ST170 problems??

coozer - 17/9/11 at 08:00 PM

Any St170 experts anyone can recommend? Not sure if I have a problem or not....

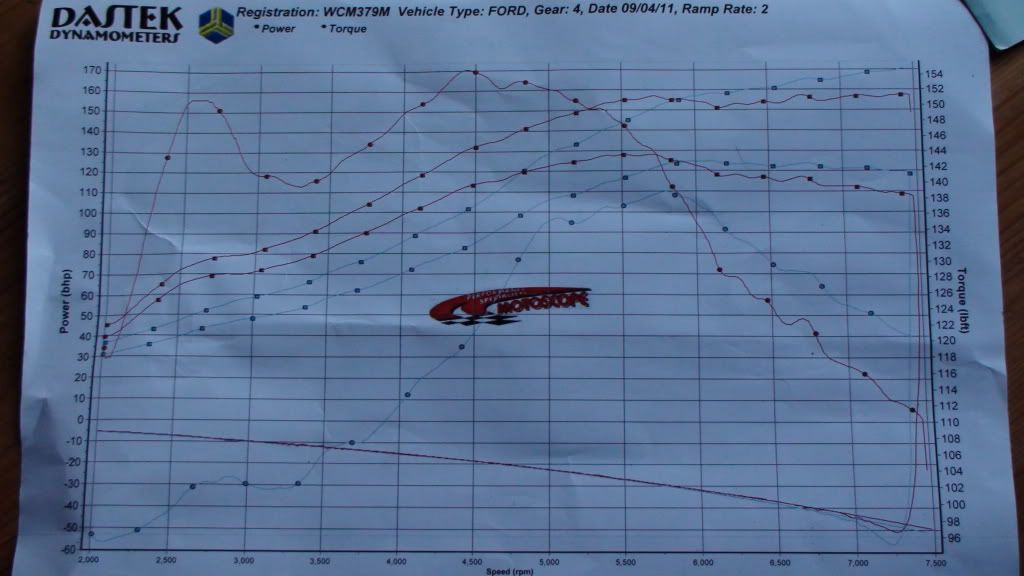

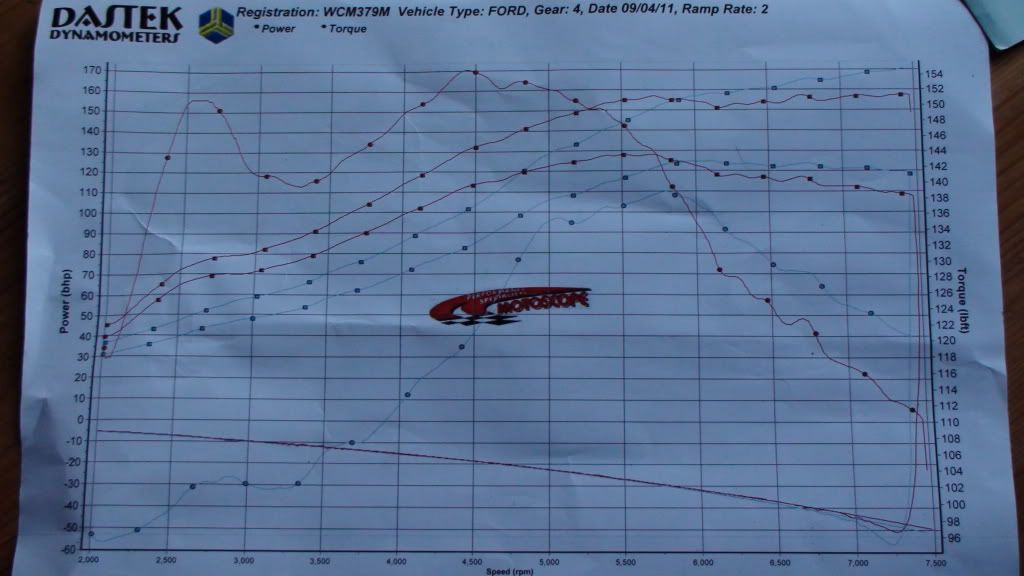

Had mine mapped early on this year and despite the 178bhp the more I think of it the more I think there is something wrong.

Not sure if the mapper was crap or the motors poorly...

