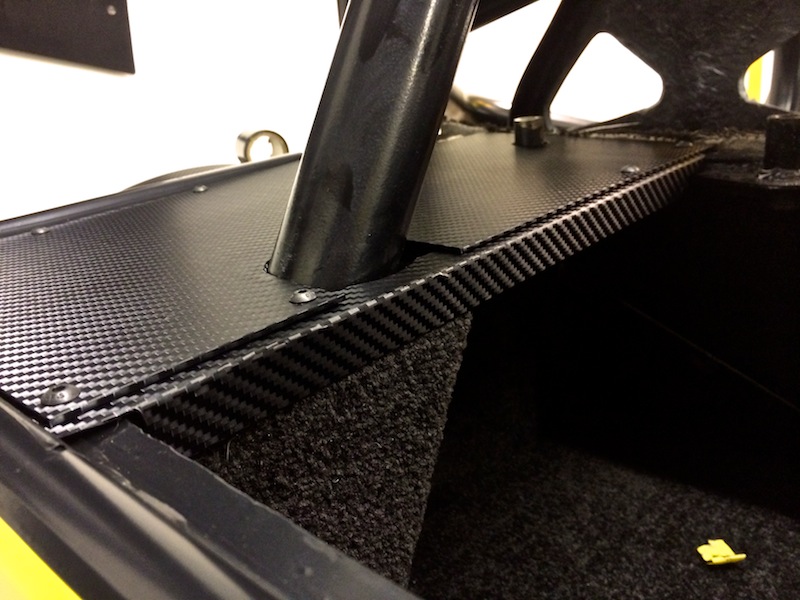

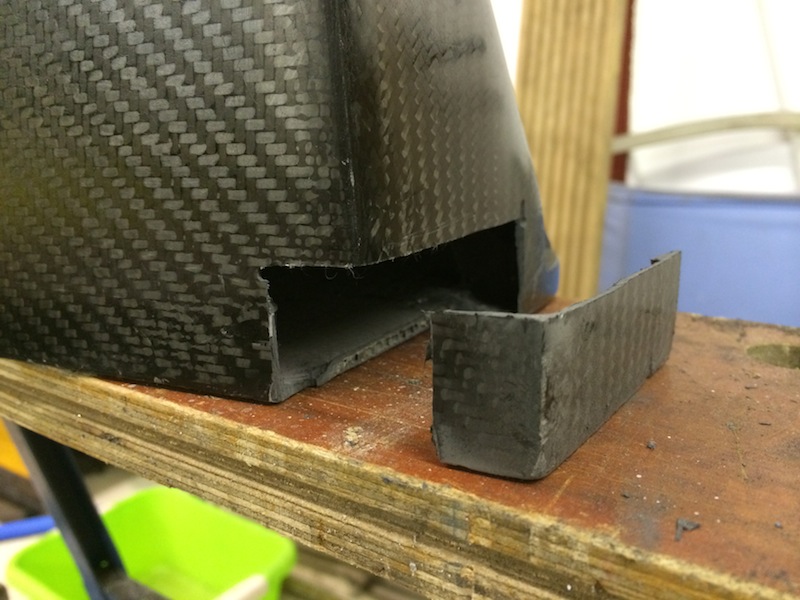

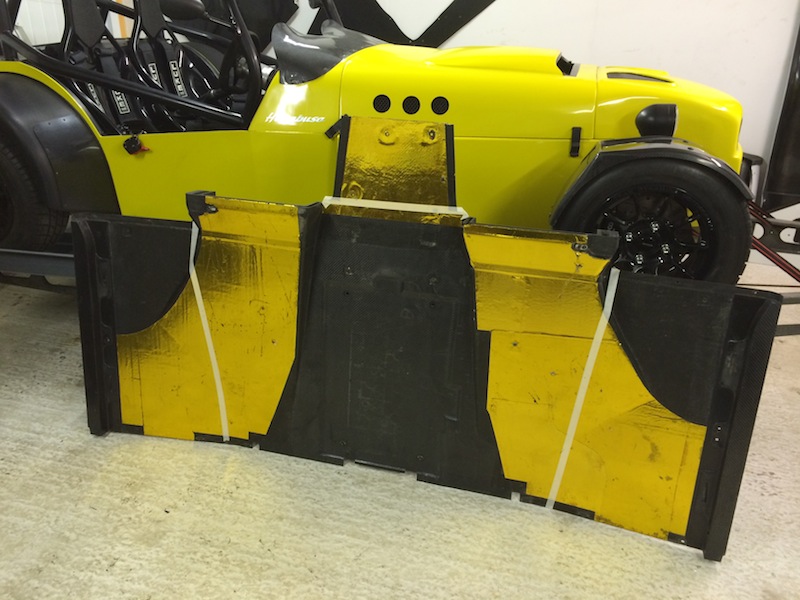

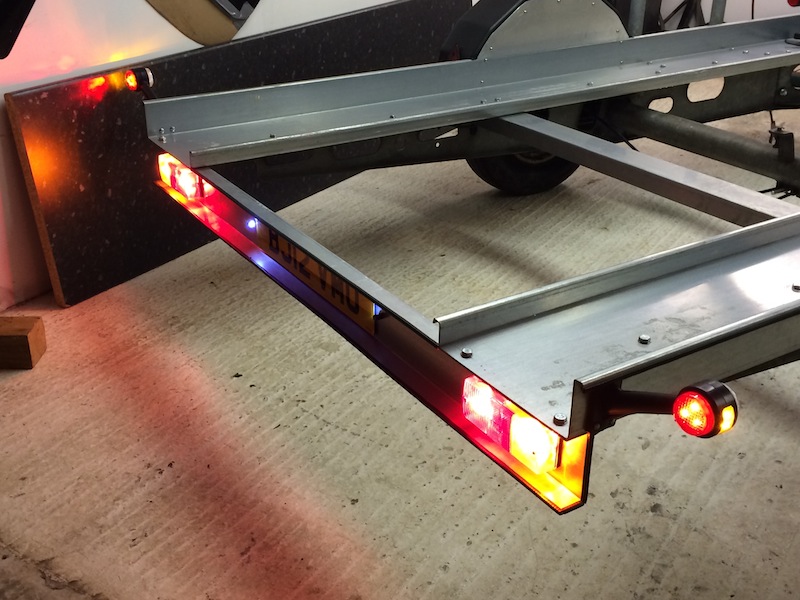

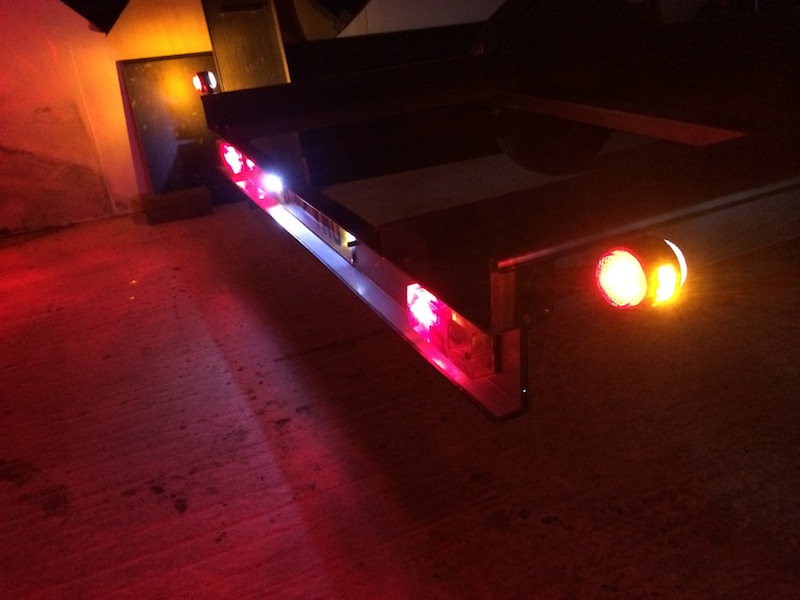

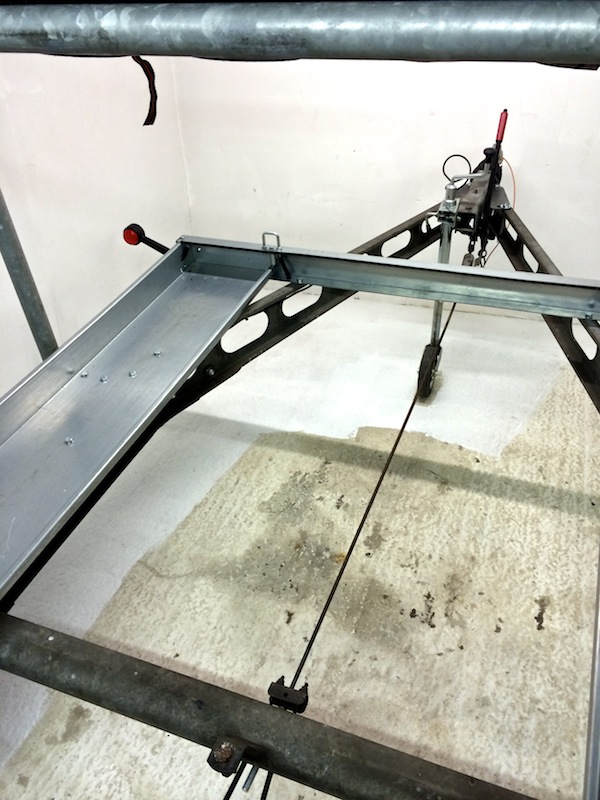

today we fitted the diffuser, and was very happy to see it weighing in lighter than some others, at 3.65kgs

Description

this is just the prototype riveted version for now, will be sold one once the final templates are made

Description

arse end up in the air, diffuser slid underneath

Description

like for like comparison, open rear diff, and rear clam acting as a parachute

Description

gloss black diffuser on, attached the the existing floor, and rear clam

Description

Exits the car by 25mm, and rounded edges

Description

Grrr

Description

All done - now onto the next task

Coopz - 1/4/12 at 05:31 AM

The carbon screen looks great... Fits really well on the MK Scuttle. Your car also looks superb keep the updates coming

yellowcab - 1/4/12 at 10:36 AM

Thanks Coopz, yeah very happy with the fitment on the screen considering they're not 'specifically' MK...

I'll keep the photos coming, don't worry

[Edited on 1/4/12 by yellowcab]

yellowcab - 12/4/12 at 04:36 PM

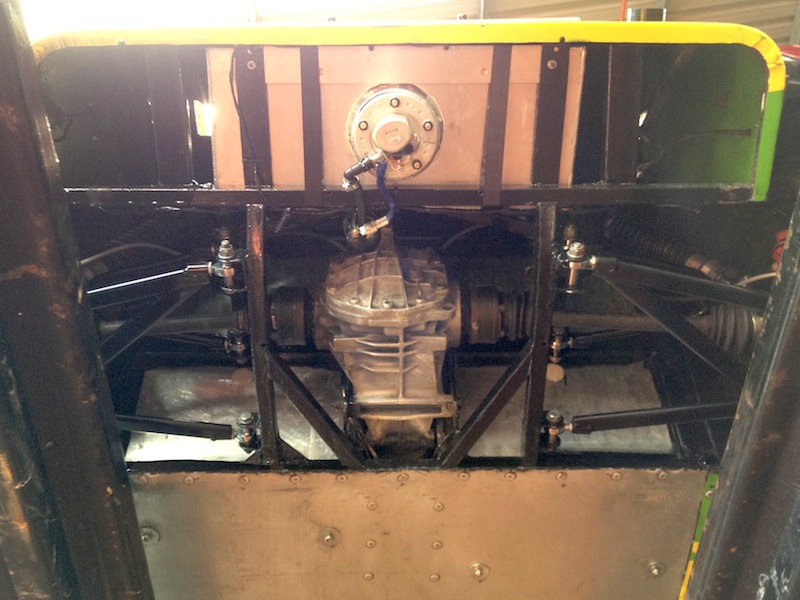

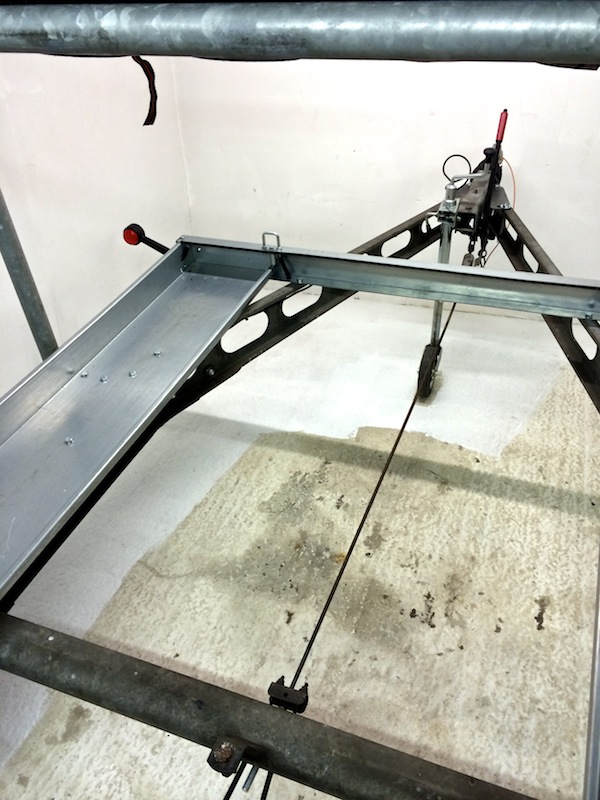

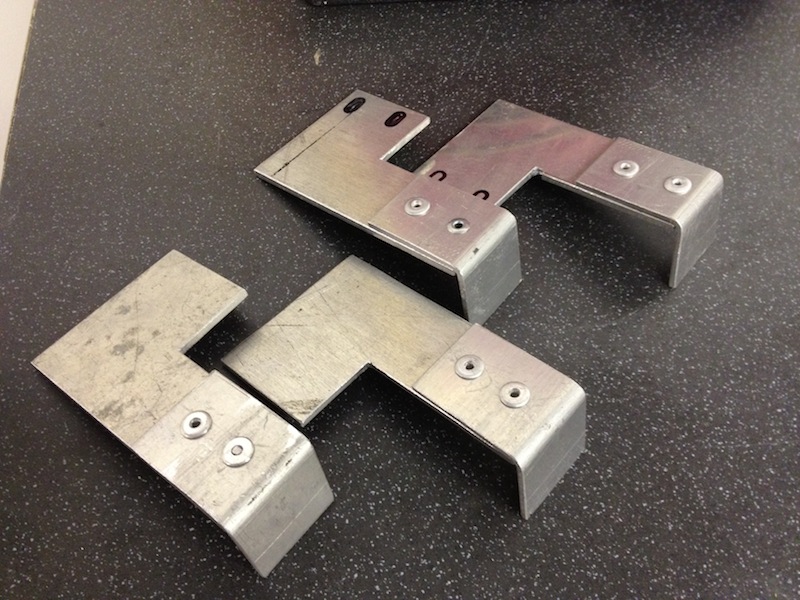

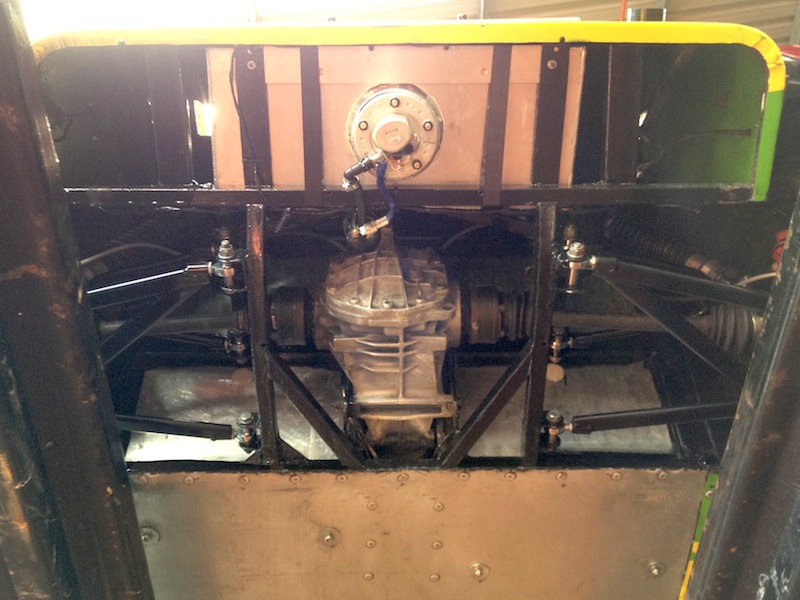

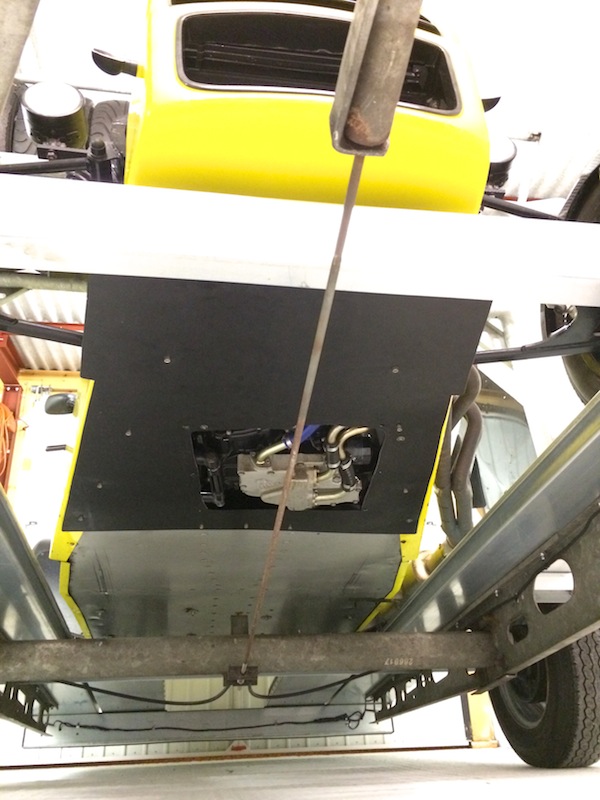

Set about making more aerodynamic changes to the car, so decided to look at the front of the car...

As it sits, completely open to the underside of the Busa lump

Description

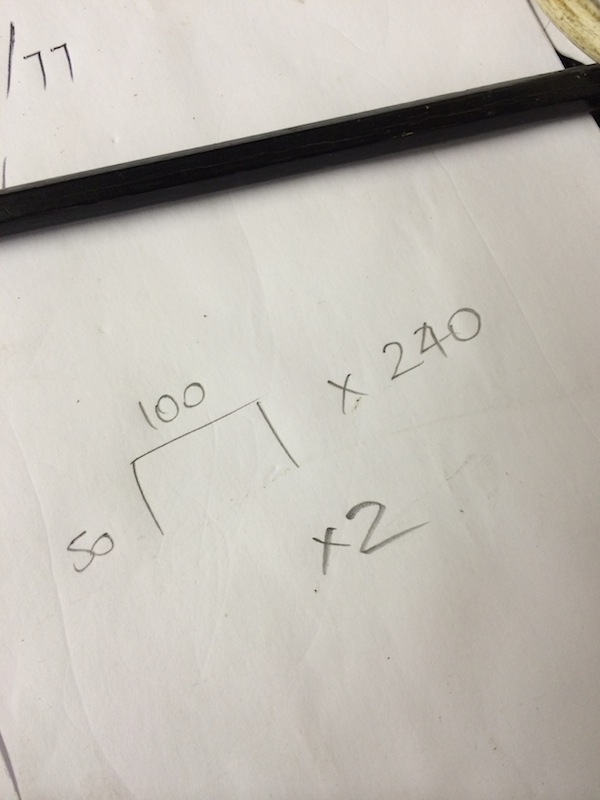

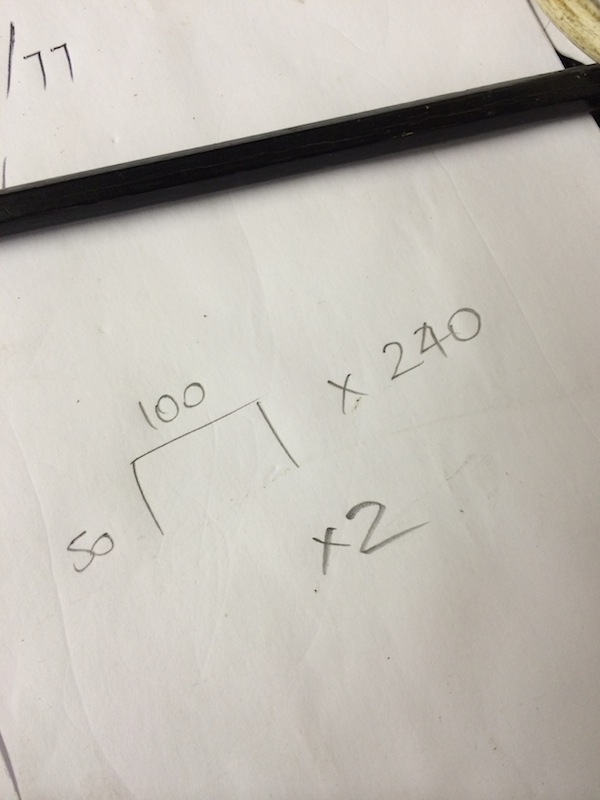

It's going to protrude the front of the underside of the nosecone by 50mm, and 60mm wider at either side (the shape isn't exact, it will be

rounded to suit the lines)

Description

Jacked the car up to ensure front arms at full droop will clear even when air-born

Description

The kick out/ change of angle - will not be a right angle, either rounded or smooth

Description

The sides follow the lines of the wider gills at the side of the engine bay

Description

Where the sump of the Busa engine hangs down, rather than boxing it off, I'll make an upside down alloy bonnet scoop facing backwards for better

aerodynamics and for hot air to escape if need be

Description

Description

Going to make it from 1.5mm alloy to keep the weight down

[Edited on 12/4/12 by yellowcab]

[Edited on 12/4/12 by yellowcab]

Nick DV - 12/4/12 at 06:13 PM

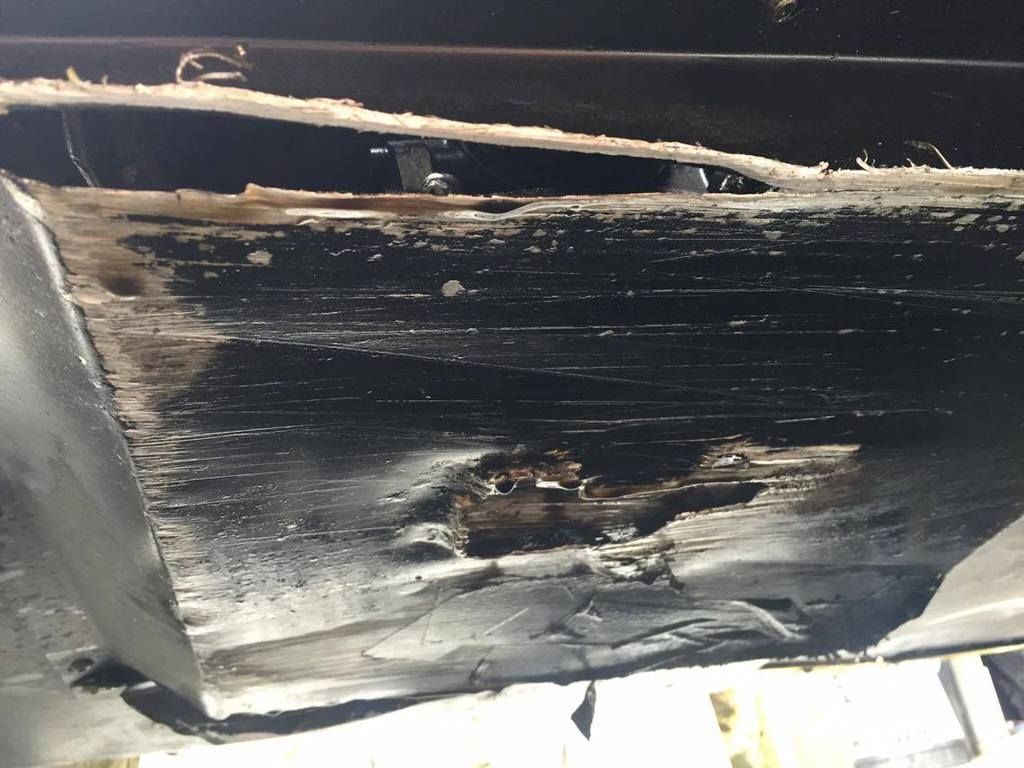

Are the marks on the bottom of the sump due to it hitting the ground?  If it is, I'd include a skid plate when you sort out the aero aids!

