coyoteboy

|

| posted on 7/3/14 at 10:29 PM |

|

|

Blow through, turbo-supercharging.

So while I'm rebuilding the tin top I decided to do something different, for a bit of a challenge and out of interest. I'm going to strap

a roots s/c in after my turbo. The turbo produces enough power for me currently but there's a big hole in the bottom end due to the 8.5:1

andthe turbo only spooling to ffull boost at about 3-3.5k. So the super will fill in the low end by pushing a half decent boost level across the

board, then having the tubby feed its inlet with a medium boost too. This will naturally multiply both boost and efficiency so I will be water/air

intercooling after each compressor.

Bypass on the s/c will keep it from pushing the throttle plate (still on the plenum) into the engine at idle/low load. Turbo wastegate referencing the

s/c output for consistent output.

Thoughts that might help before I head off on this amusing track? I notice Easton recently submitted a patent for exactly this setup!

|

|

|

|

|

luke2152

|

| posted on 7/3/14 at 10:57 PM |

|

|

I've heard going through two compressors the temperature increase is mulitpied rather then added leading to a very good intercooler being needed

|

|

|

coyoteboy

|

| posted on 7/3/14 at 11:30 PM |

|

|

Yup overall efficiency is multiplied (0.65*0.75ish for the combo I have) which work out at about 0.49%. But that's the purpose of the two

intercoolers as you suggest.

|

|

|

Canada EH!

|

| posted on 8/3/14 at 12:59 AM |

|

|

Friend had a Ford 350 tow truck with a GMC 471 diesel with a turbo in front of the supercharger (471 and 671 diesels are 2 stroke on the intake and

valve on the exhaust). The thing could pull a 40 ton semi truck.

|

|

|

coyoteboy

|

| posted on 8/3/14 at 03:22 AM |

|

|

Well I don't plan to tow many trucks but I do like the sound of that  I really am aware it's a curious way to attack it but I'm

not in it for peak power, I love grunt and low-mid end torque as it's a road car so I'm willing to sacrifice some peak to flatten it out

nice and early. I considered a variable geometry turbo but even those are quite limited and super expensive. So why not eh. What could go wrong? I really am aware it's a curious way to attack it but I'm

not in it for peak power, I love grunt and low-mid end torque as it's a road car so I'm willing to sacrifice some peak to flatten it out

nice and early. I considered a variable geometry turbo but even those are quite limited and super expensive. So why not eh. What could go wrong?

|

|

|

plentywahalla

|

| posted on 8/3/14 at 09:14 AM |

|

|

quote:

Originally posted by Canada EH!

Friend had a Ford 350 tow truck with a GMC 471 diesel with a turbo in front of the supercharger (471 and 671 diesels are 2 stroke on the intake and

valve on the exhaust). The thing could pull a 40 ton semi truck.

If you think about it, that is the only way to boost a 2 stroke. All 2 stroke diesels have a supercharger which is to scavenge the exhaust gases by

producing a pressure differential between the inlet and exhaust ports which are at the same height in the bore. It can't work as a supercharger

in a 4 stroke does as any boost pressure will vent through the exhaust port which is why they fit a valve which closes before the inlet port is

blanked.

I work with marine diesels which are often 2 strokes and I have a 27 litre 2 stroke in one of my boats. Most turbo/supercharged marine engines run the

two chargers in parrallel with a flap valve so the engine takes air from whichever is delivering the higher pressure. The supers are driven by an

electromagnetic clutch and cut out at low rpm. This enables the supers to be highly geared and deliver high boost at low engine revs but avoids the

problem of over-revving.

Rules are for the guidance of wise men ... and the obedience of fools. (anon)

|

|

|

froggy

|

| posted on 8/3/14 at 08:15 PM |

|

|

The bypass won't eliminate surge and you'll wear the supercharger rotors very quickly having the throttle after the charger in a compound

layout .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 8/3/14 at 10:03 PM |

|

|

Froggy, standard design on quite a few oem cars? (Not compound but I am not sure how the turbo would affect that? ). Intake tract will be loooong and

it would be impossible to put the throttle before the s/c without his delay. Could have 2 of them.

