Audi V8 timing belt job

coyoteboy - 24/5/13 at 12:10 PM

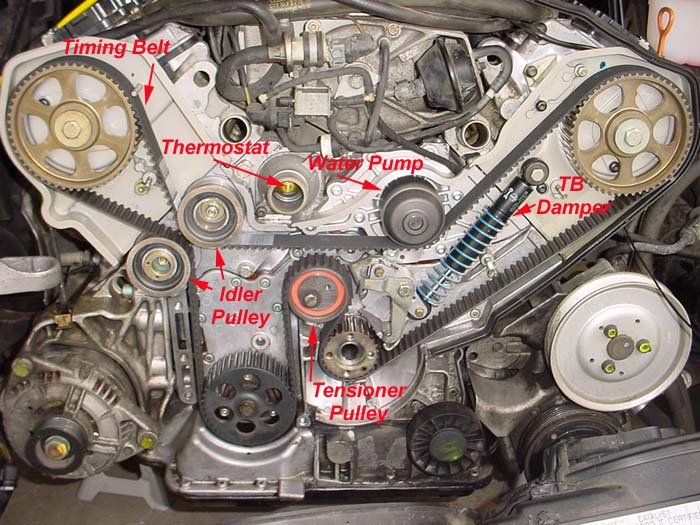

So my donor engine needs a belt change (doesn't but it's worth doing now as I need to change the water pump). Tools for the job are ~£400

alone and basically comprise a bunch of locking devices to hold all 4 cams in place with the crank (cams have a single pulley and are linked at the

opposite end with a chain so it's no more difficult than a 16v head in essence). I'm thinking I can do it the way I've done pretty much

all of my cars - bodge a few locking tools together, matchmark the cams and crank locations, take care and rotate it by hand a few cycles to ensure it

lines up.

Anyone any experience with the ABZ engine timing belt job that can highlight any potential issues?

loggyboy - 24/5/13 at 12:18 PM

These will be interference fit pulleys, meaning home made locking devices will need to be spot on, not just close enought to ensure it doesnt turn

half a turn like you could in the old days when the pulleys were keyed to the cam/crank. We are talking less than a degrees accuracy required.

Even with 2 camshaft engines its easy to get wrong. I did 2 clio 172s a recently and you tentsion the belt fully, but keep the pulley bolts loose, so

the position of the belt is irrelvent to the position of the cams/crank. then when the belts all tenstioned, you torque up the pulley bolts.

For something as complex as V8 you will need to get it right.

coyoteboy - 24/5/13 at 12:29 PM

Hmm it's just the crank pulley that I'll be taking off but I haven't checked if it's an friction fit type or keyed, I must admit.

I will have to dig in more detail but I think the tools are a tool to lock the two cam pulleys together, a set to lock each pair of cams together (not

really needed if the front set are locked but probably used for things like seal replacements if removing the front pulleys, so used in the standard

procedure).

It's the crank that'll be an issue if not keyed then. I think the official crank locker is a tooth holder on the flywheel - not a problem to

fab with the box off and no clutch fitted, but I hate keyless pulleys - they almost always take 2 attempts to get right IME!

Edit: Crank pulley is apparently keyed on the RS6 - slightly different engine but same era:

[Edited on 24/5/13 by coyoteboy]

[Edited on 24/5/13 by coyoteboy]

loggyboy - 24/5/13 at 01:15 PM

Crank might be keyed but cams arent:

http://www.audipages.com/Tech_Articles/enginemechanical/tbreplace0.html

britishtrident - 24/5/13 at 02:22 PM

There is certainly a key on the pulley in the picture.

chrism - 24/5/13 at 04:20 PM

Would it not be easier/cheaper getting an Audi specialist to do it. If the engines out and you can take it to them, it would save a significant amount

of labour cost as I believe most of the labour cost is removing everything to get access to the front of the engine and then putting it all back

again.

May cost a fair amount less than just buying the tools for the fitting labour.

Simon - 24/5/13 at 05:11 PM

quote:

Originally posted by chrism

Would it not be easier/cheaper getting an Audi specialist to do it. If the engines out and you can take it to them, it would save a significant amount

of labour cost as I believe most of the labour cost is removing everything to get access to the front of the engine and then putting it all back

again.

May cost a fair amount less than just buying the tools for the fitting labour.

My thoughts exactly. Audi will probably be scheduled so even though you've 95% of the work, they'll still want 100%, but non franchised

might come up with sensible price, plus if they screw it up, you've got some comeback.

