exhaust tuning

Would you fit a full-length exhaust system from the likes of Akrapovic, Arrow, etc. onto your BEC project (assuming it physically fitted your build),

or would you still prefer a bespoke assembly?

I'm most concerned that an OE-routed system may well be most free-flowing option considering the torturous route that it needs to follow on the

bike, but that it may still be a significantly compromised system when compared to a bespoke assembly that takes advantage of the freedom of space

that most cars can provide.

Or are we talking little to no differences?

^^^^^ Beat me to it Reman! I thought of the same Test.

Thanks, but I'm not sure I get the relevance of a video showing guys knocking dents into a V8's primaries without a brief commentary?

Are you suggesting that exhaust header design doesn't really matter?

We know it does - but to what extent is debateable!

Maybe I'm not explaining myself properly (or I'm just thick... I know, I know!).

I have the space to either use the exhaust system from the bike, or an 'off-the-shelf' aftermarket system. We know that most bike

aftermarket systems give healthy gains over OE systems - most probably because they don't have to work with the issue of emission and sound

outputs.

However, a bike specific engine exhaust design will always be dictated by the shape of the bike - the primaries and the collectors will always have to

hug the engine and swinging-arm pivot point. The designer is hugely restricted.

A third option is to have a system made for me that can take a completely different route simply because I'm not putting the engine in a bike.

I have the space to allow for less tight bends and different length primaries.

I could buy a lightweight titanium / carbon off-the-shelf system for the same price as it would cost me to get a bespoke stainless steel system made

by a fabricator.

What I'm trying to establish is: - would a knowledgeable exhaust fabricator be able to make a system that can compete in the same ball park as

the aftermarket bike exhaust players (Akrapovic, Arrow, etc) do, simply because he doesn't have to follow the restrictive path that they have to?

If the answer is 'unlikely', or it would be broadly similar, then I'm just as well buying an off-the-shelf system for the convenience

and the warranty.

I suspect that unless your racing and need an extra 2 Hp than unless you try really hard to design a really bad one, theres won't be a lot of

difference, so choose between performance, looks, brand, cost as you see fit.

Shoot me down...

A system from a top notch exhaust builder might well be as effective as one from one of the big names. I doubt if any of the aftermarket systems will

make a huge difference though, other than being noisier. I've seen claims of 5-7 bhp increase. So not a lot.

I'm not surprised either.

Honda, Yamaha et al spend a fortune on exhaust design, albeit within the constraints of noise and emission control. I read somewhere about Suzuki

using Computational Fluid Dynamics (CFD) when they were designing Hydro-formed systems.

Many exhaust builders will simply copy the design and tube lengths etc and change only the overall shape to suit a car.

That's what I would do to.

You might try asking Andy Bates who he uses maybe. His systems use tapered sections, anti-reversion steps, all sorts of tricks. If he isn't

bettering Akrapovic, Arrow, Suzuki, Honda etc. then nobody is.

The "header bashing" video was posted as a "tongue-in-cheek" ( I suspect ) demo to show why not to get too hung up on exhaust

design. Those hot gases seem to find their way out somehow!

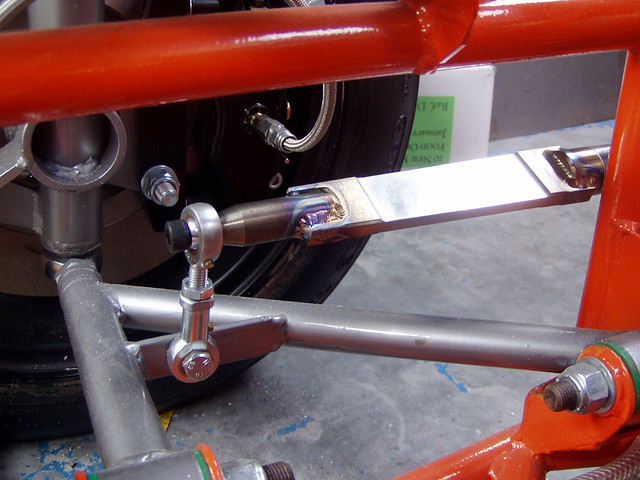

Whichever way you jump please consider using a proper "merge collector" and not a bashed tin "trouser piece".

Not necessarily for better flow, but because the latter looks 'orrible!

Lovely...

'Orrible...

Cheers guys - none of the exhaust options are cheap, so that's just the sort of info I was after. I was simply concerned that bike-specific

systems were greatly compromised by the route they have to follow.