If it is, I'd include a skid plate when you sort out the aero aids!

Cheers, Nick

yellowcab - 12/4/12 at 07:22 PM

Yep, there isn't much of the sump left lol - I will be looking for a new one in due course lol

Also, thats the main reason for the splitter, the aero benefits was secondary...

[Edited on 12/4/12 by yellowcab]

chris_harris_ - 13/4/12 at 12:23 PM

Very nice looking car. I like the mods.

What have you fixed the Aeroscreen to the scuttle with. Have you used tinnerman washers, as this was what i was thinking of doing, with countersunk

screws?

Chris

yellowcab - 13/4/12 at 12:23 PM

MOT complete, passed with no advisories!

yellowcab - 13/4/12 at 12:32 PM

Hiya Chris,

I decided to use standard 4mm stainless rivets with washers underneath them to spread the load so to speak to prevent any cracking,

Let me know what you decide to use.

andrewmorpeth - 13/4/12 at 12:41 PM

are you running a dry sump system or standard?what diff have you got?thanks

yellowcab - 13/4/12 at 12:53 PM

Running a standard wet sump, and the rear diff is a LSD standard unit with 3.14 fd

andrewmorpeth - 13/4/12 at 01:00 PM

ive just changed my diff from sierra 3.14 to a bmw 2.35 out of a 2000 320d had to change propshaft and drive shafts but what a difference!it will do

70mph in first now!still pulls away ok and car is now more driveable on road.have you had any problems with oil surge?what size oil cooler are you

using?

yellowcab - 13/4/12 at 01:14 PM

not had any problems as yet - but will be investing in an acusump system certainly lol

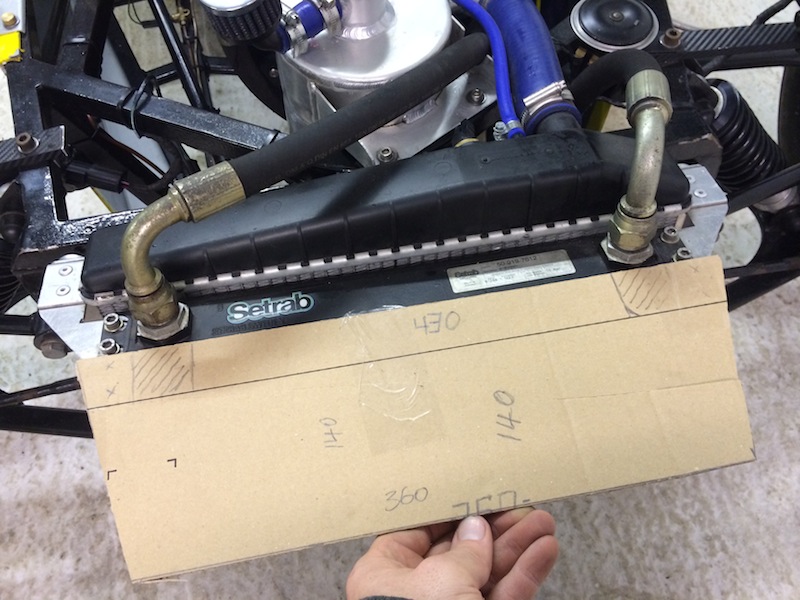

here is a quick shot i took when i had run out of fuel again lol

Description

andrewmorpeth - 13/4/12 at 01:19 PM

looks nice!have you done any trackdays yet?

yellowcab - 13/4/12 at 01:22 PM

not in this particular car no, but previously yes www.youtube.com/trackdaynova

Proby - 13/4/12 at 01:46 PM

quote:

Originally posted by andrewmorpeth

ive just changed my diff from sierra 3.14 to a bmw 2.35 out of a 2000 320d had to change propshaft and drive shafts but what a difference!it will do

70mph in first now!still pulls away ok and car is now more driveable on road.have you had any problems with oil surge?what size oil cooler are you

using?

Sorry to hijack the thread, but out of interest, what are your speeds in each gear now? Not heard of anyone trying a 2.35 from a beamer?

Nick DV - 13/4/12 at 02:09 PM

quote:

Originally posted by yellowcab

Running a standard wet sump, and the rear diff is a LSD standard unit with 3.14 fd

That doesn't look like a standard 'Busa sump from where I am looking at it from. Accusump is a good idea

Cheers, Nick

Pat_T - 13/4/12 at 02:11 PM

quote:

Originally posted by yellowcab

not had any problems as yet - but will be investing in an acusump system certainly lol

here is a quick shot i took when i had run out of fuel again lol

Description

is that near the Earl Shilton traffic lights? If so I ran out of the fuel there a couple of weeks ago too!

(I'm in Hinckley too, have been following the thread with interest, have a 2.0 C20XE Redtop powered Stuart Taylor  )

)

yellowcab - 13/4/12 at 04:43 PM

Very good eyes! Yes it's the end of Clickers, lol

Ran out of petrol twice now, one Sunday after another! lmao #ineedafuelgauge lol

Love the fact you have an XE, if I didn't get a BEC, it'd have to be a TB'd XE with Elite Seq SCCR

yellowcab - 14/4/12 at 03:21 PM

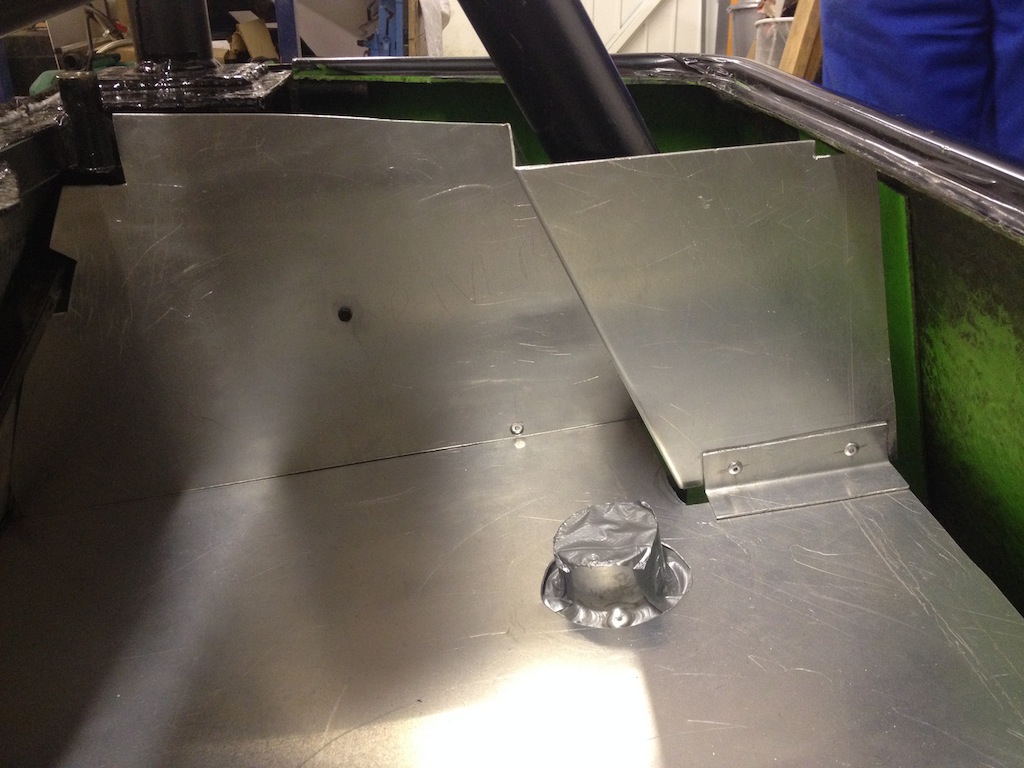

Spent some time this morning making the front aero splitter and engine under tray / sump guard... some photos of the progress...

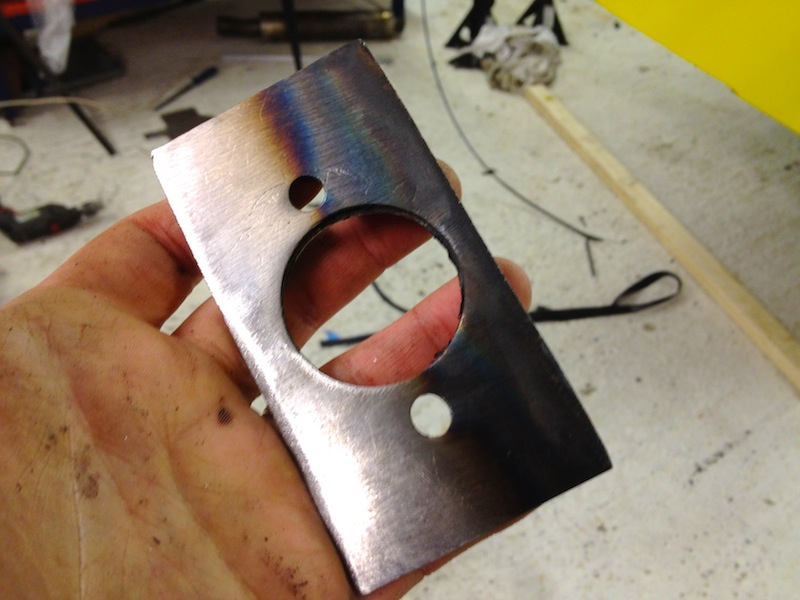

1.5mm alloy sheet cut to cardboard template

once cut out - weigh it, 2.61kgs... nice and light

will attach to the wider gills of the side of the bay, and where the flat floor begins

Obviously the sump guard isn't attached yet - we were just making sure measurements were correct at this point

From the front of the car, looking back

Protrudes out 50mm, and 60mm either edge at the front

Flat floor from front to rear now...

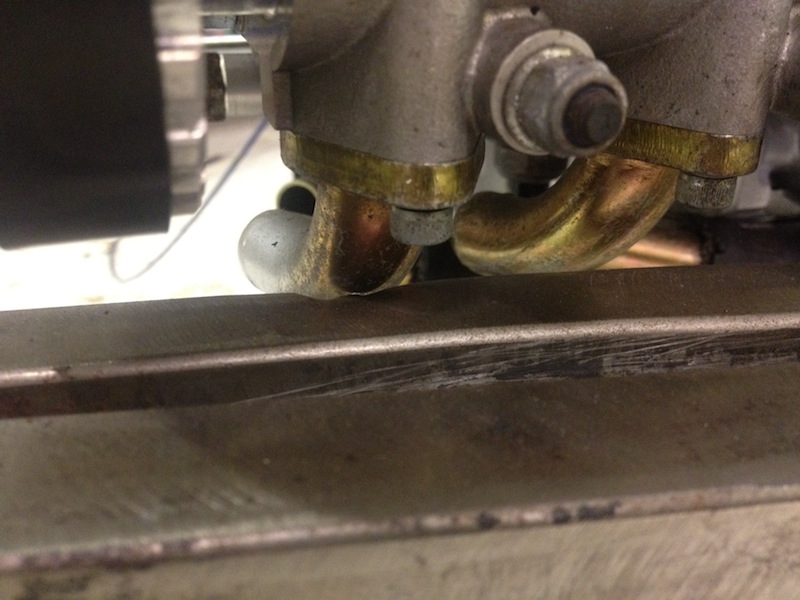

And someone was asking about the sump on the car, this is a close up... lol

chris mason - 14/4/12 at 06:57 PM

Looks like your running a Westfield Dry sump system (pace iirc)

It might be worth looking in too these, as i did find when i was searching for one myself, that the westy one was not too reliable on track

yellowcab - 17/4/12 at 11:01 AM

Having looked again - you're completely right in that it's a Westfield Dry Sump Pan, but I'm running a wet sump system lol

Twin40 - 17/4/12 at 11:38 AM

is that a bit dodgy running a dry sump pan on a 'wet' system? does is hold enough oil in it to provide lubrication?

yellowcab - 17/4/12 at 04:53 PM

it's been running like that since 2004, and being a well renown track-taxi all over the UK, Ring and Spa, I'd can only presume its fine?

I didn't build the car originally mind

Twin40 - 18/4/12 at 06:37 AM

Fair enough!! Shows what little i know! Loving the updates mate, keep them coming.

yellowcab - 18/4/12 at 01:13 PM

Please don't think I was being funny, I thought the same about the lack of oil it holds, but it seems to be fine...

Acusump will be bought anyway, just to be sure, to be sure

yellowcab - 18/4/12 at 07:26 PM

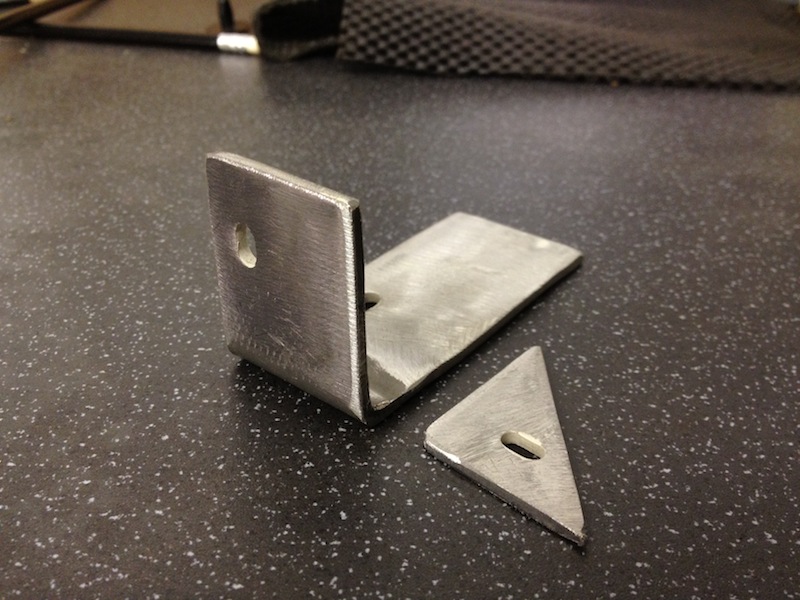

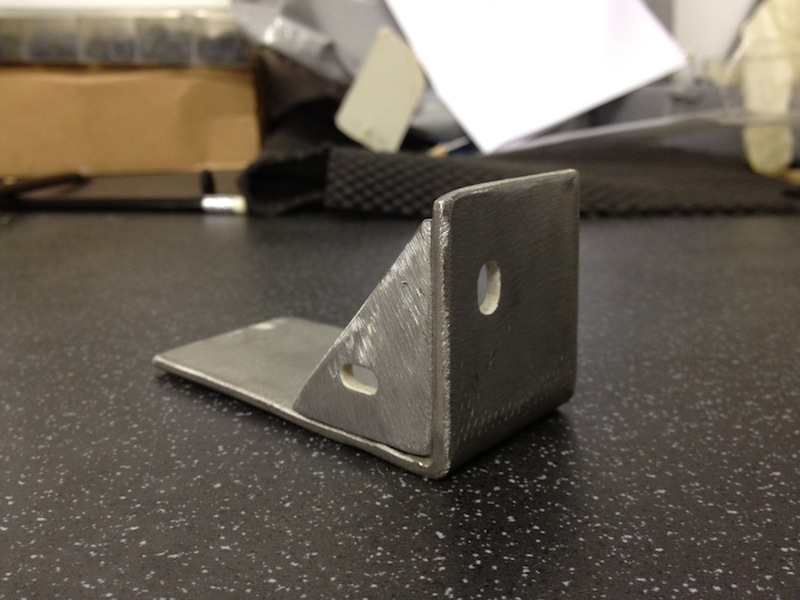

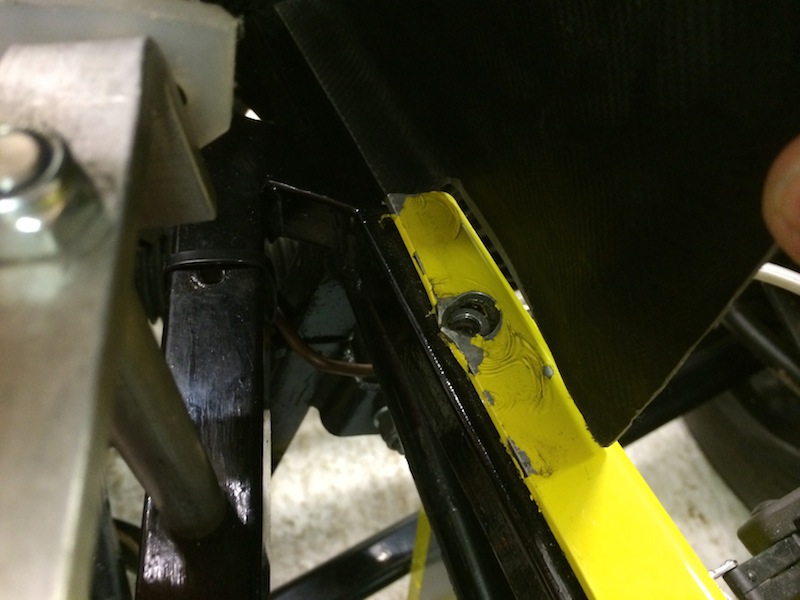

So today I went about removing, analysing, criticising, saving weight, making, and refitting...

Todays victim, the bodgery that was the header tank 'bracket'

Closer inspection, saw three spacers, different bolts, mis-fitting coach bolts, mix & match washers, cable ties, and a sloppy fitting header

tank

Parts weighing 623grams

New part, turned down aluminium bar, with threads, with a bent 'T' section for header tank fittings

Nuts on top for easy removal

Will drop through the box section in the original places

Weighing in at 146grams

Fitted

Looking forward to the winter to continue stripping down, cleaning, and refitting

yellowcab - 20/4/12 at 08:22 AM

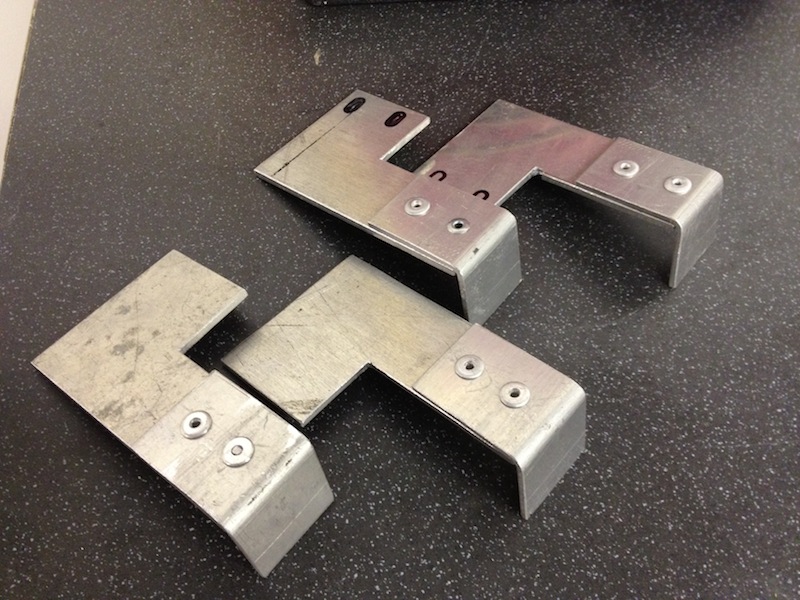

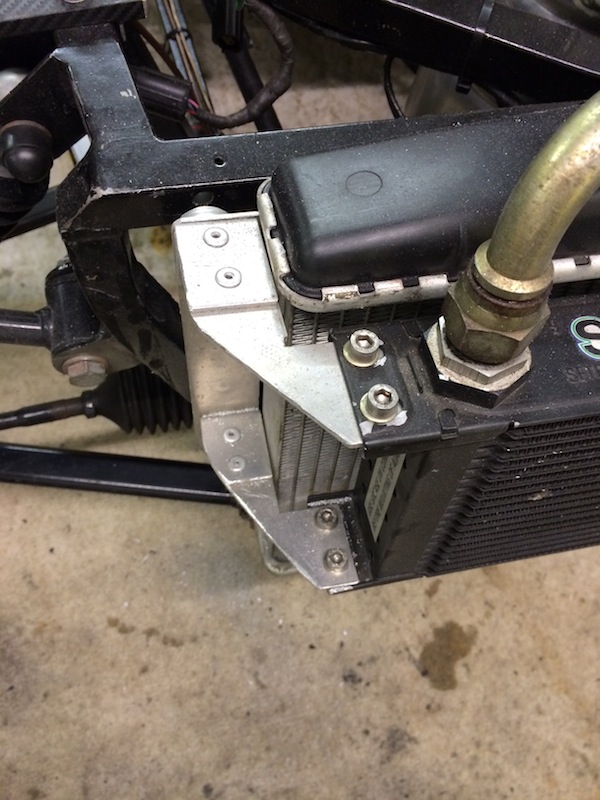

So whilst I was replacing the header tank bracket for a nicer looking and lighter version, I noticed these more weight saving to be had...

