J666AYP

|

| posted on 10/11/18 at 03:18 PM |

|

|

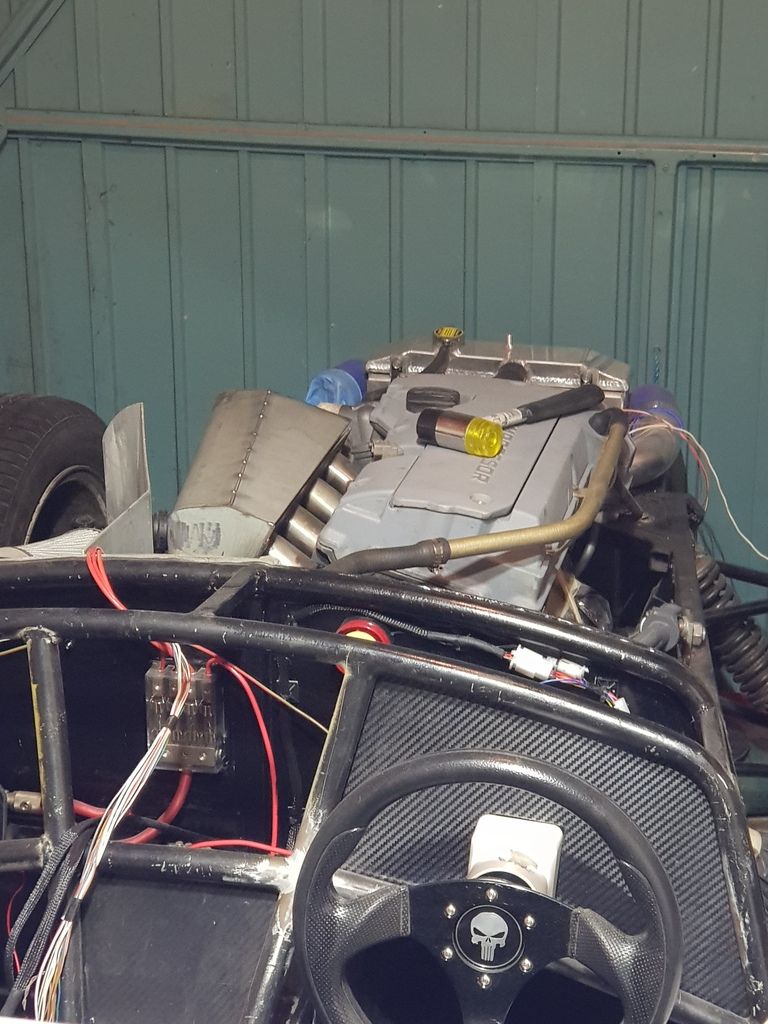

Abit of progress over the past couple of weeks.