ATB

Simon

coyoteboy - 24/5/13 at 05:36 PM

Can't easily transport it anywhere (no suitable vehicle) and I have no means of checking/correcting any job they do if they cock it up and I

can't run the engine for 6 months, at which point I have no comeback. I never use garages, ever. Seen too many expensive botch jobs, I'd

rather do a cheap botch job and only have myself to blame (never had a problem before, don't expect any with careful research).

Maybe if I could find a friendly specialist who would pop in on his way home and do it in my garage I might be tempted, but even so it's going to

cost more than the engine is worth if I'm to offer them a fair return on their time.

quote:

Crank might be keyed but cams arent: http://www.audipages.com/Tech_Articles/enginemechanical/tbreplace0.html

I'll have to assess the belt pattern and tensioning but I think everything between the cams is static, so providing I don't remove any of

the pulleys (there's no need to) I don't need to worry about anything - matchmarks and tooth counting will work fine as it always has.

[Edited on 24/5/13 by coyoteboy]

navyseamonkey2011 - 24/5/13 at 07:02 PM

Home made tools, tipex pen and check everything twice.

job done!! done let the naysayers on forums put you off!

Mark Allanson - 24/5/13 at 07:18 PM

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

froggy - 24/5/13 at 07:25 PM

Spring loaded dot punch and a spare pair of hands to keep the cams from moving while you nip the pulleys back up . I paint pen the pulleys etc then

dot the cam with the punch near to a cap . The only issue is having enough hands to keep them from moving , only done one but as your engine is out

you can lock the crank up so its not going to move .

stevegough - 24/5/13 at 07:52 PM

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

40inches - 24/5/13 at 07:54 PM

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

Now that's something to remember for future reference.

40inches - 24/5/13 at 08:00 PM

quote:

Originally posted by stevegough

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

Possibly hold the old belt in tension with an "in yer face" cable tie,pulling from across the other side of the engine, Mr Gough

Mark Allanson - 24/5/13 at 08:03 PM

quote:

Originally posted by stevegough

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

It is sometimes a bit tight, but a very small amount of slackening of the tensioner(s), without allowing any movement of the belt on the pulley lobes,

will go a very long way.

[Edited on 24/5/13 by Mark Allanson]

rdodger - 24/5/13 at 08:07 PM

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

Brilliant!

stevegough - 24/5/13 at 08:25 PM

quote:

Originally posted by 40inches

quote:

Originally posted by stevegough

quote:

Originally posted by Mark Allanson

Get a stanley knife, cut the belt longditudinaly while in position until it is completely split in two, slice the outer half and remove, feed the new

belt onto the pulleys until it touches the old remaining inner half, then cut away the inner half and slide the new belt completely onto the pulleys.

What a fantastically simple way! - the only pitfall I could forsee here is not being able to force the new belt onto the pulleys without de-tensioning

first?

Possibly hold the old belt in tension with an "in yer face" cable tie,pulling from across the other side of the engine, Mr Gough

Not finding yourself agreeing with me again, are you, yard-and-a-half?

coyoteboy - 24/5/13 at 09:54 PM

That's actually a genius method I like, but it's got the flaw of I can't change the water pump with it  But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

froggy - 24/5/13 at 10:10 PM

If it's the same code as the one I did which I think was a 40v version you need to tension the belt with the cam pulleys floating . You

can't set the tension between the two pulleys without moving them both if they are still locked to the cams

Mark Allanson - 24/5/13 at 10:11 PM

quote:

Originally posted by coyoteboy

That's actually a genius method I like, but it's got the flaw of I can't change the water pump with it  But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

You can! just cable tie the old half a belt to each pulley, release the old water pump, install the new, check that nothing has moved, continue as

described

britishtrident - 24/5/13 at 10:52 PM

quote:

Originally posted by Mark Allanson

quote:

Originally posted by coyoteboy

That's actually a genius method I like, but it's got the flaw of I can't change the water pump with it  But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

But I will remember that!

I'm gonna go old-school folks, matchmarks, locked crank and tipex is the way forward, you've given me the (possibly false) confidence

You can! just cable tie the old half a belt to each pulley, release the old water pump, install the new, check that nothing has moved, continue as

described

MG XPAG and pre-ww2 Morris engines used marks on the chain which lined up marked teeth on the sprockets .

coyoteboy - 25/5/13 at 01:52 AM

quote:

Originally posted by froggy

If it's the same code as the one I did which I think was a 40v version you need to tension the belt with the cam pulleys floating . You

can't set the tension between the two pulleys without moving them both if they are still locked to the cams

It's not, it's the 32v version, but i still don't see the need to float the cam pulleys if they were set right the first time,

it's just a like for like swap. Assuming a belt with the same number of teeth, tooth to tooth difference won't change and so relative timing

wont change either.