Rather large section of 4mm walled box section alloy, simply spacing the radiator from the from the front of the car

Overkill much, considering they're only being bodged on by one bolt at the top anyway

I still can't wait for winter to strip it all down and refurbish the chassis itself

999grams, you what, a kilo... I don't think so

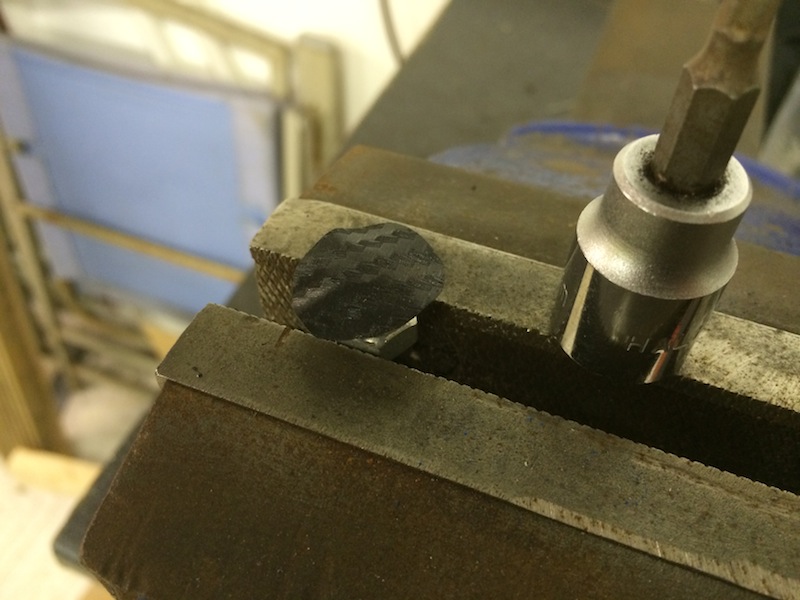

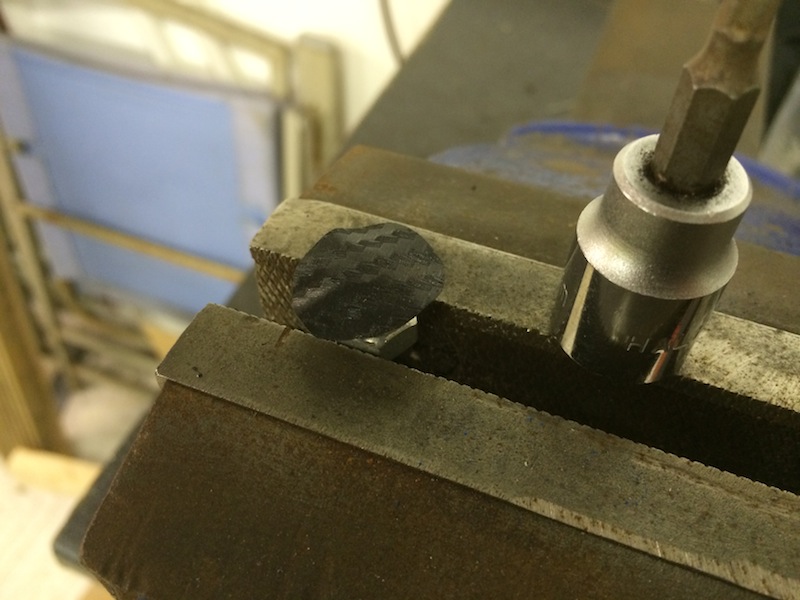

Get solid alloy tube, clean up face

Drill centre hole

Tap an M8 thread in either end

Turn them down so they look nice

141grams... win win

[Edited on 20/4/12 by yellowcab]

[Edited on 20/4/12 by yellowcab]

sdh2903 - 20/4/12 at 08:57 AM

Nice work.

Must admit bodges like that really annoy me, why go the expense of a busa engine at £0000's then fit the header tank like that!

yellowcab - 20/4/12 at 04:19 PM

I have to agree with you too... where I understand these cars are 'Lo-Cost' there is a limit...

It costs nothing to make things look nice (imo of course)

Benzo - 20/4/12 at 07:13 PM

High Mate,

You must be KeithRobinsons Mate, he was telling me and showing me pictures of your motor a few weeks ago!

Hope you are enjoying it, i miss my Busa!

yellowcab - 20/4/12 at 07:24 PM

Hello bud, that's right, I'm the little irish fellas mate  )

)

It's really enjoyable, looking forward to getting some track days booked!!!

T66 - 20/4/12 at 07:27 PM

Some nice mods going on there, keep posting the pictures. My little Fiat came from Earl Shilton

yellowcab - 20/4/12 at 07:33 PM

Thanks for the comments, the mods aren't anything spectacular or unique, just tatting whilst the weather is rubbish!

I tend to look around the car, see what can be lightened, improved, or removed lol

Even if I knock of the best part of a kilo each time, if I do that 10 times, then happy days!

sebastiaan - 20/4/12 at 07:37 PM

It seems quite a lot of stuff is bolted straight through the chassis box section. Once you get round to stripping her down for a chassis refurb,

it'll be a good idea to weld crush tubes into these holes so you can properly do up the bolts without crushing the chassis members.

Nice work by the way!

ReMan - 20/4/12 at 08:18 PM

quote:

Originally posted by Pat_T

quote:

Originally posted by yellowcab

not had any problems as yet - but will be investing in an acusump system certainly lol

here is a quick shot i took when i had run out of fuel again lol

Description

is that near the Earl Shilton traffic lights? If so I ran out of the fuel there a couple of weeks ago too!

(I'm in Hinckley too, have been following the thread with interest, have a 2.0 C20XE Redtop powered Stuart Taylor  )

)

Nice Pic

And Pat I only spoke to the previous owner of your car today who mentioned it was still local

yellowcab - 20/4/12 at 08:36 PM

eh up bumpkin, you off your jollies now then?

Benzo - 20/4/12 at 10:04 PM

quote:

Originally posted by yellowcab

Hello bud, that's right, I'm the little irish fellas mate  )

)

It's really enjoyable, looking forward to getting some track days booked!!!

he's a mini gangster that boy.. bloody nova blew me off the road last summer, i had no idea that little thing was so sharp! he hasnt got his

balls from the freezer yet and put it on the track tho

yellowcab - 23/4/12 at 12:40 AM

So this weekends rain didn't stop me tinkering lol despite getting wet several times...

So I say to the misses "just going to work on the car", "its pouring with rain" she replied... ermmmm

Hope she doesn't realise... No longer a taxi - can I change my name on here? de-taxi-stickered...

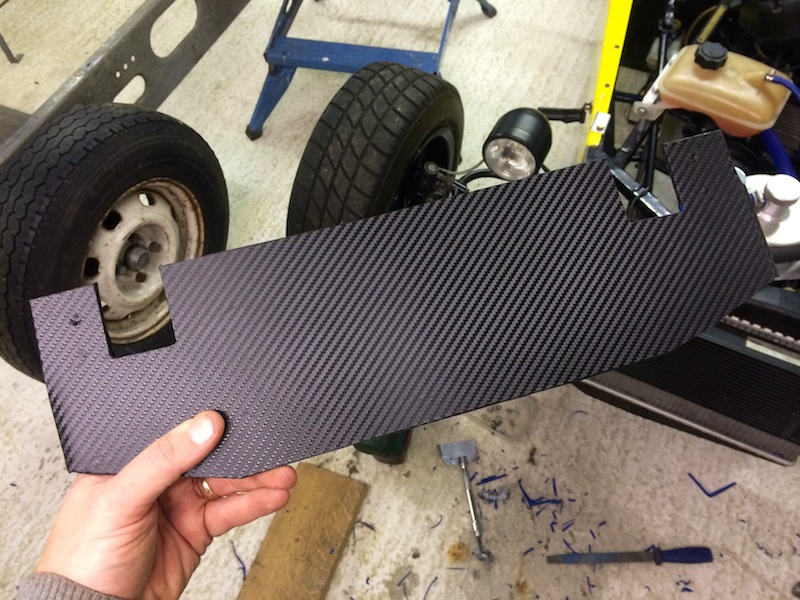

This bar that does nothing, other than hold the headlights...

Steel?! How heavy?!

1.1kg eek

Exact aluminium replacement, less than half the weight...

No need for the bit in the middle crossing the bay, nothing gets mounted on it, ditch it...

Thats better!

Now to tart them up a little, as silver doesn't "go" with the car...

3M Dinoc Carbon Wrap...

Refitted, another 909grams lighter... almost another kilo off...

yellowcab - 23/4/12 at 12:49 AM

Saving between the headlight stays, header tank bracket and the radiator mounts is already 2.315kg, not a great deal, but every little helps...

Next up is the copious amounts of spacers to bring the steering wheel out far enough so it's comfortable, and also the rear panel behind the

seats (unsure of 'proper' name for it)

This is the current setup on the car for the steering wheel to the the correct distance away that suits...

From bottom to top... standard sierra 'hub', with a sparco boss, with an OMP adjustable spacer, bolted to another OMP fixed spacer, bolted

to another OMP fixed mini spacer...

In total there are 28 bolts, 6 washers and 3 nuts... not happy with the amount of weight, joins, and possible failures... so making a completely

custom shaft from a 3" diameter x 7" long solid aluminium cylinder.

yellowcab - 23/4/12 at 01:06 AM

This is the progress so far, comments and suggestions welcome as always...

Current setup complete weighs 2.485kg

However, weigh is very much secondary in this process, first and foremost is safety, less joins, less possibly failures, secondary is aesthetics to be

honest, as I very much disliked the first version, and third would be weight

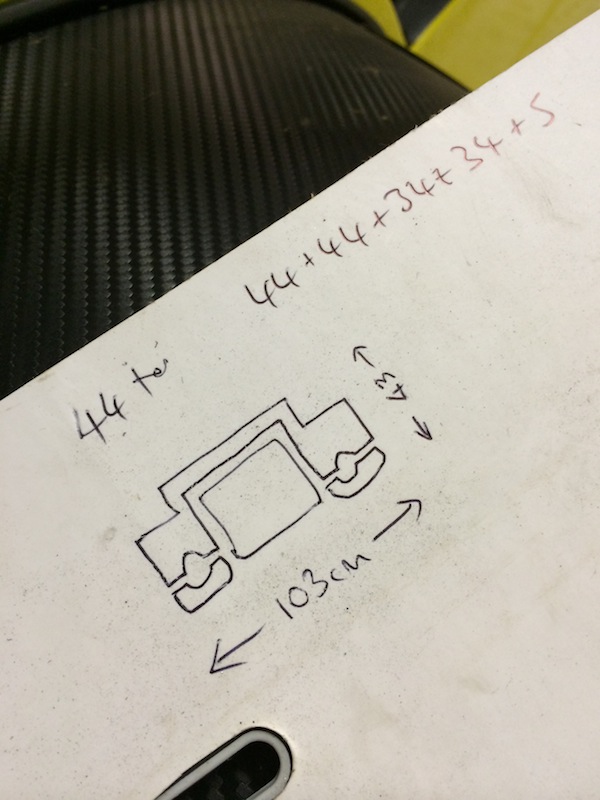

A good friend had a faff around on AutoCAD for me... so we knew exactly what we needed to make

Standard manky off the shelf Ford Sierra cast alloy boss, very out of true, not symmetrical, typical production line finish

First we wanted to be sure that what we were mating our new adapter to was true, clean and turned symmetrically... so on the lathe it went...

First up the outer face was so far out that had we have mounted our new adapter to it - the wheel would have dramatically moved (and has been doing)

as it was rotating

The centre bore where the 22mm bolt fastens was particularly chewed up, so we cleaned that up whilst we were there, to ensure a nice surface to

tighten to

All done

Very happy with the results, especially considering it's all seen too, so we made it look nice considering we could...

From a standard off the shelf Ford item, which was incredibly 'out' to something that is 100% true, symmetrical, bespoke and made for

purpose...

The end results, purely for interest, the original item was 0.571kg, the end result is 0.409kg...

The CAD drawing is below for those remotely interested... after all, thats what these forums are for, right? learning from each other... the adapter

will be hollow with a centre bore of 32mm, which gives enough room for the external diameter of the 22mm securing bolt (ext dia = 30mm).

The two ends are solid alloy 25mm x 3inch diameter to make the securing bolts blind (the bolts being from the steering wheel to the adapter (left had

side) and from the steering adapter to the above Ford Sierra hub, therefore they do not poke through the alloy end caps.

The centre tube will be turned down to 2inch diameter, with a 5mm wall, with 9x half inch holes drilled through for ease of getting the steering wheel

& adapter off again for future use of being able to put a bar through, and a wee bit of weight saving maybe

[Edited on 23/4/12 by yellowcab]

ReMan - 23/4/12 at 07:14 AM

Nice work.

You do realise that the headlight bar is structural on the bendy MK chassis dont you?

Seriously, did you get those to mount stiff enough to prevent the lights bouncing?

yellowcab - 23/4/12 at 08:50 AM

Well they're done up FT, and there is no movement upon physical persuasion by one.

However, when I pull up outside your house with no headlights, take the answer as no lol