Basically the compression was low at 148psi but this was the same across all cylinders, is this something to do with the VVT???

The other thing was peal power was at 4500 rpm and it dropped right off after that. is that down to the mapper??

All in I reckon the motor is good for over 200bhp but not sure if its down to a poorly motor or the mapper not being very good.

Any thoughts?

Steve.

DixieTheKid - 17/9/11 at 08:12 PM

The ST170 has got to be one of the hardest engines to tune, ford have already done all the work for you. You be lucky to get over 200bhp without

spending thousands and some forced induction!

lotusmadandy - 17/9/11 at 08:13 PM

The mapper was Rubbish.

also could the vernier pulley be holding the valves open

to long??

I cant imagine your motor is uncle bucked,it pulls like a train.

Andy

DixieTheKid - 17/9/11 at 09:00 PM

It's possible. But I wouldn't of thought it could be that far out. It would run like a bag of nails.

coozer - 17/9/11 at 10:02 PM

Dixie.. I'm a nutter and your thick....

I want a peep who knows about these engines.. all I want is 200bhp.

beaver34 - 17/9/11 at 10:28 PM

I'm not expert, but I would look at how your VCT is working, but they rarely make good power as far as I've ever seen

DixieTheKid - 18/9/11 at 06:47 AM

quote:

Originally posted by coozer

Dixie.. I'm a nutter and your thick....

I want a peep who knows about these engines.. all I want is 200bhp.

Thick? Im not the one that thinks im going to 200bhp out of a zetec! even a standard st170 your be lucky to get one with 170bhp. Let me know the £ per

bhp to get to 200bhp. Trust me it not worth, go buy a mk1 focus rs.

[Edited on 18/9/11 by DixieTheKid]

RichardK - 18/9/11 at 07:52 AM

Steve, as you know I've no experience of the st170 but I would look at the verniers and performamce cams to get you near the 200 mark, to

guarantee 200+ either a supercharger or blower I think is your only chance.

The above is purely what I've read over time, has your motors performance gone down then mate? You motor always seemed to pull like a train when

I've been behind it  Where did you go for mapping? Damian @ daytuner seems to be ok in Harrogate, wouldn't suggest Boggs as you have an

omex and tb's.

Where did you go for mapping? Damian @ daytuner seems to be ok in Harrogate, wouldn't suggest Boggs as you have an

omex and tb's.

Cheers

Rich

MikeRJ - 18/9/11 at 11:02 AM

quote:

Originally posted by coozer

Any St170 experts anyone can recommend? Not sure if I have a problem or not....

Had mine mapped early on this year and despite the 178bhp the more I think of it the more I think there is something wrong.

Not sure if the mapper was crap or the motors poorly...

Basically the compression was low at 148psi but this was the same across all cylinders, is this something to do with the VVT???

The other thing was peal power was at 4500 rpm and it dropped right off after that. is that down to the mapper??

That is down to either a broken rolling road or someone who simply doesn't know how to operate it. Your engine did not produce a peak of 178bhp

at 4500RPM; it's simply not possible unless you have magically been able to make a relatively standard, normally aspirated ST170 produce 208 lbft

of torque at 4500RPM.

Just to emphasis how unlikely this is, Ford claimed just 144.5 lbft at 5500RPM for the ST170. The only way you are going to get 44% higher peak

torque at a lower RPM is with forced induction.

The ST170 is notoriously hard to tune by simply making inlet and exhaust modifications. Have a look on the Ford forums, plenty of people have spent

serious money on ITB's and expensive exhausts only to be hugely dissapointed - I don't know of an ST170 producing a genuine 200bhp with only

these mods.

[Edited on 18/9/11 by MikeRJ]

coozer - 18/9/11 at 11:07 AM

quote:

Originally posted by MikeRJ

That is down to either a broken rolling road or someone who simply doesn't know how to operate it. Your engine did not produce a peak of 178bhp

at 4500RPM; it's simply not possible unless you have magically been able to make a relatively standard, normally aspirated ST170 produce 208 lbft

of torque at 4500RPM.

Just to emphasis how unlikely this is, Ford claimed just 144.5 lbft at 5500RPM for the ST170. The only way you are going to get 44% higher peak

torque at a lower RPM is with forced induction.