froggy - 25/5/13 at 06:42 AM

Your abosolutely right and I'm going to work in a minute to throw all my locking kits in the bin . Your method will work but it won't be

timed 100% . I use a firm that hire kits out for stuff like twin vanos bm s that I don't do regularly .

harvs - 25/5/13 at 08:58 AM

Hi

You should be able to get the new belt in the right position, but when you release the tensioner the relative position between crank and cams will

shift slightly I think (maybe not as much as a whole tooth, but a little none the less). If the cams are floating this movement due to tensioning will

happen before the cams are locked in position, so will be fine. But if the cams aren't loosened first, the timing will likely be a little out.

I've not experience of this (yet), so don't know how much of an issue the timing being out a little will be, but it's obviously not

ideal.

froggy - 25/5/13 at 09:09 AM

It normally shows up as a slightly rough idle or throws up a crank /cam coherence code. Most common one I've seen is the Renault k4m series

engines where people have done belts by paint marks then have issues with idle and stalling on light throttle .

On something with a very long run between the cams you can't get the tension between the two right

coyoteboy - 25/5/13 at 07:27 PM

Work with me on this because I'm failing to see the complication that requires floating of the pulleys (other than initial robotic assembly at

the factory).

Physical relationship between the two cams is set by a distance on the belt, say 50 teeth on the old belt. Tension in the belt at that point is a

factor of belt tensioner and cam resistance. If you replace the belt with another one of the same tooth pitch, and make the assumption they have some

quality control capability, you can expect the 50teeth on the new belt at the same tension to be the same distance as between the same two points on

the old belt when it was new too.

Same distance between the leading can and the crank too means they are locked together and therefore the only variable could be tooth to tooth length

of the belt. Are you suggesting the belts are that poorly matched that stretching with tensioner puts them wildly out? Or that variation of less than

a degree drastically affects the engine to the point of misfire?

PS did a belt change on a 16v Renault engine with friction can pulley (my first with that new feature), could not get it happy with the correct

locking tools, worked fine when I did it the old way. Possibly the cause of my dislike of locking kits.

Anyway, if this tension problem exists (which I'm not doubting it does to some unknown extent) wouldn't all engines with long runs and keyed

timing be impossible to time correctly and never have existed before? Keyed timing pulleys is exactly the same situation as not loosening the floating

pulleys, which has worked for decades worth of all manner of engines? I'm not questioning pointlessly, I just don't blindly follow the herd

without investigating the reasons for the stampede first.

[Edited on 25/5/13 by coyoteboy]

froggy - 26/5/13 at 12:02 AM

mark chandler - 26/5/13 at 08:09 AM

I cannot see why you worry about tension either using the belt cut system (very clever), tension is only an issue if you have the pulleys loose, they

are not so no need to worry.

Look at this another way, you have a correctly set up car and turn the engine the wrong way and the tensions will be all over the place, turn it the

right way and everything is restored because nothing fixed has changed.

Doing this 1/2 belt cut would have saved me near tears when I changed the belt on my 928 Porsche, I got lost on belt routing as well as tension on

that

40inches - 26/5/13 at 10:12 AM

quote:

Originally posted by mark chandler

I cannot see why you worry about tension either using the belt cut system (very clever), tension is only an issue if you have the pulleys loose, they

are not so no need to worry.

Look at this another way, you have a correctly set up car and turn the engine the wrong way and the tensions will be all over the place, turn it the

right way and everything is restored because nothing fixed has changed.

Doing this 1/2 belt cut would have saved me near tears when I changed the belt on my 928 Porsche, I got lost on belt routing as well as tension on

that

This makes perfect sense to me. Does that make me a pain in the arse too?

daviep - 26/5/13 at 01:06 PM

quote:

Originally posted by 40inches

quote:

Originally posted by mark chandler

I cannot see why you worry about tension either using the belt cut system (very clever), tension is only an issue if you have the pulleys loose, they

are not so no need to worry.

Look at this another way, you have a correctly set up car and turn the engine the wrong way and the tensions will be all over the place, turn it the

right way and everything is restored because nothing fixed has changed.

Doing this 1/2 belt cut would have saved me near tears when I changed the belt on my 928 Porsche, I got lost on belt routing as well as tension on

that

This makes perfect sense to me. Does that make me a pain in the arse too?

Doesn't male you a pain in the arse, just means you don't understand fully yet.

Froggy and harv are 100% correct. I've gotten away wthout locking kits loads of time, I've also been caught once with a VW TDI engine which

hunted at idle after doing the timing belt, did the belt the correct way and problem sorted.