yellowcab - 23/4/12 at 06:50 PM

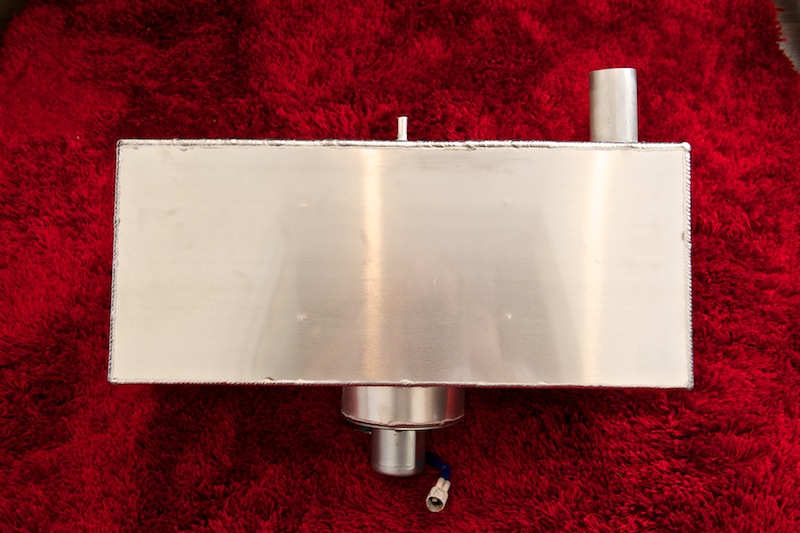

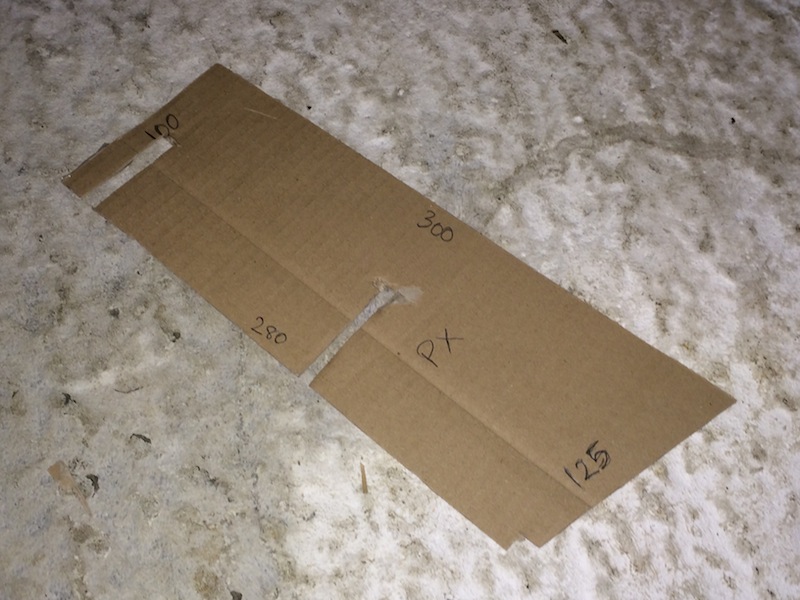

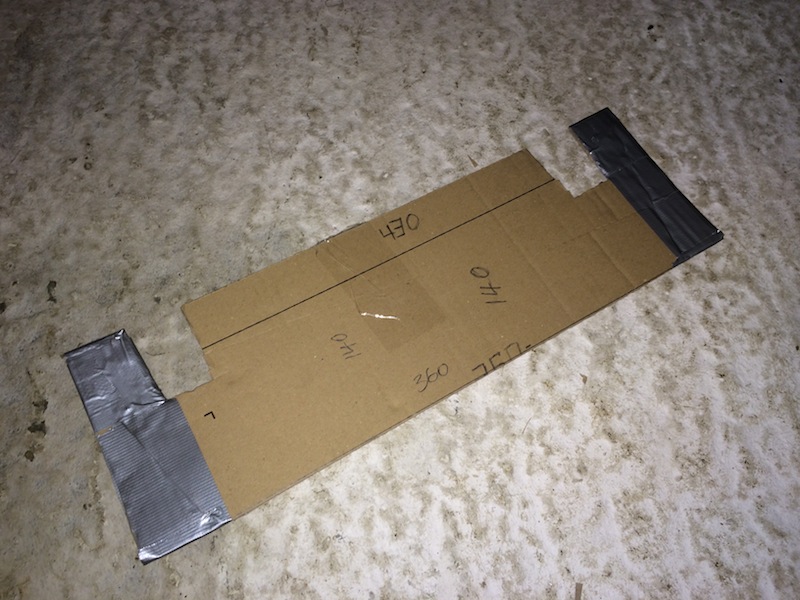

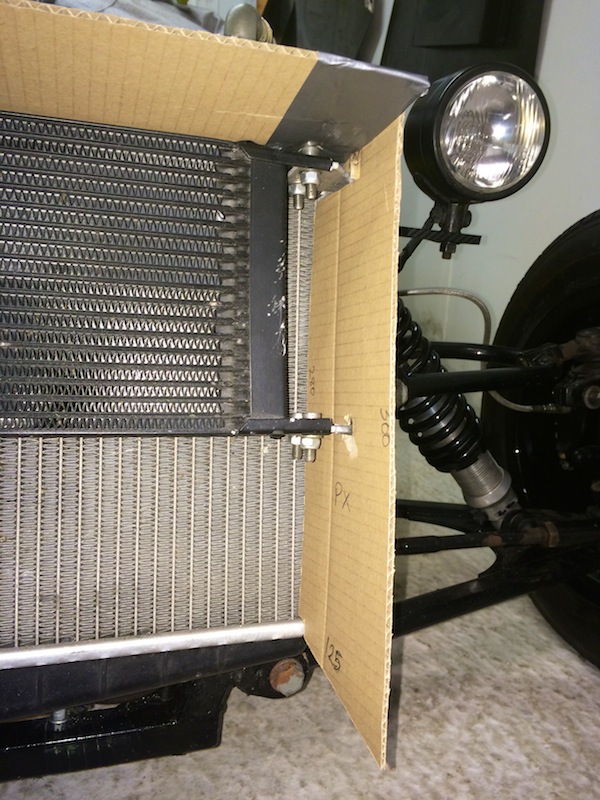

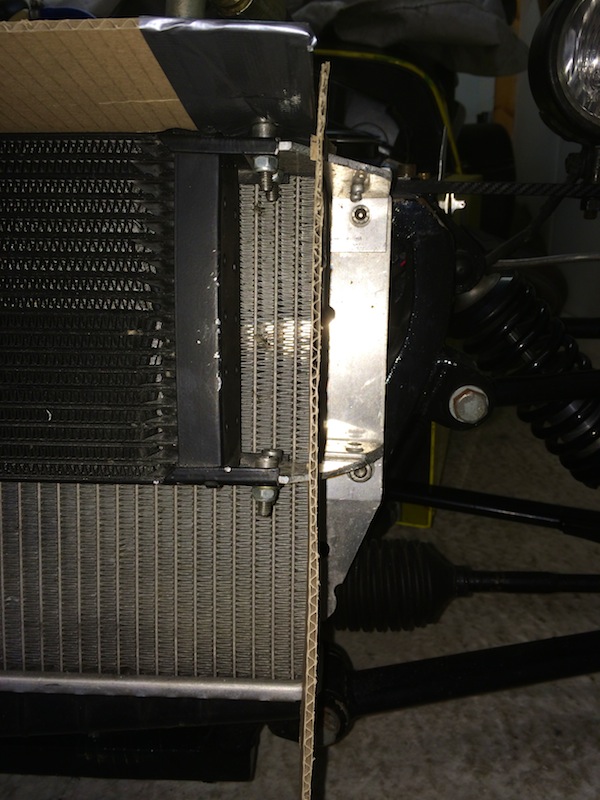

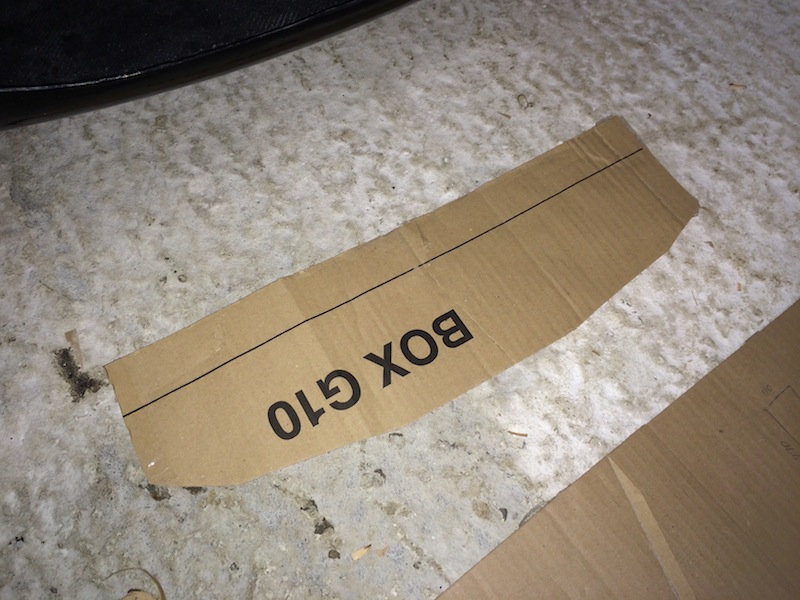

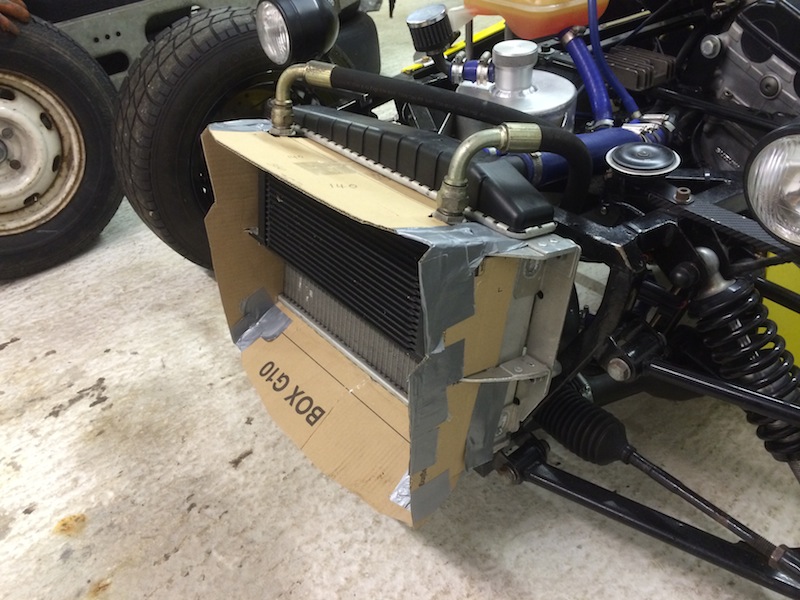

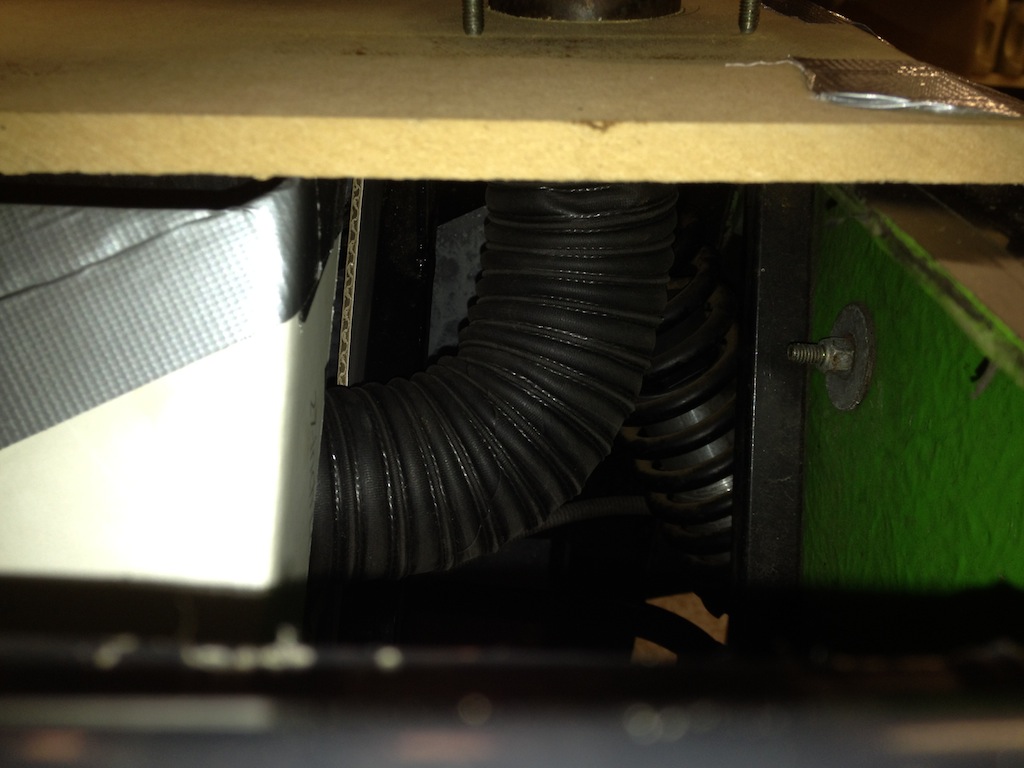

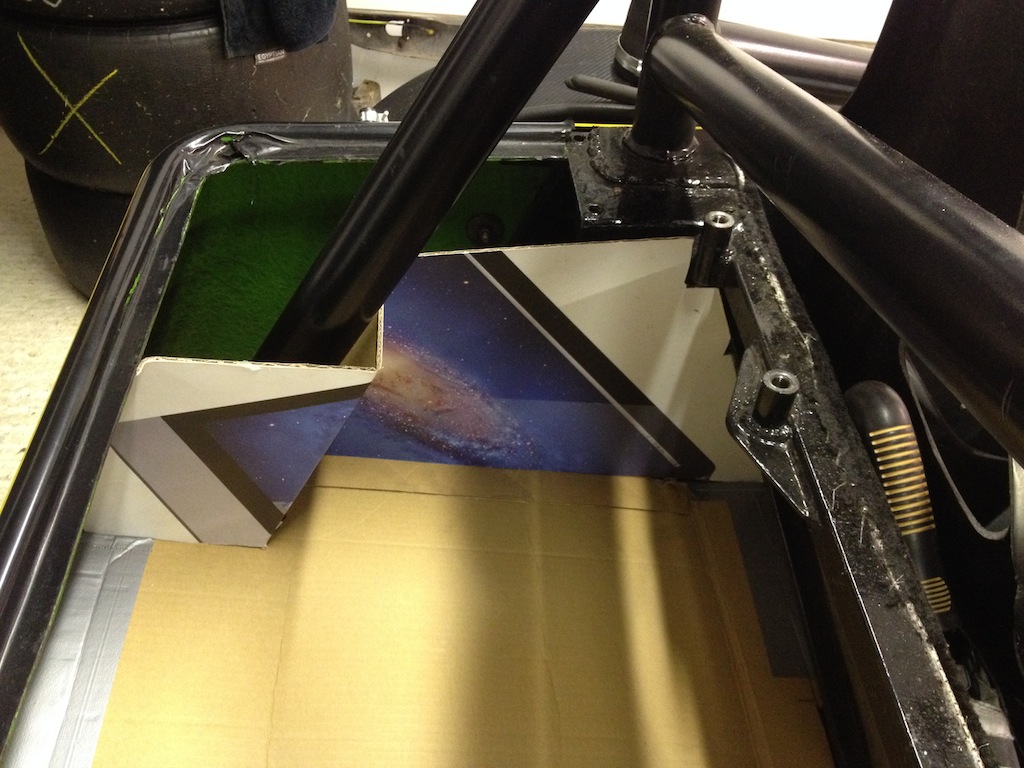

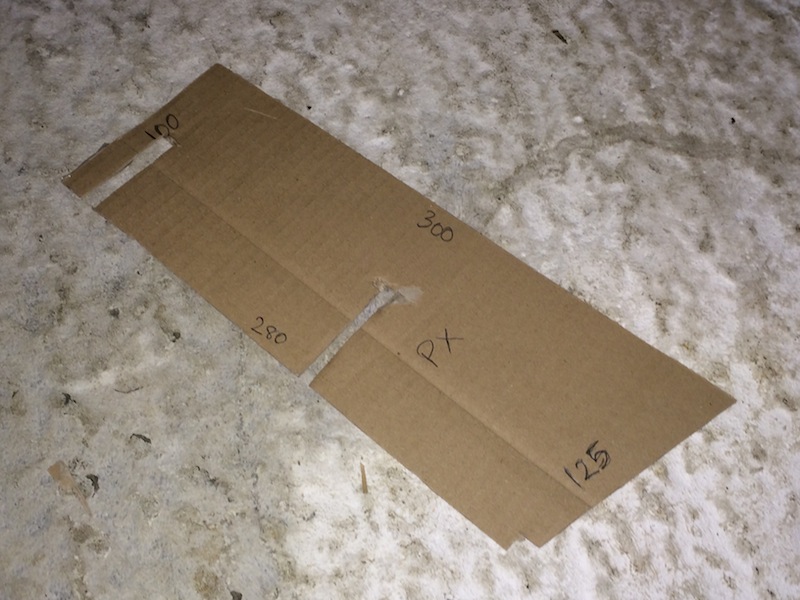

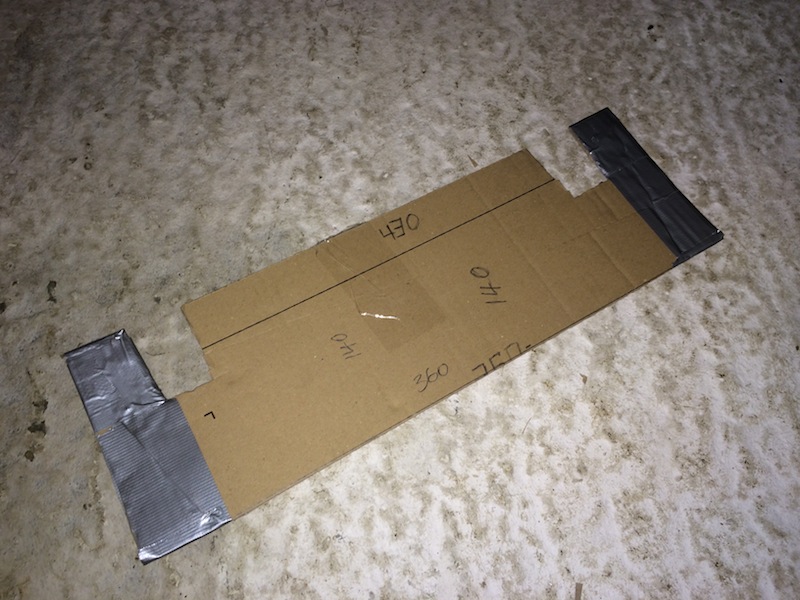

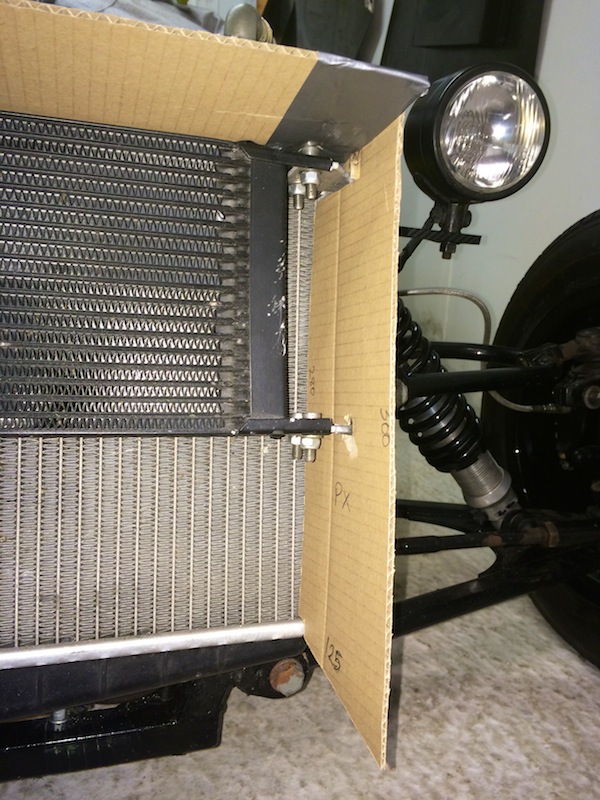

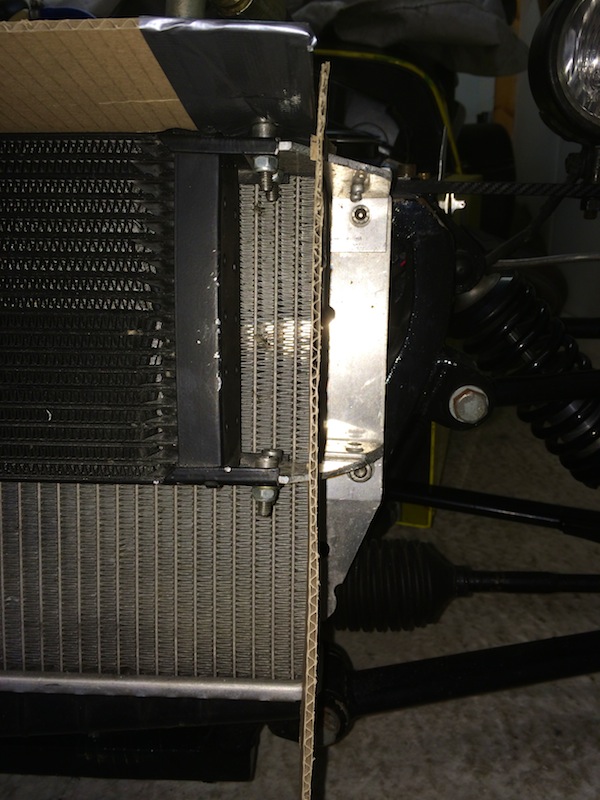

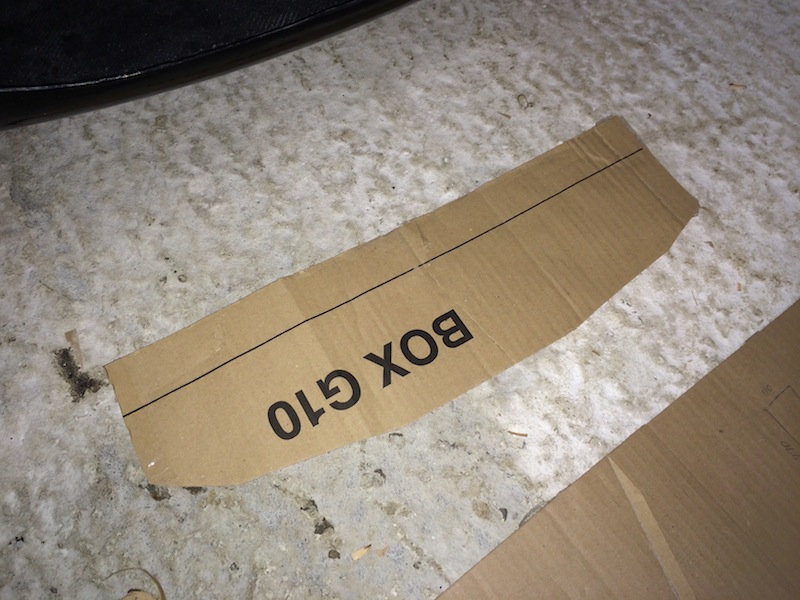

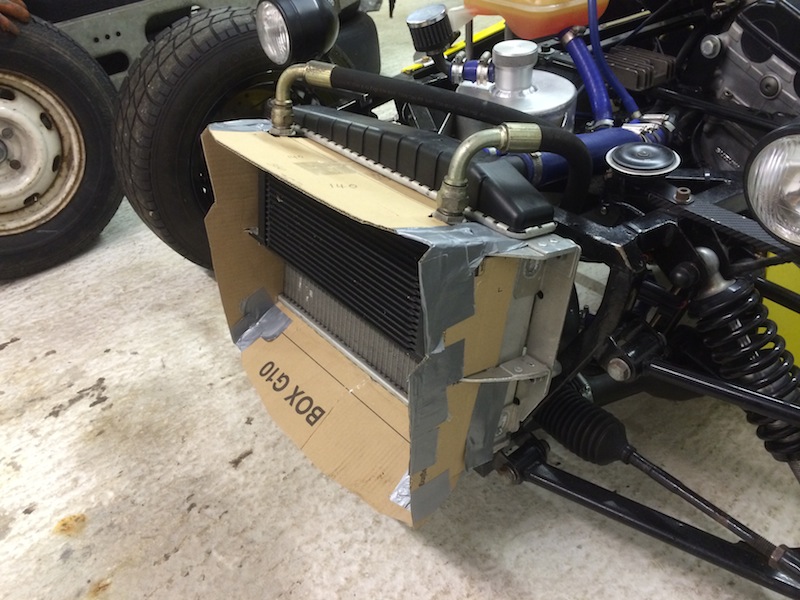

Today I tinkered and had a play around with making a MK Indy Hayabusa Airbox to quieten down the induction noise...

Boshed together some cardboard for a very rough shape

Plonked it on to see what it'd look like, and how it'd fit

Fits but marginally too high (even with bonnet scoop) and is also too long front to back, needs trimming by 55mm

Can see the height problem, but I thought the scoop would accommodate this - it doesn't lol

So I made a MK2, which is smaller in length front to back, and height... here is a photo with the bonnet on, it clears by 11mm all-round

A directed cut from the front of the car with the nose cone removed so I can see the clearance

Front end with air box template on

Funky photo just because I like the Kawasaki green inside

yellowcab - 23/4/12 at 06:52 PM

Also had a quick play with the steering adapter, here is the solid chunk 2.22kg of alloy

On the lathe and beginning of the turning down

This is the centre down to 50mm... which will be turned down further to 42mm, then a centre 32mm hold bored out

That is all for this evening...

SausageArm - 23/4/12 at 07:17 PM

Interesting stuff and a great car, keep the pictures coming, it's a great thread to read.

What kind of lathe do you have?

[Edited on 23/4/12 by SausageArm]

yellowcab - 23/4/12 at 07:28 PM

It's my neighbour doing the lathing but he has a Myford Super, if that means anything to you lol...

I was just about to knock this thread on the head and delete it, as there doesn't seem to be any traffic or interest

wylliezx9r - 23/4/12 at 07:39 PM

I find it interesting too. Don't delete ! LOL

Proby - 23/4/12 at 07:47 PM

Don't knock it on the head! I have been reading, great pic and an interesting read. Keep it up! (and ow, I'll try to put a few extra

comments on)

ReMan - 23/4/12 at 08:00 PM

Is the lathe in his bedroom?

I can see wallpaper behind it

yellowcab - 23/4/12 at 08:04 PM

Cheers chaps, the lack of comments sometimes makes me uneasy, as I don't really have much experience with MK Indy's nor Hayabusa engines,

infact, it's my first one so I hope someone would pipe up and comment if i was doing something incredibly wrong, or hadn't thought about

something!

I like the interaction of a forum as that's what it's all about :-)

Colin, yes, it's in his front bedroom sat next to his milling machine lol

[Edited on 23/4/12 by yellowcab]

wylliezx9r - 23/4/12 at 08:16 PM

Have you tested the car with the front and rear diffusers yet ? I'm very interested in this as my car with it's little zx9r seems to be

hitting a brick wall @ around 100mph, I think the backend is acting like a parachute. I imagine it will be beneficial to have a flat as floor as

posissble.....It's good enough for F1 cars afterall

yellowcab - 23/4/12 at 08:21 PM

The rear diffuser has made a major improvement, not only 110mph+ but the stability...

The rear clam acting as a parachute not only slows you down, but it would lift your rear end up causing loss of traction with the slightest blip in

the road... Therefore it feels so much more planted at high speeds and feels much more sucked to the road...

Speak to Steve @ SA Fabrication he'll knock you one up no problems

ReMan - 23/4/12 at 08:23 PM

4200 Views is pretty good I'd have said?

Keep it up

yellowcab - 23/4/12 at 08:24 PM

Sorry, only answered half your question...

The front aero splitter hasn't been fitted yet I am in the process of making the scoop to accommodate the sump that hangs below the rest of the

car...

Which reminds me, I must get back onto that... Don't want to stray onto any more projects, cheers for the reminder :-)

yellowcab - 23/4/12 at 08:25 PM

4135 of those is probably me updating lol

Pat_T - 23/4/12 at 09:46 PM

I'm still reading too! Nice work with the vinyl, i've been wrapping my entire car the last few days, i'll get some pics up soon!

sdh2903 - 23/4/12 at 10:00 PM

Milling machine and lathe in a bedroom. Certainly beats working in a cold garage!

Is he single by any chance? either that or a very understanding partner

either that or a very understanding partner

yellowcab - 24/4/12 at 07:22 PM

Only a small update on the steering adapter, my neighbour turned down the centre section slightly more, but the heat in generates is vast, so had to

keep taking small bits off bit by bit... so anyone want a dumbbell? lol its getting there slowly

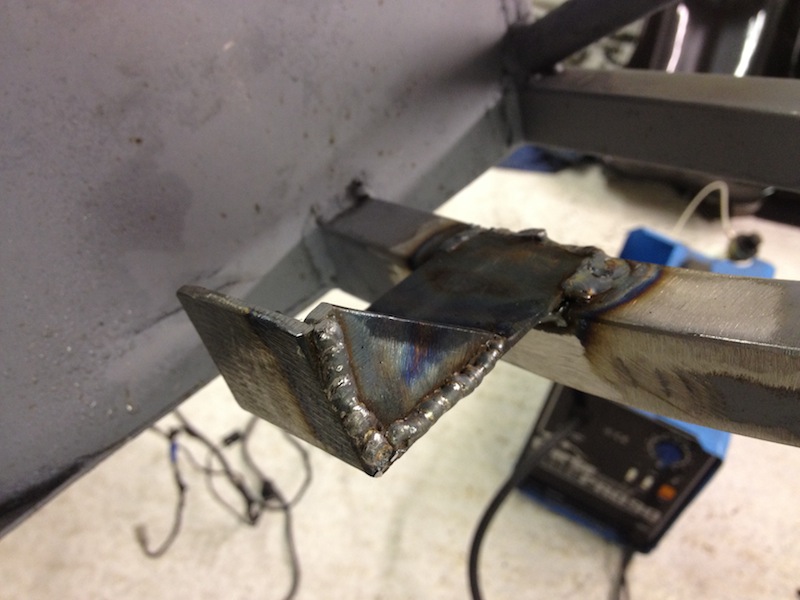

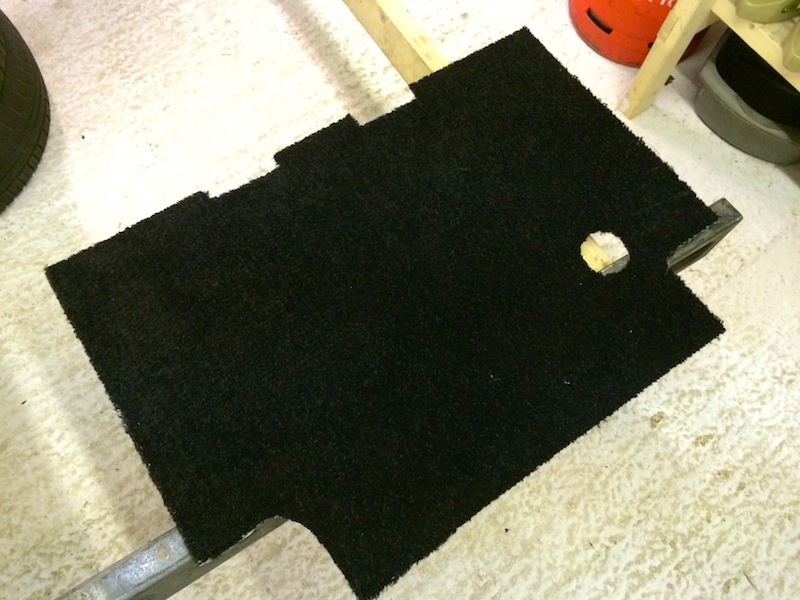

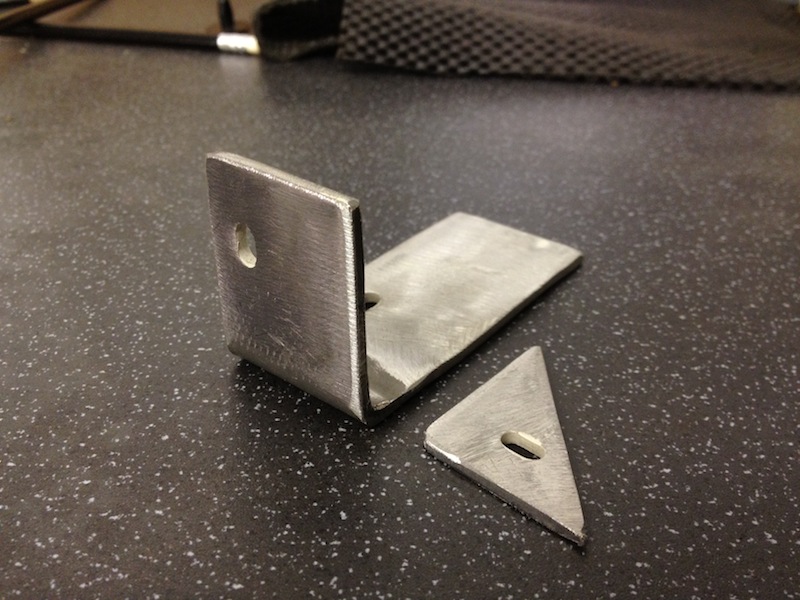

Thanks to the reminder from wylliezx9r, we cracked on with making the 'scoop' for the front aero splitter/ engine bay skid tray