Why do you not think it does that?

The RR printout shows 178 @ 4711rpm and 241nm @ 4419.

Back to the original Q, any actual experts on here??

MikeRJ - 18/9/11 at 11:12 AM

quote:

Originally posted by coozer

quote:

Originally posted by MikeRJ

That is down to either a broken rolling road or someone who simply doesn't know how to operate it. Your engine did not produce a peak of 178bhp

at 4500RPM; it's simply not possible unless you have magically been able to make a relatively standard, normally aspirated ST170 produce 208 lbft

of torque at 4500RPM.

Just to emphasis how unlikely this is, Ford claimed just 144.5 lbft at 5500RPM for the ST170. The only way you are going to get 44% higher peak

torque at a lower RPM is with forced induction.

Why do you not think it does that?

The RR printout shows 178 @ 4711rpm and 241nm @ 4419.

Back to the original Q, any actual experts on here??

Basic common sense tells me it's wrong.

BHP = (Torque * RPM) / 5252

so

Torque = ( BHP * 5252 ) / RPM

211.6 lbft = ( 178 * 5252 ) / 4419

Your torque figure of 241 Nm converts to ~178 lbft, so what your numbers suggest is that your peak torque is lower than the torque at peak power.

Utter nonsense.

I know it's not what you want to hear, but the figures simply don't stack up. You need to find a better rolling road establishment with an

operator that knows what they are doing. Constantly asking for "actual experts" is not going to change the fact that your numbers are

fundamentally incorrect.

EDIT to put actual peak power RPM in.

[Edited on 18/9/11 by MikeRJ]

coozer - 18/9/11 at 11:48 AM

OK, the RR guy, who is weber recommended and knew his socks, reckons the LACK of compression was the reason it peaked early and then tailed off. He

was of the opinion that it was good for 200 if the torque kept building. He spoke about a motor he had built for a customer that made 155bhp and was

hugely disappointed... but mines not like that. Obviously.

Now, I've heard that due to the inlet cam being floppy when theres no oil pressure, ie, during cranking, can lead to comp figures being low. The

other theory is the motors overheated at some point and cooked the rings...

I did a lot of research on the Focus and other Ford forums and do know that in standard form these motors can be disappointing, BUT I'm not as

you can see it makes 178bhp. It made 166 on a different RR with poorly setup bike carbs. The printout for that is in my blog. If you compare it with

this one it looks very similar....

Bog stand 2.0l zetecs are good for over 200bhp. Is there any reason an ST170 can't do the same????

iank - 18/9/11 at 12:08 PM

Bog standard Zetec's don't get close to 200bhp. You need to spend a lot of money on upgraded cams and head work to see that.

RichardK - 18/9/11 at 12:46 PM

quote:

Originally posted by iank

Bog standard Zetec's don't get close to 200bhp. You need to spend a lot of money on upgraded cams and head work to see that.

Here a rough guide...

Dunnell Page

Love

Rich

DixieTheKid - 18/9/11 at 03:14 PM

Your get to about 190bhp if your lucky but your need to change the cams, change to throttle bodies, de cat stainless exhaust and a complete remap,

been there and done it my mates Derek's motor.

If I remember rightly the early st170 had to have an update to the ecu by ford. You have installed throttle bodies I see, what management are you

running and how is that running in conjunction with the vvt? I may have to my now words here, if you haven't killed the rings and the compression

is low (dont know what it should be on the st) you could have a little monster in there!

RichardK - 18/9/11 at 03:34 PM

I believe he's running an OMEX 600 ecu.

coozer - 18/9/11 at 04:13 PM

GSXR750 TB's + Omex 600. Dunnell exhaust type...

VVT is triggered by the ecu via a relay at 1500rpm and above 25% tps.

Just been outside fitting a new air filter...

[Edited on 18/9/11 by coozer]

DixieTheKid - 18/9/11 at 06:58 PM

I think the only way to be sure is to pull the head off and check the valves and rings. What should the compression be in psi on and new car? You can

expect a small loss. But for the cost of a head gasket, cam belt and a set of bolts you can be sure 100% that the internals are fine and set to work

in the timing. The st has bigger inlet valve than a standard zetec and stronger springs, could be the valve seats if your really unlucky.

