http://www.andersensmith.freeserve.co.uk/wiringloom6.pdf

Its seems to be a subject that comes up regularly on here so i have decided to give it its own post....

I hope it is of help to some out there.

also here is a further article on fitting relays (wrapped up in a method of fitting a cooling fan over ride switch and fan warning lamp)

http://www.godspeed.me/forums/viewtopic.php?f=14&t=1289

both written by me so feel to ask questions...

Dave

[Edited on 29/4/12 by snowy2]

That will be very helpful for al the guys on here trying to wire up a kit car from scratch

Why did you not post this 14 years ago!

steve

thanks it looks very helpful and a lot of time must have gone in to it

that is great, and good timing too, as after the plumbing, the wiring is the next job.

thanks

Perhaps ChrisW can make it a *sticky*?

[Edited on 28/4/12 by HowardB]

quote:

Originally posted by steve m

That will be very helpful for al the guys on here trying to wire up a kit car from scratch

Why did you not post this 14 years ago!

steve

That's a great write up thanks,can this be made a sticky for all to see & so it does not get lost.

A very good, helpful & very informative piece But ........... I do question one part, not all "scotch locks" are created equal and as

such they should not all be derided.

quote:

DO NOT under any circumstances use scotch locks (or similar) to make any connection whatsoever on your wiring loom. And if by some horrible quirk of fate you do have to use one, make it as temporary as possible and completely remove it from the loom, and make a proper spur joint at the earliest opportunity. I am sure that under ideal and damp free conditions it will be the case that scotch locks ( or similar) will make very good and long lasting connections. However my years as a mechanic, fitting alarms and tow bars etc. and then subsequently fault finding on them lends me to believe that these conditions do not exist in the automotive industry. From personal experience it seems that scotch locks eventually have a similar effect as slowly hammering flat a section of water pipe would do, so benefit from bitter experience, and take my advise on this matter. I cannot stress this point enough!

I was speaking generaly as a mechanic most folks who would be thinking of rewiring their car would not go for the types you show. also they would not

be too carefull how they are fitted or if they are the right size.

most faults found on tow bars and alarms could be traced to the use of these connectors. if your rewiring your car why use them and ask for problems

if not used correctly? Especially if doing it correctly is easier and more reliable?

Most folks are amateurs and some jobs are daunting so these articles were written with them in mind.

as i have said most (90%+) of electrical faults on aftermarket equipment could be cured by removing the scotch locks.......as i say in the article

they are perfectly good when used correctly. it is very difficult to do so in the automotive world.

quote:

Originally posted by snowy2

I was speaking generaly as a mechanic most folks who would be thinking of rewiring their car would not go for the types you show. also they would not be too carefull how they are fitted or if they are the right size.

most faults found on tow bars and alarms could be traced to the use of these connectors. if your rewiring your car why use them and ask for problems if not used correctly? Especially if doing it correctly is easier and more reliable?

Most folks are amateurs and some jobs are daunting so these articles were written with them in mind.

as i have said most (90%+) of electrical faults on aftermarket equipment could be cured by removing the scotch locks.......as i say in the article they are perfectly good when used correctly. it is very difficult to do so in the automotive world.

quote:

Originally posted by Hector.Brocklebank

I fully agree with you, but maybe it might be prudent to inform the non-professional, who is thinking of undertaking their own wiring, of some of the higher quality, more acceptable types of consumables that are available, instead of only (correctly) advising against those horrible cheapo style scotch locks.

quote:

Originally posted by snowy2

Again why would you use these "snap" connectors? they are primarily to save time in commercial applications, over a week they can make a considerable time saving and the connections will last as least as long as the warranty. We are building cars for our selves and we expect the best job we are capable of. If electrics are not your strong point your fault finding isn't going to be any better. You don't need to save time in your build (an hour or so in a build of several hundred hours is no saving at all.) so why not do it properly and save the potential problems for the commercial operators and their time saving dodges.

Dont get me wrong, i not having a pop i like the banter, and a healthy debate can lead to a better understanding of the issues.

I use some soldered connections on my car, however i don't recommend soldering for those who have never done it as its easy to get it wrong (or at least a poor joint that will fail) also for some applications in cars they are a liability as they are prone to cracking due to the vibration.

