Timing Light help

bikecarbfred - 2/11/18 at 06:26 AM

I have a question:

Scenario as follows;

I have a 36-1 trigger wheel mounted on the crank.

Missing notch on the VR sensor indicates 90 degrees before TDC

Timing light is hooked on spark lead number 1

Car is stationary and will be turned on and idling at 1000rpm

1) at this stage ideally what position on the trigger wheel tooth should the light be flashing knowing each tooth represent 10 degrees.

I would like to discuss this in stages if possible guys.

SPYDER - 2/11/18 at 11:01 AM

Hi Fred. In stages then...

What engine?

Is it on EDIS?

Do you have a TDC timing mark on engine and pulley? ( Probably not, else you wouldn't be asking)

What ECU are you using?

Can you "fix" the timing for test purposes?

Do you know what the timing should be at idle?

My guess is that you are on EDIS4 and the flash should show between 7 or 8 teeth between the sensor and the missing tooth, depending on your idle

advance.

Engine should be properly warm as there could be an offset during warmup.

If your idle advance is 10 deg BTDC then 8 teeth

If your idle advance is 20 deg BTDC then 7 teeth

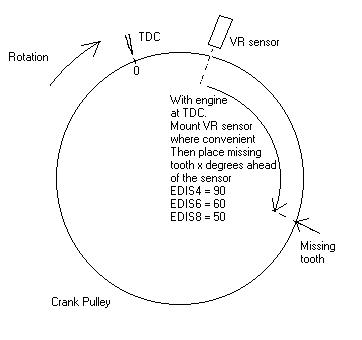

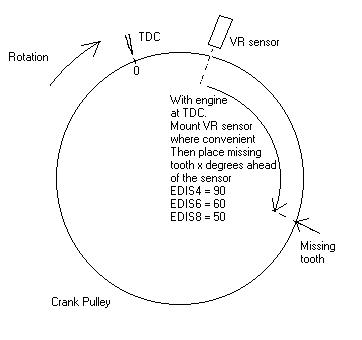

This "guess" is based on your setup being something like this, taken fron the MS manual...

Give us more info and the "guess" could be a little more concrete.

bikecarbfred - 2/11/18 at 11:44 PM

Yeah your diagram is how i have done it. EDIS4 using megajolt ecu.

I will be using the generic default map on megajolt just to get me going.

Let's say it's 20 degrees BTDC at idle and 25 degrees BTDC at 2000rpm

does that mean I can tipex a the tooth that relates to the above on the trigger wheel and the timing light should be flashing on it?

rusty nuts - 3/11/18 at 07:41 AM

Probably better to ignore the number of teeth and locate true TDC , fit a pointer then mark the toothed wheel to line up with your pointer? Will you

actually use a timing light to programme your ECU.?

SPYDER - 3/11/18 at 02:56 PM

So do you have any TDC marks or not?

If not, do you have the means to set the engine to TDC accurately?

Did you fit the toothed wheel and sensor yourself?

If you really have to use the toothed wheel to check timing AND you are sure that the wheel is set correctly with respect to TDC then your tippex mark

for 20 deg BTDC at idle would be 7 teeth from the missing one. Try and get a thin mark rather than a blob.

bikecarbfred - 3/11/18 at 07:14 PM

@ spyder; Yes I have TDC mark which you can only see when fitting the timing belt.

What I did then was to fit the trigger wheel to the pulley and place the sensor facing the missing tooth at 90 degrees before TDC.

So now that every part is fitted correct all i can see from above the engine is the trigger wheel 36-1 teeth.

@ rusty nuts. i will just use the megajolt default map to run in the cams and then the pistons for couple hundred miles.