I've always been a bit suspicious of advertised gains based purely on exhaust design, but I accept that there's a 'science' to

getting it right. I figured that if an OE, Aftermarket, and well-designed Bespoke system were all going to be in the same performance ballpark, then

it's probably wisest for me to go with an off-the-shelf solution.

Swings and roundabouts though - I can get a super-light Ti bike-specific exhaust system, but to use it I'll have to mount the engine a few inches

higher than I might of if I was using a bespoke design. I guess its a similar situation when considering the COG-related benefits of having your 65kg

engine mounted 3 inches higher...negligible in the real world!

What car is it for Scootz? There must be a fair few "off the shelf" solutions available for popular engine/car combinations.

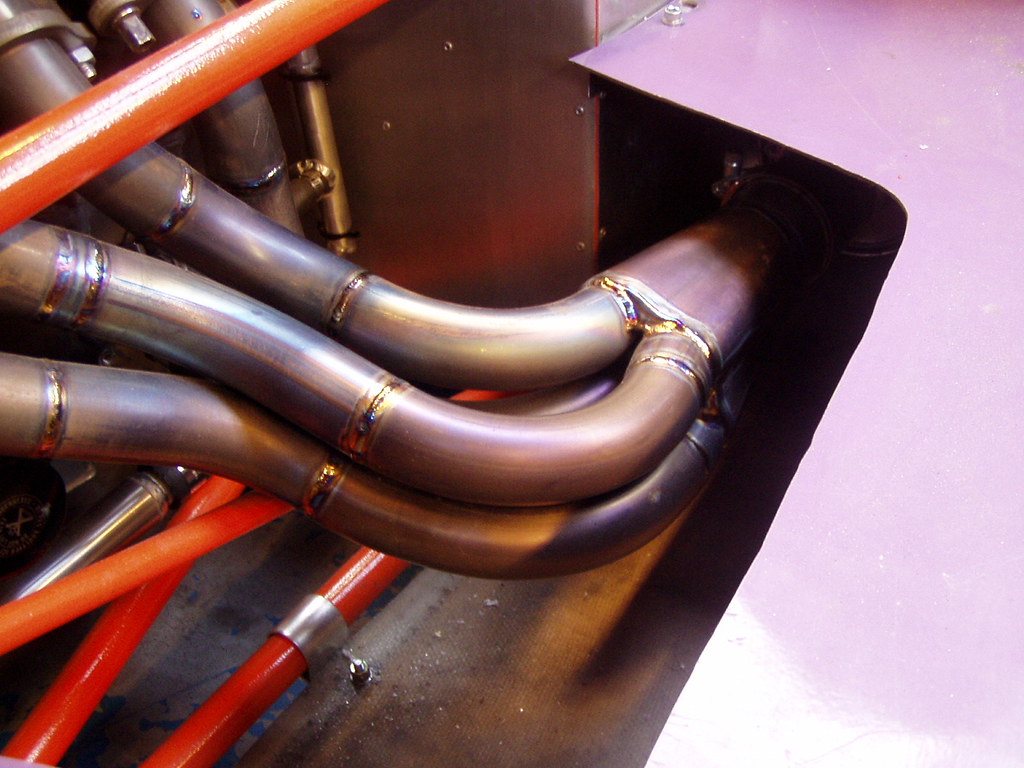

We bought two standard (titanium) exhausts and cut them into straight bits and curved bits. It then became what amounts to a "cut and shut"

job. Hardest bit was forming a titanium collector from sheet. Apologies for not making a merge collector out of Ti.

The end result was functional, light and cheap. We used a standard ZX9 titanium can and put a slash cut end on it.

I know its not "equal length" but the car runs fine despite that.

qw2

by Geoff Lee, on Flickr

qw2

by Geoff Lee, on Flickr

Crikey  that's purdy!

that's purdy!

Did you have much difficulty welding the Ti to mild?

The system is titanium from end to end. My co-builder was, and is, the best welder fabricator I know of. There are various ti bits on the car. Anti

roll bar blades, paddle shift, various brackets.. All from ti out of the works scrap bin.

I think they can weld dissimilar metals at work but that is with the benefit of a huge vacuum chamber electron beam welder.