Cornishman - 18/9/11 at 07:19 PM

Just worth pointing out that MikeRJ has accidentally used the wrong RPM figures in his calculations thus causing some confusion. He has substituted

the RPM for peak torque into the peak power calculation therefore giving the false impression that a practically impossible set of figures have been

produced.

If you look at the print out CAREFULLY and run the figures as I have just done then they seem fine mathematically.

Not wishing to cause offence to anyone but thought it worth pointing out as I am following the thread with interest to help decide what engine to run

for the 2013 season (1.3 xflow for 2012!).

Steve

nz_climber - 19/9/11 at 01:17 AM

Not familar with ST170 VVT system. Is it a continuously variable or just switched on off in the standard car?

What do the A/F ratios look like above 5000rpm?

Most VVT systems turn on at where you have set, but also turn off higher in the rev range, to work this out you need to do back to back runs on the

dyno, with it off, and with it on fully and have the switch point and switch back point where the graphs cross each other.

If it is a continuously variable system and you are just switching it on at x rpm that could explain the situation as you cam timing will be way out

(depending how far it actually moves)(have heard toyota continuous systems can move in excess 30 degrees, but controlled by the ecu and don't

move that far in normal operation)

But first I would be looking at taking it to another dyno shop, and comparing the numbers, maybe they got the gear calculations wrong and the rpm

scale is all mucked up.. (I would say you got the right power just in the wrong part of the rev range)

paulf - 19/9/11 at 09:32 PM

These were also my thoughts, I remember hearing that above a certain rev range most VVT systems retard the cam for better power at top end revs.I know

most people are using a simple on off switch for ST170s and have considered experimenting with a pulse width modulated system to allow the advance to

be mapped via a separate control box but haven't yet found a cheap ST170 engine to experiment with.

Paul

quote:

Originally posted by nz_climber

Not familar with ST170 VVT system. Is it a continuously variable or just switched on off in the standard car?

What do the A/F ratios look like above 5000rpm?

Most VVT systems turn on at where you have set, but also turn off higher in the rev range, to work this out you need to do back to back runs on the

dyno, with it off, and with it on fully and have the switch point and switch back point where the graphs cross each other.

If it is a continuously variable system and you are just switching it on at x rpm that could explain the situation as you cam timing will be way out

(depending how far it actually moves)(have heard toyota continuous systems can move in excess 30 degrees, but controlled by the ecu and don't

move that far in normal operation)

But first I would be looking at taking it to another dyno shop, and comparing the numbers, maybe they got the gear calculations wrong and the rpm

scale is all mucked up.. (I would say you got the right power just in the wrong part of the rev range)

ianjenn - 20/9/11 at 06:33 AM

the st170 VVT is a simple on off switch. Basically there is a solenoid that opens an oil channel. It is the oil pressure that varies the advance. It

is not possible to modulate electrically. The oil pressure will equalise either side of the solenoid whether it is fully or part open.

djtom - 20/9/11 at 02:04 PM

The ST170 VVT is not a simple on-off system, the solenoid in the original installation is driven by a PWM feed by the ECU to continually vary the oil

pressure to the hydraulic cam. The cam angle can change by over 30 degrees (IIRC), which usually accounts for the massive step in the power curve that

results from just switching the VVT on/off. Someone posted a power curve the other day with the VVT switched in at 3000 rpm - the power went from 40

to 80 bhp by about 3200rpm....

Tom

ianjenn - 20/9/11 at 05:56 PM

from my observation what you are suggesting defies the laws of physics. the solenoid blocks one oil channel with no control on return. therefore as

soon as the valve opens even a fraction the pressure would equalise. In addition when applying varying voltage and current to the solenoid there is no

difference in operation.

MikeRJ - 20/9/11 at 09:50 PM

The ST170 has a continuously variable cam timing system. The ECU does not provide a fixed PWM duty cycle to get a particular timing value, but

instead sets it on a closed loop basis by measuring the phase difference between the crank and cam position sensors and control the solenoid duty

cycle to hold whatever phase difference is required by the ECU map. This is the same system used on the smaller Zetec SE and the larger V6 and V8

engines Ford makes in the US.