I just want to learn more about timing lights and how they work.

mcerd1 - 3/11/18 at 08:42 PM

To get the best out of a timing light you need marks every ~2 degrees in the range you'll be using it (say between 8 and 16 for starters - more

if you want to check the full range of operation)

36-1 teeth is nothing like accurate enough to be useful

Also for a performance build the cam belt alignment marks are almost never accurate enough either, ideally you need a large protractor and a piston

stop to confirm true TDC, then mark your pulley for the timing light based off that

[Edited on 3/11/2018 by mcerd1]

bikecarbfred - 4/11/18 at 01:07 AM

just had a thought about this, what's the need of a timing light. I suppose it's just good to check that the initial timing matches what

megajolt is programmed too?

but once you find for example megajolt's 10 degrees matches what the timing light shows then there's no need to check any further?

mcerd1 - 4/11/18 at 08:30 AM

Pretty much, but it'll really help to know what the offset is

The chances of of the VR sensor being off a few degrees are pretty high, which doesn't matter if you just add/subtract that offset from the whole

map

Also being able to check the timing with a light is a good diagnostic tool

Angel Acevedo - 4/11/18 at 09:14 AM

One of the Megasquirt manual has this warning twice.

"It is essential that ignition timing is confirmed with a timing-light on EVERY install."

I WILL heed it whenever I get to it.

HTH.

AA

bikecarbfred - 6/11/18 at 08:49 PM

right so i have a proper TDC marker on the crank pulley and can confirm it's accurate.

I now mark a thin-ish white line on the tooth on the trigger wheel that is along this marker.

and then mark a few more, say for example the next tooth before and the one before that representing 10, 20 & 30 degrees BTDC

oh i so wished i did all of this when the engine was on the stand lol.

now once this is done and i set 10 degrees advance as my idle i expect the flashing light to be showing what?

mcerd1 - 6/11/18 at 09:00 PM

quote:

Originally posted by bikecarbfred

now once this is done and i set 10 degrees advance as my idle i expect the flashing light to be showing what?

10° with the EDIS on its own - otherwise it should show whatever the megajolt ECU is telling it at that time

have you got a laptop you can use while its running to get the live data off the ECU ?

[Edited on 6/11/2018 by mcerd1]

bikecarbfred - 6/11/18 at 09:05 PM

yes sure, have laptop with megajolt software on it.

i can't remember , it's been a while. but pretty sure there's a highlighted box in green which moves around the timing chart which

shows you what degrees the timing is at that very point

SPYDER - 7/11/18 at 11:06 AM

quote:

Originally posted by bikecarbfred

right so i have a proper TDC marker on the crank pulley and can confirm it's accurate.

I now mark a thin-ish white line on the tooth on the trigger wheel that is along this marker.

and then mark a few more, say for example the next tooth before and the one before that representing 10, 20 & 30 degrees BTDC

oh i so wished i did all of this when the engine was on the stand lol.

now once this is done and i set 10 degrees advance as my idle i expect the flashing light to be showing what?

If everything is correctly set up the light will flash at the EIGHTH tooth from the missing tooth.

Make sure the engine is properly warm and the tickover is correct.

IF you can fix the advance temporarily using the software then do so.

Are you using MAP or TPS for load sensing?

bikecarbfred - 7/11/18 at 08:09 PM

Using TPS;

Need to start engine get straight up to 2000rpm to run in new cams.

Angel Acevedo - 8/11/18 at 02:44 AM

quote:

Originally posted by bikecarbfred

Using TPS;

Need to start engine get straight up to 2000rpm to run in new cams.

This can be done in several starts

even if AFR is a little bit off you can manage to run a few minutes at a time with no major problems.

bikecarbfred - 8/11/18 at 06:41 AM

@ angel you mean to run in cams. run it for 5 minutes then turn it off if needs be then turn on again run in for 5 minutes again until 20 minutes of

2000rpm is achieved

@ ma man spyder: crank rotates clockwise. so do we mark the eighth tooth anti clockwise from the missing tooth or clockwise?

Angel Acevedo - 8/11/18 at 01:57 PM

quote:

Originally posted by bikecarbfred

@ angel you mean to run in cams. run it for 5 minutes then turn it off if needs be then turn on again run in for 5 minutes again until 20 minutes of

2000rpm is achieved

...

Yes, optimal would be as much as you can, but is paramount that you maintain high revs, if temperature is not controlled, or you have oil issues, you

should shut down inmediately....

Troubleshoot and next start, once you have oil pressure 2-3 seconds, bring rpms to required RPMs.

Last new cam I used stated 2500, I have just read a Cam Break in page in the net and it statees 3000, so make sure to check the cam spec sheet which

must have a detailed break in procedure.

One more thing to consider is that for break in mineral oil is preferred over synthetic.

Sorry if this has veered off from topic.

Regards.

Angel Acevedo