MK9R

|

| posted on 1/10/09 at 07:17 AM |

|

|

Bolt on front end?

Was looking at the front of the chassis making plans on where to cut it to start the rebuild. Looking at the damaged/repaired tubes it looks like the

best place to cut will be just behind the rear lower wishbone mount, where there is a vertical upright between the upper and lower chassis rails. I

can then make a new front end on the bench and join it back onto the chassis when complete. I was thinking the best way to join the main chassis rails

would be to get a solid insert machined that would slide inside the the chassis tubes between the join, then the do the necessary welding. But then

we (well dad) had a thought, why not close off the chopped off front of the main chassis (cross members, triangulation) and have 2 flat plates either

side which then bolt to flat plates on the front section of the chassis (which house all suspension). This would make future suspension damage repairs

easy as i could just build a new front section and bolt it on, i could almost have a spare front end to take to meets incase of an incident.

The car is a fisher fury with lowered race chassis by the way.

Any thoughts?? Any cars out there with a similiar setup?

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

|

|

Mr Whippy

|

| posted on 1/10/09 at 07:30 AM |

|

|

I think a drawing of what you propose would be a good idea.

Nothing against it, as its similar to the F1 cars with their bolt on rear ends. My main concern would be the bolts being ripped out the brackets

earlier than the original tube would have failed so I think the brackets would have to be quite substantial to be totally safe.

Fame is when your old car is plastered all over the internet

|

|

|

Staple balls

|

| posted on 1/10/09 at 07:44 AM |

|

|

What about alignment?

My gut feeling is you'll be introducing a lot of joints made to locost tolerances, so might end up with some interesting handling quirks.

|

|

|

MK9R

|

| posted on 1/10/09 at 07:57 AM |

|

|

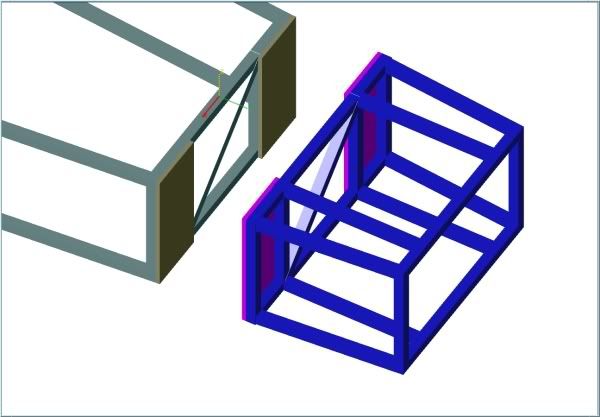

A very simple mock up (no suspension pick ups and chassis tubes not all shown)

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

MK9R

|

| posted on 1/10/09 at 07:59 AM |

|

|

quote:

Originally posted by Staple balls

What about alignment?

My gut feeling is you'll be introducing a lot of joints made to locost tolerances, so might end up with some interesting handling quirks.

It will be easier to get the front end accurate on the bench, then spend some time lining up the assembly with the main chassis before bolting it

together. Should be far easier to get accurate this way than trying to weld directly onto the existing chassis (which won't be bare by the way)

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

iank

|

| posted on 1/10/09 at 08:06 AM |

|

|

In theory if you make a significant modification to the chassis design during a repair/rebuilt then you'll need to re-IVA the car.

I say in theory because it would be rather difficult for anyone to prove it wasn't like that for the original test.

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

MK9R

|

| posted on 1/10/09 at 08:07 AM |

|

|

quote:

Originally posted by iank

In theory if you make a significant modification to the chassis design during a repair/rebuilt then you'll need to re-IVA the car.

I say in theory because it would be rather difficult for anyone to prove it wasn't like that for the original test.

car isn't road registered, so doesn't matter

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

iank

|

| posted on 1/10/09 at 08:13 AM |

|

|

quote:

Originally posted by MK9R

quote:

Originally posted by iank

In theory if you make a significant modification to the chassis design during a repair/rebuilt then you'll need to re-IVA the car.

I say in theory because it would be rather difficult for anyone to prove it wasn't like that for the original test.

car isn't road registered, so doesn't matter

Excellent

--

Never argue with an idiot. They drag you down to their level, then beat you with experience.

Anonymous

|

|

|

brianthemagical

|

| posted on 1/10/09 at 08:26 AM |

|

|

I'd say it sounds like a good idea. I was shocked when i first saw how old school F1 chassis were bolted together, they looked as though

they'd fall apart.

How accurate are your building faccilities? You could just have some kind of pin or overlapping brackets to line everything up, making up a jig to

keep future parts the same.

As for strength, it should be fine. Most of the bolts would be in single shear for most of the time. The main problem would be keeping it all rigid as

both sections are losing a lot of their support. Also, there will be a small weight increase.