BTW Is the ABZ a CCW rotation engine?

Cheers

Davie

coyoteboy - 26/5/13 at 07:15 PM

Still not seeing the complication that requires floating of the pulleys (assuming you don't HAVE to float the pulleys to get the belt on, of

course) and no-one seems to be able to explain it, though they're good at posting funny images

Assuming a keyed crank, keyless (but un-removed) cams, there's no need at all that I can see. The belt tooth spacing has to be accurate (or else

you'd have belt failure in no time due to the teeth not matching the pulley) and there's fixed tooth-size relationships between the various

rotary parts. Rather than just making smart remarks, if someone knows better and can explain it - do so. If you can't explain it, you obviously

don't understand it either? All of the failures with keyless pulleys I've read about (done by others) have come about because they

didn't realise the pulley floated OR through the mistake that caught me out on my first attempt - they used the locking tool to lock the cams and

crank but the crank locking tool doesn't lock the crank from rotating clockwise, meaning a slight shift occurs which knocks the timing out a

degree or two.

FWIW the engine is a clockwise rotating engine, when looked at from the timing belt end.

quote:

Look at this another way, you have a correctly set up car and turn the engine the wrong way and the tensions will be all over the place, turn it the

right way and everything is restored because nothing fixed has changed.

Exactly, so long as the tooth-tooth distance hasn't changed and the tension at the longest stretch between cam and crank is the same after a

couple of rotations, the relationship between cam and crank remains the same. It's easy to check with matchmarks?

I believe this discussion isn't really relevant to the ABZ if it has the keyed crank as it is effectively a "normal" engine at that

point, I'll only know if I pull the pulley off and find it's keyless, but even then I could matchmark crank and pulley

[Edited on 26/5/13 by coyoteboy]

daviep - 27/5/13 at 12:41 AM

If you want accurate timing you need to have some method of being able to make sure any slack in the belt is taken up with the cam(s) in the correct

position in relation to the crank.

I can't provide a definitive explanation of why this happens but I can say for definate that if you lock the cams and crank and fit a new belt

there will certainly be some slack in the belt between the crank and the cams which is on the untensioned side of the belt. There are two ways to get

rid of this slack.

1: The correct procedure is to slacken the cam pulley(s) and allow the tensioner to take up the slack with the cam(s) and crank still in the correct

position, then retighten the cam sprocket(s)

2: The wrong way is to remove one of the locking pins and allow either the crank or cam(s) to rotate so that any slack is moved to the tensioner side

of the belt. Doing this means that with the belt correctly tensioned the crank and cam are no longer correctly aligned.

I certainly don't share your confidence in the manufacturing tolerances of timing belts.

I'm not trying to make smart remarks and I have used various methods when fitting belts but it depends on how precise you want /need to be,

marking the belt and pulleys on a pinto or similar works fine, doing the same on a modern engine with crank and cam sensors doesn't.

Cheers

Davie

coyoteboy - 27/5/13 at 06:27 PM

Just to note, I wasn't claiming you were being smart arsed - that was aimed elsewhere, and in jest. I can accept when I'm being an idiot, I

just don't follow the herd without seeing the evidence of the threat myself.

If the tolerances of the belt tooth-tooth lengths were that bad the belt would rip itself to pieces on the pulleys. And to get a belt that is the same

overall length with the same tooth count, the average must be pretty damn close (+- 0.1mm or so). There might be fractions of a degree difference

(which I suppose could affect the ECU reading the cam/crank if sufficient separation isn't available on the tooth outputs) but that in itself

won't affect the running of the engine (assuming the ECU doesn't have a hiccup) - hell, on a V8 there will be a good degrees worth of

stretch in the belt on its longest run anyway I'd wager. I've done quite a few timing belts in my time, through all manner of means, and

never known one that had a problem when the matchmarks lined up afterward. Floating pulleys makes perfect sense in a high speed factory production

environment - automated assembly is a synch when you're not having to line up keyways with a robot, but I genuinely don't think it's

for any reason outside of that. I do beleive that if you let it slip a few degrees during assembly you're in trouble and the ECU will have a fit,

but I don't believe the variation in belt dimensions would be even close to that and my previous experience gives me (possibly false)

confidence.

I'm willing to put my trust in the knowledge that the belts are bloody accurate and tooth counts negate any issue, when I pull it apart, put it

back and fire it up and ram 32 valves through 8 pistons you can chuckle at me, but to be honest a new engine is cheaper than buying the official tools

and the cheapo tools won't hold it to the accuracy you claim is needed

[Edited on 27/5/13 by coyoteboy]