The solenoid is like a tiny spool valve, supplying pressure to one side or the other of the variator vanes, and allowing the non-pressure side to

drain back into the sump.

MikeRJ - 21/9/11 at 01:37 PM

You are free to call it drivel but that doesn't stop it being true. Ask yourself why the solenoid valve is driven by a PWM signal if the phaser

is only supposed to work fully retarded or fully advanced? Also have a read of this, in particular the

following quote (my emphasis):

quote:

"The intake camshaft is equipped with an electro-mechanical control mechanism, which allows the cams maximum opening point, relative to

crankshaft degrees, to be varied between 85 and 145 degrees after top-dead-center on the intake stroke."

Considering none of the numbers add up on that dyno plot and the dyno operator hasn't even corrected for humidity or atmospheric pressure, I

don't see how you can put any faith in them.

beaver34 - 21/9/11 at 04:25 PM

to be honest your attitude towards people trying to help your cause isnt great! why would they help you if your going to answer there replys like that

coozer - 22/9/11 at 11:28 AM

Sorry if it comes over like that, but it seems every time I post any questions about my engine it gets hijacked and turns into a argument about how

the vvt works.

I know how it works, I know how it works in my car and I'm quite happy with it.. I'm perplexed by the low comp figures and looking for a bit

more power....

Rob Allison - 25/9/11 at 10:10 AM

Done a bit on the ST170 with a mate who has one in a mk1 escort on bike carbs with megajolt.

When setup at motorscope without vvt it made almost 170bhp. Then they tried just switching the vvt on (5Volt) it was a bit hit and miss but had a big

spick in torque at 2500 rpm. but due to the bodge trying to get it on the results were not realy usable.

But the VVT is not just a turn on at a set rpm. It has a map of its own through the rev range and it is a vairable signal to the solenoid as said.

Just putting 5 Volts on will just move the cam to its max setting.

But caution. The VVT should not be switch below 2000rpm. This is something to do with the cam timing causing piston to valve contact. I'm not too

sure on the exact point in the rev range that the max cam timing will cause this just i know it will happen. So it is possible that your compression

loss could be due to this ??

I'm trying to find the cam timing map for an ST170 in my mk2 escort. Below is the plot from the mk1 escort. The spike at the 2500rpm point is the

use of the vvt.

Rob Allison - 25/9/11 at 12:16 PM

Heres some ST info copied

The 170PS 2.0-litre Duratec ST engine has been developed from the standard 130PS 2.0-litre Ford Focus (Zetec)engine with several new features,

including:

∑ New, high-flow aluminium cylinder head with larger inlet valves and higher lift intake and exhaust camshafts for higher peak rpm levels

∑ Continuously variable intake valve timing

∑ High compression, cast-aluminium pistons and forged steel connecting rods

∑ Dual mass flywheel

∑ New dual state intake (DSI) manifold, using long runners for low-end torque and shorter runners for higher peak power outputs

∑ Larger bore free-flowing stainless steel exhaust system, tuned for enhanced performance sound.

Duratec STís new aluminium cylinder head features enlarged intake ports to increase its flow potential. It is fitted with larger intake valves (33.5

mm) to further Duratec STís free-breathing character. Stiffer springs on both the intake and exhaust valves help to facilitate a higher red-line.

Focus ST170 has an indicated red line of 7,200 rpm on the tachometer and rev-limiter intervention beginning at 7,350 rpm.

Fuel is delivered to the cylinders via an electronically controlled, high-output fuel pump. With precise electronic control of the fuel delivery to

the injectors, no return fuel loop is required. The system contributes to ST170ís Euro Stage IV emissions capability.

Variable valve timing technology gives Duratec ST combustion efficiency that eliminates the need for a close-coupled catalyst in the exhaust system.

This enhances its flow characteristics and performance capabilities further.

Duratecís intake camshaft is equipped with an electro-mechanical control mechanism that allows the camís maximum opening point, relative to crankshaft

degrees, to be varied between 85 and 145 degrees after top dead centre. Variability is calibrated according to engine speed, load and operating

temperature. It is accomplished by changing oil pressure on either side of a piston in a helix between the cam and its drive pulley.