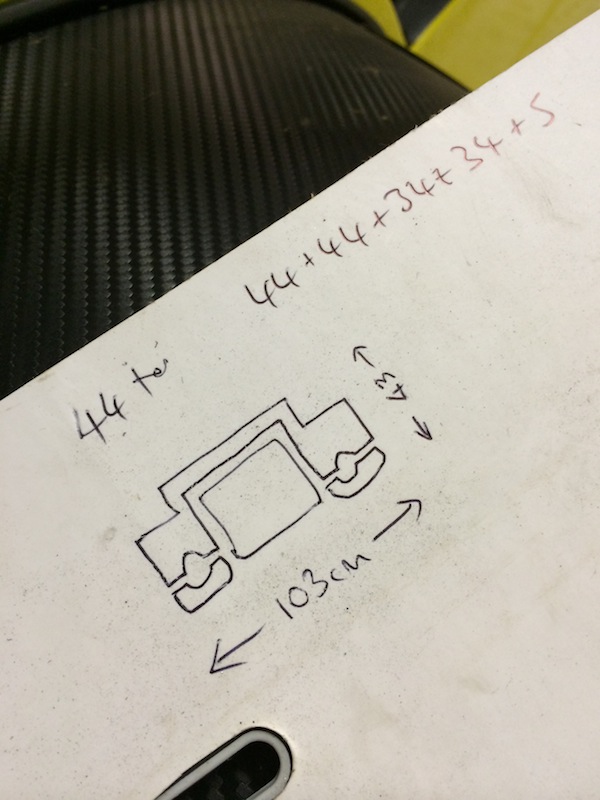

Took some detailed measurements and worked out all the angles that were needed, cuts and folds

So you generally bend from the outside in, remembering which way to go, 25mm up, which will be rivnutted on, then 50mm down (the depth of the sump

hanging down)

Leaving a 135degree bend down to meet the existing metal

Nicely butted up

This is the scoop that will be facing backwards to let hot air escape

All done, was going to weld the angle, but there is absolutely no point, so not doing so

Rested ontop of the splitter, I will use rivnuts for this section, so I can get to the oil filter and sump plug without dropping the whole splitter

How it will look once on the car

welderman - 25/4/12 at 07:57 AM

Keep up the good work, great reading

[Edited on 25/4/12 by welderman]

wylliezx9r - 25/4/12 at 09:05 AM

Nice bit of folding on that sump cover fair play !

yellowcab - 25/4/12 at 10:06 AM

Hey thanks for the kick up the backside, it wouldn't have got done without your reminder!

Today the weather is crap, so it's a turning day, steering adapter progress day!

yellowcab - 25/4/12 at 05:19 PM

So due to the shocking weather, and no garage yet - a very much 'indoor' day today - so efforts turned to turning (see what i did there

lol)

Rough cut the steering spacers, down to the correct 45mm OD centre bore...

Final geared cut to create the nice smooth shine, before emerying for polish

Radius cut into steering wheel end for decorative purposes only

Photo of said lathe for those interested...

2 of the three plastic bags full so far...

Centre bore drilled to half inch, then turned out to 32mm to cater for the OD of a 22mm socket, which is 30mm

Thats it for today folks

DavidW - 25/4/12 at 07:56 PM

Great thread, please keep updating!

David

chris_harris_ - 25/4/12 at 08:18 PM

This is great reading. Keep up the good work, and inspiration for the rest of us!

yellowcab - 26/4/12 at 03:42 PM

Continued crappy British weather and no garage leaves me with still slow moving 'indoor' work...

Had the air box drawn up in AutoCAD so I have precise measurements and angles to work to, this box is 5.5litres of air, I know the standard Busa box

is around 8.5litres, but considering I've seen highly tuned race cars run off the Pipercross PX-600 airboxes which are less than 3litres,

I'm happy with the design and size...

This is the box, you will notice that the leading edge is going to be left open altogether, or boxed off with a slot cut into it to marry ups with my

bonnet vent, after all, the sole reason for the box is to reduce induction noise...

Slow work but I'm happy with how its taking shape... final polish on the lathe to be done once the holes are drilled and tapped

A far cry from the original 2.2kg chunk lol

12x half inch, or 3/4 inch holes will be drilled in it to aid removal in the future

Mike insisted on smooth boring the inside despite it not being seen lol

yellowcab - 27/4/12 at 11:53 AM

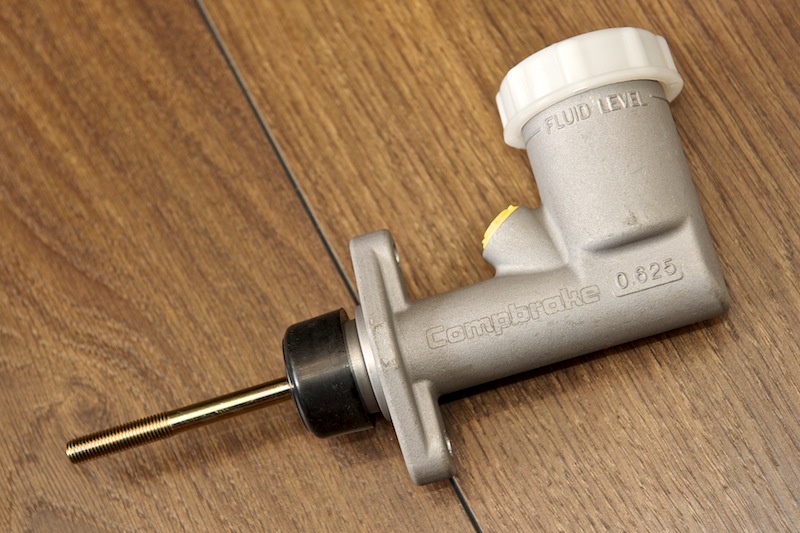

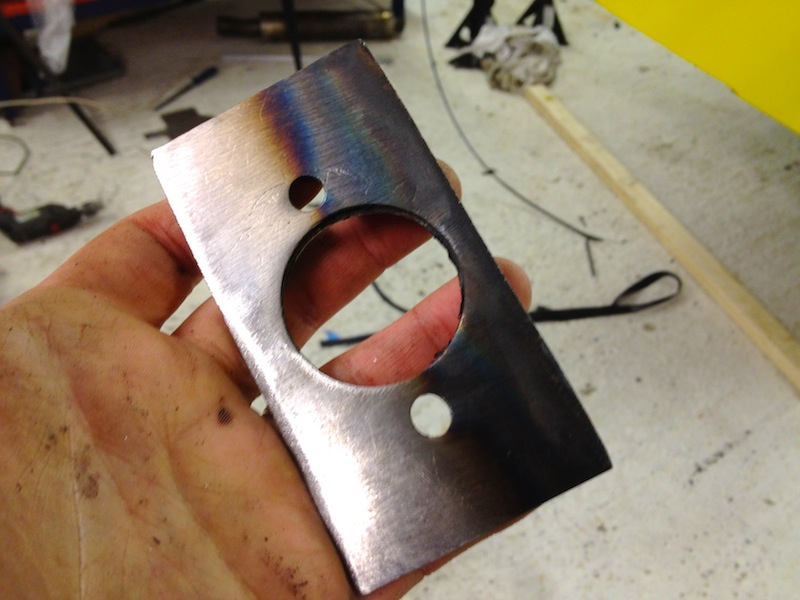

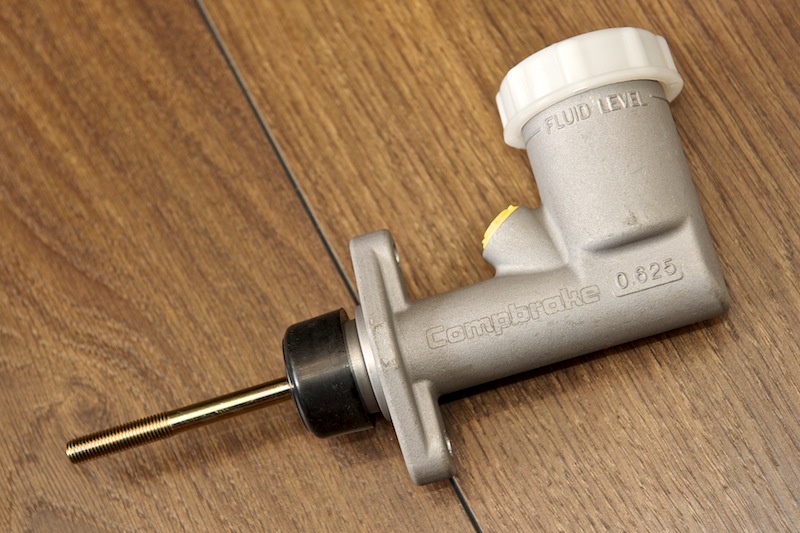

Cant see where to post about Brakes... doesn't seem to fall into any particular category - so I will ask the readers of my thread instead

lol...

Will brakes that have been removed from an MK Indy with Cortina uprights, fit straight onto my Sierra uprights? or will I have to make some new alloy

callipers brackets/ spacers?

yellowcab - 27/4/12 at 05:55 PM

Long awaited and slow progress but well worth it, we have a finished custom article, yay!

Decided we didn't like the 'bolted on' look from the steering spacer to the Sierra hub, so we turned out the diameter so the spacer

would sit snug 'inside' the Sierra hub

Like so... looks like one unit

Two finished bits

We drilled and tapped 6 holes in the conventional holes if ever I change steering wheels

Total setup, with all bolts 1.673kgs, down from the original 2.485kg, thus saving 812grams, best part of a kilo, but please remember the weight was

secondary, and we could have made it with a thinner side wall, but at the end of the day, its steering the damn bathtub! So safety comes first!

Finished look, off the car - because its pissing down again lol

[Edited on 27/4/12 by yellowcab]

afj - 27/4/12 at 06:55 PM

Spot on looks

SeaBass - 27/4/12 at 07:53 PM

Very tidy... I'm reading this thread too.

ReMan - 27/4/12 at 08:22 PM

quote:

Originally posted by yellowcab

Cant see where to post about Brakes... doesn't seem to fall into any particular category - so I will ask the readers of my thread instead

lol...

Will brakes that have been removed from an MK Indy with Cortina uprights, fit straight onto my Sierra uprights? or will I have to make some new alloy

callipers brackets/ spacers?

Are you sure it's an Indy with Cortina hubs?

Either way, not a straight swap, but why would you want to?

yellowcab - 27/4/12 at 08:30 PM

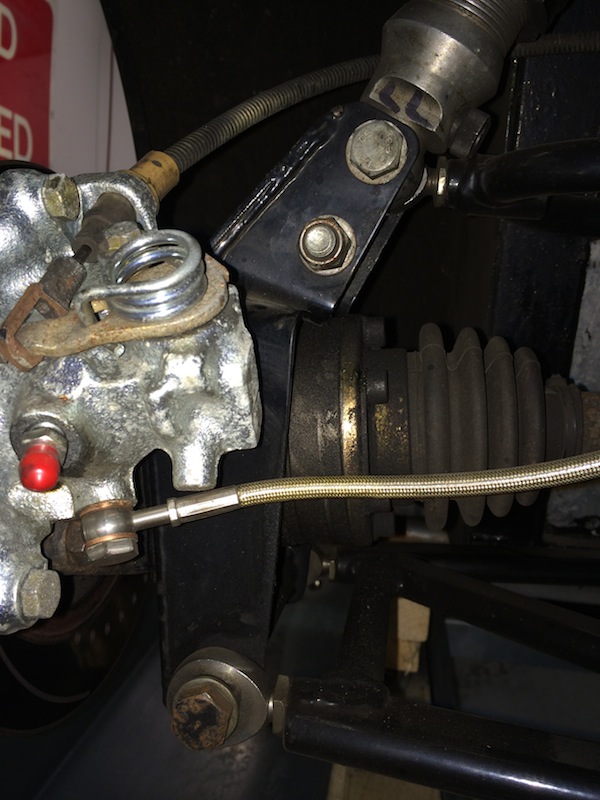

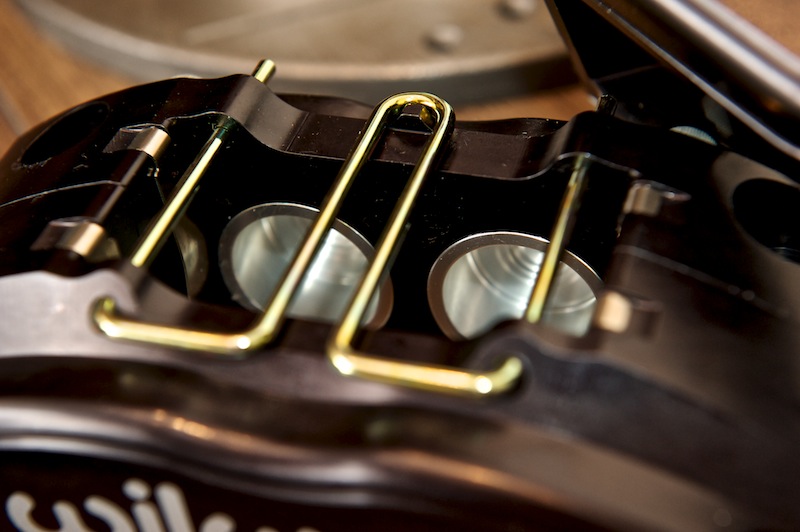

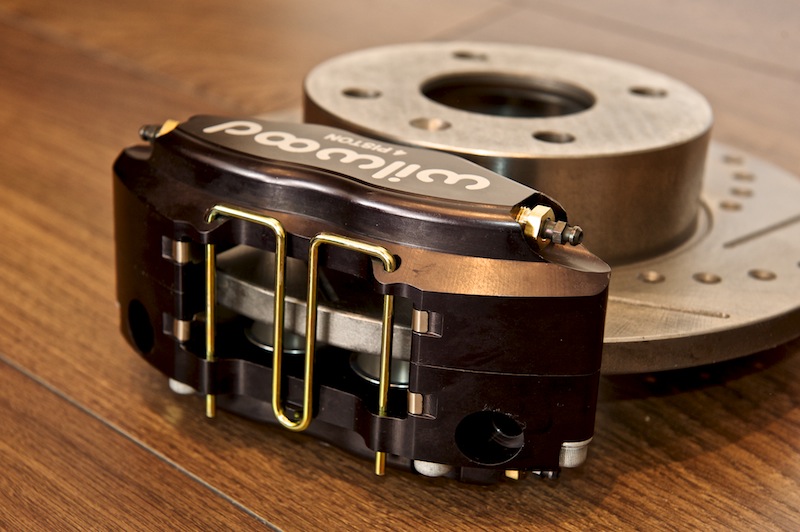

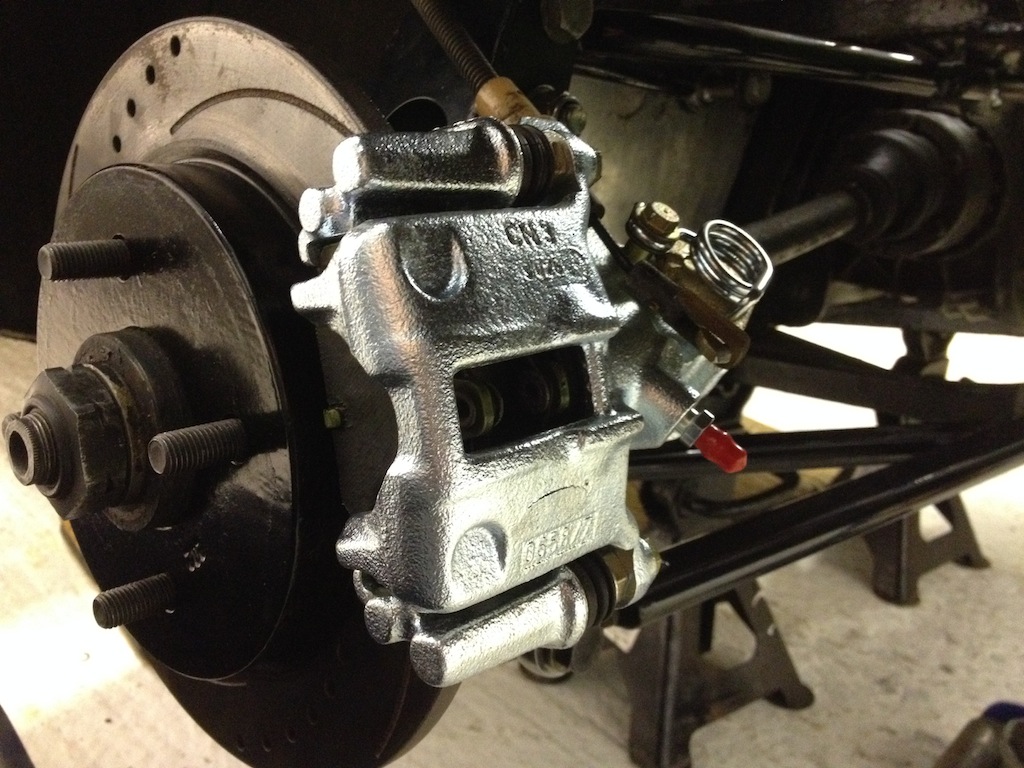

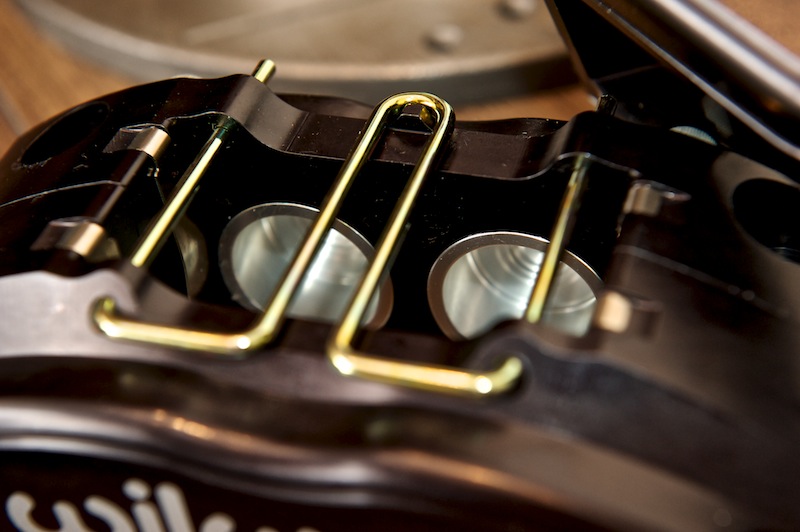

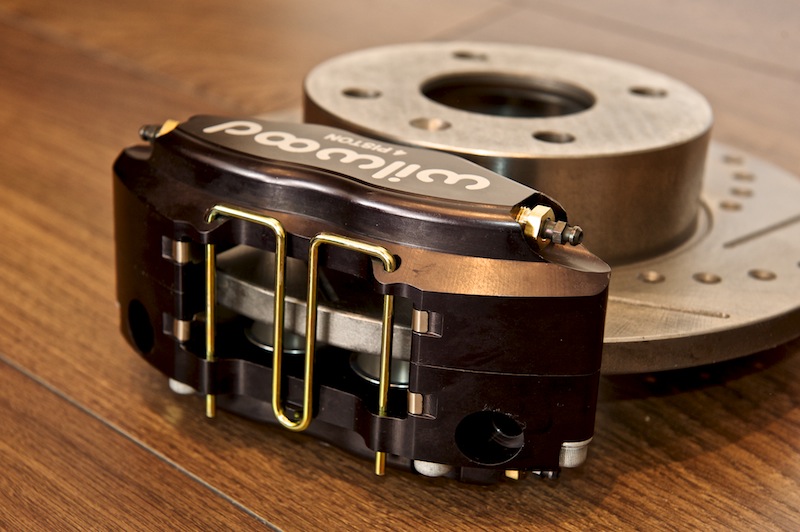

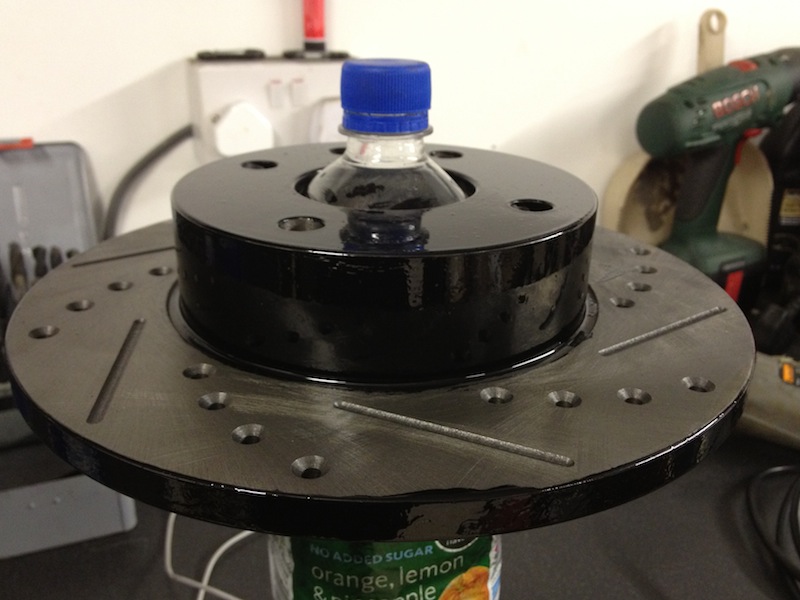

They're Wilwood 4-pot calipers, 245mm drilled & vented disks and Mintex 1144 that have been removed from Jon Ison's MK Indy with Busa (I

think it's an Indy?)