I have just rewired my own car after an extensive winter rebuild and some (read almost everything) modifications, i used the method described above,

the dash was rewired in an afternoon sat in my front room comfortable and warm.....

the rest of the car was done in most of the following afternoon. If you don't like the idea of the "chock" blocks finish the wiring and

then replace them with proper terminals. That said in 4 years since the first time i did the job and over 20,000 miles i never suffered any problems

as a result of using them (they did not work loose) they did allow me to modify my wiring as i altered various things (like fitting an electric

fan)

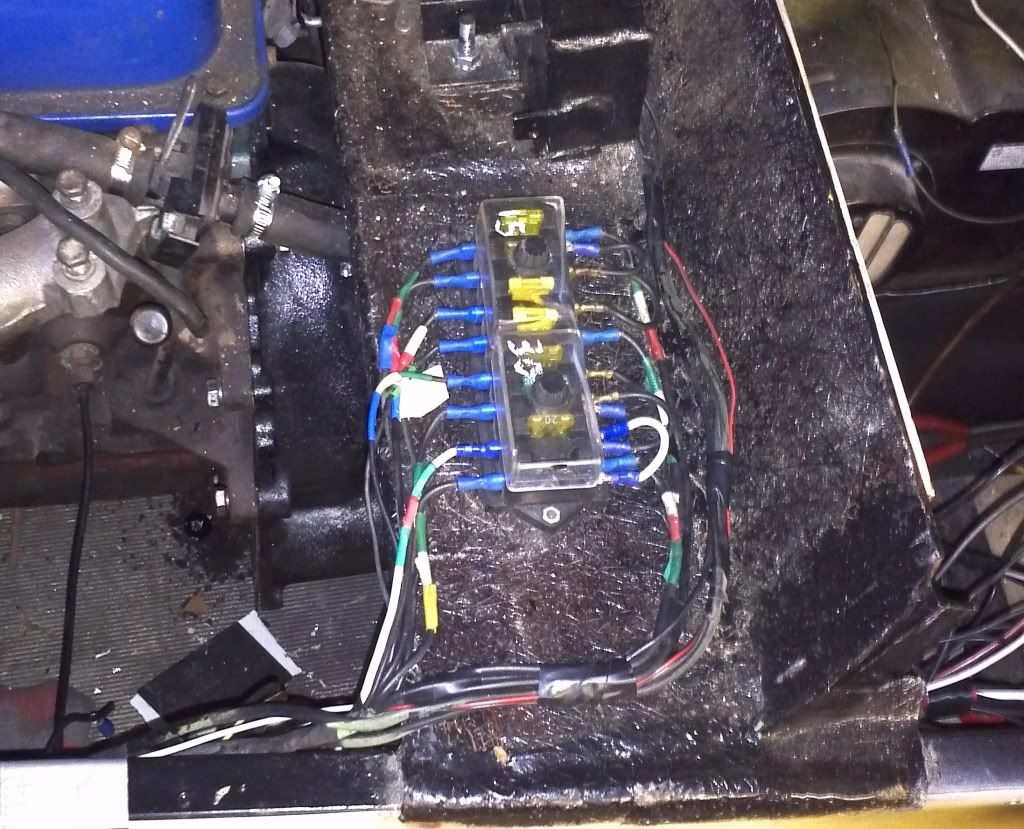

and here is the fuse box,

once the loom is all wrapped it will look nice and tidy

Just keeping it current. Chris has said he will make the post a sticky.

quote:

Originally posted by snowy2

Just keeping it current. Chris has said he will make the post a sticky.

Apparently several folks have asked and besides folks don't do searches. if its not on page one they ask the question again. Your right it is simple, but a lot of builders really struggle with electrics.

Save the .pdf to your drive and read it when you want to, job done.

Has anyone here used this method? ....other than me that is, i know of one or two for sure, but some feed back will help me make it simpler if it needs it.

Just putting this in a more visible place ;-)

just putting this at the front of the list for easier finding...

Old post, I know. I know what to do, but the execution looks like crap, and it all falls apart in no time. I need a professional rewire, but don't know where to turn where I live.

Its as tidy as you need to make it as for falling apart in no time, my current car has done 22000 miles with no problems (over 4 years) the first car

i did using this system back in 1989 (and its still on the road) still has the wiring loom in place (the new owner claims never to have touched it as

he doesn't understand electrics...) it had done 18000 miles when he bought it in 1991, it gets used most summers and he uses it quite a bit.