What makes you think the bypass won't handle the pressure spike? The Old fashioned pneumatic ones may not but this is electronically controlled

and I'm hoping fast enough.

[Edited on 8/3/14 by coyoteboy]

|

|

|

froggy

|

| posted on 8/3/14 at 10:17 PM |

|

|

Which production compound charged car are you referring to ??

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 8/3/14 at 10:31 PM |

|

|

I'm not, I'm referring to s/c only. Most oem compound ones are s/c > turbo> throttle

[Edited on 8/3/14 by coyoteboy]

|

|

|

froggy

|

| posted on 8/3/14 at 10:46 PM |

|

|

Your talking about a compound system with the supercharger after the turbo , the only oe system is the vw which isn't compound just uses the s/c

to get the turbo spinning and isn't permanently engaged so isn't subject to surge anyway .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 9/3/14 at 12:26 AM |

|

|

I never said they were compound in vw. However compound charging has been done many times both with turbo first and supercharger. That said what

mechanism and conditions of damage do you forecast?I'm wondering what I've missed.

It's late, and I'm tired, but I can't see why you would see surge outside the normal operating regime of either compressor. The vw

system runs compound for and intermediate period but not at high boost but the times my setup would see surge is when the throttle is slammed shut.

The turbo would see nothing worse than normal but the supercharger would see the shut throttle and compress against it, as the intake volume

compresses the bypass would be opening allowing that to escape. If it were significant overlap a turbo-type BOV could be installed?

Certainly my plan would be to instrument the hell out of each stage in the early trials!

[Edited on 9/3/14 by coyoteboy]

|

|

|

froggy

|

| posted on 9/3/14 at 10:27 AM |

|

|

It doesn't matter what you try and fit to release the pressure spike it won't react quick enough . Having the throttle upstream of the

charger is less of an issue as the pressure can move back to a degree but with a turbo behind it running at a slightly higher pressure than the

charger gives it nowhere to go . I tried using two bov and a bypass before putting the throttle before the charger which cured it but added more issue

s trying to package a decent chargecooler without having a huge plenum volume and poor throttle response . The other issue is you will be running the

turbo at a much lower pressure to avoid going over 2bar . I used a Holset hx35 with a 65lb compressor and ran 11b from the turbo to get 26psi at the

manifold with water meth spraying into the charger to keep the case cool . I didn't intercool between turbo and charger as the air temps

weren't that high and the water meth did a much better job .

Spent a year with several different layouts before selling the setup and buying a properly sized turbo with a built 2.3 motor to replace the 2.0 and a

slightly lower diff and have a lighter and quicker car .

The man you need to speak to is frank profera on lotursport.org who built the twin charge exige .

Vgt turbos are much more promising but the only affordable units are the holsets which are just a bit too big to use on a 4 Cyl petrol engine . I

could run a lot of ignition at very high boost as the a/r was over2.0 with the vane fully open and back pressure to boost 2psi apart .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 9/3/14 at 01:20 PM |

|

|

Thanks for the feedback, good to hear from someone with experience. What type of bypass were you using and what type of charger? I'm thinking I

can easily program the bypass to open early based on rate of throttle closure. Not possible with an old school vac driven one but it depends how fasti

can get it to respond too. Merc use it as boost control so it should be reasonably fast.

|

|

|

coyoteboy

|

| posted on 9/3/14 at 05:49 PM |

|

|

I've actually found conflicting info on the VW twincharging setup. It's definitely a blow-through setup though, but it looks to be

filter>super with bypass >turbo>IC>throttle and once the S/C flow is out-done by the turbo the bypass opens on the S/C.I guess this would

reduce the surge seen by the S/C as the tubby would be hit by the primary wave but still...