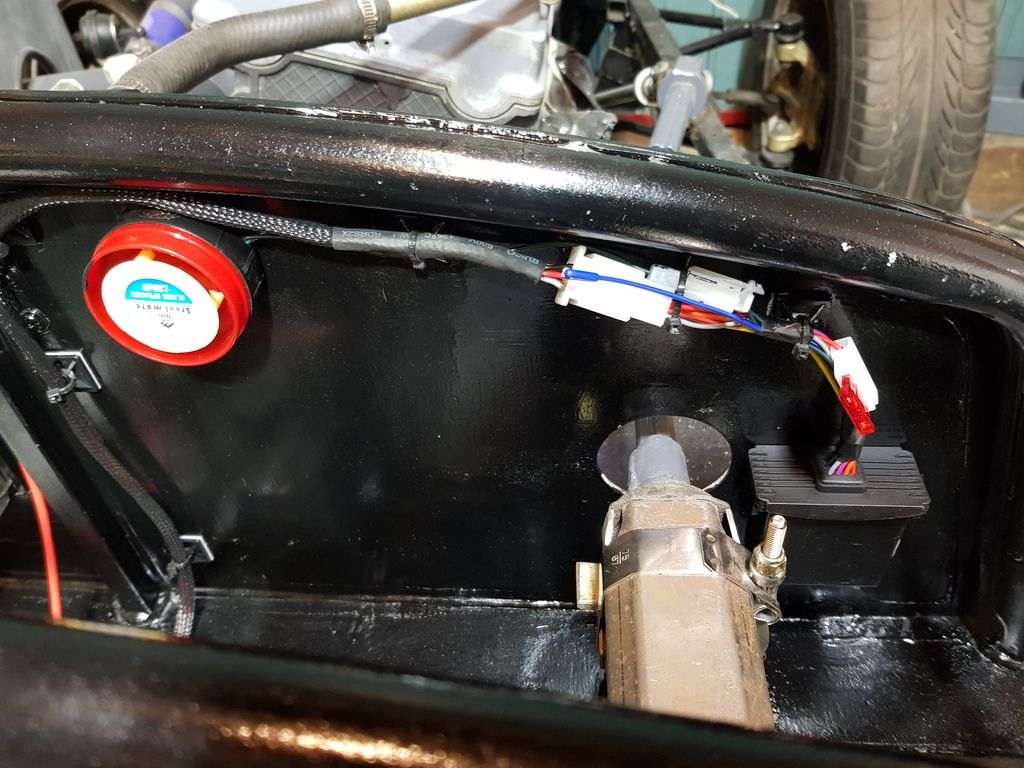

• Have started covering the car loom in braid and routing the wires.

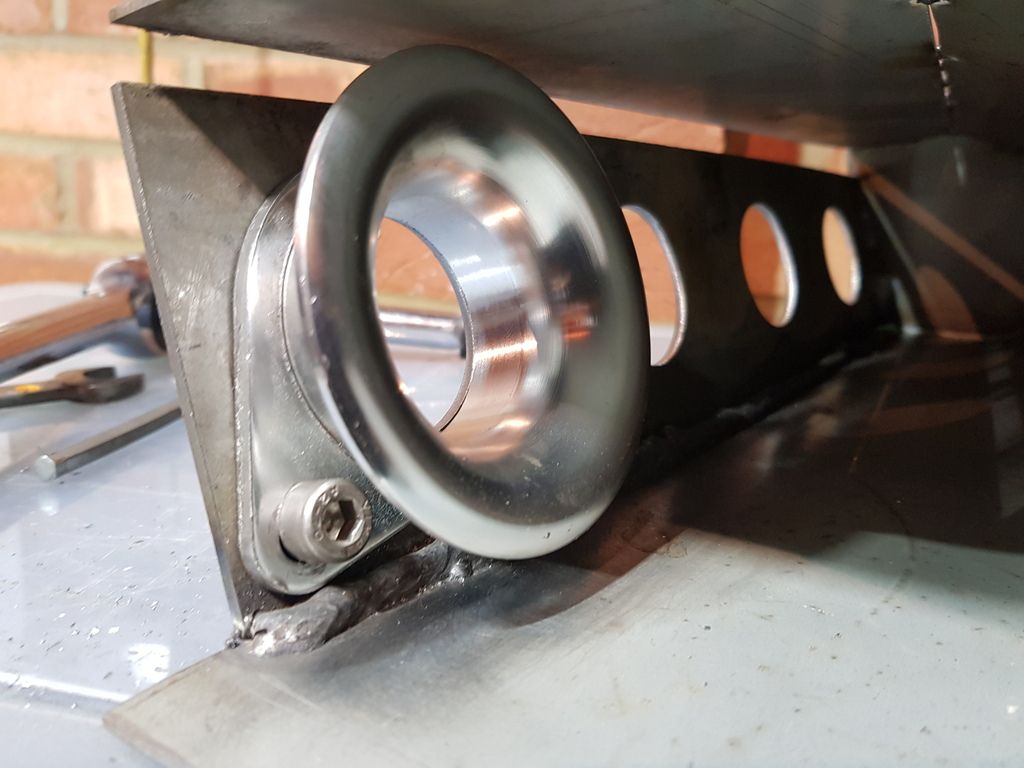

• Knocked up the cowling/cover for the steering column. Found a pipe conector in the local hardware shop, have turned town some alloy and ABS bungs so

its a very tight fit with no screws needed. And it cost me a grand total of £0.89p. A lick off paint and it will be spot on.