Going new brakes for unsprung weight advantage of alloy calipers, will make up some new brackets then, just wasn't sure of the holes will be in

the correct place... :-)

ReMan - 27/4/12 at 08:49 PM

Right, that's different

Std cCortina calipers would have been debatable

yellowcab - 27/4/12 at 08:52 PM

and now? lol

will they fit you reckon?

Jon Ison - 27/4/12 at 08:53 PM

Jon here, no it's a locost cortina uprights, as I said when you collected them 99.99999% sure there not a direct fit onto sierra uprights, I

would see what rally design want for a set of adaptors, the cortina ones fitted will sell.

Reading your "blog" and the desire to save weight a very small part of one og my wing stays is still on one of the callipers, remove that

and a few grams will be lost

Great to meet you btw, shame we didn't have a little more time to chew the fat, put this thread on my watch list.

[Edited on 27/4/12 by Jon Ison]

yellowcab - 27/4/12 at 09:04 PM

Hey Jon,

Thanks for dropping in... totally get you regarding fitment and I gave them a good clean up last night with IPA & brake cleaner, noticed a bit of

your wingstay is still attached lol

When I bought the at it was already really light, so looking forward to getting it back on the corner scales!

yellowcab - 27/4/12 at 10:01 PM

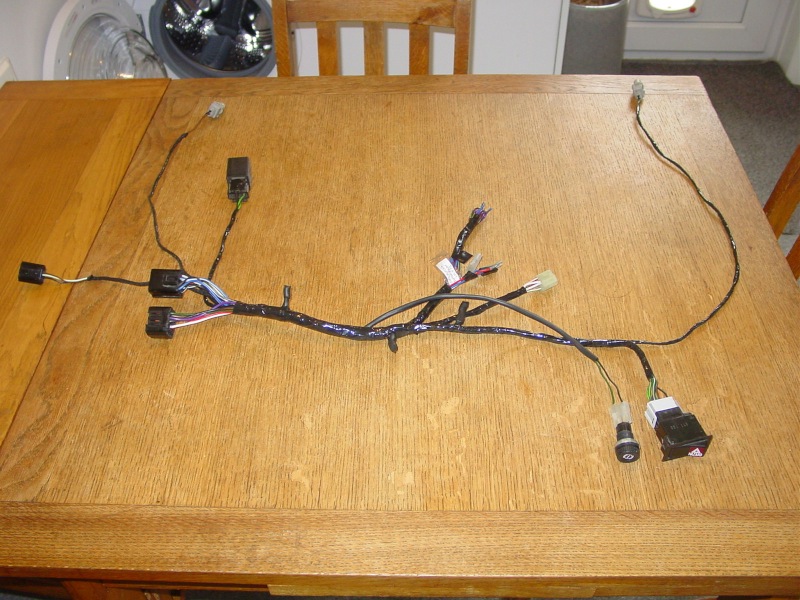

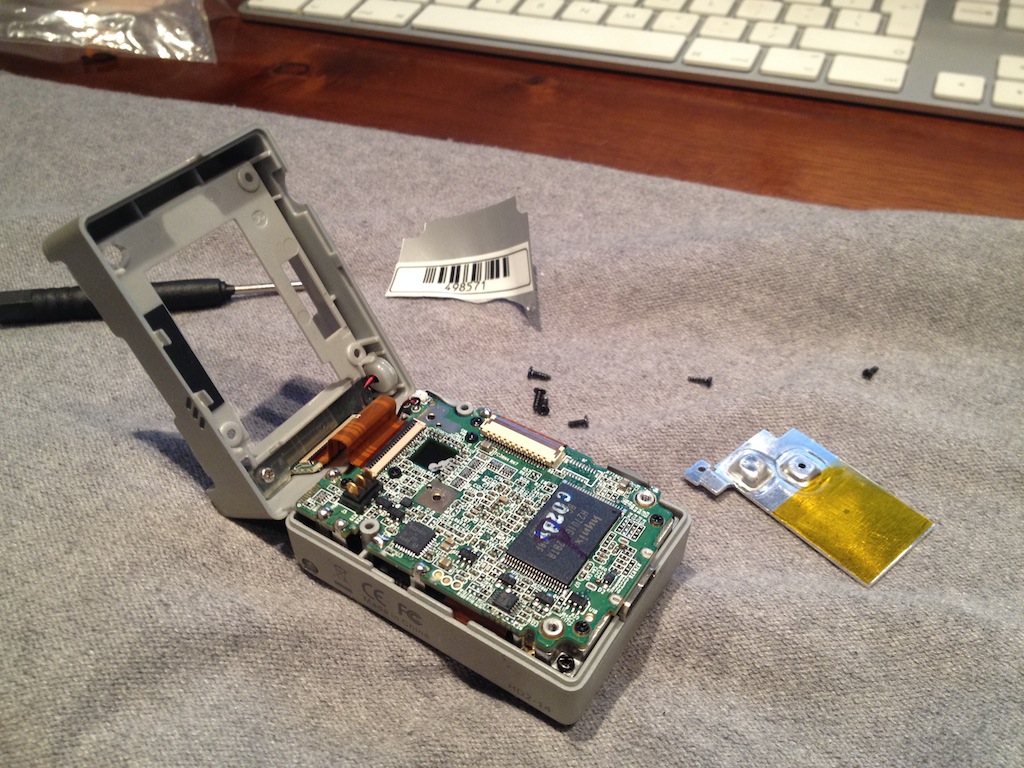

Now we're onto them, here are the pics of said brakes from Jon  Thanks again

Thanks again

yellowcab - 29/4/12 at 08:05 AM

Lack of garage took its toll last night, half way through the night it seems the car cover blew off, and I came out this morning to my MK full of

water, proper bathtub stylie...

The seats full of water, floorpan, harnesses, steering wheel soaked as it was sat in the passenger seat awaiting refitting goes without saying

everything is soaked considering its not stopped raining

Hashtagpissedoff

ReMan - 29/4/12 at 08:38 AM

Make sure you have some drain holes in the floor

It dries quicker when you jetwash the inside of the car

Otherwise the rest is remarkably durable, needs to be in this weather

yellowcab - 29/4/12 at 09:05 AM

another weight saving tip from Colin... Good shout, currently there are none, so there is about 2inches of what in my car currently

bobinspain - 29/4/12 at 10:28 AM

quote:

Originally posted by yellowcab

Cheers chaps, the lack of comments sometimes makes me uneasy, as I don't really have much experience with MK Indy's nor Hayabusa engines,

infact, it's my first one so I hope someone would pipe up and comment if i was doing something incredibly wrong, or hadn't thought about

something!

I like the interaction of a forum as that's what it's all about :-)

Colin, yes, it's in his front bedroom sat next to his milling machine lol

[Edited on 23/4/12 by yellowcab]

I've been following your thread all the way along. I haven't piped up, as although I have the same car a great deal of what you're up

to (lathe-work and talk of milling machines) reminds me of my 'engineering workshop theory and practice' O-level in 1965. Since then,

I've been a 'pen-pusher' and much of what you're up to is quite frankly, beyond me.

Keep up the good work though. Just because I've nothing to add doesn't mean I'm not interested, (not to mention lost in admiration).

Well done!

Bob.

Bob.

yellowcab - 2/5/12 at 11:32 PM

Got bored tonight so decided to pop out to take some photos...

[Edited on 2/5/12 by yellowcab]

welderman - 3/5/12 at 06:00 AM

pictures and keep up the good work.

pictures and keep up the good work.

Most weight saving thing i did was loose a stone and a half of fat !

Proby - 3/5/12 at 06:59 AM

Awesome pictures Olz, can I book some lessons please????  Your car looks great!

Your car looks great!

snippy - 3/5/12 at 08:35 AM

Looking at the 2nd photo above it looks like you`ve fitted eyelashes to your headlights!  Then I realised it`s just the circular bonnet vents in the

back ground. Have a look you`ll see what I mean

Then I realised it`s just the circular bonnet vents in the

back ground. Have a look you`ll see what I mean

[Edited on 3/5/12 by snippy]

yellowcab - 3/5/12 at 01:18 PM

haha totally see what you mean, oh it does look very feminim!

I'm up for doing a shoot on anyone's car if they're up for it...

Let's hook up and I'll show you the ropes

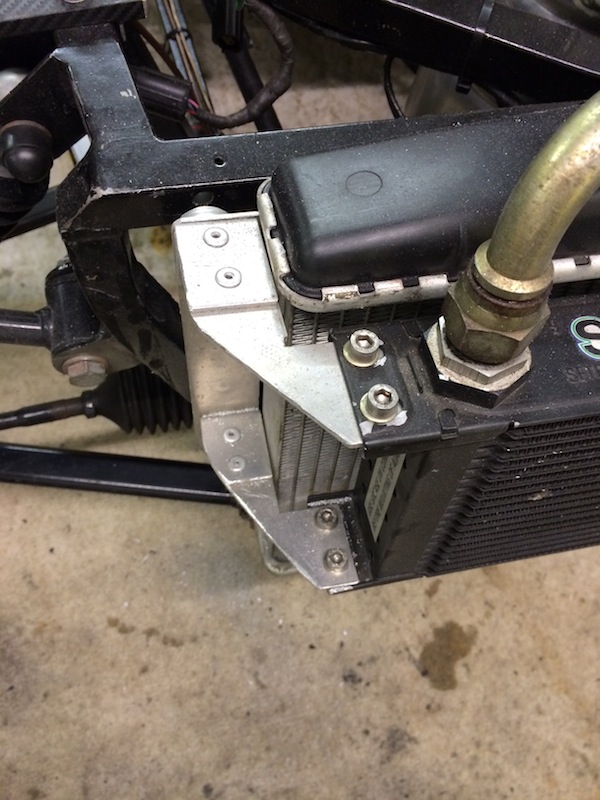

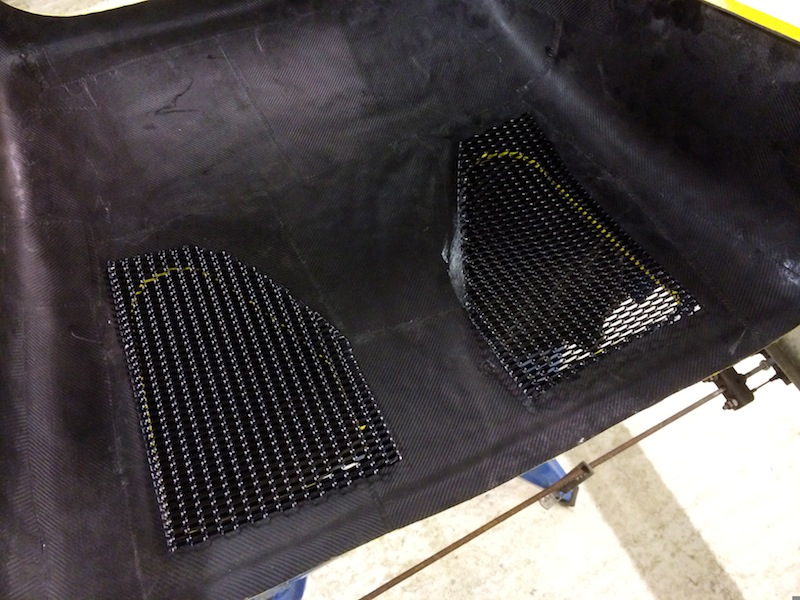

yellowcab - 4/5/12 at 07:12 PM

Firstly would like to apologise to Colin/ ReMan - I said I'd pop over today to lend a hand but I completely forgot, wasn't intentional,

intact, I was oblivious until the wife said 'are you not going over Cols anymore...' - Sorry bud! D'oh!

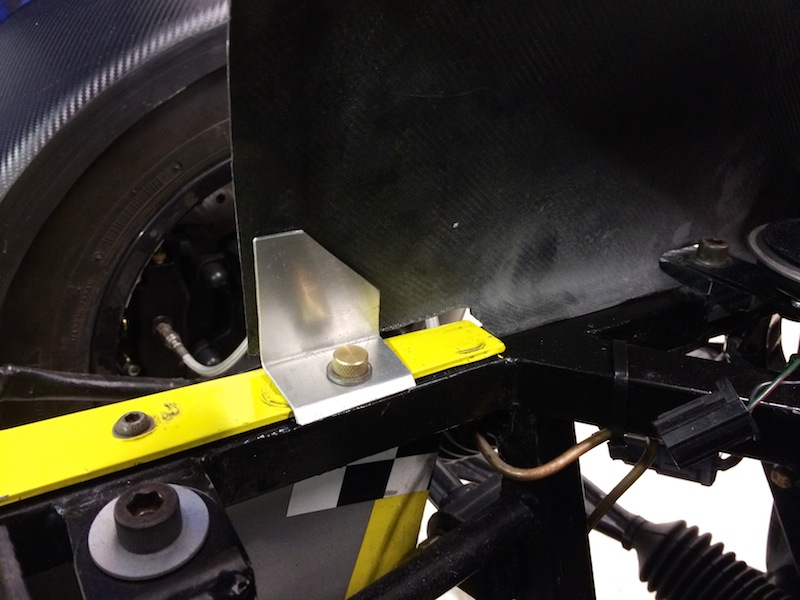

Not much of an update, got the front aero diffuser / splitter powder coated, had it back today

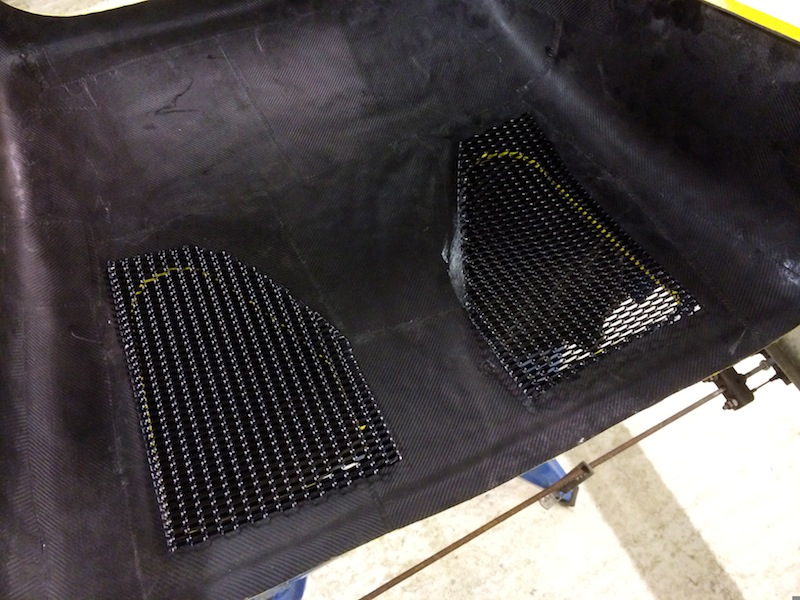

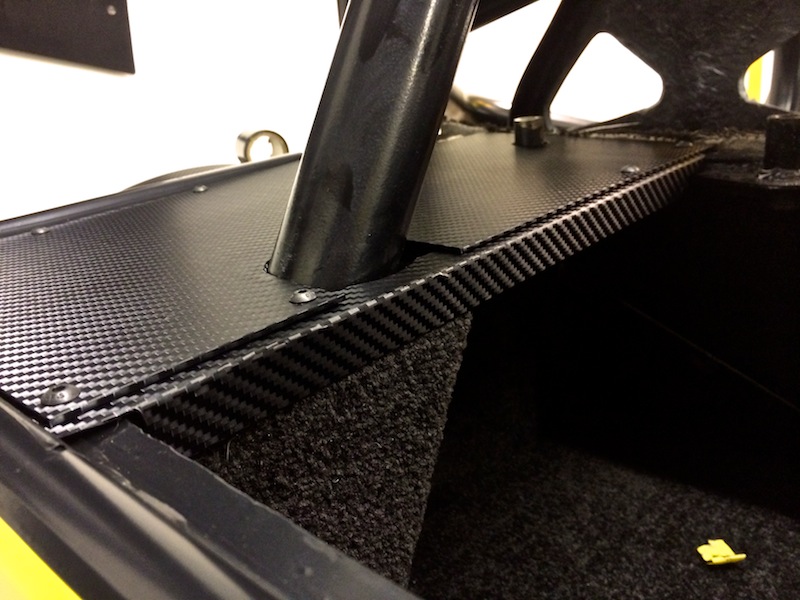

Open under side before and after...

Side on view for those that sent me a message asking for one

Open rear end to let out hot air

Made the centre piece removable for oil changes, and quick fixes

Engine bay look in through OSF

Looking down towards nosecone & rad at front, from standing at passenger side

Offside, side view of flat floor from inside bay

That's all folks!

maccmike - 4/5/12 at 07:34 PM

I love your car!!!

But if I had one critism, its yours and not mine!

Custardpants - 4/5/12 at 09:19 PM

cool, looks good. Hows the airbox?

yellowcab - 4/5/12 at 09:27 PM

ahh funny you should mention that - in the process of finding a way of making as big as air box as possible, with a cubic air capacity of at least

8.5cu/litres.

we made one which was 5.5 but didn't favour it as it was too restrictive, so ditched it and started again...

this is where we are upto on AutoCAD, so we know precise dimensions, angles and capacity that will fit inside the engine bay, and clear the bonnet

& vent...

this is the new design... which keeps the original air filter in situ - which in turn will mean that I can leave the front leading edge that will

'butt' up to the bonnet vent open

This has a capacity of 9.42cu/litres of air

[Edited on 4/5/12 by yellowcab]

jaik - 6/5/12 at 05:31 PM

Just thought I'd let you know I'm enjoying this thread, keep up the good work, it's giving me some great ideas for when I get mine

[Edited on 6/5/12 by jaik]

yellowcab - 6/5/12 at 05:41 PM

Cheers!

Wanted: Hayabusa updated clutch.

Trip home from Stoneleigh didn't quite go to plan, clutch decided to depart and smash into thousands of pieces after a spirited drive again...

lol

hashtag/bagofspanners

Proby - 6/5/12 at 06:08 PM

Spotted your car today at Stoneleigh, looked as good in the flesh!  sorry to hear about the clutch, if its like changing a blade clutch (which

I'm sure it can't be much different), then its a piece of cake!

sorry to hear about the clutch, if its like changing a blade clutch (which

I'm sure it can't be much different), then its a piece of cake!

yellowcab - 6/5/12 at 06:23 PM

Music to my ears as always Proby!

Thanks for your photos on your gear indicator btw, very very helpful!!!

PAUL FISHER - 6/5/12 at 07:24 PM

Its always a good idea aswell to change the oil and filter, after your clutch has gone like that, bits of it get everywhere

noc231073 - 6/5/12 at 07:43 PM

Just fit a genuine Suzuki clutch with heavy duty springs .. Way better than any of the after market upgraded clutches

Any easy to change .

yellowcab - 6/5/12 at 08:00 PM

Wonderful - thanks for the advice...

Paul - it was also my intention to do exactly that as I haven't changed the oil since I've owned the car yet...

So is it as straight forward as removing the end plate, and diving in?

ReMan - 6/5/12 at 08:07 PM

http://www.carlsalter.com/suzuki-service-manuals.asp

As said If you want me to bring a 10mm spanner....

PAUL FISHER - 6/5/12 at 08:14 PM

Yes simple job, drain oil, remove cover, remove clutch bolts and springs, remove plates and steels, then refit new clutch in reverse order. Removing

old gasket from the cover and cleaning everything up etc takes longer than changing the clutch itself, but its a only 1 hour job at the most

[Edited on 19/05/04 by PAUL FISHER]

yellowcab - 6/5/12 at 09:39 PM

Helpful as always, this forum!

Thanks Colin, and Paul for the quick run down, so a 10minute job with Colin Reman on the case, yeah?

ReMan - 6/5/12 at 09:54 PM

Shore ting

PAUL FISHER - 6/5/12 at 09:58 PM

quote:

Originally posted by yellowcab

Helpful as always, this forum!

Thanks Colin, and Paul for the quick run down, so a 10minute job with Colin Reman on the case, yeah?

Oh no,, it doe's not work like that, with a fellow locostbuilder round helping out it always turns into a 3 to 4 hour job at least, kettle on

time, chin wag time, talk over car mods time etc etc

yellowcab - 7/5/12 at 10:00 AM

Do people with Busas tend to have a list of 'suppliers' in their favourites that they'd like to share?

Nick DV - 7/5/12 at 10:23 AM

quote:

Originally posted by yellowcab

Do people with Busas tend to have a list of 'suppliers' in their favourites that they'd like to share?

For genuine Suzuki parts, your local dealer will be the best place, but for stuff like oils, you can shop around - as long as you get the right stuff.

For your uprated springs try Big CC or someone like that.

Cheers, Nick

BobM - 8/5/12 at 04:28 AM

quote:

Originally posted by yellowcab

Do people with Busas tend to have a list of 'suppliers' in their favourites that they'd like to share?

As already stated most stuff from local Suzuki dealer but I also occasionally used to get stuff from Powertec, now changed their name to Radical

Performance Engines:

http://www.rpeonline.co.uk/categories/Suzuki-Hayabusa/

Also on Ebay (often have more stuff than currently):

http://stores.ebay.co.uk/Powertec-Engineering-Ltd

Also occasionally stuff from BigCC Racing:

http://www.bigccracing.com/shop/category.asp?idCategory=50

yellowcab - 8/5/12 at 06:32 PM

Thanks for your replies guys, I've bookmarked all those ready for future use.

Weather was nice (ish) today, so I thought I'd drain the oil in preparation for having a look at the condition of the clutch...

So off came the sump plug and oil filter and let it drain... thought I might swell whip off the end cover just to have a nosey at the carnage

inside...

I've read theres no need to remove the 3x 5mm alleys, just the 8mms on the outside, so I did that...

Oh, hello... ermmm... thats alarming, one spring and bolt missing, and the remaining five were finger tight - no need for a rachet or spanner

here...

So here is the spring... and blind caps from the inside of the black plate

Thought I'd have a mooch for the bolt itself lol, please if you see anything that doesn't look right - just say...

No wear, no swarf, no chunks from any ring gears missing

Off came the sump - no swarf... absolutely none

May replace this lol

I presume the gasket is a standard item?

One of the victims...

Does this look OK still?

Would these grazes concern you?

Looks OK here too

At this point, we were confused as to how the bolt managed to work its way loose, get battered around the engine/ gearbox with no damage, no swarf,

and all teeth on all the ring gears still...

Decided to poke my camera up into the engine & box itself to take more detailed pics

Looks fine in here:

No swarf in the box side:

Oh hello Mr. Gilbert

Very clean, no clinks, no marks

Seems as though a bolt was there, as it had poked a hole in the side of the first plate, the piece of alloy to the left is the bit, and the spring

obviously

Got rid of the oil... and this little beauty had come out the sump plug hole whilst draining the oil lol

My questions are...