It's not compound when done this way as the S/C can always only flow a fixed mass flowrate and will eventually "draw through" the

S/C, but it's not really parallel either.

|

|

|

froggy

|

| posted on 9/3/14 at 06:25 PM |

|

|

Eaton blowers can have an upstream throttle but they aren't designed to .once you have the low end increase in flow to get the turbo towards its

efficient zone you then have to overcome the limitations of cramming the charger with more and more mass and pressure whilst trying to Get rid of the

heat . Before using water meth sprayed into the blower it got seriously hot very quickly .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 9/3/14 at 07:09 PM |

|

|

How were you runningthe bypass though, there's a lot of evidence of overheat issues if the bypass isnt opening at the correct load and not

opening fully due to hot cams holding high plenum pressure at part load. Assuming decent intercooler between parts you're just increasing the

s/c heating effect by having its inlet pressure higher. The stacked inefficiencies will naturally be higher but only by 10-15% which equates to 30c or

so assuming zero intercooling anywhere.

I could potentially run parallel and have both contributing at full boost (it's very easy for me to run any combination in the car due to

location) but I'm not convinced. As it is I'm running the stock turbo right up at its sensible limit 18psi peak and never seeing inlet

temps above 35c after the cooler.

|

|

|

coyoteboy

|

| posted on 10/3/14 at 10:59 AM |

|

|

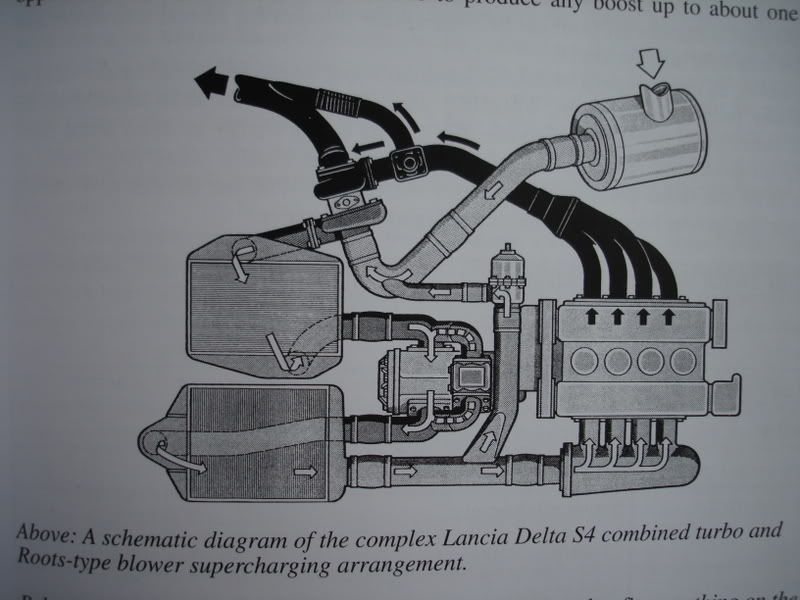

My initial thought is exactly how the lancia delta S4 did it in fact... Hard to tell what tweaks they made to the throttle setup though.

And I believe the Nissan Superturbo...

[Edited on 10/3/14 by coyoteboy]

|

|

|

froggy

|

| posted on 10/3/14 at 07:18 PM |

|

|

20yrs ago it was a solution to a problem that technology has pretty much answered with modern ball bearing and vnt turbos . If I did it again I would

copy vw,s system which would leave a normal turbo setup untouched .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 10/3/14 at 08:03 PM |

|

|

I don't think modern turbos have answered the call tbh, there seems to be zero solutions in the market for my car that can make decent power

without horrendous lag and late spool, despite it being one of the best know turbocharged engines out there. If I'm honest I want to do it

because I can, and because it's a lot cheaper than buying a turbo that might get part way there. Plus i prefer massive low down torque to

stupidly high top end. Its a solution that would be being used regularly these days except for the added complexity that OEMS shy away from, as a one

off project it's more than viable when I managed to get a very low milage, great condition charger for under a hundred notes delivered. Since I

can literally bolt on the s/c and clock the turbo round in a weekend, then just connect up the hoses i'm going to give it a whirl I figure I

might as well soon how it goes! Switching back to stock is as simple as declocking the turbo and removing the hoses.

|

|

|

froggy

|

| posted on 10/3/14 at 09:44 PM |

|

|

So your going to feed the turbo with the supercharger ? Its only going to compress the mass that the engine can make at the rpm range that can't

get the turbo moving so I don't see any huge increase in torque on a turbo engines modest compression ratio . What car is it anyway ?