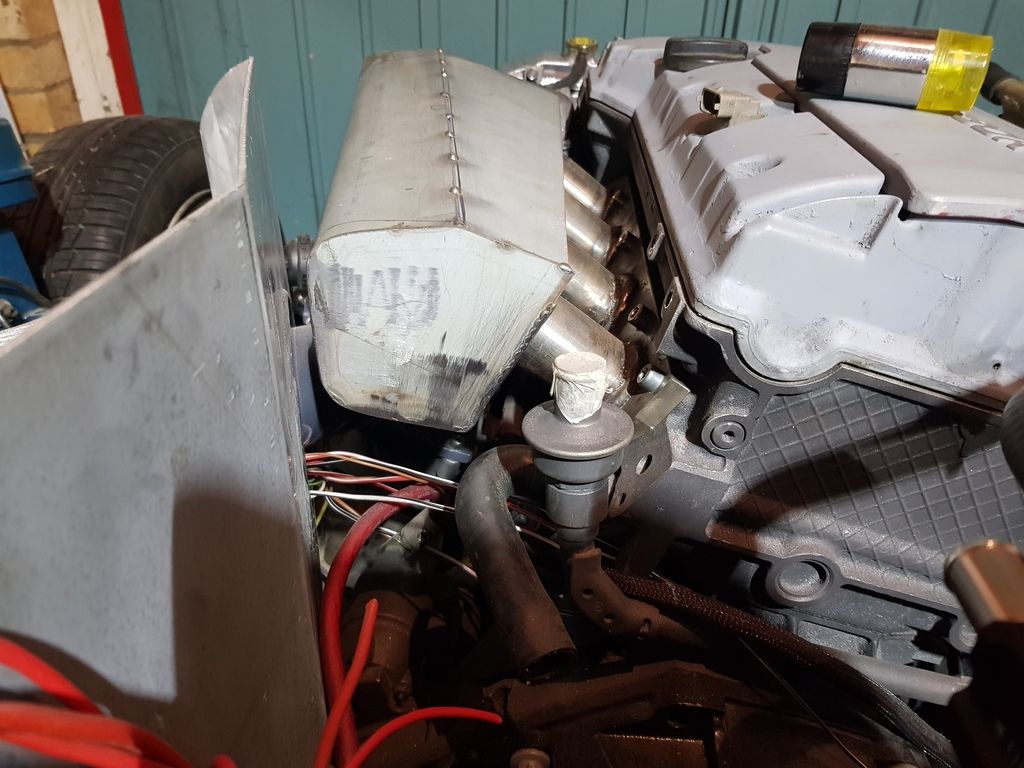

• PAULD was kind enough to knock up a inlet manifold flange for me, I have cut my tubes up and started knocking up some injector seats on the lathe.

Just need to get over to the welding shop to swap my gas bottle over then I can start throwing some sparks round the garage.

• The main power cables have been swapped for some lighter ones and fixed in place.

• Alarm is fitted and working.

• I have also thought up a great security device for the handbrake (well redneck engineering haha).