What 'actually' needs replacing, obviously the uprated clutch springs, and bolts... and yes I'll do them up...

Do I need to replace the black outer cover just because some of the innards have been scraped off?

Do I necessarily need to replace the bare alloy plate where the 6 bolts pass through because of the hole? I'm guessing not as its all a wet

system anyway...

Any advice, or warnings, or photos that are alarming - please say!

Look forward to hearing your thoughts

Olz

[Edited on 8/5/12 by yellowcab]

Nick DV - 8/5/12 at 06:50 PM

Not sure what to advise re the results of the bolt/spring coming out, but first impressions to my very untrained eye, is that you got away lightly.

Now that your sump is off, and I can see how shallow it is, I can't believe that you have had no oil starvation problems!  Has the car been on

a circuit or just fast road use? Maybe it says something for the 'Busa oil system.

Has the car been on

a circuit or just fast road use? Maybe it says something for the 'Busa oil system.

Cheers, Nick

PAUL FISHER - 8/5/12 at 07:33 PM

Looks to me you have been lucky, no real damage done, if the clutch was ok before the bolt came out (ie was not slipping) you could just get away with

springs and bolts, torque them up to the correct setting which is not very much, only about 26 ftlbs but check in the manual, alot of people over

tighten them, snap them or stretch them.

While you have the plates out you may aswell micrometer them up to see how worn they are.

PAUL FISHER - 8/5/12 at 07:40 PM

Just add I would just reuse the alloy clutch cover, no real damage done to it

And the grazes/scratch marks on the basket are just grinder marks from the manufacturing process to remove casting marks.

[Edited on 19/05/04 by PAUL FISHER]

ReMan - 8/5/12 at 08:05 PM

See it's dead easy is'nt it

To echo Paul, I'd re-use it all, even the gasket.

Just need a new set of springs and bolts

My guess someone who'se stripped one of those alloy? bolts before ( I have the t shirt) has been too careful tightening them up?

Check them all but otherwisse get it back together pronto

yellowcab - 8/5/12 at 08:44 PM

Thanks chaps for all your help and advice.

You're right, just going to replace springs with RPE 10% updated ones, and a new bolt. :-)

Oh, bought a new sump pan too lol

BobM - 9/5/12 at 05:25 AM

quote:

Originally posted by Nick DV

Now that your sump is off, and I can see how shallow it is, I can't believe that you have had no oil starvation problems!  Has the car been on

a circuit or just fast road use? Maybe it says something for the 'Busa oil system.

Has the car been on

a circuit or just fast road use? Maybe it says something for the 'Busa oil system.

It's a dry sump, isn't it?

BobM - 9/5/12 at 05:30 AM

quote:

Originally posted by yellowcab

What 'actually' needs replacing, obviously the uprated clutch springs, and bolts... and yes I'll do them up...

Do I need to replace the black outer cover just because some of the innards have been scraped off?

Do I necessarily need to replace the bare alloy plate where the 6 bolts pass through because of the hole? I'm guessing not as its all a wet

system anyway...

Any advice, or warnings, or photos that are alarming - please say!

I'd say you've been a lucky boy

I agree with the others, all you need to replace is the bolt and spring.

Looking at your pics, the damage to the pressure plate and the outer cover look purely cosmetic. The steel plate I could see looked pristine with no

signs of bluing. Your basket looks in good shape too - when they wear they get grooves around the inside which cause the plates to stick in them and

you get a grabby/juddery clutch. I've reused sump gaskets many times before without problem.

Nick DV - 9/5/12 at 11:41 AM

quote:

Originally posted by BobM

quote:

Originally posted by Nick DV

Now that your sump is off, and I can see how shallow it is, I can't believe that you have had no oil starvation problems!  Has the car been on

a circuit or just fast road use? Maybe it says something for the 'Busa oil system.

Has the car been on

a circuit or just fast road use? Maybe it says something for the 'Busa oil system.

It's a dry sump, isn't it?

Doesn't look like it cos the hose is only linking the to outlet ports on it. They don't connect to anything!

Cheers, Nick

yellowcab - 9/5/12 at 01:02 PM

Wet sump system with a dry sump pan to help with under car clearance issues

Massive thanks to Mike, along with Rob & Lee @ RPE - they've sorted me out with everything I need...

Gen Suzuki Oil Filter

Replacement 'post'

Replacement 'bolt' that goes into above 'post'

6x 10% uprated clutch springs

3x Clutch pulls/ pressings

And the 2x 4" thin piece of circular metal that go under the last cork clutch plate

All arriving tomorrow, off to Shell petrol station to get some Shell Ultra 15w50 as thats what RPE advised

So from thinking my replacement 'clutch' was going to set me back around £280 ish... the total cost after discounts is around £36

BobM - 9/5/12 at 01:06 PM

quote:

Originally posted by yellowcab

Wet sump system with a dry sump pan to help with under car clearance issues

Ah, I was wondering about the odd hose arrangement! Looks to me like you still need more clearance!

quote:

Originally posted by yellowcab

All arriving tomorrow, off to Shell petrol station to get some Shell Ultra 15w50 as thats what RPE advised

Generally recommended to avoid fully synthetic oil intended for car engines to avoid clutch slip.

yellowcab - 9/5/12 at 01:10 PM

The sump pan was like this from before I bought the car... so who knows what its been scraped on...

Seems to flat, and uniform scrapes to be the odd speed bump here and there, but what do I know lol

Such nice and helpful guys at RPE - very impressed

yellowcab - 13/5/12 at 05:03 PM

Just waiting on a new Westfield dry sump pan before I decide to put the clutch back together.

On a side note, thinking unsprung weight - 1x 15" wheel + tyre = 16.2kg, which means the set of four is 64.8kgs in total

Does anyone have the information of what both 13" Team Dynamic Pro Race 1.2 + tyre weighs... and a 13" Minilite + tyre weighs?

jaik - 13/5/12 at 05:21 PM

I'm pretty interested in the wheel & tyre weights too, it's quite easy to find wheel weights, but without the tyres it's

meaningless for comparing different sizes.

ReMan - 13/5/12 at 06:31 PM

http://www.locostbuilders.co.uk/viewthread.php?tid=166487

locoboy - 13/5/12 at 08:53 PM

I have just found this thread and its great, good honest down to earth work, no Bulls**t just a bloke fettling things, having fun and learning along

the way, keep it going, nice car and nice photos too...........

mangogrooveworkshop - 13/5/12 at 10:23 PM

Very tidy... I'm reading this thread too

1 make sure the vent pipe from the diff has a catch bottle or vents outside your diffuser. ps Diffs get very hot

2 make doubly sure the radiator over flow leads to the outside of you under tray .

3 Put some strength into the top mount for your steering as you have added a long leaver to the steering column (when you drive it in anger you will

be shockedhow soft the top mount is.)

locoboy - 14/5/12 at 08:15 PM

I would advise you use threadlock on the bolts you use in your rivnuts for your removable undertray bulge. The ally undertray will probably be subject

to quite high vibration and you don't want it falling off after all your hard work!

yellowcab - 14/5/12 at 08:30 PM

then the rivnuts themselves would spin in the holes when you try and remove the bolts lol

already considered it mind, but I totally appreciate what you're saying lol

sdh2903 - 14/5/12 at 09:02 PM

Just use spring washers instead of thread lock, should do the trick. Worth doing as like said there will be a fair bit of resonance.

yellowcab - 15/5/12 at 04:37 PM

finally after whats felt like years of waiting for planning permission, i finally i have a man-shack

no more getting wet!

[Edited on 16/5/12 by yellowcab]

aka_shortie - 15/5/12 at 04:56 PM

That man cave looks massive, i want one lol.

You going to box it out / insulate it? Heard they suffer ventilation / condensation problems

yellowcab - 15/5/12 at 04:59 PM

galvanised steel roof has anti-condensation backing thankfully, else i probably wouldn't have opted for it...

the idea is to insulate walls with loft insulation, then 'dab & grab' plasterboard, kitchen vinyl black & white checkered flooring,

and insulating back of garage doors, add a PIR security light & alarm, then to put sofa, tv, fridge, coffee machine in the corner, and some carpet

as i hate laying on a hard floor lol

aka_shortie - 15/5/12 at 05:02 PM

Impressive, cannot wait to see it finished.

Hope you actually have some garden left lol

yellowcab - 15/5/12 at 05:04 PM

hopefully going to have an exhaust extraction pipe too, so can run the car with garage doors closed to stop people peeking in

ReMan - 15/5/12 at 08:49 PM

TBH I find that amount of space offensive

(Sobbing into chips)

Custardpants - 15/5/12 at 08:54 PM

Omg thats amazing! My garage is just too full of workbenches, lathes and machinery - i know, didums. Can't get anywhere around the car though!

yellowcab - 16/5/12 at 09:30 PM

Just awaiting new dry-sump pan from Westfield tomorrow, then will be back on with the clutch rebuild so I can drive the bugger again...

The slight misfire issue that was occasional might have had something to do with HT leads 1 & 4 weren't clicked down, just resting ontop of

the spark plug lol

Looking forward to driving it with the new clutch shims & pawls fitted, with the verbal help an LCBer

ReMan - 17/5/12 at 06:40 PM

quote:

Originally posted by yellowcab

galvanised steel roof has anti-condensation backing thankfully, else i probably wouldn't have opted for it...

the idea is to insulate walls with loft insulation, then 'dab & grab' plasterboard, kitchen vinyl black & white checkered flooring,

and insulating back of garage doors, add a PIR security light & alarm, then to put sofa, tv, fridge, coffee machine in the corner, and some carpet

as i hate laying on a hard floor lol

IS THE FRIDGE IN YET?

puma931 - 17/5/12 at 06:59 PM

when is the shed warming party?

Proby - 17/5/12 at 07:51 PM

That garage space looks hhhuuuwwaaggee! Very nice!

yellowcab - 18/5/12 at 06:39 PM

hiya guys, sorry not been on much... been tinkering, not made fantastic progress, but its going in the right direction for the man-cave.

here are some pics so far... after spending ages at looking at RaceDeck, and Eva Anti Fatique garage floor tiles, and then picking myself up off

the floor when i worked out 30m2 of the stuff, I opted for smooth white garage floor paint

That was last night, so let it dry over night and really happy with the single coat that we applied, and it sealed the bare concrete at the same

time...

Off I pop to Wickes to take advantage of their 'Make Your Home more Energy Efficient' guff... 2x rolls of 100mm loft insulation

Cut into strips, to place in between the concrete ribs of the garage

Done... nice and cosy - already reduced / eliminated echo

So the idea was to 'no more nails' the plasterboard, to the exposed ribs of the concrete, but it doesn't seem to be working - so might

have to drill/ rawl plug/ and screw the plasterboard on

HowardB - 18/5/12 at 06:53 PM

Wow, that is better than my house,...

yellowcab - 18/5/12 at 06:54 PM

lol don't you start aswell, already had the wife comment a few times on... "so when is the bathroom getting done?"

yellowcab - 19/5/12 at 06:57 PM

knackered, tired, cold, itchy...

hashtag/ihateloftinsulationwithapassion

yellowcab - 19/5/12 at 07:33 PM

couple of progress pics of partial plaster boarding, the centre piece left as thats where generator & exhaust extraction ducting will exit the

garage

walls will be painted white same as flooring

bit left to do - taking longer than i anticipated but I wasn't originally intending on following the angle of the garage roof

and my car fits in with plenty of space - yay!

yellowcab - 23/5/12 at 11:04 PM

finally finished... feels like it's took forever

So after building some work benches, we decided to clear out because it'd be rude not to have a little photoshoot in the studio lol

rb968 - 23/5/12 at 11:09 PM

Shangri-la mate.

Lovely photos as well. Not jealous at all

Rich

RK - 23/5/12 at 11:32 PM

That is just rude. I'm sorry, but children are on here from time to time.

Well done all round! Fancy a trip to Canada to do mine like that? While yer at it, you can make my car look like that too.

cosmick - 24/5/12 at 07:16 PM

Judging by the colour of your tyres, i think you should have waited for the paint to dry before driving in to your new spangly garage. Your car looks

lost in there. Hang on, how did it get in there with no clutch?

cosmick - 24/5/12 at 07:20 PM

I have seen these kind of photo booths before, All white with white walls to photograph cars in and so on. I don't think this is a garage at all.

I think this is a photo booth.

Proby - 24/5/12 at 08:06 PM

Very  will be a shame to get it dirty in there!

will be a shame to get it dirty in there!

tegwin - 24/5/12 at 09:06 PM

Nice garage. Are you going to insulate the roof? Seems odd to do the walls but not the ceiling :-)

yellowcab - 25/5/12 at 07:02 PM

the plasterboarding is purely for aesthetics really and being able to reduce echo, we only got the insulation because it was free... so the intention

wasn't trying to keep heat in as such... i hear what you're saying though, but wouldn't want to board the roof as it'll reduce the

little height even moreso

Pat_T - 12/6/12 at 09:28 PM

any updates?

maccmike - 12/6/12 at 09:55 PM

I f'kin hate you!

yellowcab - 13/6/12 at 08:00 AM

Update is, clutch is fixed and put back together with uprated clutch springs.

Feels solid, very bitey, and clutch pedal even more stiff than before now - but have been advised by Mike that I need to move the fulcrum down towards

the floor (pivot) point in order to get a easier pedal, and more forgiveness on bite point...

That's just a 'for now' until I get a new clutch MC...

Other than that - efforts have turned towards the garage, it's pretty much done now  )

)

yellowcab - 13/6/12 at 08:14 PM

most boring update ever - but i bought a 17" Longacre mirror, and got advised to make my own brackets, so I did lol

Not great, nor pretty, but it holds the mirror nice and secure... just need to file the undersides off to match the contour of the mirror sticky out

bits

these bits the lugs that hang down just need filing down

drilled a second hole in the mirror itself so it tilts slightly towards the driver, so i can see over my right shoulder

Like so... fitting it straight gives you lots of rear passenger viewing, but no rear drivers...

hashtag/thatisall

yellowcab - 13/6/12 at 08:17 PM

infact i'm going to remove the brackets, and make the holes elongated so i can pull the passenger side of the mirror out moreso

cosmick - 13/6/12 at 08:25 PM

You Tart!!!!! Men are supposed to scratch their balls when they sit in a car not do their make up or keep looking at themselves in the mirror. Well

done for getting the clutch back together and the car back on the road.

yellowcab - 13/6/12 at 08:31 PM

All thanks to you Mike - thanks for your constant help and support - you still on the premium rate 0891 number?

You can 'just' see the air box in the pic from the back of the car looking forward  )

)

yellowcab - 13/6/12 at 08:38 PM

Oh I've just found some dead old photos from doing the clutch

After spending hours and hours on the phone to Mike - I have it together again

Advised by the god himself to buy these clutch pawls from Radical - so I did... haven't a clue what they do - apparently take the

'ramp' out of the clutch, but I'm buggered if I can feel any difference

Misses popped to Asda, and asked me to watch the boy for a couple of hours, so he mucked in... 3 weeks old FTW

New dry sump pan from westfield at a bargain price from eBay

test run - pulled over to check for leaks, noises, leaks, leaks, leaks, noises - but there were none (note - air box mike)

that is all

[Edited on 13/6/12 by yellowcab]

yellowcab - 15/6/12 at 10:57 PM

So after meeting Mike (the god) at Stoneleigh, he advised me to scrap the air box construction idea considering there was a much simpler way of

sorting my induction noise out... fit a standard Busa air box, so I did

Finished the final de-taxi'ing of the car now, some might have liked the decals, I personally didn't, so yay - I'm "just another

yellow kit car" now

[Edited on 15/6/12 by yellowcab]

cosmick - 16/6/12 at 09:55 AM

The car is starting to look really good now and slowly ironing out all the little niggles. One point to share is the airbox is not Hayabusa but GSX R

with the same diameter intake rubbers. Cheaper to buy and same volume. Get the intake hooked up to the air scoop and have some ram effect next. Have

you done the clutch pedal mod yet?

[Edited on 16/6/12 by cosmick]

yellowcab - 16/6/12 at 10:16 AM

Thanks Micky Blue Eyes... the car is 'slowly' getting to where I want it to be...

Pedal is on the agenda - along with some long awaited track days!

perksy - 16/6/12 at 03:51 PM

That looks very nice indeed

and so much better without the stripes imho

Gti6boy - 16/6/12 at 04:32 PM

I love your car so much

I just purchased the same but chopped down the brackets to as small as they could go. The passenger side was cut 10mm bigger as I had the same

problem

yellowcab - 16/6/12 at 04:51 PM

Ahhh you're much posher than me with your proper brackets! lol

yellowcab - 21/6/12 at 06:26 AM

Finally after owning the car for 11 weeks, I've booked the first 'track' day

Off to RAF Barkston Heath on Saturday for their Autotest/ Slalom/ Drift day at an airfield, which is perfect for what I want in practising in the car,

and getting it setup to how I want.

I'd only get black-flagged at Donington for 'testing' / pushing limits, and the boys in blue seem also to have a problem if you do it

on the road - so seems ideal.

Myself, a friend in his drift MX5 and Col 'ReMan' are all going up to get wet! wahooo

So I managed to find some crabby wheels with tyres to stick on the rear for hooning around as I don't want to send my R888s up in smoke, it was a

gamble as I didn't actually know what setup was on the car already... so bought these Borbets for £30 with 3 tyres

They fit, so thats a bonus, but only on the rear - the front cycle wings are so tight around the 195-50-15 tyres at the front, that these 195-60-15

tyres foul - that doesn't matter, just means that I will run crappy tyres to trash on the rear

Fit OK, 4x108 stud pattern, ET40, 6J 15

Gave them a clean up - and getting one tyre removed, and putting my Maxi Tarmac rally tyres on two of them for when I want some rear wheel grip lol

Also bought a Go-Pro HD Hero2 Motorsport Edition camera, and then got ripped off by having to buy a roll cage mount lol - so I'll have some

footage of me not being able to to drive lol

ReMan - 21/6/12 at 07:15 AM

I signed up on the undersrtanding that the sun would be shining

yellowcab - 21/6/12 at 07:25 AM

Girl !

yellowcab - 23/6/12 at 08:50 PM

Holding a drift/ slide, arse hanging left, we were travelling left also towards the blue cone on the left hand side of the photo

Hanging back down the main straight

[Edited on 23/6/12 by yellowcab]

cosmick - 23/6/12 at 09:07 PM

Glad to see you have finally been able to drive the car in anger where you can experience the true performance of a Hayabusa powered car. It looked

like a lot of fun.

yellowcab - 23/6/12 at 09:27 PM

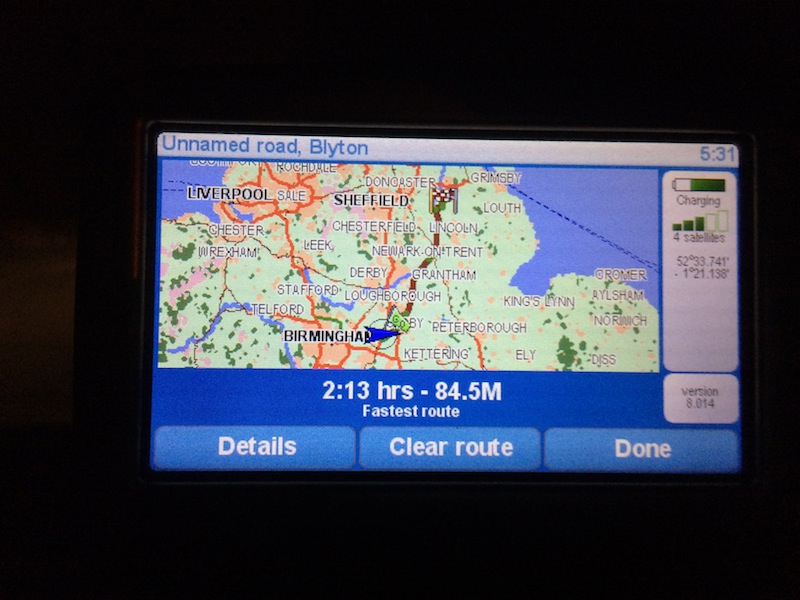

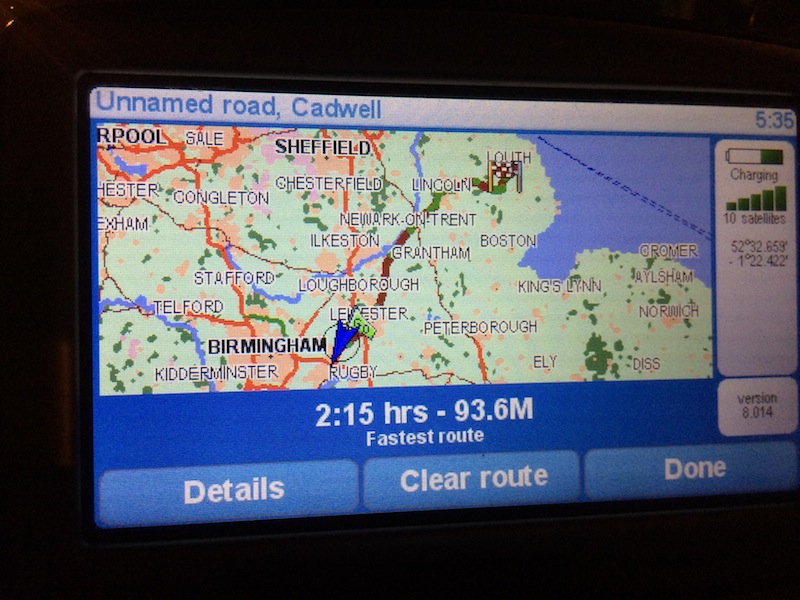

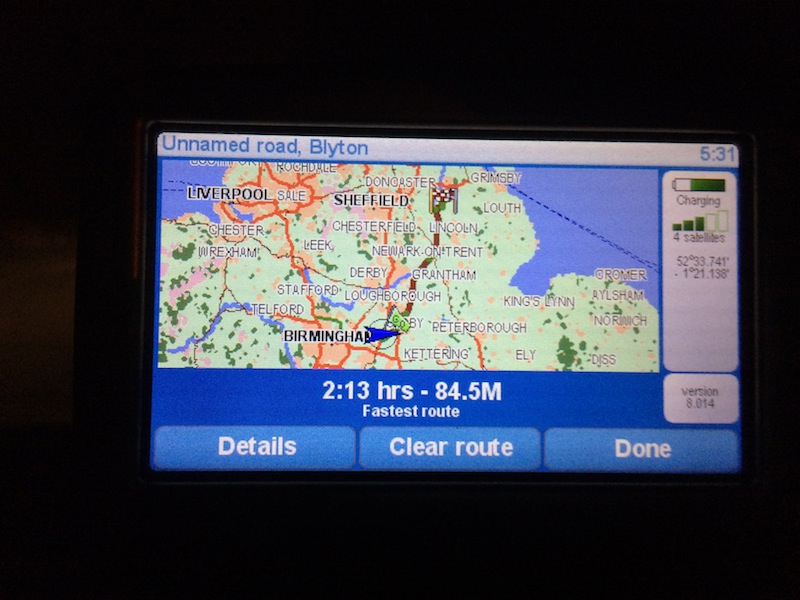

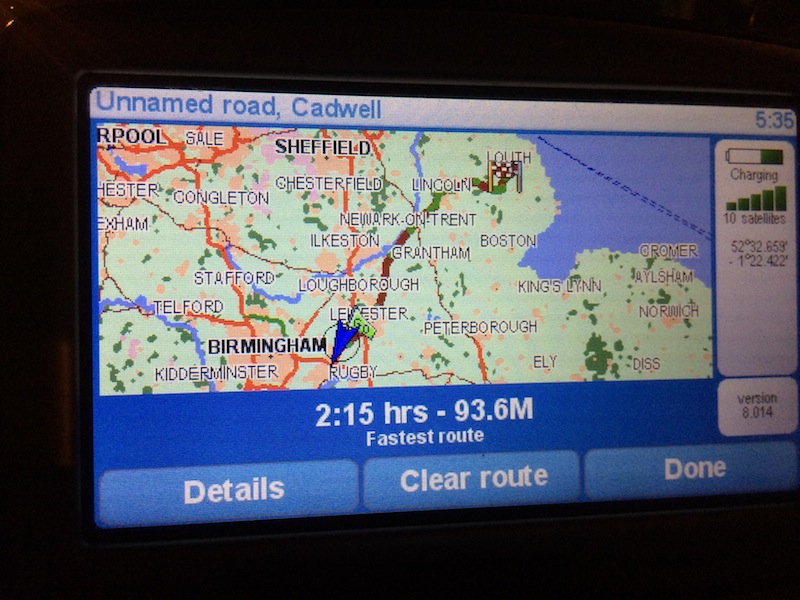

Me & ReMan on the way there, filling up...