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 10/3/14 at 11:07 PM |

|

|

No my plan was the same as the Lancia coincidentally (supercharger fed by the turbo), possibly bypass the s/c up top, maybe not. I should be able to

push 6-10psi into the engine using the s/c alone without taking it outside is limits at redline but really heading into hot waters. Turbo normally

just copes with shoving 18psi across the range (14 from about 2900+) but starting to get outside its happy zone past 5500. I don't expect any

increase in top end which will be limited by the turbos capability to flow at low pressure, but that will be aided by increased exhaust flow due to

the s/c to some degree. Piece of cake for me to run a second water-air ic inline as I've already increased the rad up front by ~4x and water

volume by 2x and pump flow increased (stock setup is proven fine to around 350-400)

3SGTE by the way.

I suspect I'll have to digitally run the bypass based off the manifold vacuum reading and use a PD controller - press the throttle lightly and

it slowly closes the bypass to bring it in slowly, slam the throttle and it slams the bypass shut, same in reverse. Combined with a decent

single-piston BOV and some measurement I'll see how it goes. Looks like I should be able to get the valve fully open in about 1/10th of a second

which is slow but not horrendous.

[Edited on 11/3/14 by coyoteboy]

|

|

|

froggy

|

| posted on 11/3/14 at 08:56 PM |

|

|

I can't see any way of disengaging the supercharger without a big drop in boost pressure with the turbo gate running low enough to control

compounded pressure . The ability to produce pressure is not in dispute but the mass of air depends on what the turbo can flow . Some very good info

on engineering tips forum from a couple of people trying various ways of plumbing . Throttle before the blower removes all these issues . With a

normal sized bypass the air will run in a loop around the blower in part load , throttke in the right place restricts flow in so the bypass

doesn't need to be very big .

Quite a few mx5,s use twin throttles to avoid this without having to do away with the plenum throttle .

[IMG]http://i144.photobucket.com/albums/r187/froggy_0[IMG]

|

|

|

coyoteboy

|

| posted on 11/3/14 at 11:29 PM |

|

|

You're right, it would be difficult to transition between combined and turbo-only.

I'll start by maintaining both and see how I can progress the two over, potentially. One way it could be worked is to have the wastegate

pressure reference taken from in front of the throttle, as the SC is phased out (slowly, by opening the bypass, I can't clutch it out) the

wastegate will progressively shut, hopefully balancing without a dip now that the exhaust flow is sufficiently high. The obvious problem from this is

that if the bypass is shut, mid throttle, and poorly phased, the turbo could see an overspeed/boost situation as it's reference is behind closed

doors. I'm not sure how likely that is, I'll think on that and the risks.

The bypass on this charger seems to be as big as the inlet bore and appears to be used to regulate boost on the standard car, which may help reduce

part load efficiency issues and I'd be happy for the air to be recycled on part load - it'll heat up but I'll have to wait and see

how much. Alternatively I could vent to atmosphere (noisy but worth considering!) or back to the airbox but that loads the second IC a bit more than

I'd like. From the footage I can see, it sounds like the S4 vented to atmosphere on throttle lift and part load potentially as well as

bypassing.

The engine the S/C came from (Merc M271) has the throttle post-S/C and no throttle pre-S/C either, but it does have a significantly longer intake

routing between S/C and throttle than I have:

You can actually see the size of the bypass, roughly, in this image above - it's immediately to the right of the throttle and is the same

diameter as the outlet pipework (approx 55-60mm).

Cheers for the tips, I'll wander over to the MX5 forums and see what shenanigans go on there, they may have a throttle option I can use if

necessary but it seems that it's really quite common not to use it (quite a few GM's use them without bypass OR pre-throttle from what

I've read but I'd have to see that in the flesh to believe it I think).

[Edited on 11/3/14 by coyoteboy]

|

|

|

Mr Whippy

|

| posted on 12/3/14 at 12:46 AM |

|

|

it's amazing how much of that engine is plastic

|

|

|