Jay

|

|

|

|

|

J666AYP

|

| posted on 12/11/18 at 10:11 PM |

|

|

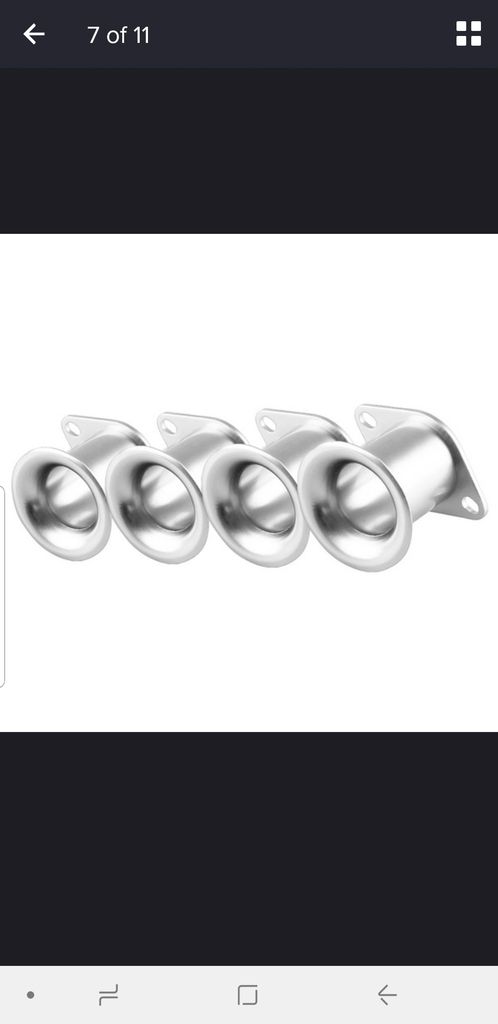

Got some nice little 45mm ID velocity stacks on route from china and started welding up the manifold. Has had two very heavy passes with the welder so

it should never leak.

[Edited on 12/11/18 by J666AYP]

|

|

|

SJ

|

| posted on 13/11/18 at 08:18 AM |

|

|

I love the handbrake lock!

|

|

|

nick205

|

| posted on 13/11/18 at 05:17 PM |

|

|

quote:

Originally posted by SJ

I love the handbrake lock!

Ditto - nice touch!

|

|

|

Angel Acevedo

|

| posted on 13/11/18 at 06:02 PM |

|

|

quote:

Originally posted by nick205

quote:

Originally posted by SJ

I love the handbrake lock!

Ditto - nice touch!

Even better, put a gaiter on top and talk about Stealth Security....

Beware of what you wish.. for it may come true....

|

|

|

J666AYP

|

| posted on 13/11/18 at 06:46 PM |

|

|

Cheers gents.

Angel.... Already on that Idea mate:

They should neaten up the holes in the gaitor.

Jay

|

|

|

J666AYP

|

| posted on 15/11/18 at 05:46 PM |

|

|

Yep that works.

|

|

|

gremlin1234

|

| posted on 15/11/18 at 06:38 PM |

|

|

whilst the hand brake lock looks good and functional

it would not pass iva as an immobiliser, because they are not allowed to work on any part of the braking system.

|

|

|

J666AYP

|

| posted on 15/11/18 at 07:17 PM |

|

|

Gremlin1234,

It already has a alarm and immobiliser fitted, this is just a extra bit of security for when its parked up in some of the dodgey areas I visit.

Jay

|

|

|

gremlin1234

|

| posted on 15/11/18 at 07:18 PM |

|

|

quote:

Originally posted by J666AYP

Gremlin1234,

It already has a alarm and immobiliser fitted, this is just a extra bit of security for when its parked up in some of the dodgey areas I visit.

Jay

good, but don't let it be seen at iva ;-)

|

|

|

J666AYP

|

| posted on 15/11/18 at 07:25 PM |

|

|

Gremlin, those are "inspection holes" in the gaiter wink wink.

Jay

|

|

|

Iomlocosts4

|

| posted on 17/11/18 at 04:47 PM |

|

|

Nice job! I can't wait to start myself!

|

|

|

MikeRJ

|

| posted on 17/11/18 at 09:46 PM |

|

|

You might want to think about either triangulating the front lower wishbones, or adding a curved plate to help distribute the bending stress.

Particularly with a fairly heavy, powerful engine the design of yours is prone to failure due to the straight edge of the shock mounting plate turning

a nice strong triangle into a weak trapezium shape.

|

|

|

J666AYP

|

| posted on 17/11/18 at 10:24 PM |

|

|

MikeRJ,

I have welded this brace into both lower wishbones, will that not be enough? If not I will seam a plate into them.