bahhh broke it again, but fixed it

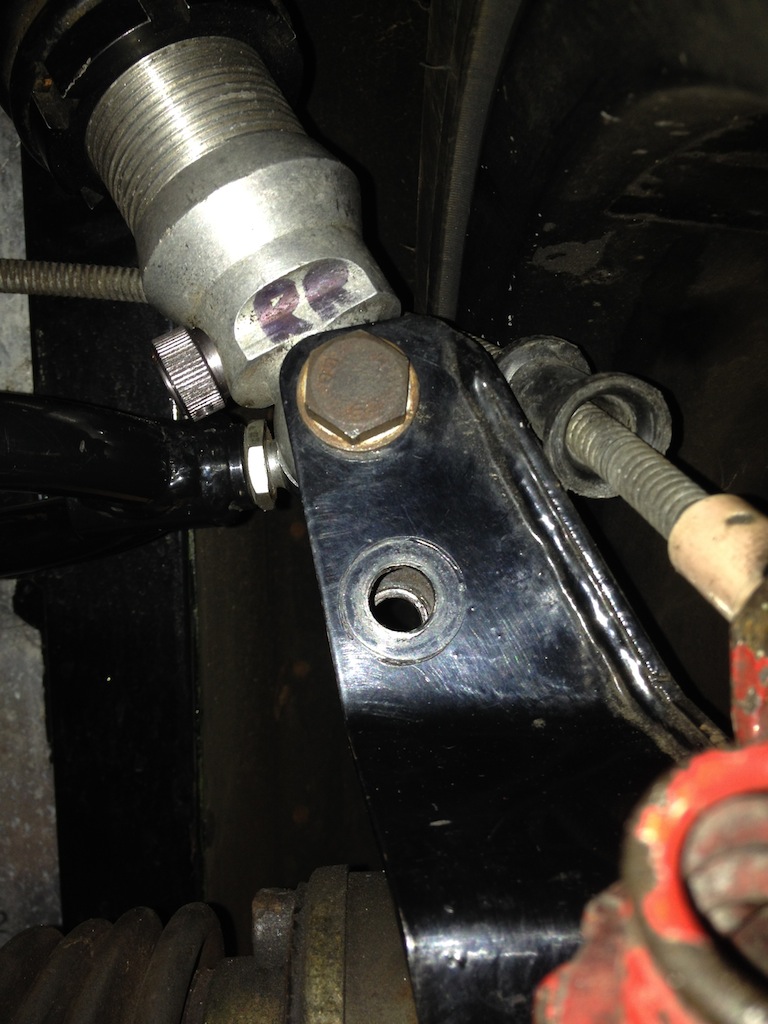

seems the previous owner had hit the bottom of the rear near side wheel, causing the upright to fracture giving me major positive camber on the

nearside, and the correct negative camber on the offside... does anyone know where I can get a replacement rear upright?

[Edited on 23/6/12 by yellowcab]

daniel mason - 23/6/12 at 09:33 PM

Crikey! All seems pretty corroded back there. Have you stripped it down and had a deeper look

yellowcab - 23/6/12 at 09:43 PM

Not yet - only got home about 2 hours ago lol

Video is now live: http://www.youtube.com/watch?v=ddflS7W_tAk&feature=youtu.be

Enjoy

yellowcab - 23/6/12 at 10:16 PM

One handed sprint video...

PS: no, I didn't like the way the white apex pole looked at me 54s lol

http://www.youtube.com/watch?v=ffczZKGhFyQ&feature=youtu.be

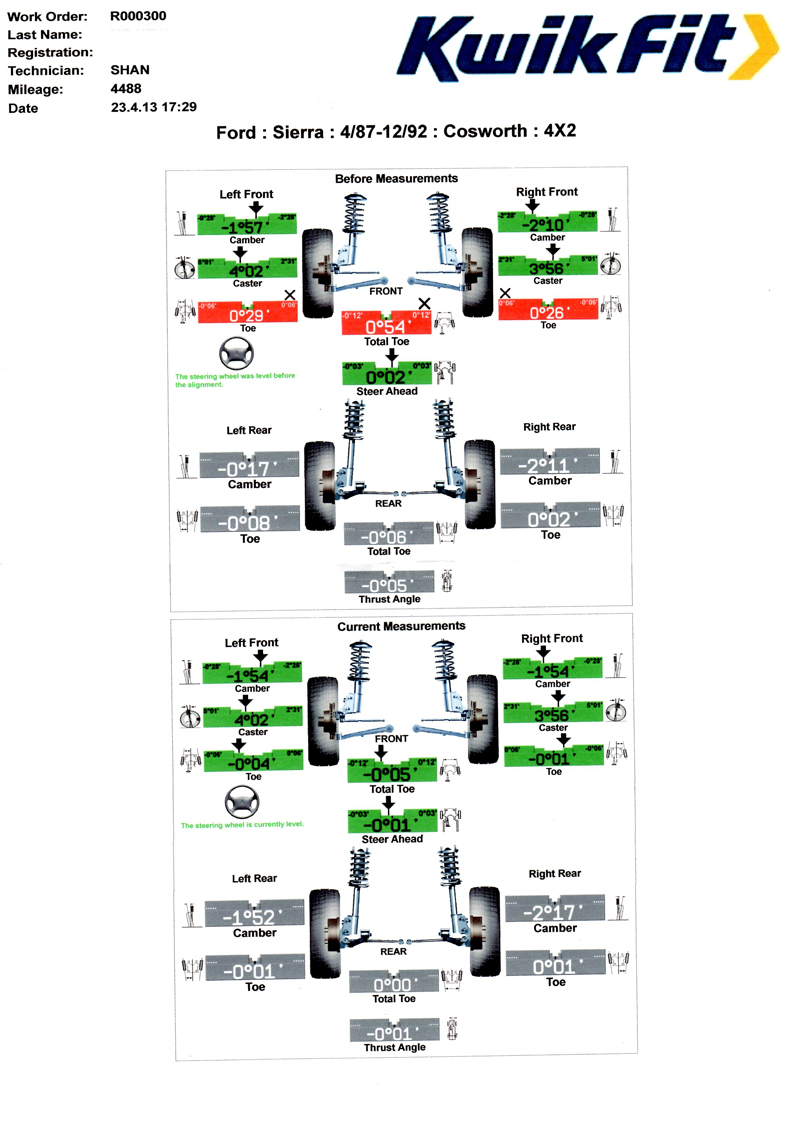

yellowcab - 24/6/12 at 11:43 PM

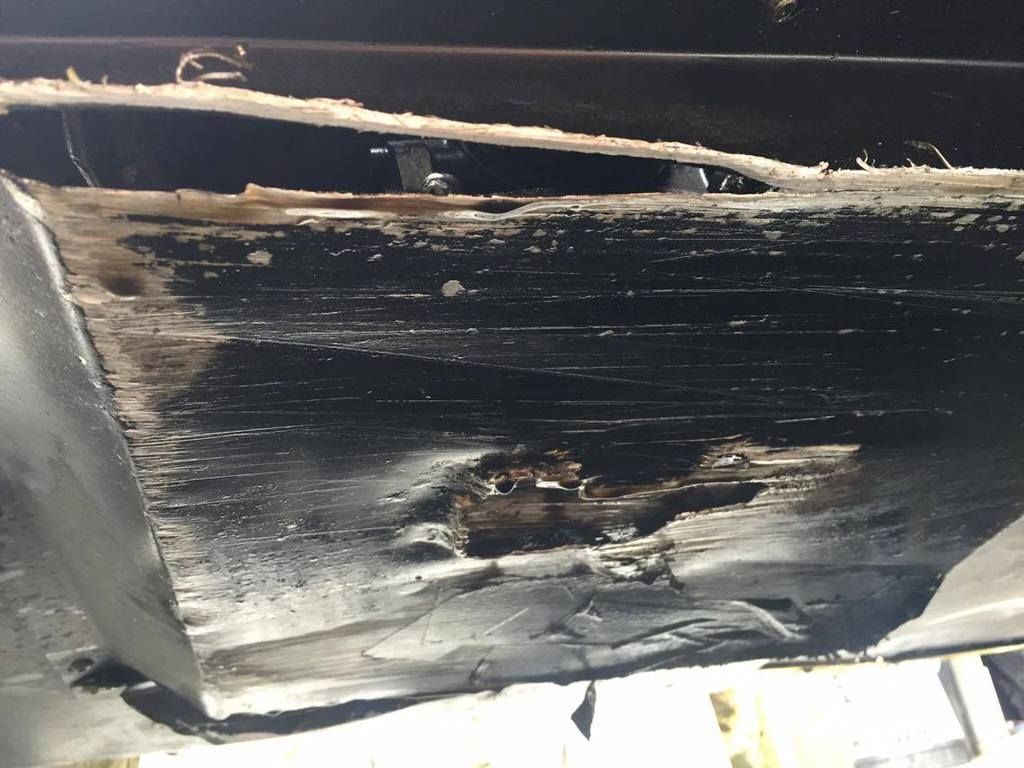

So, it seems that the fracture in my rear upright may have already been there - but the trackday on Saturday certainly worsened it, I had a mooch back

through some old photos - this is what I found...

The day I bought it in January

About 4 weeks ago

Weekend before last...

Noticed positive camber at the rear at the track day on Saturday and found these fractures

Saturday evening, arriving home after track day

This evening, after tinkering with the car

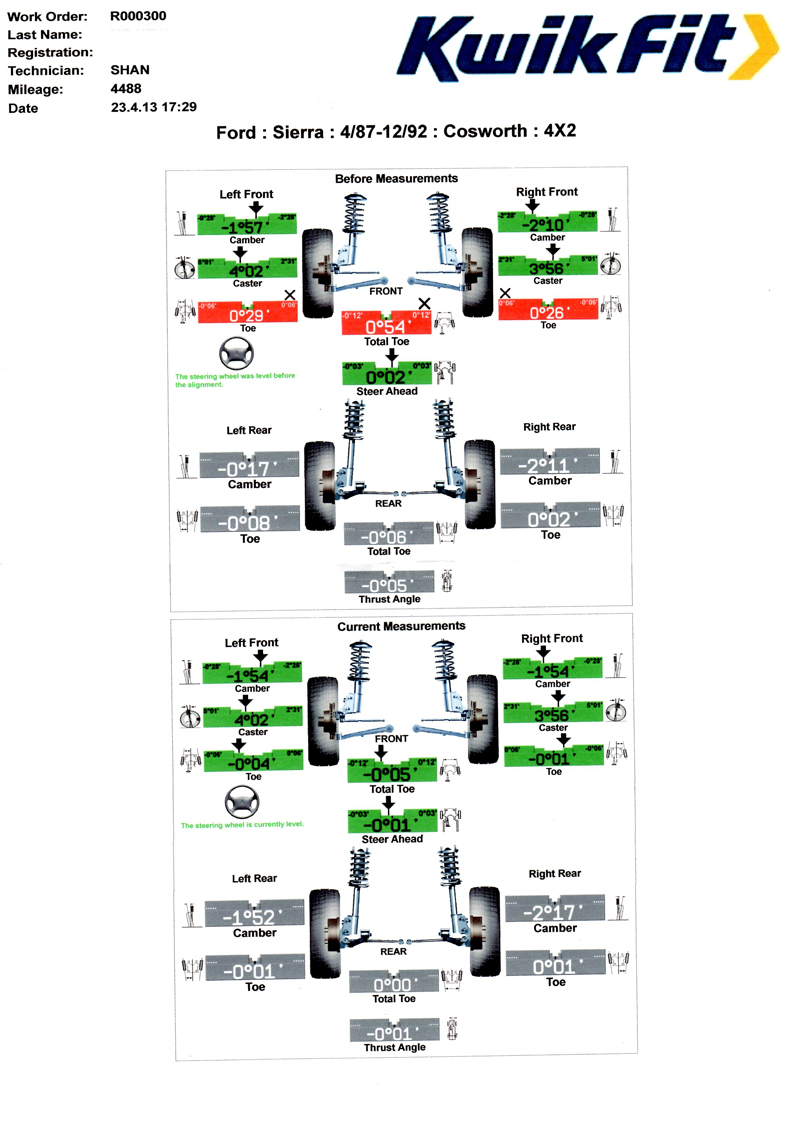

My guess of +postive 2deg camber wasn't far out:

Offside rear looks fine, as it should, nicely tucked under

neg 1.5degrees of camber, cool

The rough surface, bumps, drifting has obviously made it more apparent, and we spotted it before it did any real damage.

yellowcab - 24/6/12 at 11:50 PM

So on with tonights other activities, I took some bits of and had a bit of a tidy up

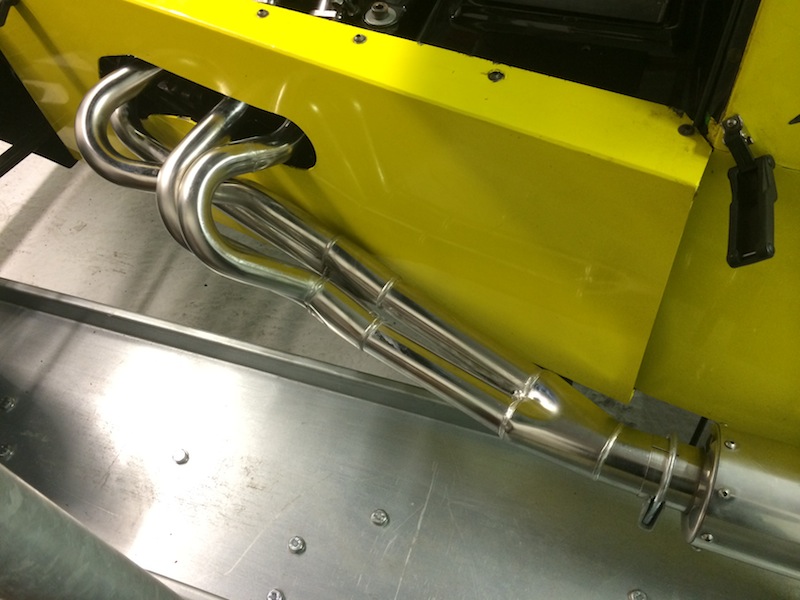

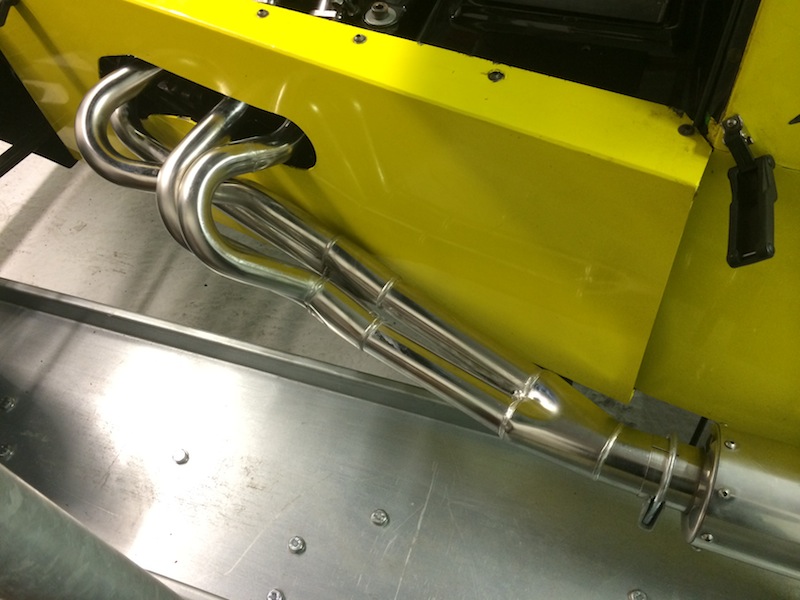

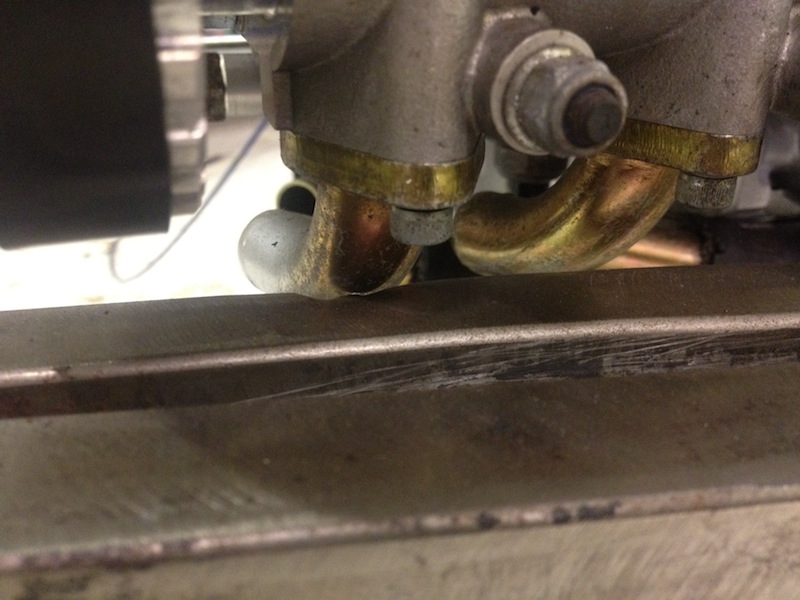

The manifold heat wrap got torn on Saturday, so I decided to take it all off

Where the wrap was being held on the primaries right near the head with jubilee clips, I noticed that it wouldn't slide down the primary to

outside the car, as it was hitting something

Popped the camera inside to see that the triangulation bar is bent and is rest on the manifold primary - this is probably what the resonation through

the car is, or would you not think such a think could cause vibration? either way - I don't like it, any ideas of how I can correct it?

Meanwhile, I spat on her, and gave her a wipe

[Edited on 25/6/12 by yellowcab]

yellowcab - 25/6/12 at 12:02 AM

Got chatting to a Caterham owner who was particularly fast and well planted around the Sprint circuit, and just by eye he said the rake of my car was

definitely out... I think I remember him saying that the rear of the car should be circa 25mm higher than the front?

So tonight I measured the corner of the chassis

Drivers front, 130mm from the ground:

Drivers rear, 121mm from the ground

Passenger rear, 118mm from the ground

Passenger front, 122mm from the ground

So all in all, my rear is lower than the front by 12mm at maximum, and 9mm at minimum.

Would anyone mind measure theirs for me please? so I know whether just to raise the rear, or to raise the front aswell?

I appreciate wheel & tyre sizes play a part in height from the ground, but its more the difference between front and rear that I'd like...

for reference I'm on 15" wheels, with 205/50/15 tyres.

Thank you in advance for anyone willing to do this for me.

For how skittish the car was on Saturday, not surprised given the factors so far - but going one further, the car currently has 450 lb springs on

each corner, front and rear - so I whipped off the fronts, but not sure what to put where out of what I have

Again, any advice on what setup I should start with before my next test day, would be greatly appreciated.

I obviously have 4x 450 lb springs aswell as the above, if it helps make a decent combination

Currents:

[Edited on 25/6/12 by yellowcab]

ReMan - 25/6/12 at 07:15 AM

Mines 140 rear 110 front

Of those springs, *personally* I'd go for the 275 front and 350 rear

The only think is I guess that those are 8" 275's?

which *might* put you too low at the front, you'd have to try it. I know 8 and 9 inch have been used on indy

[Edited on 25/6/12 by ReMan]

yellowcab - 25/6/12 at 07:32 AM

Yes you're correct, the 275lb springs are 8" the others are 8.5".

Damn 110 at the front is low!

My sump would almost be touching the floor of I dropped a further 20mm... However it's answered my question that your rear is 30mm high than

front respectively.

bobinspain - 25/6/12 at 07:48 AM

Factory build MK Indy Busa-R. Chassis: 115mm front, 140mm rear. 15" Wheels, Toyo 888s.

I have the billet sump with swing arm pickup.

I still need a ramp to get on/off the driveway owing to the peculiar sloping geometry, (see photo archive).

Lowest point under the car is the electric reverse.

Great job by the way and superb photographs.

[Edited on 25/6/12 by bobinspain]

Davegtst - 25/6/12 at 07:54 AM

It seems a bit strange that some MK engines are mounted lower than others. My sump is pretty much level with the lower chasis rails with the billet

sump fitted which allowed me to fit a flat panel under the entire engine bay. Re the handling have you thought about taking it to someone like

procomp who can set it up properly and advise on the best spring rates.

yellowcab - 25/6/12 at 09:44 AM

I'm not adverse to taking it somewhere for the final corner weighting as that's specialist bits of equipment, but I'm the type of

person that wants to do 99.999% of it myself through research and development, trial and error.

I'd never dream of taking it somewhere as it is without even giving it a go myself, just not in my nature, and I love nothing more than to

tinker, learn and improve.