On cold start-up, VVT helps to provide a precise combustion calibration that facilitates quick light up of the underbody exhaust catalyst before

adjusting to a profile for high combustion efficiency. As a result, SVE could position the catalyst unit Ė incorporating premium metallic elements Ė

approximately 900 mm away from the cylinder head face to give Duratec ST its free exhaust flow with reduced back pressure. A second catalyst unit is

located downstream in the exhaust.

The exhaust system is constructed entirely of stainless steel, tuned for its throaty performance sound. Its exhaust manifold, cleverly designed for

package efficiency in the Focus engine bay, is created of equal-length tubular headers in a four-to-two-to-one configuration. The design combines the

first and fourth cylinder exhaust tubes and the second and third cylinder exhausts, respectively, before the resultant two pipes are combined into one

to enter the catalyst. The exhaust pipe diameter is 65 mm.

Robust elements were incorporated in Duratec STís top end to reflect the additional performance demands being placed on the engine. These include

stronger, lightweight, cast aluminium pistons with larger, 20 mm wrist pins and robust, sinter-forged connecting rods.

ss1turbo - 25/9/11 at 01:14 PM

I suspect that the VVT would work in conjunction with the dual length runners in order to improve the torque curve to be honest - any talk regarding

emissions is, at the end of the day, all about efficiency and not always about lean running.

If you're running throttle bodies/carbs/whatever isn't as it came from Ford, then you have already changed the inlet system - and its not

all about cam timing as thats only part of the story.

IIRC (and i'm not an expert on it) the early VVT systems (Honda? Toyota? Rover?) were not much more than an on/off system whereas now its become

a totally variable system allowing tuning as the engine passes up the rev range (and this is where the OE dual runner system would come in). On OE

power curves, you tended to see almost a "double dip" torque curve as one cam timing profile ran out and the other kicked in. The dual

length runners would possibly switch in and out as this change occured to again change the torque figure - and all of this only applies to full

throttle! What it may be used for at cruise and 50% throttle may be completely different.

If an ignition advance curve was just two settings, you'd have a very strange torque curve as well..and that tends to look like a map of the Alps

when viewed in 3D. Why should the cam advance/retard map be any different?

I think it was the Rover VVC engine that for more power, you just junked the VVC system and fitted a different (fixed) cam...

Rob Allison - 25/9/11 at 01:45 PM

The above was a quote for the standard ST170 as fitted into the Focus. So standard inlet, exhaust etc

DixieTheKid - 25/9/11 at 02:30 PM

The easy answer is to throw it in the bin and start again, listen to what people are telling you. You need a NASA engineer and lots of cash to see any

big BHP gain. If your worried about compession, go back to basics as i said before. Pull the head off, check the rings and valves. Simple!........

Rob Allison - 25/9/11 at 05:47 PM

Don't know where you get that idea. ST vvt is fine, you just need to run it right. Over 200bhp has been seen without opening up the st.

Or fit delete vvt cams and there good for 206bhp.

DixieTheKid - 25/9/11 at 06:59 PM

quote:

Originally posted by Rob Allison

Don't know where you get that idea. ST vvt is fine, you just need to run it right. Over 200bhp has been seen without opening up the st.

Or fit delete vvt cams and there good for 206bhp.

I would like to see that!

Rob Allison - 25/9/11 at 07:12 PM

One version http://www.catcams.co.uk/acatalog/Latest_News.html

DixieTheKid - 25/9/11 at 08:00 PM

LOL! Yeah without opening up the engine!

quote:

New Cat Cams Ford Duratec ST170 VVT delete profiles deliver impressive gains New Cat Cams non-VVT cam profiles for track day / rally use

High lift / short duration format to maximise torque and power Precision CNC ground from new steel billets Designed to work with original

Ford mechanical valve gear Original front camshaft seals (which is normally fitted around the VVT sprocket) can be maintained thanks to a

clever billet design Drop in profile with no piston to valve clearance issues Cat Cams adjustable pulleys required due to VVT deletion

Designed to work with carburettors or independent throttle bodies Dyno proven to produce 207 bhp / 177 lb.ft of torque Ideal for track day

and kit car applications Priced at £643.81 including VAT @ 17.5%, part number 2301013 Contact Cat Cams UK on 0845 51 95 720

Let me tell you that you will spend more getting to 200bhp then it will cost you to buy a MK1 Focus RS engine package.... So why do it?

