Suspension

b14wrc - 4/2/17 at 07:33 PM

Hi all,

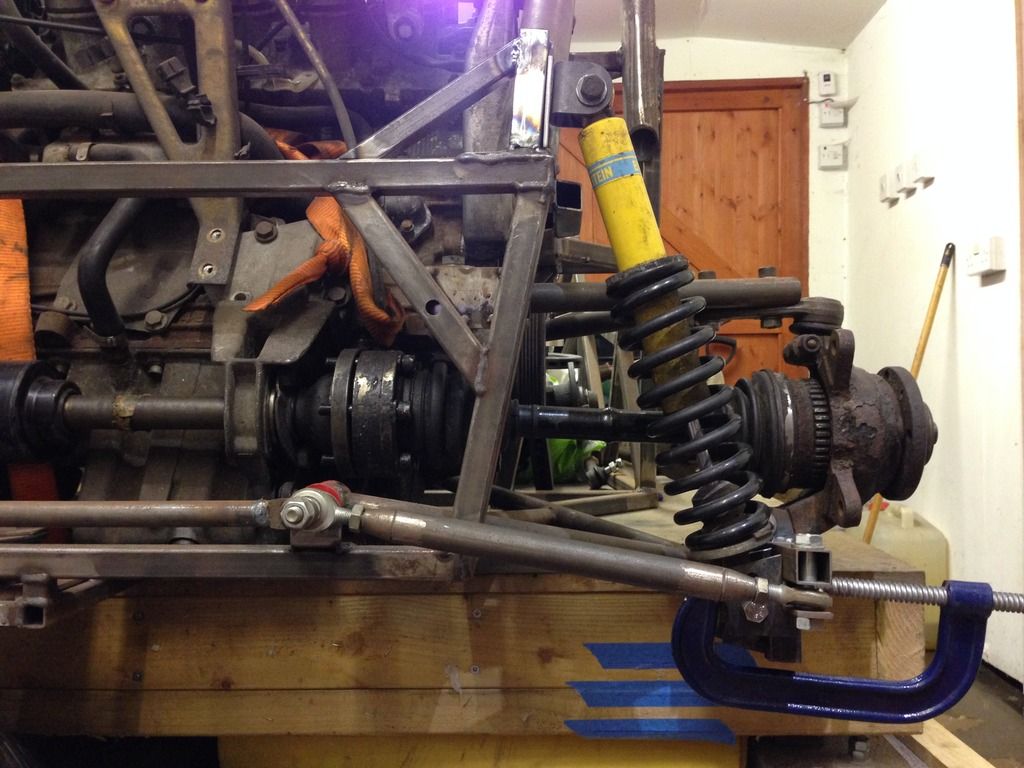

Good days effort I reckon, I have fabricated my top mounts for my rear shocks and tacked them on. Pleased with the final fit, only thing I'm now

concerned is how much the springs will compress once on the floor and the motor is in, I'm hoping it's right. I'll do a trial soon.

Need another bottle of Argon for the TIG to finish off the welds.

Rob

[Edited on 4/2/17 by b14wrc]

hkp57 - 5/2/17 at 04:08 AM

Looks like it will be plenty strong, one question though I would be concerned about (but it may be due to the angle of the photos)

There does not seem to be enough droop to allow for roll in the corners, you may find it picking up the inside wheel a lot

b14wrc - 5/2/17 at 11:58 AM

Hey,

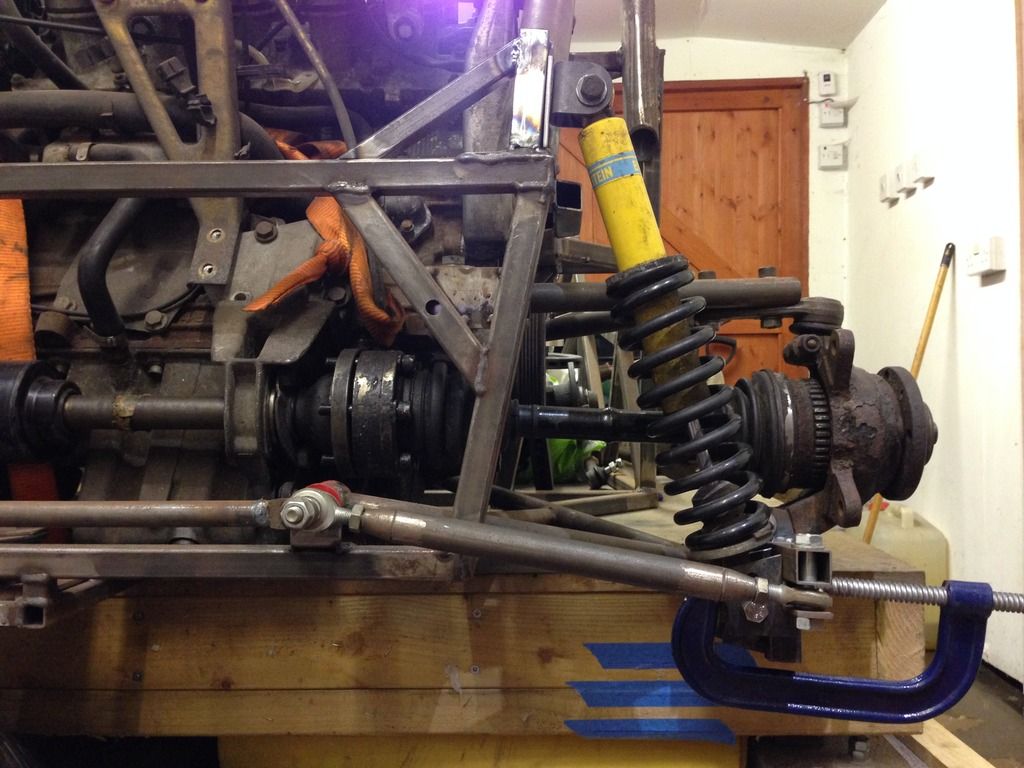

That concern is why I posted the photos, cheers. Here is a better photo:

Currently full droop will be at the bottom blue masking tape line, and the bumps stops will be hit at the top blue line. I figure the ride height will

be around the middle line. This would be 125mm, my chassis rakes up quite a lot at the back, so the actual car will look like its sitting about 50mm

higher.

Bumps stops will be 90mm clearance from the road.

I can look at making the droop 25-30mm more if you think necessary?? I'm running 17" wheel on the rear. I really need to get it all on the

ground and see where it sits, hard to estimate at the moment.

I am going to fit an anti roll bar too.

[Edited on 5/2/17 by b14wrc]

hkp57 - 5/2/17 at 01:15 PM

The rule of thumb in some suspension design books are you should aim so at rest your drive shafts are straight and then you have 2:1 ratio for

compression : droop

b14wrc - 5/2/17 at 01:36 PM

I've read the speed pro series " the sports car and kit car suspension and brakes book".

Tried to set it up best I can from that. My shafts exit the gear box as low as possible. I think I could lower it a bit more, but until I've seen

it on the ground, it will still be trial and error. Not sure exact Spring rates on those shocks....