P1010053[

/url] by [url=https://www.flickr.com/photos/96668592@N04/]Geoff Lee, on Flickr

P1010053[

/url] by [url=https://www.flickr.com/photos/96668592@N04/]Geoff Lee, on Flickr

P1010011[

/url] by [url=https://www.flickr.com/photos/96668592@N04/]Geoff Lee, on Flickr

P1010011[

/url] by [url=https://www.flickr.com/photos/96668592@N04/]Geoff Lee, on Flickr

Hi Scootz

Hopefully I can shed some light on your query

Obviously we build an awful lot of systems for bike engines cars and have done a fair few for bikes too.

The first thing is to stop thinking of it as a bike engine and start thinking of it as a bike engine in a car

The header design that suits a high revving super bike engine employed in a lightweight bike may result in a less than

Ideal power delivery for the same engine in a car

Donít get me wrong, they will make reasonable power and torque but we have found the trick is to build a system that widens and lifts the peak torque

value as much as possible.

Some race pipes that focus on 10-12000 power delivery can actually make things worse as whilst itís quite possible for a racer on a 170 kg bike to

keep it singing up here

It is an entirely different proposition pulling a 500kg car

Trust me pipe design has a huge impact on the shape of the cube and top end bhp

A few years ago when we were doing a lot of work on development of the CBR1000rr engines we managed to acquire a full works super bike system, the

manufacturer is irrelevant but suffice to say it was not available to non works teams

Whilst it made reasonably good power, itís power curve and torque graph was positively asthmatic low down and into the

Midrange

We then backed to backed on our own system and found another 6 bhp and much fatter torque curve

Some of the losses in the bike pipe are due to the tortuous bends required for packaging no doubt

We also found that on our own pipes we got to a point where as we shortened primaries the peak power continued to raise but the torque dropped off

By adding scavenge link pipes to the primaries we could keep the peak power and retain the torque

I have seen plenty of examples of this over the years and the problem is a superboke engine will feel fast even on a badly designed system, basically

you donít know what you havenít got

Recently we did a replacement system for a locoblade, we found 8bhp and beefed the torque curve up, the owner couldnít believe the difference and

apparently itís more economic now too

This is not meant to be a sales pitch purely our observations based on real time back to back testing

To sum up - whilst OEMs have access to big r&d budgets and testing facilities, ultimately they are constrained by packaging and price point for

what is a mass produced vehicle

The same is true of airbox design - believe me the stock CBR1000rr airbox is woeful but does what it has to in the space available

My personal opinion is superbike systems belong on superbikes and superbike systems for car application at a different kettle of potatoes

😀

Hope that helps

Andy

Thanks Andy. Great write-up! Where the bloody hell do you find the time to run a busy business AND field random enquiries from the likes of me!?

It makes perfect sense to move the torque further down the rev-range if you can.

I guess I'm owe you some fresh business after all the help you've given me over the years, so I won't jump in just yet and I'll

give you a shout when I get to the exhaust stage instead.

I'd imagine if I did go for a bespoke system, then my head would suggest the Radical way of doing things - 2 headers coming round either side of

the heads and merging above the gearbox.

Oh man, my memory - here's me talking about Radicals and then I remember that you had already done a successful midi design with the Sabre! How

did you package its exhaust?

I had a quick peek at Google images, but could only find this shot of the Sabre rump... I've found Wally quicker!

quote:

Originally posted by SPYDER

The system is titanium from end to end.

Its funny isn't it that aftermarket system purveyors always talk about increased horsepower. Never torque. They must have heard of "the area under the curve" but they never seem to mention it!

Hi Scootz

My pleasure fella - On sabre we bring the pipes out on one side altogether

Several reasons for this

1 - Iíve worked on plenty Radicals and get pissed off burning myself on the headers which

Are right where you want to work most of the time 😀

2. CBR1000rr primaries are short, real short and so if building to tuned length you will be stretching the pipes to much to get either side of head

and back in again within the optimum pipe length

3 - bringing the pipes over the top tends to subject some really sensitive parts to a lot of heat - TBís Airbox, sensors, loom etc

I will see if I have a picture of sabre system for you - if not I will take some in the morning

Beat regards

Andy

quote:

Originally posted by scootz

....He certainly is a very tidy welder!

P1010130[

/url] by [url=https://www.flickr.com/photos/96668592@N04/]Geoff Lee, on Flickr

P1010130[

/url] by [url=https://www.flickr.com/photos/96668592@N04/]Geoff Lee, on Flickr Ah yes the very talented Eldon

He has resisted all my attempts to come and work with me over the years but has taught me no end

Not to mention sold me some very nice fabrication kit

Would loved to have worked with him - a true master of his trade

I remember popping in when you were building that car - what a peach!

Attention to detail was phenomenal