One advantage would be that you'll be able to test differnt designs, such wishbone lengths and mounting positions and triangulation.

|

|

|

MK9R

|

| posted on 1/10/09 at 08:35 AM |

|

|

quote:

Originally posted by brianthemagical

How accurate are your building faccilities?

Standard locost builder in the garage, use a wooden base and clamp down all tubes before tack welding. Will be accurate enough for this job. Alignment

can be done using strings spirit levels etc, but then the geo set up can dial out any small inaccuracy.

quote:

Originally posted by brianthemagical

As for strength, it should be fine. Most of the bolts would be in single shear for most of the time. The main problem would be keeping it all rigid as

both sections are losing a lot of their support. Also, there will be a small weight increase.

I would expect the chassis to be stiffer, as at the moment there is nothing substantial between the chassis rails between the engine and suspension,

this way there would be a sbstantial amount of cross bracing, so hopefully redce the twisting. Yes definetly a small weight increase. Currently myself

and car are 536kg, so only 6kg over the minimum, weight, so if does increase slightly no real problem. But then again i am getting new body work this

winter and could order the lightweight race version, this would offset the increase in chassis weight

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

rallyingden

|

| posted on 1/10/09 at 08:40 AM |

|

|

What about steering column ?

Also with all that strengthening at the nose, next shunt you have will simply bend main chassis further back.

RD

|

|

|

MK9R

|

| posted on 1/10/09 at 08:44 AM |

|

|

quote:

Originally posted by rallyingden

What about steering column ?

Also with all that strengthening at the nose, next shunt you have will simply bend main chassis further back.

RD

Steering column fits, just the mock up picture is only a representation of the theory.

I understand what you say about it bending main chassis, i would have to design the front to be as sacrificial as possible.

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

nick205

|

| posted on 1/10/09 at 09:51 AM |

|

|

Nothing wrong with bolt on subframes - the E-Type is one example where the whole front end from the passenger bulkhead is a bolt on assembly.

The suqareness and alignment will require some careful work, but not beyond locost fabrication.

One thought.....looking at you're model I suspect any front end impact might generate chassis damage further back as the sub-frame itself will

be pretty stiff.

|

|

|

TimC

|

| posted on 1/10/09 at 09:55 AM |

|

|

Isn't your degree in this type of stuff? Its a very interesting idea.

Is there a Fury on the RGB grid that is anything like the original anymore?

|

|

|

MK9R

|

| posted on 1/10/09 at 09:56 AM |

|

|

quote:

Originally posted by nick205

Nothing wrong with bolt on subframes - the E-Type is one example where the whole front end from the passenger bulkhead is a bolt on assembly.

The suqareness and alignment will require some careful work, but not beyond locost fabrication.

One thought.....looking at you're model I suspect any front end impact might generate chassis damage further back as the sub-frame itself will

be pretty stiff.

its just a representation, will do proper design that takes this into account

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

MK9R

|

| posted on 1/10/09 at 09:58 AM |

|

|

quote:

Originally posted by TimC

Isn't your degree in this type of stuff? Its a very interesting idea.

Is there a Fury on the RGB grid that is anything like the original anymore?

I did aerospace, so suppose it had similar things i could apply, but it was a long time ago and my brain is now mush.

No standard furys left, they all fell apart or got destroyed

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

andyharding

|

| posted on 1/10/09 at 10:50 AM |

|

|

I like the idea but not the design at all.

Think about the reason a spaceframe is as strong as it is, tubes in compression and tension how they are strongest. Instead of bolting 2 flat plates

together at the joint which will be heavy and I think flex unless it's very thick plate why not join the main tubes by having an insert in one

half that slides up the other and then a bolt through with compression tube? Keeps everything light and strong.

Are you a Mac user or a retard?

|

|

|

MK9R

|

| posted on 1/10/09 at 11:02 AM |

|

|

quote:

Originally posted by andyharding

I like the idea but not the design at all.

Think about the reason a spaceframe is as strong as it is, tubes in compression and tension how they are strongest. Instead of bolting 2 flat plates

together at the joint which will be heavy and I think flex unless it's very thick plate why not join the main tubes by having an insert in one

half that slides up the other and then a bolt through with compression tube? Keeps everything light and strong.

Point taken.

This is a picture of the fastest car in RGB at the moment, i like! Will be speaking to Derek and having a nose at the car at our next meet

Cheers Austen

RGB car number 9

www.austengreenway.co.uk

www.automatedtechnologygroup.co.uk

www.trackace.co.uk

|

|

|

nick205

|

| posted on 1/10/09 at 11:36 AM |

|

|

^^^^^^ ^^^^^^

Tha looks rather nice!

|

|

|

Canada EH!

|

| posted on 1/10/09 at 06:22 PM |

|

|

It also means that the next prang goes into the plate structure, which is also replacable.

|

|

|