Jay

|

|

|

J666AYP

|

| posted on 21/11/18 at 06:24 AM |

|

|

Abit more progress on the inlet manifold Mk3.5 Just need the velocity stacks to land on the doorstep now :-/

|

|

|

Bluemoon

|

| posted on 22/11/18 at 09:58 AM |

|

|

quote:

Originally posted by J666AYP

MikeRJ,

I have welded this brace into both lower wishbones, will that not be enough? If not I will seam a plate into them.

Jay

I think mike is talking in terms of vertical motion, lateral is fine for the lower bone as it makes a triangle with the mounts (i.e. the brace is not

needed). On the locost the wishbone design fails where the plate meets the bones as this is a stress riser since the damper/spring load really wants

to shock loads from the odd pothole ect cause the wishbones to fold up... MK and others have got around this by making the plate thin out into a U

shape to remove the stress riser on the wishbone. Worth doing a search on "wishbone failure". Basically in an ideal world, the wishbone

would only be under compression or tension but the shock absorber mount puts it under bending, in an ideal world the shock mounting would be at the

same place as the pivot for the upright, clearly this is not physically possible. MK and Caterham have there own solutions to this...

Caterham moves the wishbone pivot as far out as possible:

MK us the U-shaped plate (note the plate is welded in the center of the tubes NOT the top):

Example of failure;

Dan

[Edited on 22/11/18 by Bluemoon]

[Edited on 22/11/18 by Bluemoon]

|

|

|

J666AYP

|

| posted on 22/11/18 at 04:34 PM |

|

|

Aaah that makes sence, silly me looking at the wide end of the wishbones haha.

Will get some bracing in the narrow end next time the wishbones are off.

Thanks for the input gents.

|

|

|

J666AYP

|

| posted on 22/11/18 at 04:41 PM |

|

|

Todays been a good day! my velocity stacks turned up yay! bit of a bummer that they were too long to keep inside the factory sized body (its a mission

of mine to keep it sleek and subtle). Had to turn them down in the lathe but they fit nice now.

Trial fitting...

|

|

|

J666AYP

|

| posted on 23/11/18 at 03:33 PM |

|

|

Yep that works

|

|

|

Iomlocosts4

|

| posted on 23/11/18 at 05:10 PM |

|

|

Looking good!

quote:

