It's similar to this but longer:

I've cut out out of 2mm steel (plentiful & all I have at the moment), is this too thick to start with? Seems very difficult, any ideas? Rest of the exhaust parts are 1.5mm.

[Edited on 9/12/08 by Benzine]

I've just used Cone Layout to make a cone for the collector I'm making. I've traced it onto the metal and cut it but how do you go

about bending it?

It's similar to this but longer:

I've cut out out of 2mm steel (plentiful & all I have at the moment), is this too thick to start with? Seems very difficult, any ideas? Rest

of the exhaust parts are 1.5mm.

[Edited on 9/12/08 by Benzine]

Would a stainless steel household funnel do the job? just thinking that all, and 2mm does seem a bit ott, more like 1mm as its strength will be

achieved when in shape me thinks.

Cheers Rich

Seems a bit thick to me!

Can you roll/form it around something - I'm thinking along the lines of the way Uncle Ron shows how to form the curves of an ally bonnet in THE

BOOK. Large bit of wood (log maybe), clamp one edge and start persuading it around.

Yeah it does seem too thick. Humbug! Humbug!

Humbug, Mr Baldrick?

Need to get some thinner metal. I hate buying it, I can get some locally but only in huge sheets or I can get the right quantity online but have to

wait a few days

Yes, what do you want?

2mm is thick without the correct tooling.

To form the cone you should draw a fan shape (lines close together) on the template and then gradually put a slight bend in each line. Slowly a

conical shape will appear.

Long process.

HTH

Nige

i could do it in 10mm stainless if you want, but not exactly locost or light weight.

If your struggling, could make one up in mildsteel and post it, let me know

Hi Benzine,

I assume you don't have a brake press, folder or rollers.

Do you have a good vice, piece of thick wall pipe, (steel scaffold tube) and a hammer? Nylon mallet would be good.

Paul G

edit to say: If you U2U me a phone number I'll talk you through the technique.

(I can talk quicker than I can type)

[Edited on 9/12/08 by 907]

you want a 16g cone rolled ?

i think a scaffold and a hammer , you would do it with that and maybe some gentle heat .

what inlet/outlet diameters ?

a set of rollers with a piece of angle jammed in the right hand side with the smaller end of the cone touching this angle and just roll piece of

cake

2mm is just making life very difficult for yourself. 16 gauge is about as thick as you'd need to be honest, and you can form that by hand by gently bending it in radial lines over a piece of stout pipe held in your vice (e.g. bit of scaffold tube).

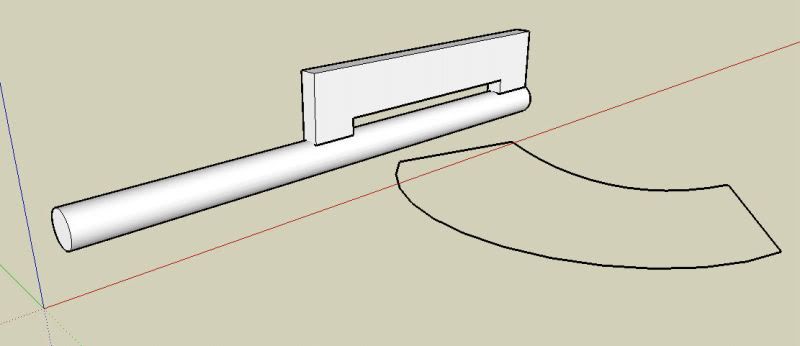

When I did the cones (four of them!!), I cut out the shape (16swg stainless) and made up a tool to go in a vice.

The tool consisted of a length of tube (about an inch in diameter) with a piece of plate welded at both ends with a gap underneath so cone shape could

be put under the plate and held in place while it was bent around the tube. Bent them by hand

ATB

Simon

Just done a quick "Sketchup" - picture speaks a thousand words, and all that

ATB

Simon

I made a half-cone out of substantial sheet (for a Hillman Imp rear spring turret) , very neatly, by hammering (nylon/rubber/wood spacer) around a heavy steel tube. Heavy steel tube in this case was a handy lamp-post outside my house..... dink dink...

Thanks for the help ^__^ In the end I found some perfect metal - an old ammo crate I had lying around that used to be a PC case. I've cut the

cone shapes out and they're much easier to bend