For the article i left it "rough" looking to show how easy it could be to put together, it takes half an hour to wrap the loom in proper

self amalgamating loom tape.

as for using "chock" blocks in part of the loom it was always the intention of mine to replace them with "proper" connectors but

if i am honest they are the least troubling part of the loom in use, they tend to be the bullet connectors, which is why i don't recommend using

them.

if your building a car wiring up your car is part of the build process and a fair few builders need an easy way to do it. if your building something

like a Westfied where every thing arrives in a box ready to "go" can you really say you have built the car or just assembled it? My good

friend has a Mk3 Cortina he stripped and restored but he doesn't claim he has been building a car.

So this article was offered up for those who are looking to say they built their car from scratch and want to do as much themselves as they can. It

also has the practical benefit of saving you a hundred pounds or so.

Hi guys hope you dont mind me butting in here but Eddie99 on here, will have a very good quality looms at stoneligh this year, to work with Sierra

stalks and come with relays and fuse box all wired in all.

You will need to do is lay the loom in you car cut the tail ends to length connect your lights and secure the loom and off you go.

Im away this weekend but will be home monday night and will put on a picture of the loom that i have for my car if anyone is interested

This question has come up again and i thought it would help to move it to the front of the posts lists again to help some find it again

Perfect, just subscribing

i hope it is of use to you, any problems you can PM me.....Dave

This would be the article your looking for.....

Thanks Dave and everyone else it has been great

quote:

Originally posted by snowy2

quote:

Originally posted by Hector.Brocklebank

I fully agree with you, but maybe it might be prudent to inform the non-professional, who is thinking of undertaking their own wiring, of some of the higher quality, more acceptable types of consumables that are available, instead of only (correctly) advising against those horrible cheapo style scotch locks.

Again i could have advised the use of the better quality ones.....except i am also tracing faults on our fleet of new (2 year old) hgv trailers which use these connectors frequently for the LED side lights, and after replacing the INOP side lights i have checked some of them and found them to be OK, it was the connectors that were faulty....... (not all of them, but enough)

My advice stands.

Besides i offer this article as a helpful aide to the hobby i have been involved with for over 20 years now and i have noticed that electrics are the most frequently quoted "problem". i am not affiliated with any company and have no axe to grind, nor do i feel i should give any extra advise on alternative connection devices when those i recommend are easy to get, cheap to buy and reliable in use.

Again why would you use these "snap" connectors? they are primarily to save time in commercial applications, over a week they can make a considerable time saving and the connections will last as least as long as the warranty. We are building cars for our selves and we expect the best job we are capable of. If electrics are not your strong point your fault finding isn't going to be any better. You don't need to save time in your build (an hour or so in a build of several hundred hours is no saving at all.) so why not do it properly and save the potential problems for the commercial operators and their time saving dodges.

Dont get me wrong, i not having a pop i like the banter, and a healthy debate can lead to a better understanding of the issues.

well done Axle......hope my little article was of help....and that you gave it a try ;-)

Here it is....

Been told the link no longer works....

So here is a link to my google drive.

https://drive.google.com/file/d/0B2jAUFXnhFYCTm1IU1NhTENoSEVNMk95akw1UzFZR3NmckxN/view?usp=drivesdk

Hope it still helps someone...

Now working. And useful!

Thank you very much!

Glad it's still of help....

Hi Snowy.

I bought a Summit Racing Harness, and it comes with its instructions, but I have some thoughts that I am quite sure I have read this in the forum, but

canīt find them.

- I plan to install Terminal blocks to join the Fuse Block to the actual harness. Is this a good Idea?

The above means that I will have a very short run to the terminal block, and then to the appropriate electric component.

- I plan to use a Megasquirt and plan to do the same thing with it too. Is it a good idea? Or is it better to have one run of cable even from the

sensors/ijectors, etc to the ECU?

- Is it worth it to do so with the Dash?

- Somewhere I read to install the electrical component first and trace cables back to fuse box; doing so will leave excess cable bunching up near the

fuse box, leaving the option to cut and splice or use the Terminal Blocks as above.

I Have got to the point where chassis is almost finished, but still have uspension, Brakes and fuel lines uninstalled. Do you think it is wise to

carry on with wiring at this point or do you reckon it would be better to install everything else before attacking the wiring?

Thank you very much for your time and contribution to this forum.

Angel Acevedo

If you want to go a bit non-locost, lots of interesting ideas and reccomendations on wiring here.

quote:

Originally posted by rodgling

If you want to go a bit non-locost, lots of interesting ideas and reccomendations on wiring here.