Originally posted by J666AYP

Yep that works

|

|

|

J666AYP

|

| posted on 24/11/18 at 01:06 AM |

|

|

Cheers buddy,

Jay

|

|

|

J666AYP

|

| posted on 24/11/18 at 01:19 AM |

|

|

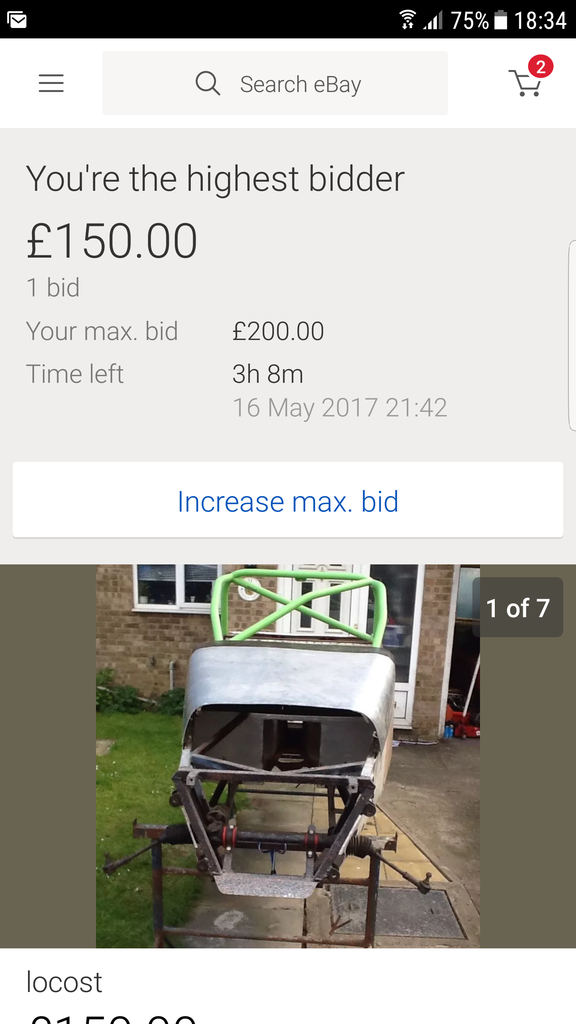

Just been looking back through some old photos trying to find where a coolant hose goes to and I'm shocked at how far its come along. The time,

effort and ear bashings from the wife are starting to pay off abit I think

|

|

|

J666AYP

|

| posted on 26/11/18 at 12:10 AM |

|

|

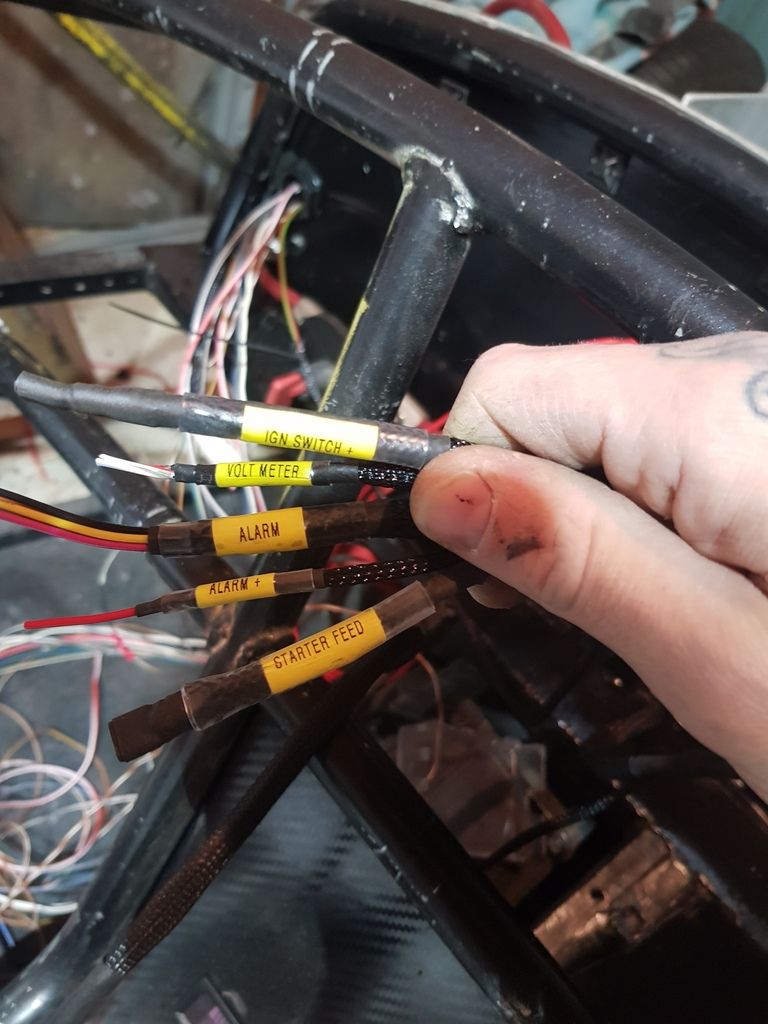

Playing with the label maker and some clear heatshrink. Has worked quite well.

|

|

|

big_wasa

|

| posted on 26/11/18 at 01:38 PM |

|

|

What label machine have you got ?

I've got two looms to build and that would add a nice touch.

Cheers

|

|

|

J666AYP

|

| posted on 26/11/18 at 03:29 PM |

|

|

quote:

Originally posted by big_wasa

What label machine have you got ?

I've got two looms to build and that would add a nice touch.

Cheers

Just a cheapy amazon one mate and some clear heatshrink tube from china. Let me know what you want and I will run some off for you if you want.

Jay

|

|

|