[Edited on 25/9/11 by DixieTheKid]

coozer - 25/9/11 at 08:28 PM

Somebody PLEASE delete this thread....

scutter - 25/9/11 at 10:27 PM

Coozer, give me a week whilst I do a stint on nights and I'll compression test my St170 lump in the Locost, I should be good as it made 188

earlier this year without the VVC even being switched on

I'll get back to you. Dan.

silky16v - 3/8/12 at 12:14 PM

Not wanting to stir all this up again but i've brought Coozer's old MNR Vortx

I'm having the car mapped in the next week and having spoken to my tuner he suggests that switching the VVT on around 2250rpm and then off again

around 5600rpm will give 180BHP+ on Throttle Bodies & this is possible on Omex 600 ECU

But he also said ideally i just install the DTA Pro 60 ecu that has full variable cam control, but at the moment i can't justify the cost of

this.

So we will have a play around with the VVT and try some different setting and i will report back my finding

MikeRJ - 3/8/12 at 01:40 PM

quote:

Originally posted by Cornishman

Just worth pointing out that MikeRJ has accidentally used the wrong RPM figures in his calculations thus causing some confusion. He has substituted

the RPM for peak torque into the peak power calculation therefore giving the false impression that a practically impossible set of figures have been

produced.

If you look at the print out CAREFULLY and run the figures as I have just done then they seem fine mathematically.

Not wishing to cause offence to anyone but thought it worth pointing out as I am following the thread with interest to help decide what engine to run

for the 2013 season (1.3 xflow for 2012!).

Steve

I know this was a long time back, but I hadn't noticed your post before. You are absolutely right, I did accidentally swap the peak and power

RPM figures. However, even with the correct numbers the results still make no sense even allowing for my cock up.

code:

RPM Claimed Power(bhp) Claimed Torque (nm) Claimed Torque(lbft) Calc power from claimed torque(bhp) Calc torque from claimed power(lbft)

4419 174.861 241.12 177.84 149.63 207.82

4711 178.36 235.13 173.423 155.59 198.84

Not only do the claimed power and torque not match up at the given RPM, a 2.0L normally aspirated production engine running on pump fuel simply can

not make 175bhp at just 4419RPM. That equates to a BMEP of over 15bar, beyond the capability of e.g. a normally aspirated Formula 1 engine, or a

NASCAR V8 and makes something like a BMW M3 CSL look pretty pathetic with it's 13.7bar

coozer - 3/8/12 at 07:17 PM

For gods sake dont start this off all over again...

mtechmatt - 13/2/14 at 07:34 PM

I thought I would jump in for 2 reasons:

A) I have mapped several ST170s.

Those of you whom are under the impressions that a standard Focus St170 strapped down to a dyno makes 170bhp are wrong, they make usually around

155bhp. Our particularly nackared test car (see point B) makes 135bhp. Fact, pure and simple.

If you fit throttle bodies (and I mean good ones) and map it properly, and just do the old 'switch on the solenoid trick (which is NOT how Ford

do it, as stated by Mike, closed loop PWM) you will get crica 195 with a lumpy map and poor bottom end torque. My personal best is 197.4. headwork

(which you cant do much of, better off building from a blacktop) will take you to maybe 220bhp.

The second reason:

B)We are in the process of finishing the design of this little product which gives full VVT control on the ST170, mappable and accurate cam

positioning using closed loop cam/crank angle tracking, that will work with ANY engine management system, and thought it may be of interest to some of

you

http://motorsport-electronics.co.uk/index.php/vvtpro.html

Cheers,

Matt

Xtreme Kermit - 13/2/14 at 08:23 PM

Holy thread resurrection!!!

mtechmatt - 13/2/14 at 08:47 PM

hehe I just couldnt let these dreams of 200+bhp, from an ST170 go by un-corrected lol

Where did you go for mapping? Damian @ daytuner seems to be ok in Harrogate, wouldn't suggest Boggs as you have an

omex and tb's.

Where did you go for mapping? Damian @ daytuner seems to be ok in Harrogate, wouldn't suggest Boggs as you have an

omex and tb's.